sensor YAMAHA WR 450F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 93 of 426

CABLE ROUTING DIAGRAM

2-42

1. Clutch switch lead

2. Engine stop switch lead

3. Clutch cable

4. Brake hose guide

5. Headlight lead

6. Speed sensor lead

7. Indicator light coupler

8. Meter assembly optional switch coupler

9. Meter assembly coupler

10. Speed sensor coupler

11. Start switch lead

12. Plastic band

13. Throttle cable

14. Front brake hose

A. Route the throttle cable, clutch cable, clutch switch lead, engine stop switch lead and start

switch lead between the cable guide of the meter

bracket and handle crown. The cables and leads

may be routed in any order.

B. Clamp the wire harness, clutch switch lead and start switch lead to the meter bracket. The clamp

shall be located at a pos ition where there is no

slack with the handle turned fully to the left.

C. Connect the headlight lead to the headlight.

D. Clamp the start switch lead to the handlebar by the plastic band.

E. Clamp the engine stop switch lead and clutch switch lead to the handlebar by the plastic band.

F. 40°±10°

G. Vertical direction

H. Pass the engine stop switch lead under the han- dlebar.

Page 139 of 426

ELECTRICAL SYSTEM

3-41

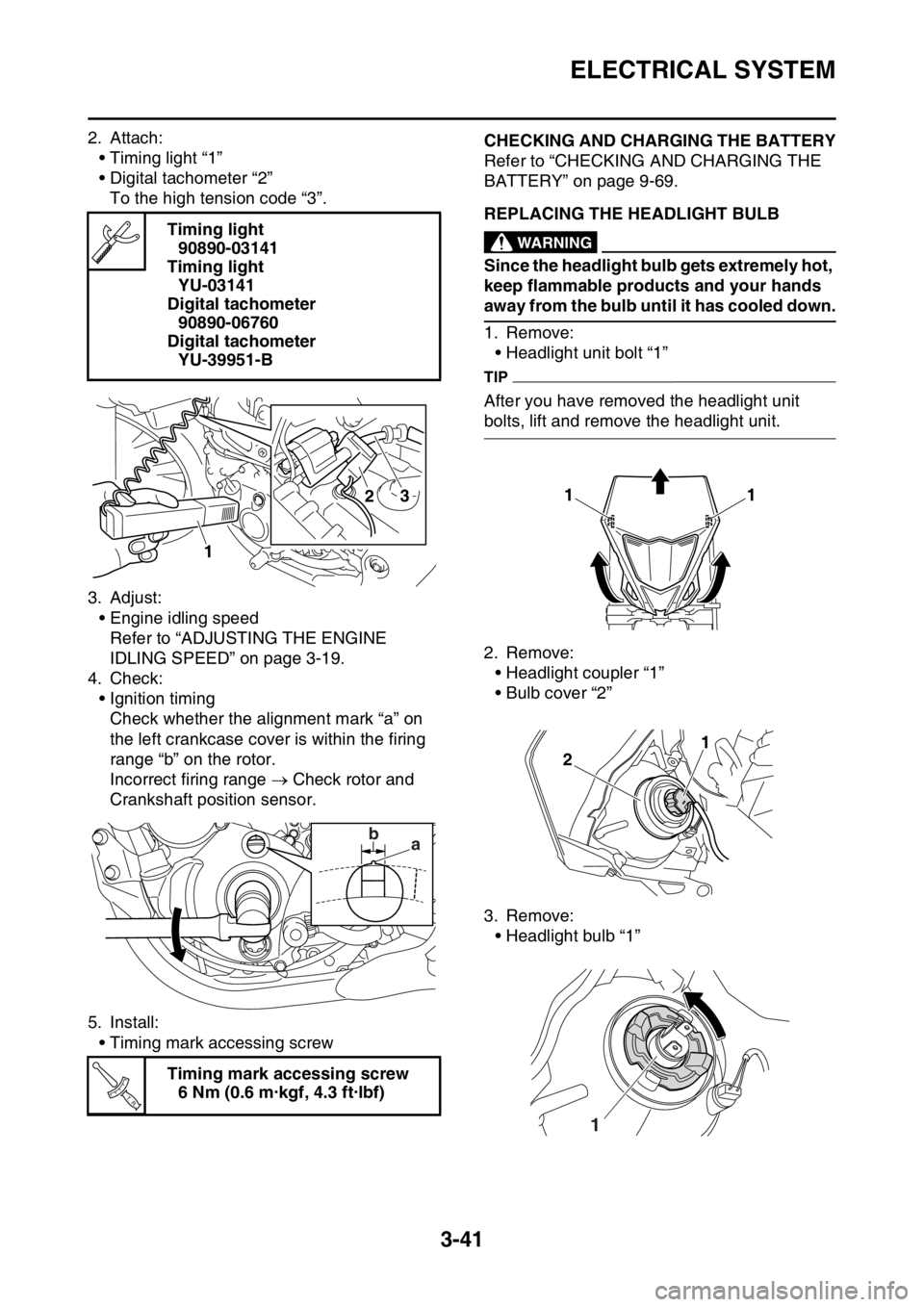

2. Attach:• Timing light “1”

• Digital tachometer “2”To the high tension code “3”.

3. Adjust: • Engine idling speedRefer to “ADJUSTING THE ENGINE

IDLING SPEED” on page 3-19.

4. Check: • Ignition timingCheck whether the alignment mark “a” on

the left crankcase cover is within the firing

range “b” on the rotor.

Incorrect firing range Check rotor and

Crankshaft position sensor.

