sensor YAMAHA WR 450F 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 293 of 426

GENERATOR AND STARTER CLUTCH

6-66

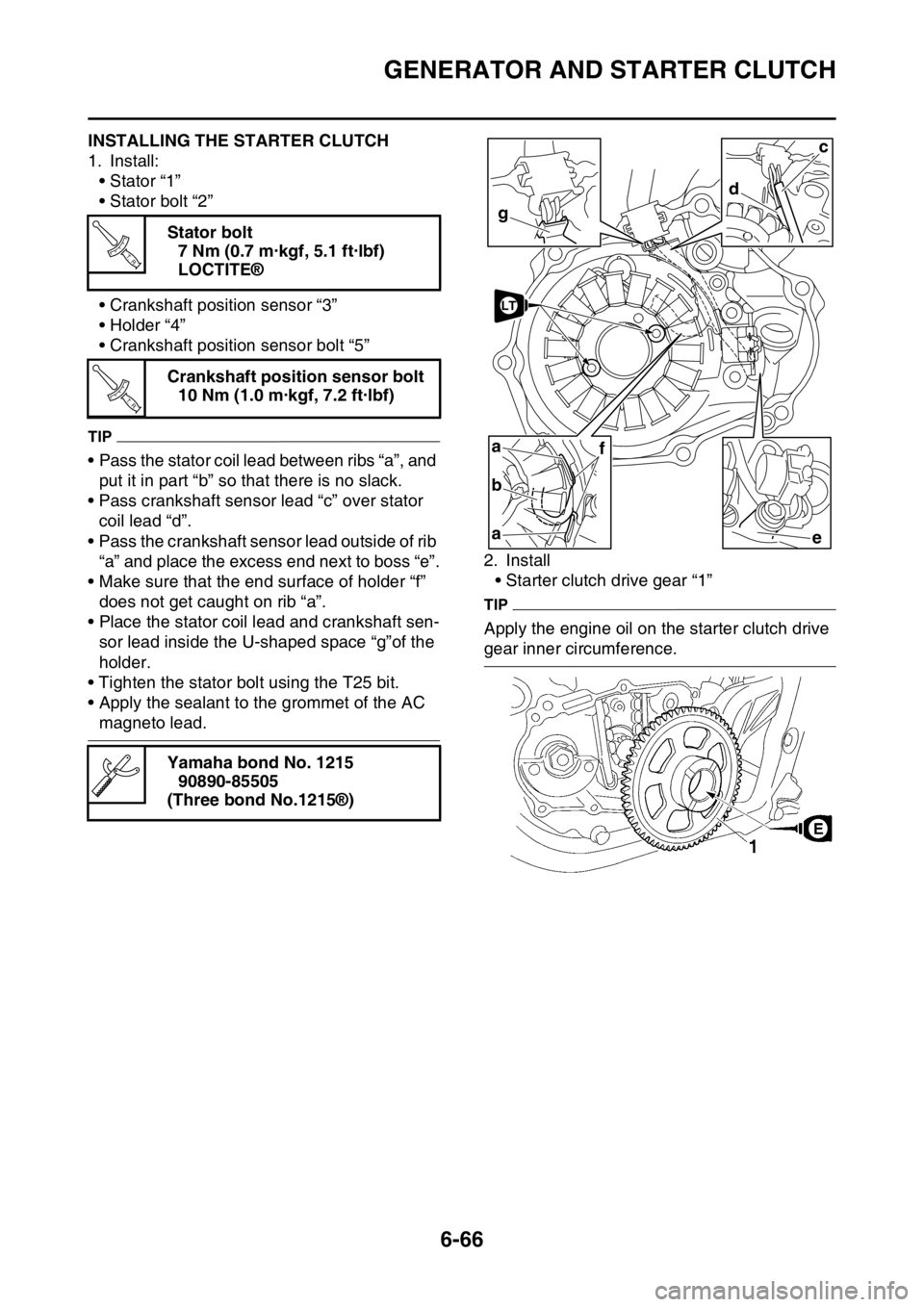

EAS2GC1308INSTALLING THE STARTER CLUTCH

1. Install:• Stator “1”

• Stator bolt “2”

• Crankshaft position sensor “3”

• Holder “4”

• Crankshaft position sensor bolt “5”

TIP

• Pass the stator coil lead between ribs “a”, and put it in part “b” so that there is no slack.

• Pass crankshaft sensor lead “c” over stator

coil lead “d”.

• Pass the crankshaft sensor lead outside of rib “a” and place the excess end next to boss “e”.

• Make sure that the end surface of holder “f” does not get caught on rib “a”.

• Place the stator coil lead and crankshaft sen-

sor lead inside the U-shaped space “g”of the

holder.

• Tighten the stator bolt using the T25 bit.

• Apply the sealant to the grommet of the AC

magneto lead. 2. Install

• Starter clutch drive gear “1”

TIP

Apply the engine oil on the starter clutch drive

gear inner circumference.

Stator bolt

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

LOCTITE®

Crankshaft position sensor bolt 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Yamaha bond No. 1215 90890-85505

(Three bond No.1215®)

T R..

