check engine YAMAHA WR 450F 2016 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 341 of 426

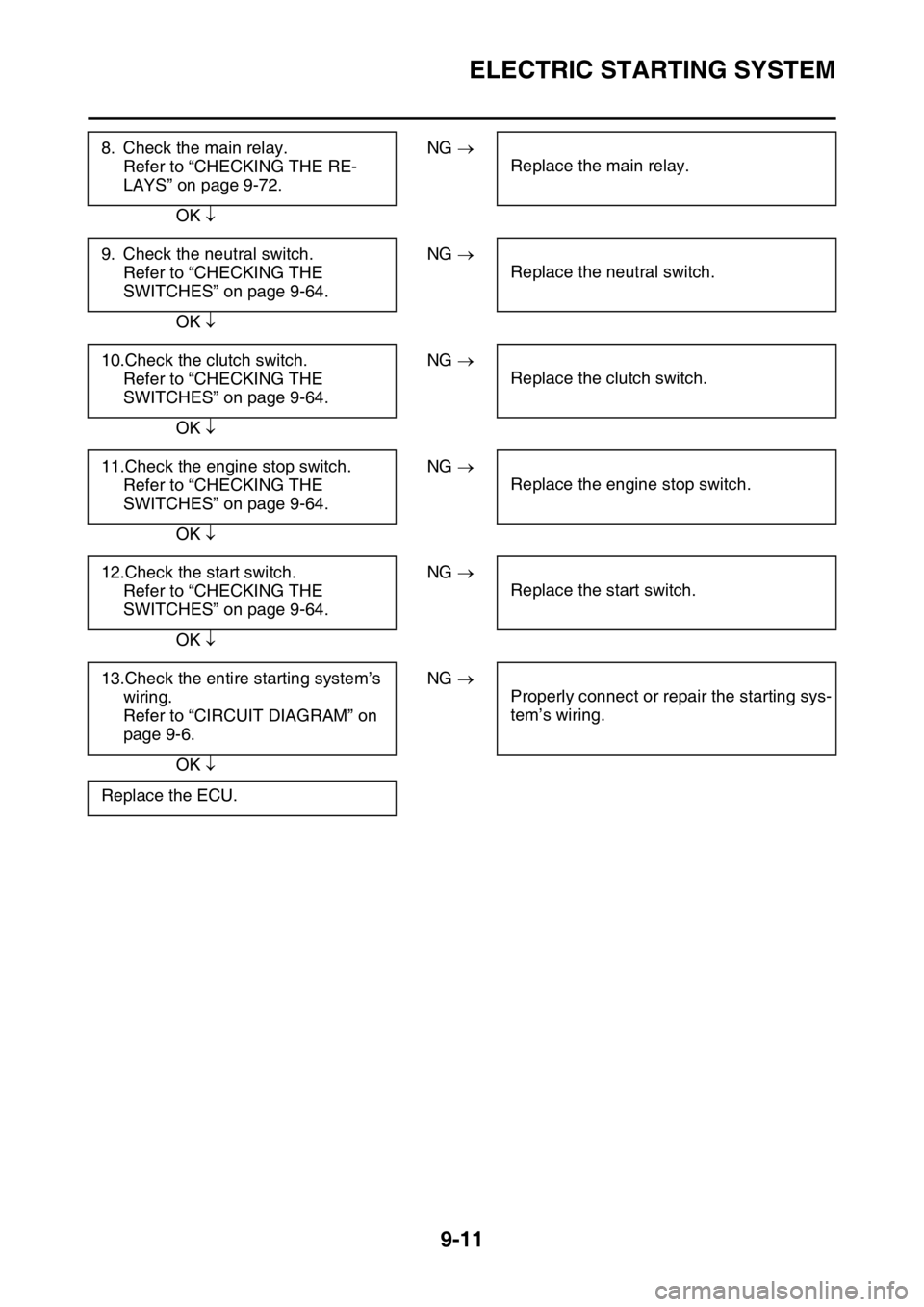

ELECTRIC STARTING SYSTEM

9-11

8. Check the main relay.Refer to “CHECKING THE RE-

LAYS” on page 9-72. NG

Replace the main relay.