5. Install: • Timing mark accessing screwEAS2GC1133CHECKING AND CHARGING THE BATTERY

Refer to “CHECKING AND CHARGING THE

BATTERY” on page 9-69.

EAS2GC1134REPLACING THE HEADLIGHT BULBEWA

WARNING

Since the headlight bulb gets extremely hot,

keep flammable products and your hands

away from the bulb until it has cooled down.

1. Remove:• Headlight unit bolt “1”

TIP

After you have removed the headlight unit

bolts, lift and remove the headlight unit.

2. Remove:

• Headlight coupler “1”

• Bulb cover “2”

3. Remove: • Headlight bulb “1”

Timing light

90890-03141

Timing light YU-03141

Digital tachometer 90890-06760

Digital tachometer YU-39951-B

Timing mark accessing screw 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

2

1

3

ba

T R..

11

1

2

1

Page 154 of 426

GENERAL CHASSIS

5-2

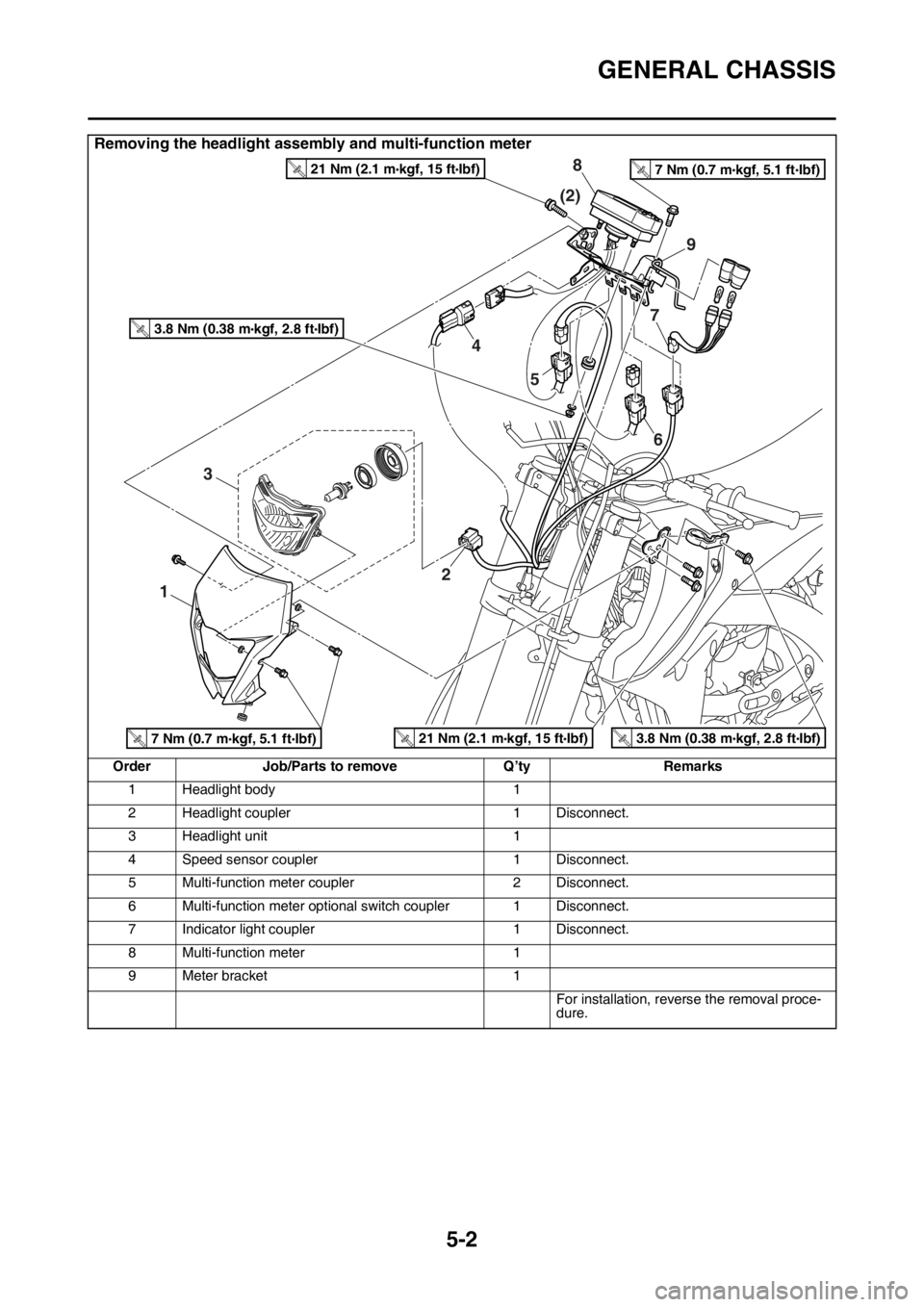

Removing the headlight assembly and multi-function meter

OrderJob/Parts to remove Q’tyRemarks

1 Headlight body 1

2 Headlight coupler 1 Disconnect.

3 Headlight unit 1

4 Speed sensor coupler 1 Disconnect.

5 Multi-function meter coupler 2 Disconnect.

6 Multi-function meter optional switch coupler 1 Disconnect.

7 Indicator light coupler 1 Disconnect.

8 Multi-function meter 1

9 Meter bracket 1

For installation, reverse the removal proce-

dure.