T R..

g

d

c

ea

a

b

f

LT

Page 311 of 426

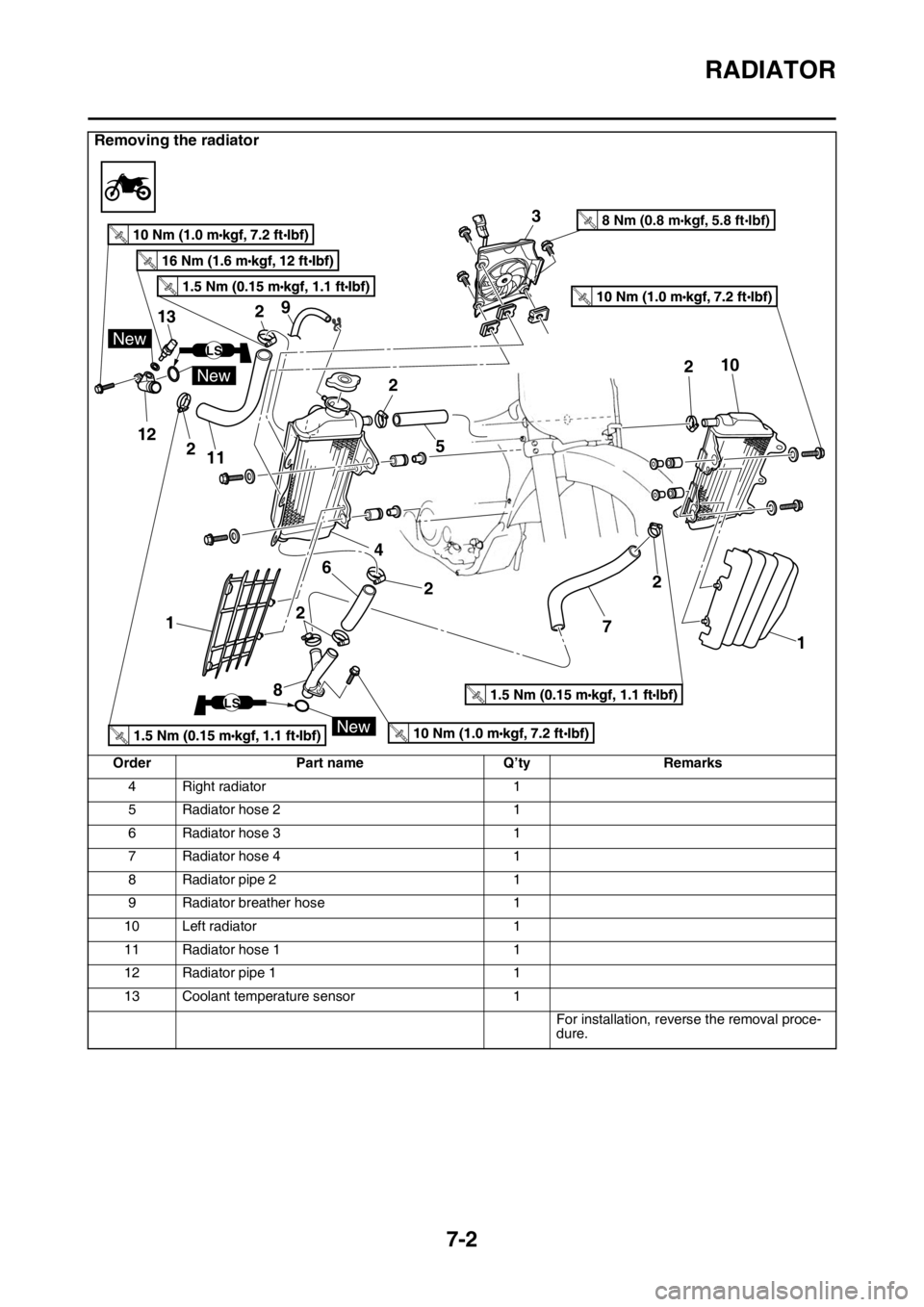

RADIATOR

7-2

4 Right radiator1

5 Radiator hose 2 1

6 Radiator hose 3 1

7 Radiator hose 4 1

8 Radiator pipe 2 1

9 Radiator breather hose 1

10 Left radiator 1

11 Radiator hose 1 1

12 Radiator pipe 1 1

13 Coolant temperature sensor 1

For installation, reverse the removal proce-

dure.

Removing the radiator

Order Part name Q’tyRemarks

12

13

New

New

New

LS

LS

3

4 58 Nm (0.8 m kgf, 5.8 ft Ibf)T.R.