OK

9. Check the neutral switch. Refer to “CHECKING THE

SWITCHES” on page 9-64. NG

Replace the neutral switch.

OK

10.Check the clutch switch. Refer to “CHECKING THE

SWITCHES” on page 9-64. NG

Replace the clutch switch.

OK

11.Check the engine stop switch. Refer to “CHECKING THE

SWITCHES” on page 9-64. NG

Replace the engine stop switch.

OK

12.Check the start switch. Refer to “CHECKING THE

SWITCHES” on page 9-64. NG

Replace the start switch.

OK

13.Check the entire starting system’s wiring.

Refer to “CIRCUIT DIAGRAM” on

page 9-6. NG

Properly connect or repair the starting sys-

tem’s wiring.

OK

Replace the ECU.

Page 360 of 426

FUEL INJECTION SYSTEM

9-30

EAS2GC1375ECU SELF-DIAGNOSTIC FUNCTION

The ECU is equipped with a self-diagnostic function in order to ensure that the fuel injection system

is operating normally. If this function detects a malfunction in the system, it immediately operates the

engine under substitute characteristics and illuminat es the engine trouble warning light to alert the

rider that a malfunction has occurred in the syst em. Once a malfunction has been detected, a fault

code number is stored in the memory of the ECU.

• To inform the rider that the fuel injection system is not functioning, the engine trouble warning light

flashes while the start switch is being pushed to start the engine.

• If a malfunction is detected in the system by th e self-diagnostic function, the ECU provides an ap-

propriate substitute characteristic operation, and al erts the rider of the detected malfunction by illu-

minating the engine trouble warning light.

Engine trouble warning light indication and fuel injection system operation

* The warning light flashes when any one of the foll owing conditions is present and the start switch

is pushed:

Checking the engine trouble warning light

The engine trouble warning light comes on for around 2 seconds when pushing the start switch to

turn on the meter light and the engine trouble warning light comes on while the start switch is being

pushed. Warning light indica-

tion ECU operation Fuel injection opera-

tion Vehicle operation

Flashing* Warning provided when unable to start

engine Operation stopped Cannot be operated

Remains on Malfunction detected Operated with substi- tute characteristics in

accordance with the

description of the mal-

functionCan or cannot be oper-

ated depending on the

fault code

12: Crankshaft position sensor 41: Lean angle sensor (open or short circuit)

30: Lean angle sensor (latch up detected) 50: ECU internal malfunction

(faulty ECU memory)

33: Ignition coil (Malfunction detected in the primary wire

of the ignition coil)

a. The meter light does not come on.

b. The meter light comes on.

c. Light OFF

d. Light ON for 2 seconds

ab

cd c

Page 361 of 426

FUEL INJECTION SYSTEM

9-31

ECU detects an abnormal signal from a sensor

If the ECU detects an abnormal signal from a sensor while the vehicle is being driven, the ECU illu-

minates the engine trouble warning light and provides the engine with alternate operating instructions

that are appropriate for the type of malfunction.

When an abnormal signal is received from a sensor, the ECU processes the specified values that are

programmed for each sensor in order to provide the engine with alternate operating instructions that

enable the engine to continue operating or stop operating, depending on the conditions.

EAS2GC1376TROUBLESHOOTING METHOD

The engine operation is not normal and the engine trouble warning light comes on.

1. Check: • Fault code number

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the Yamaha diagnostic tool. Refer to “YAMAHA DIAGNOSTIC TOOL” on page 9-32.

b. Check the fault code number disp layed on the Yamaha diagnostic tool.

c. Identify the faulty system with the fault code number.

d. Identify the probable cause of the malfunction.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Check and repair the probable cause of the malfunction.

3. Perform the reinstatement action for the fuel injection system. Refer to “Confirmation of service

completion” in the appropriate table in “TROUBLESHOOTING DETAILS” on page 9-35.

4. After pushing the engine stop switch, push the start switch to check whether the fault code no. is

displayed.

TIP

If another fault code number is displayed, repeat steps (1) to (4) until no fault code number is dis-

played.

5. Erase the malfunction history in the diagnostic mode. Refer to “SENSOR OPERATION TABLE”

(Diagnostic code No.62).