4 (2)

6

7

8

9

5

1

3 2

21 Nm (2.1 m kgf, 15 ft Ibf)T.R.3.8 Nm (0.38 m kgf, 2.8 ft Ibf)T.R.

3.8 Nm (0.38 m kgf, 2.8 ft Ibf)T.R.

21 Nm (2.1 m kgf, 15 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

7 Nm (0.7 m kgf, 5.1 ft Ibf)T.R.

Page 156 of 426

FRONT WHEEL

5-4

EAS2GC1154

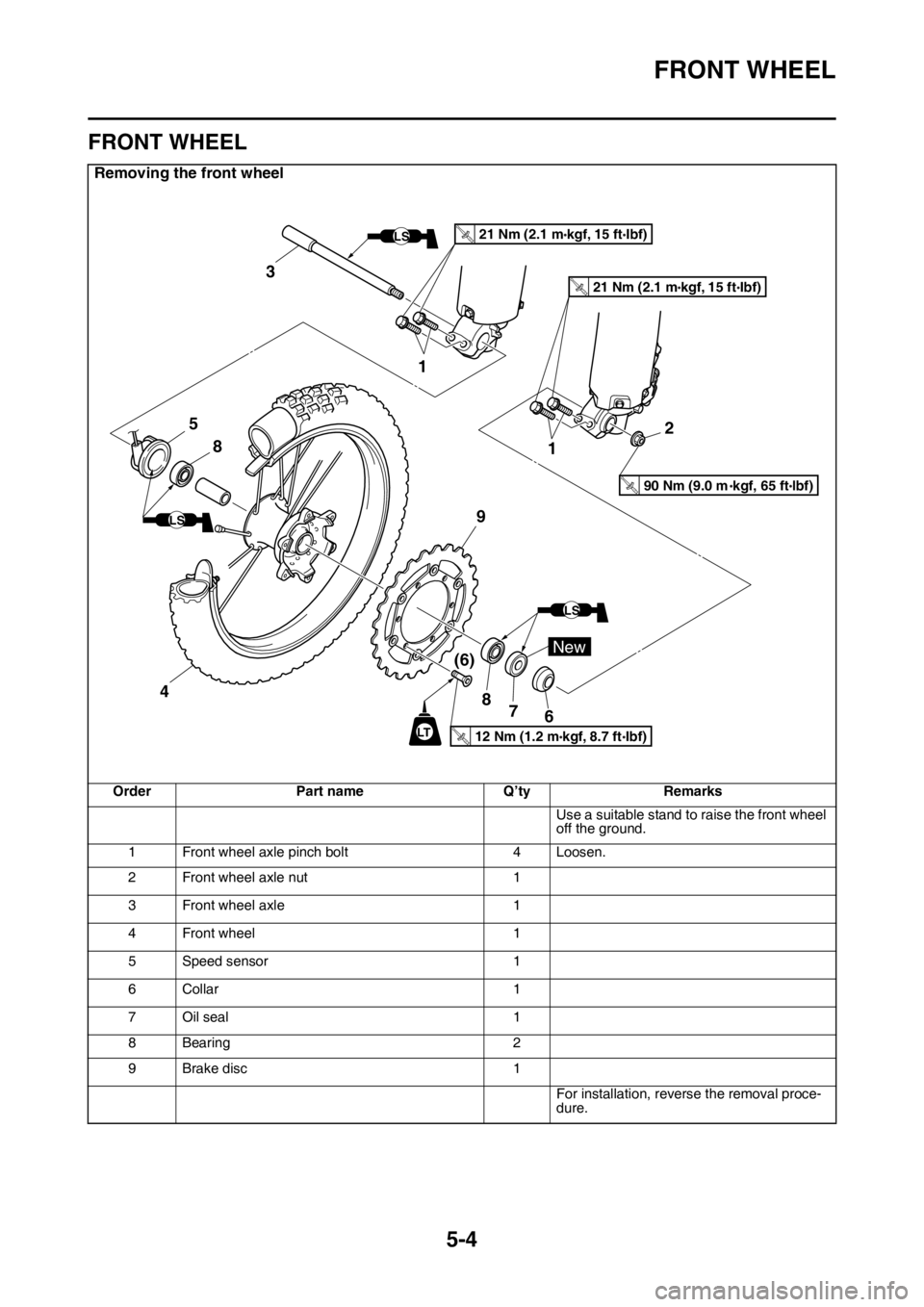

FRONT WHEEL

Removing the front wheel

OrderPart name Q’tyRemarks

Use a suitable stand to raise the front wheel

off the ground.

1 Front wheel axle pinch bolt 4 Loosen.

2 Front wheel axle nut 1

3 Front wheel axle 1

4 Front wheel 1

5 Speed sensor 1

6Collar 1

7 Oil seal 1

8 Bearing 2

9 Brake disc 1

For installation, reverse the removal proce-

dure.

12 Nm (1.2 m kgf, 8.7 ft Ibf)T.R.

New

LT

LS

LS

LS

8

7

8

(6)