6

7

8 9

10

11 2

2

2

2

2

2

2

1

1

Page 317 of 426

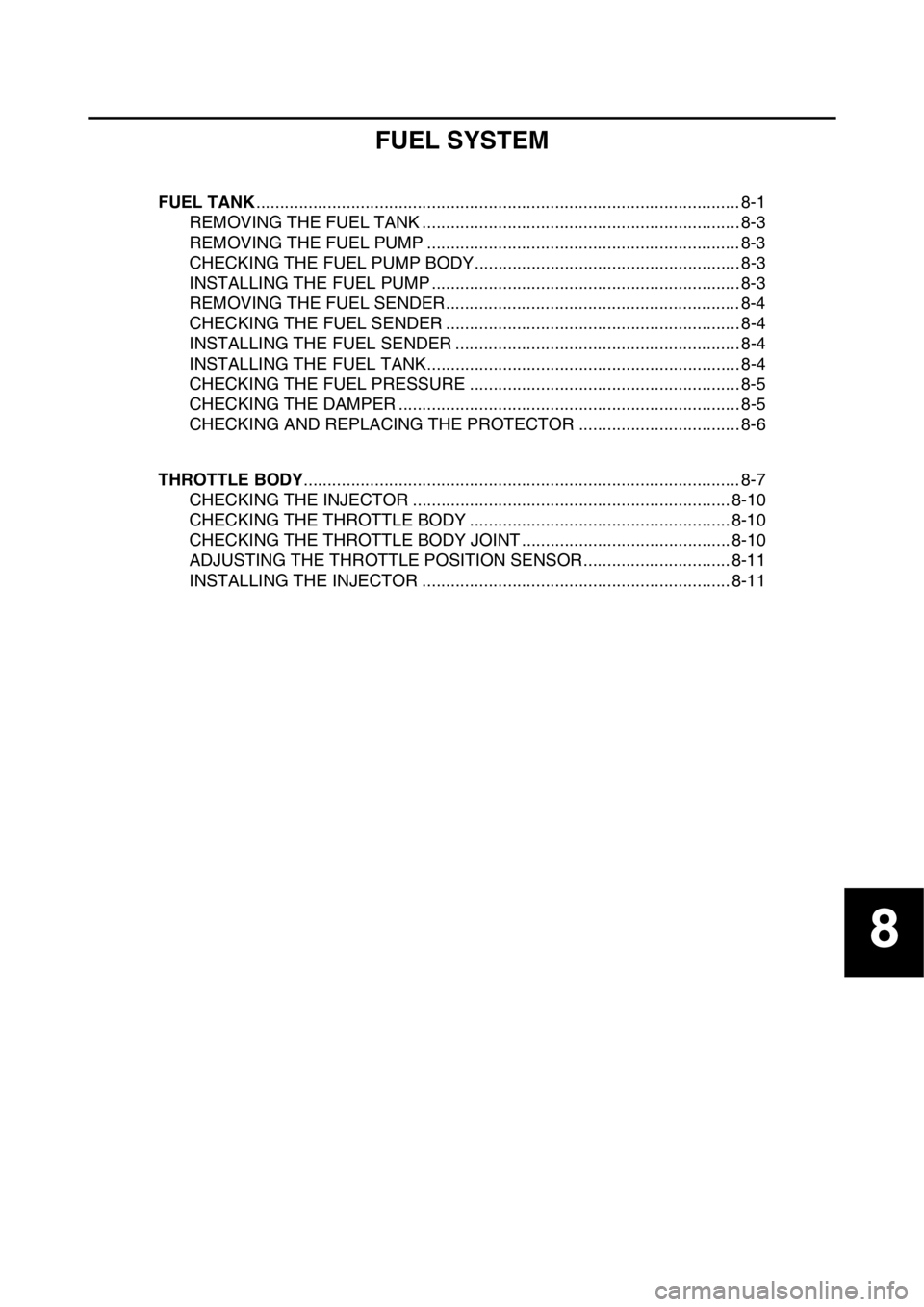

8

FUEL SYSTEM

FUEL TANK...................................................................................................... 8-1

REMOVING THE FUEL TANK ................................................................... 8-3

REMOVING THE FUEL PUMP .................................................................. 8-3

CHECKING THE FUEL PUMP BODY........................................................ 8-3

INSTALLING THE FUEL PUMP ................................................................. 8-3

REMOVING THE FUEL SENDER.............................................................. 8-4

CHECKING THE FUEL SENDER .............................................................. 8-4

INSTALLING THE FUEL SENDER ............................................................ 8-4

INSTALLING THE FUEL TANK.................................................................. 8-4

CHECKING THE FUEL PRESSURE ......................................................... 8-5