TIP

Turning off the meter light will not erase the malfunction history.

The engine operation is not normal, but the engine trouble warning light does not come on.

1. Check the operation of the following sensors an d actuators in the diagnostic mode. Refer to

“TROUBLESHOOTING DETAILS” on page 9-35.

If a malfunction is detected in the sensors or ac tuators, repair or replace all faulty parts.

If no malfunction is detected in the sensors and ac tuators, check and repair the inner parts of the

engine. Fault code No. No fault code No.

Check and repair. Refer to “TROUBLESHOOT-

ING DETAILS” on page 9-35.

Monitor the operation of the sensors and actua-

tors in the diagnostic mode. Refer to “TROU-

BLESHOOTING DETAILS” on page 9-35 and

“LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE

ACTIONS” on page 10-5. Check and repair.

01: Throttle position sensor signal (throttle angle)

30: Ignition coil

36: Injector

Page 365 of 426

FUEL INJECTION SYSTEM

9-35

6. ConditionThe current conditions are displayed. (Detected/Recovered)

7. Symptom

The symptoms of the detected malfunction are displayed.

8. Diagnosis code The diagnosis codes related to the detected malfunction are displayed.

9. FFD (only for models that can display freeze frame data) The mark “ ” is displayed when the freeze frame data is available.

10.ECU conduction time (hour: minute: second)

The total ECU conduction time (total hours the vehicle’s start switch was ON) when the malfunc-

tion was detected is displayed.

11.Number of main switch operation after detection

The number of times the meter light comes on by pushing the start switch between the malfunction

detection and code reading is displayed.

12.Number of occurrences The number of malfunction occurrences between th e malfunction detection and code reading is

displayed.

EAS2GC1378TROUBLESHOOTING DETAILS

This section describes the measures per fault c ode number displayed on the diagnostic tool. Check

and service the items or components that are the probable cause of the malfunction following the or-

der given.

After the check and service of the malfunctioning part have been completed, reset the diagnostic tool

display according to the reinstatement method.

Fault code No.:

Fault code number displayed on the diagnostic tool when the engine failed to work normally.

Diagnostic code No.:

Diagnostic code number to be used when the diagnostic mode is operated.