9

1 2

1

3

21 Nm (2.1 m kgf, 15 ft Ibf)T.R.

21 Nm (2.1 m kgf, 15 ft Ibf)T.R.

4

90 Nm (9.0 m kgf, 65 ft lbf)T.R.

5

6

Page 159 of 426

FRONT WHEEL

5-7

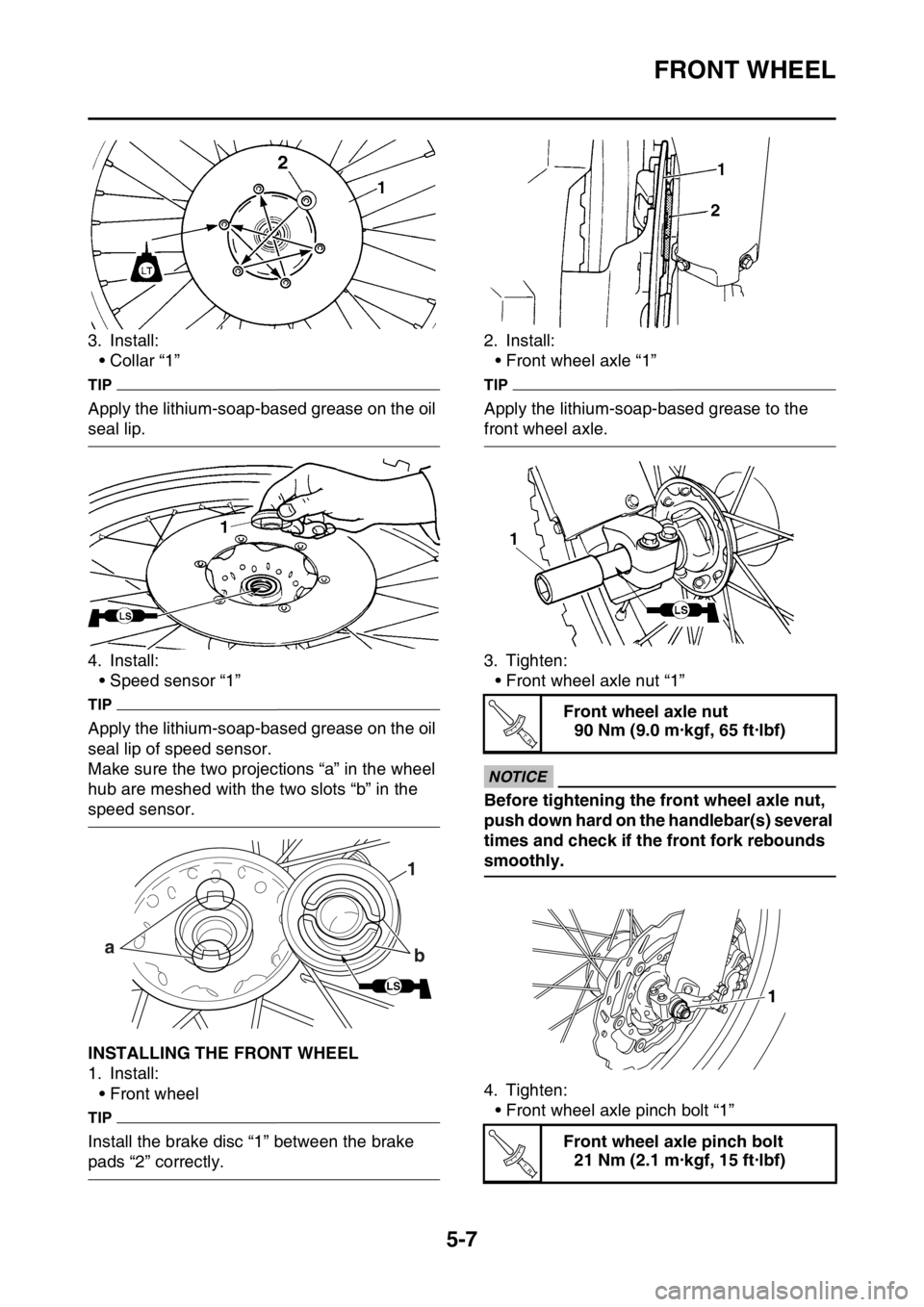

3. Install:• Collar “1”

TIP

Apply the lithium-soap-based grease on the oil

seal lip.

4. Install:

• Speed sensor “1”

TIP

Apply the lithium-soap-based grease on the oil

seal lip of speed sensor.

Make sure the two projections “a” in the wheel

hub are meshed with the two slots “b” in the

speed sensor.

EAS2GC1159INSTALLING THE FRONT WHEEL

1. Install:• Front wheel

TIP

Install the brake disc “1” between the brake

pads “2” correctly. 2. Install:

• Front wheel axle “1”

TIP

Apply the lithium-soap-based grease to the

front wheel axle.

3. Tighten:

• Front wheel axle nut “1”

ECA

NOTICE

Before tightening the front wheel axle nut,

push down hard on the handlebar(s) several

times and check if the front fork rebounds

smoothly.

4. Tighten:• Front wheel axle pinch bolt “1”1

a b

LS

Front wheel axle nut

90 Nm (9.0 m·kgf, 65 ft·lbf)

Front wheel axle pinch bolt 21 Nm (2.1 m·kgf, 15 ft·lbf)

T R..

1

T R..