CHECKING THE DAMPER ........................................................................ 8-5

CHECKING AND REPLACING THE PROTECTOR .................................. 8-6

THROTTLE BODY ............................................................................................ 8-7

CHECKING THE INJECTOR ................................................................... 8-10

CHECKING THE THROTTLE BODY ....................................................... 8-10

CHECKING THE THROTTLE BODY JOINT ............................................ 8-10

ADJUSTING THE THROTTLE POSITION SENSOR............................... 8-11

INSTALLING THE INJECTOR ................................................................. 8-11

Page 324 of 426

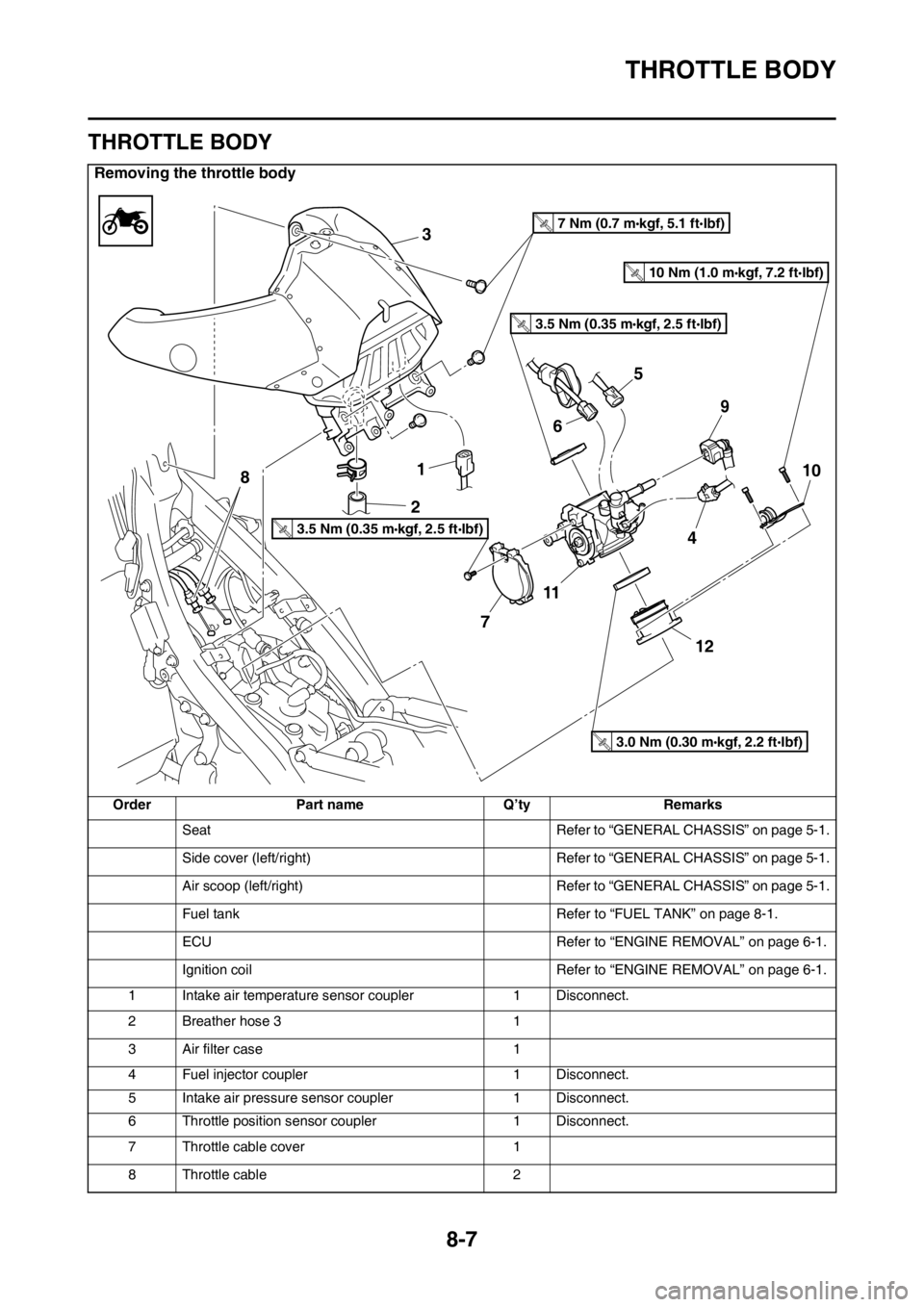

THROTTLE BODY

8-7

EAS2GC1351

THROTTLE BODY

Removing the throttle body

OrderPart name Q’tyRemarks

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

ECU Refer to “ENGINE REMOVAL” on page 6-1.

Ignition coil Refer to “ENGINE REMOVAL” on page 6-1.