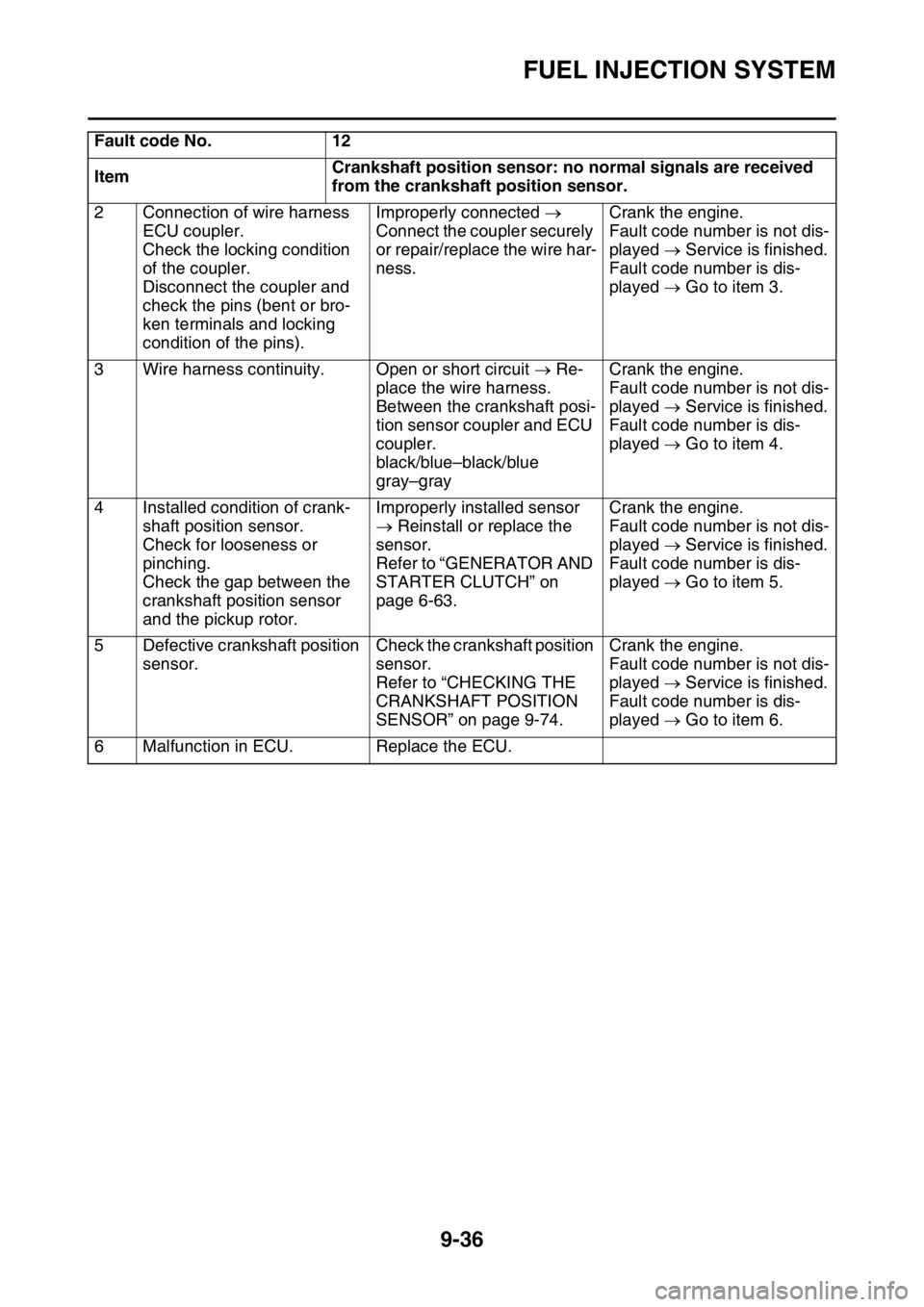

Fault code No. 12

Item Crankshaft position sensor: no normal signals are received

from the crankshaft position sensor.

Fail-safe system Unable to start engine

Unable to drive vehicle

Diagnostic code No. —

Diagnostic tool display —

Procedure —

Item Probable cause of malfunc-

tion and check Maintenance jobConfirmation of service

completion

1 Connection of crankshaft po- sition sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 2.

Page 366 of 426

FUEL INJECTION SYSTEM

9-36

2 Connection of wire harness ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 3.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between the crankshaft posi-

tion sensor coupler and ECU

coupler.

black/blue–black/blue

gray–gray Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 4.

4 Installed condition of crank- shaft position sensor.

Check for looseness or

pinching.

Check the gap between the

crankshaft position sensor

and the pickup rotor. Improperly installed sensor

Reinstall or replace the

sensor.

Refer to “GENERATOR AND

STARTER CLUTCH” on

page 6-63. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 5.

5 Defective crankshaft position sensor. Check the crankshaft position

sensor.

Refer to “CHECKING THE

CRANKSHAFT POSITION

SENSOR” on page 9-74. Crank the engine.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 6.

6 Malfunction in ECU. Replace the ECU. Fault code No. 12

Item Crankshaft position sensor: no normal signals are received

from the crankshaft position sensor.