Page 203 of 426

FRONT FORK

5-51

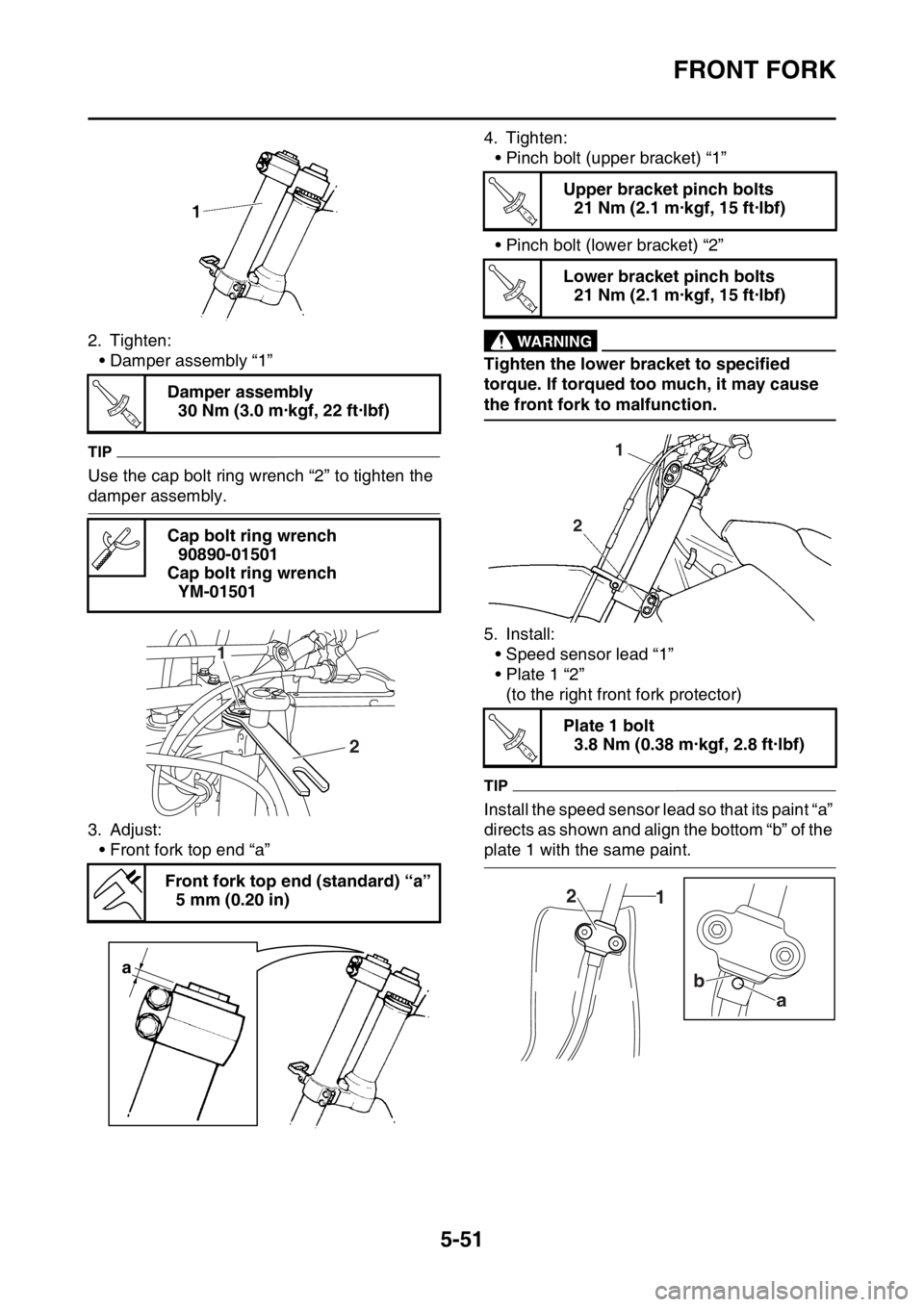

2. Tighten:• Damper assembly “1”

TIP

Use the cap bolt ring wrench “2” to tighten the

damper assembly.

3. Adjust:

• Front fork top end “a” 4. Tighten:

• Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

5. Install:• Speed sensor lead “1”

• Plate 1 “2”(to the right front fork protector)

TIP

Install the speed sensor lead so that its paint “a”

directs as shown and align the bottom “b” of the

plate 1 with the same paint.

Damper assembly

30 Nm (3.0 m·kgf, 22 ft·lbf)

Cap bolt ring wrench 90890-01501

Cap bolt ring wrench YM-01501

Front fork top end (standard) “a” 5 mm (0.20 in)

T R..

2

1

a

Upper bracket pinch bolts21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

Plate 1 bolt 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

T R..

2 1

T R..