1 Intake air temperature sensor coupler 1 Disconnect.

2 Breather hose 3 1

3 Air filter case 1

4 Fuel injector coupler 1 Disconnect.

5 Intake air pressure sensor coupler 1 Disconnect.

6 Throttle position sensor coupler 1 Disconnect.

7 Throttle cable cover 1

8 Throttle cable 2

3

1

2

7

11

12

10

9

4

8

6

5

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

3.5 Nm (0.35 m kgf, 2.5 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

3.0 Nm (0.30 m kgf, 2.2 ft Ibf)T.R.

10 Nm (1.0 m kgf, 7.2 ft Ibf)T.R.

Page 326 of 426

THROTTLE BODY

8-9

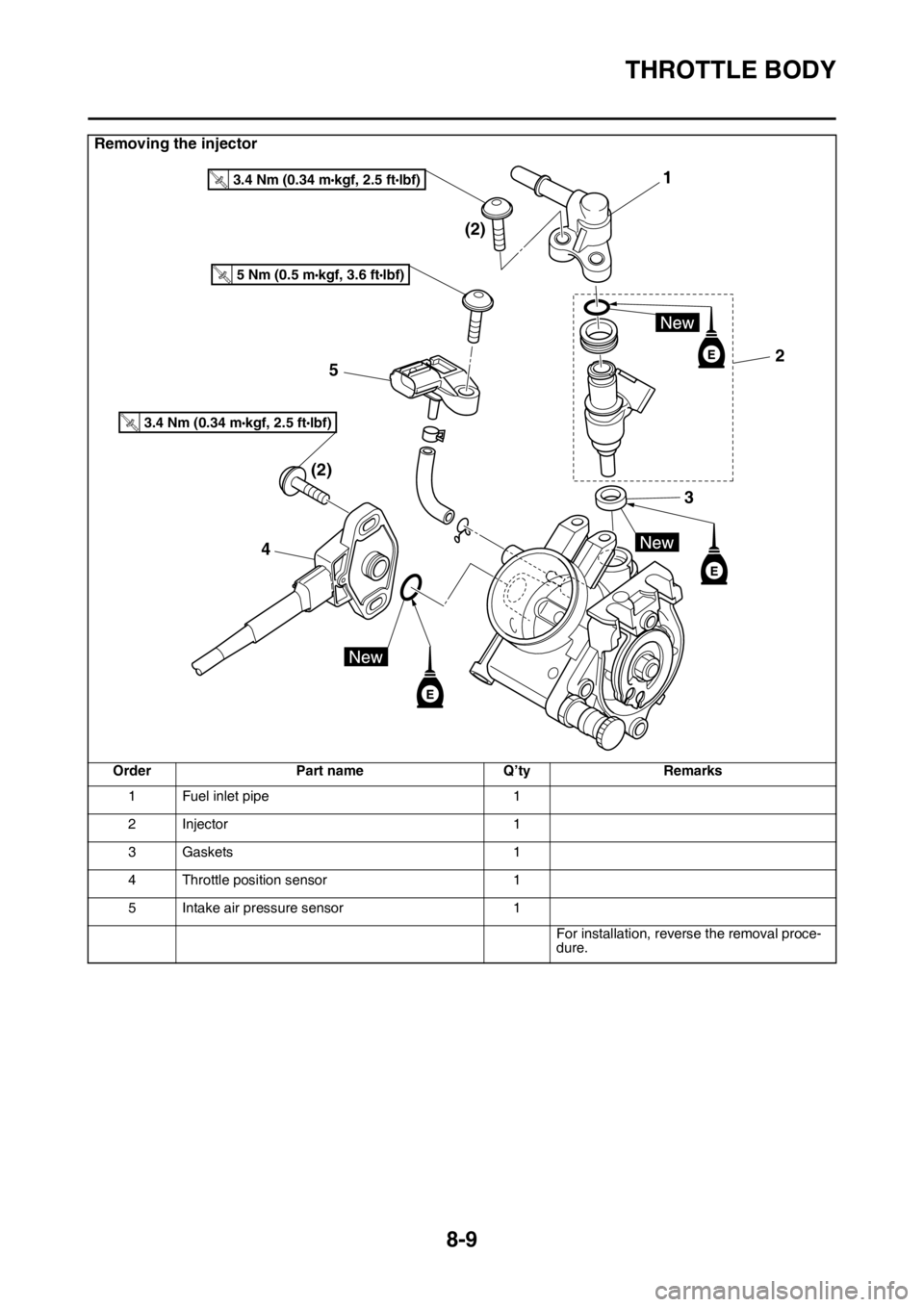

Removing the injector

OrderPart name Q’tyRemarks

1 Fuel inlet pipe 1

2Injector 1

3 Gaskets 1

4 Throttle position sensor 1

5 Intake air pressure sensor 1

For installation, reverse the removal proce-

dure.

1

2

(2)

(2) 5

4 3

T.R.3.4 Nm (0.34 mlbf)

kgf, 2.5 ft

T.R.5 Nm (0.5 mlbf)

kgf, 3.6 ft

T.R.3.4 Nm (0.34 mlbf)

kgf, 2.5 ft

Page 327 of 426

THROTTLE BODY

8-10

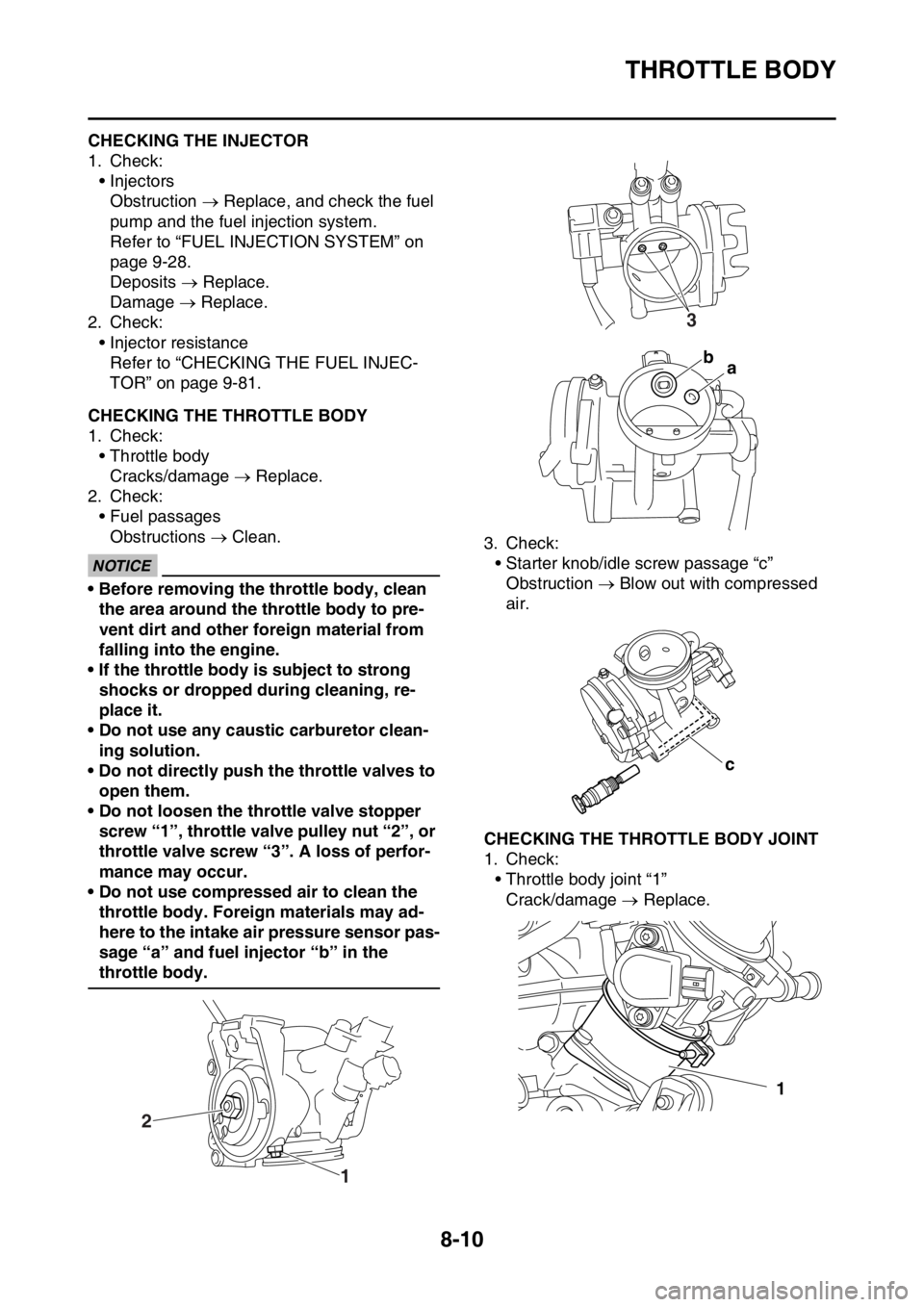

EAS2GC1352CHECKING THE INJECTOR

1. Check:• InjectorsObstruction Replace, and check the fuel

pump and the fuel injection system.

Refer to “FUEL INJECTION SYSTEM” on

page 9-28.

Deposits Replace.

Damage Replace.

2. Check:

• Injector resistanceRefer to “CHECKING THE FUEL INJEC-

TOR” on page 9-81.

EAS2GC1353CHECKING THE THROTTLE BODY

1. Check:• Throttle bodyCracks/damage Replace.

2. Check:

• Fuel passagesObstructions Clean.

ECA

NOTICE

• Before removing the throttle body, clean

the area around the throttle body to pre-

vent dirt and other foreign material from

falling into the engine.

• If the throttle body is subject to strong shocks or dropped during cleaning, re-

place it.

• Do not use any caustic carburetor clean- ing solution.

• Do not directly push the throttle valves to open them.

• Do not loosen the throttle valve stopper screw “1”, throttle valve pulley nut “2”, or

throttle valve screw “3”. A loss of perfor-

mance may occur.

• Do not use compressed air to clean the throttle body. Foreign materials may ad-

here to the intake air pressure sensor pas-

sage “a” and fuel injector “b” in the

throttle body. 3. Check:

• Starter knob/idle screw passage “c”Obstruction Blow out with compressed

air.