1

2

a

b

Page 204 of 426

FRONT FORK

5-52

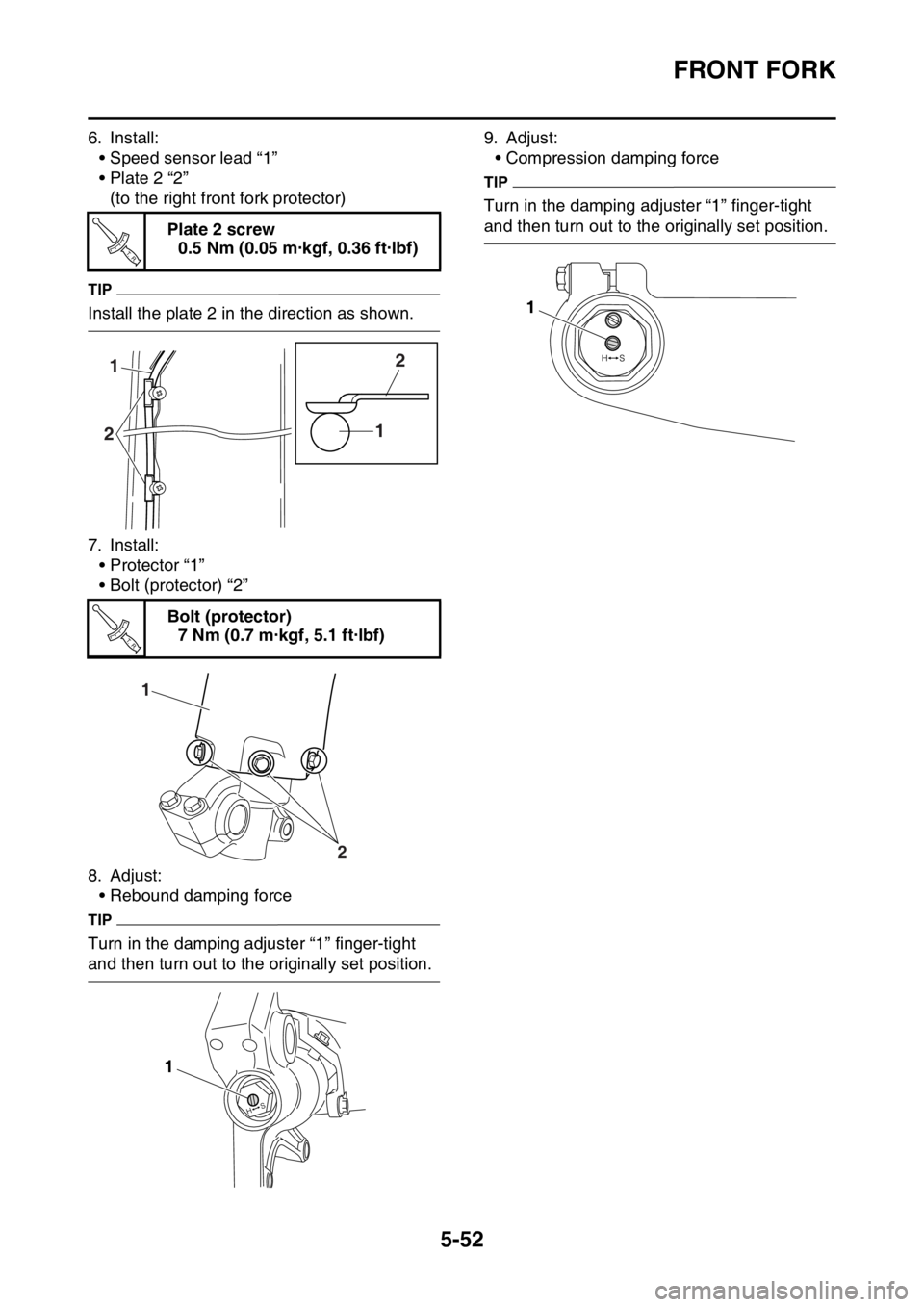

6. Install:• Speed sensor lead “1”

• Plate 2 “2”(to the right front fork protector)

TIP

Install the plate 2 in the direction as shown.

7. Install:• Protector “1”

• Bolt (protector) “2”

8. Adjust: • Rebound damping force

TIP

Turn in the damping adjuster “1” finger-tight

and then turn out to the originally set position. 9. Adjust:

• Compression damping force

TIP

Turn in the damping adjuster “1” finger-tight

and then turn out to the originally set position.

Plate 2 screw

0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

Bolt (protector) 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

1

2 12

T R..

1

2

1

1

Page 209 of 426

STEERING HEAD

5-57

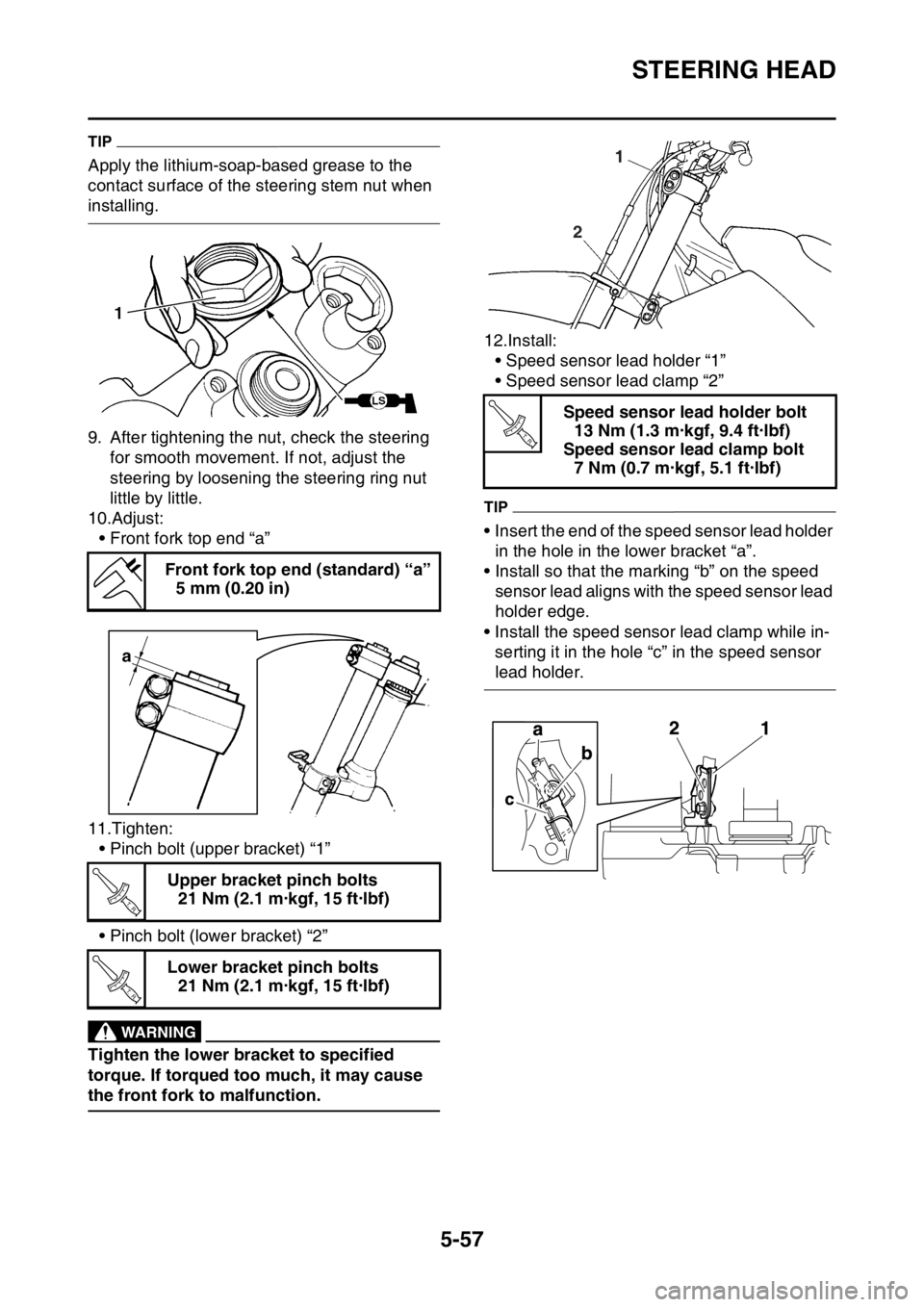

TIP

Apply the lithium-soap-based grease to the

contact surface of the steering stem nut when

installing.

9. After tightening the nut, check the steering for smooth movement. If not, adjust the

steering by loosening the steering ring nut

little by little.

10.Adjust:

• Front fork top end “a”

11.Tighten: • Pinch bolt (upper bracket) “1”

• Pinch bolt (lower bracket) “2”

EWA

WARNING

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction. 12.Install:

• Speed sensor lead holder “1”

• Speed sensor lead clamp “2”

TIP

• Insert the end of the speed sensor lead holder

in the hole in the lower bracket “a”.

• Install so that the marking “b” on the speed sensor lead aligns with the speed sensor lead

holder edge.

• Install the speed sens or lead clamp while in-

serting it in the hole “c” in the speed sensor

lead holder.

Front fork top end (standard) “a”

5 mm (0.20 in)

Upper bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

Lower bracket pinch bolts 21 Nm (2.1 m·kgf, 15 ft·lbf)

a

T R..

T R..

Speed sensor lead holder bolt13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Speed sensor lead clamp bolt 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

2 1

T R..

Page 230 of 426

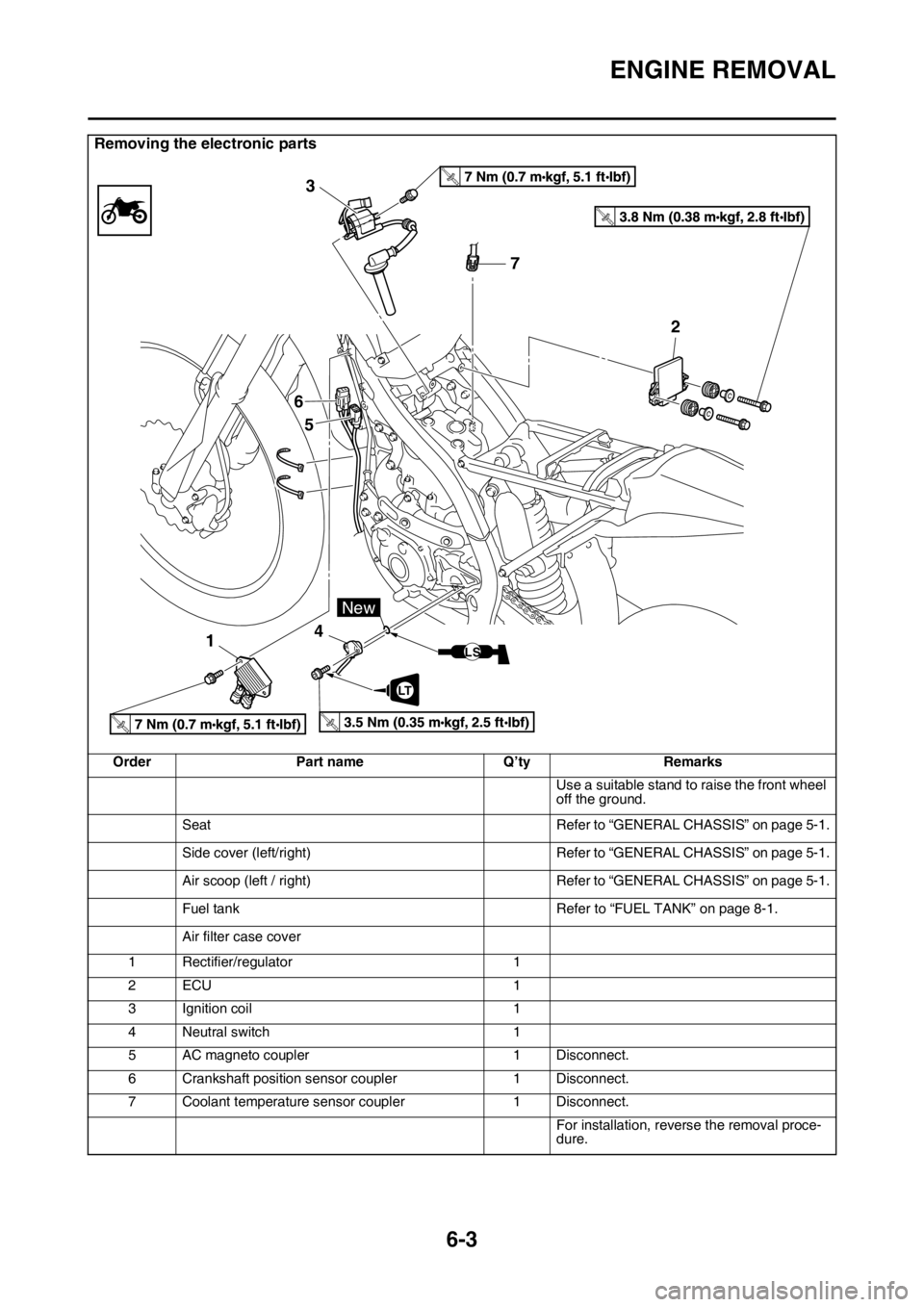

ENGINE REMOVAL

6-3

Removing the electronic parts

OrderPart name Q’tyRemarks

Use a suitable stand to raise the front wheel

off the ground.