EAS2GC1354CHECKING THE THROTTLE BODY JOINT

1. Check: • Throttle body joint “1”Crack/damage Replace.

1

2

3

ba

c

1

Page 328 of 426

THROTTLE BODY

8-11

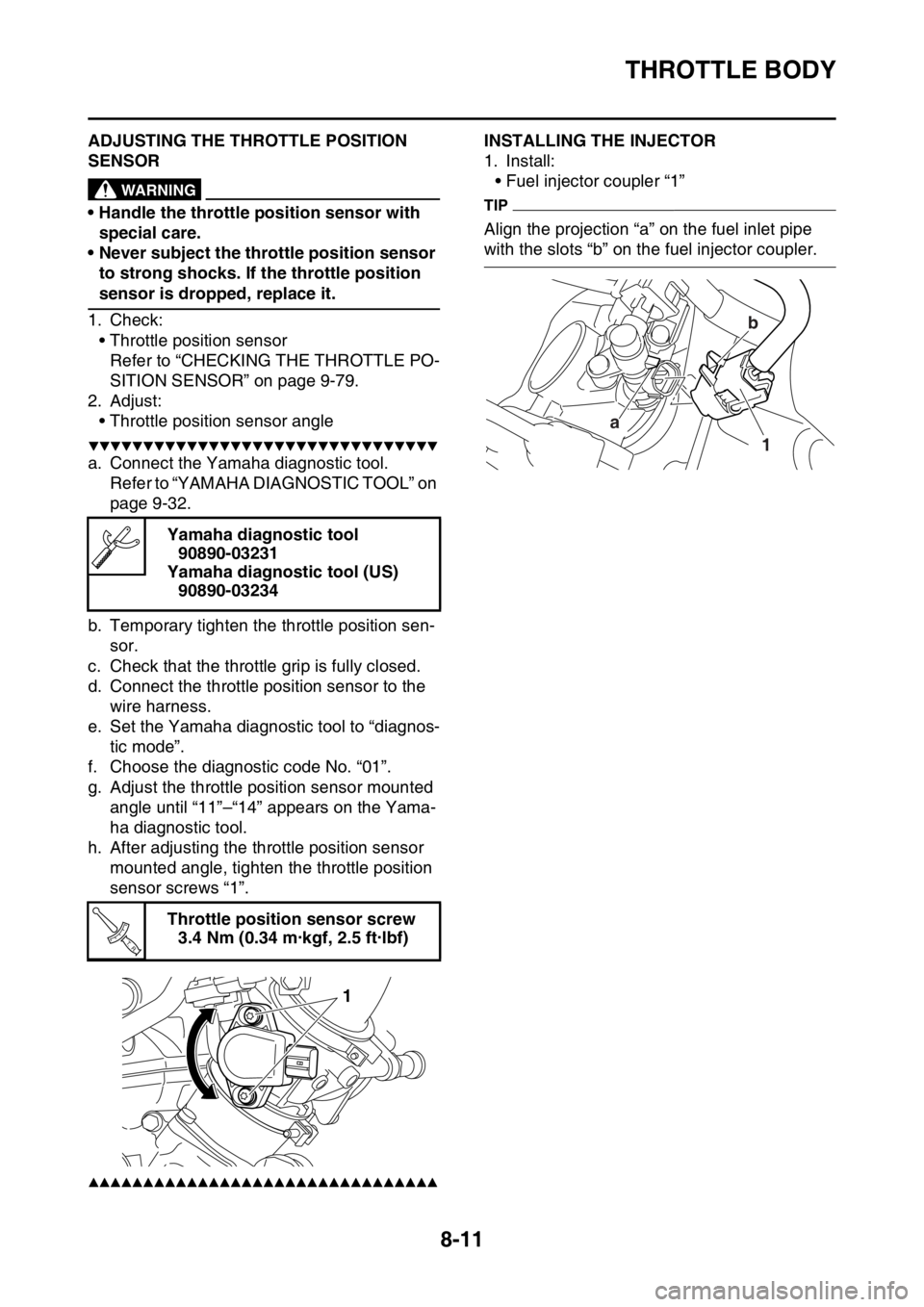

EAS2GC1355ADJUSTING THE THROTTLE POSITION

SENSOR

EWA

WARNING

• Handle the throttle position sensor with special care.

• Never subject the throttle position sensor

to strong shocks. If the throttle position

sensor is dropped, replace it.

1. Check: • Throttle position sensorRefer to “CHECKING THE THROTTLE PO-

SITION SENSOR” on page 9-79.

2. Adjust: • Throttle position sensor angle

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool. Refer to “YAMAHA DIAGNOSTIC TOOL” on

page 9-32.

b. Temporary tighten the throttle position sen- sor.

c. Check that the throttle grip is fully closed.

d. Connect the throttle position sensor to the wire harness.

e. Set the Yamaha diagnostic tool to “diagnos- tic mode”.

f. Choose the diagnostic code No. “01”.

g. Adjust the throttle position sensor mounted

angle until “11”–“14” appears on the Yama-

ha diagnostic tool.

h. After adjusting the throttle position sensor mounted angle, tighten the throttle position

sensor screws “1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1356INSTALLING THE INJECTOR

1. Install:• Fuel injector coupler “1”

TIP

Align the projection “a” on the fuel inlet pipe

with the slots “b” on the fuel injector coupler.

Yamaha diagnostic tool 90890-03231

Yamaha diagnostic tool (US) 90890-03234

Throttle position sensor screw 3.4 Nm (0.34 m·kgf, 2.5 ft·lbf)

T R..

1

1

a

b

Page 330 of 426

ELECTRICAL COMPONENTS....................................................................... 9-60

CHECKING THE SWITCHES .................................................................. 9-64

CHECKING THE BULBS AND BULB SOCKETS .................................... 9-67

CHECKING THE FUSES ......................................................................... 9-68

CHECKING AND CHARGING THE BATTERY ........................................ 9-69

CHECKING THE RELAYS ....................................................................... 9-72

CHECKING THE DIODE .......................................................................... 9-73

CHECKING THE IGNITION SPARK GAP................................................ 9-73

CHECKING THE SPARK PLUG CAP ...................................................... 9-73

CHECKING THE IGNITION COIL ............................................................ 9-74

CHECKING THE CRANKSHAFT POSITION SENSOR........................... 9-74

CHECKING THE LEAN ANGLE SENSOR............................................... 9-75

CHECKING THE STARTER MOTOR OPERATION ................................ 9-75

CHECKING THE STATOR COIL ............................................................. 9-76

CHECKING THE RECTIFIER/REGULATOR ........................................... 9-76

CHECKING THE SPEED SENS OR ......................................................... 9-77

CHECKING THE FUEL SENDER ............................................................ 9-77

CHECKING THE RESISTER ................................................................... 9-77

CHECKING THE RADIATOR FAN MOTOR ............................................ 9-78

CHECKING THE COOLANT TEMPERATURE SENSOR........................ 9-78

CHECKING THE THROTTLE POSITION SENSOR ................................ 9-79

CHECKING THE THROTTLE POSITION SENSOR INPUT VOLTAGE .. 9-79

CHECKING THE INTAKE AIR PR ESSURE SENSOR ............................ 9-80

CHECKING THE INTAKE AIR TEMPERATURE SENSOR ..................... 9-80

CHECKING THE FUEL INJECTOR ......................................................... 9-81

Page 333 of 426

IGNITION SYSTEM

9-3

1. Joint connector

2. Joint connector

4. AC magneto

9. Battery

10.Frame ground

11.Starter relay

12.Main fuse

22.ECU (engine control unit)

23.Ignition coil

24.Spark plug

30.Joint connector

35.Lean angle sensor

36.Engine stop switch

48.Frame ground

49.Ignition coil sub-lead

50.Negative battery lead

Page 334 of 426

IGNITION SYSTEM

9-4

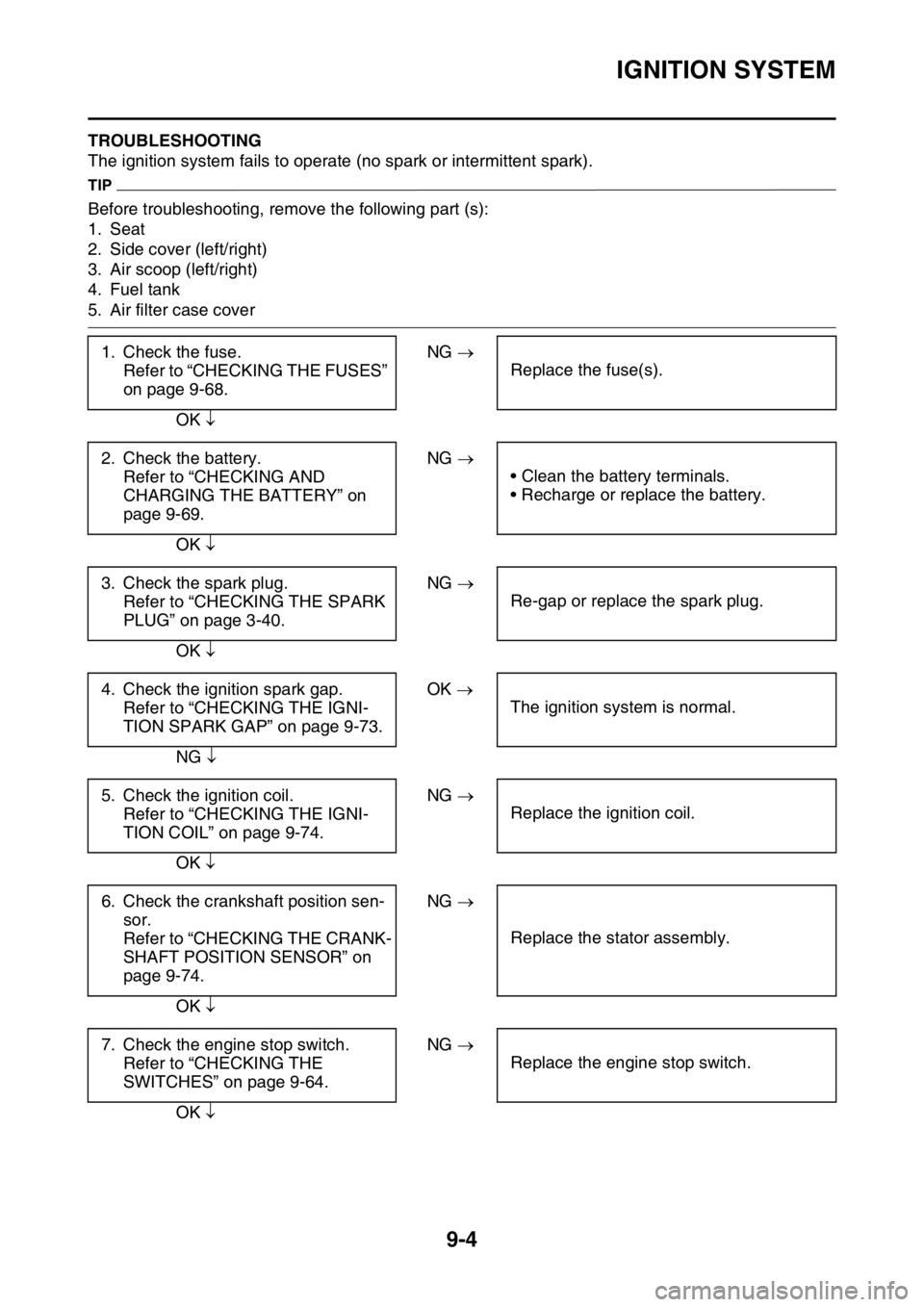

EAS2GC1360TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part (s):

1. Seat

2. Side cover (left/right)

3. Air scoop (left/right)

4. Fuel tank

5. Air filter case cover1. Check the fuse. Refer to “CHECKING THE FUSES”

on page 9-68. NG

Replace the fuse(s).

OK

2. Check the battery. Refer to “CHECKING AND

CHARGING THE BATTERY” on

page 9-69. NG

• Clean the battery terminals.

• Recharge or replace the battery.

OK

3. Check the spark plug. Refer to “CHECKING THE SPARK

PLUG” on page 3-40. NG

Re-gap or replace the spark plug.

OK

4. Check the ignition spark gap. Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 9-73. OK

The ignition system is normal.

NG

5. Check the ignition coil. Refer to “CHECKING THE IGNI-

TION COIL” on page 9-74. NG

Replace the ignition coil.

OK

6. Check the crankshaft position sen- sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 9-74. NG

Replace the stator assembly.

OK

7. Check the engine stop switch. Refer to “CHECKING THE

SWITCHES” on page 9-64. NG

Replace the engine stop switch.

OK