Seat Refer to “GENERAL CHASSIS” on page 5-1.

Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-1.

Air scoop (left / right) Refer to “GENERAL CHASSIS” on page 5-1.

Fuel tank Refer to “FUEL TANK” on page 8-1.

Air filter case cover

1 Rectifier/regulator 1

2ECU 1

3 Ignition coil 1

4 Neutral switch 1

5 AC magneto coupler 1 Disconnect.

6 Crankshaft position sensor coupler 1 Disconnect.

7 Coolant temperature sens or coupler1 Disconnect.

For installation, reverse the removal proce-

dure.

T.R.

T.R.

T.R.T.R.

7

3

6 5

1 4 2

LT

New

LS

Page 291 of 426

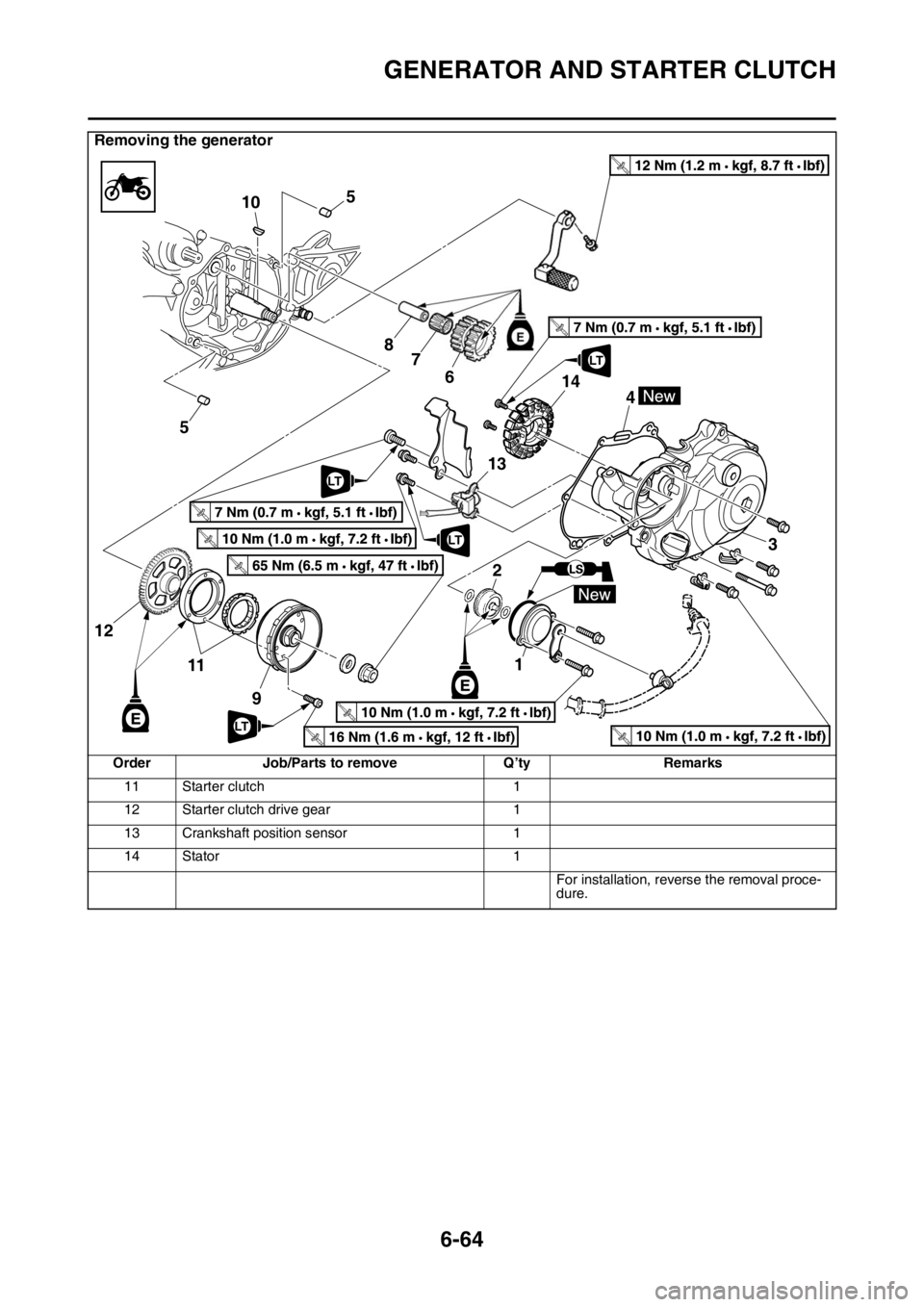

GENERATOR AND STARTER CLUTCH

6-64

11 Starter clutch1

12 Starter clutch drive gear 1

13 Crankshaft position sensor 1

14 Stator 1

For installation, reverse the removal proce-

dure.

Removing the generator

Order Job/Parts to remove Q’tyRemarks

T R..

T R..

T R..

5

5 10

87

6

21

13 3

4

11 9

12

T R..

T R..

T R..LT

LT

T R..

T R..

14

LT

LT