Page 367 of 426

FUEL INJECTION SYSTEM

9-37

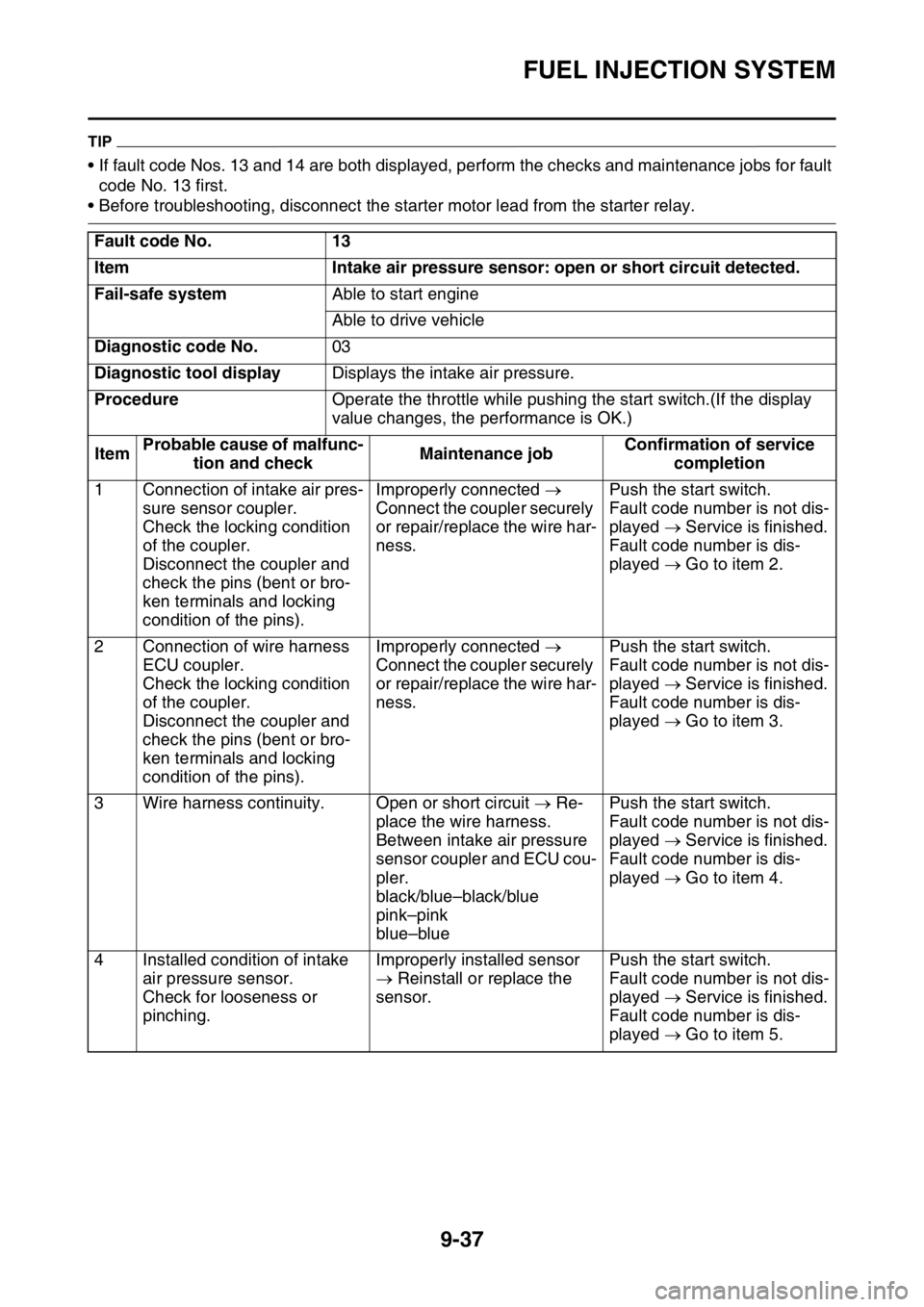

TIP

• If fault code Nos. 13 and 14 are both displayed, perform the checks and maintenance jobs for fault

code No. 13 first.

• Before troubleshooting, disconnect the star ter motor lead from the starter relay.

Fault code No. 13

Item Intake air pressure sensor: open or short circuit detected.

Fail-safe system Able to start engine

Able to drive vehicle

Diagnostic code No. 03

Diagnostic tool display Displays the intake air pressure.

Procedure Operate the throttle while pushing the start switch.(If the display

value changes, the performance is OK.)

Item Probable cause of malfunc-

tion and check Maintenance jobConfirmation of service

completion

1 Connection of intake air pres- sure sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 3.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between intake air pressure

sensor coupler and ECU cou-

pler.

black/blue–black/blue

pink–pink

blue–blue Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 4.

4 Installed condition of intake air pressure sensor.

Check for looseness or

pinching. Improperly installed sensor

Reinstall or replace the

sensor. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 5.

Page 368 of 426

FUEL INJECTION SYSTEM

9-38

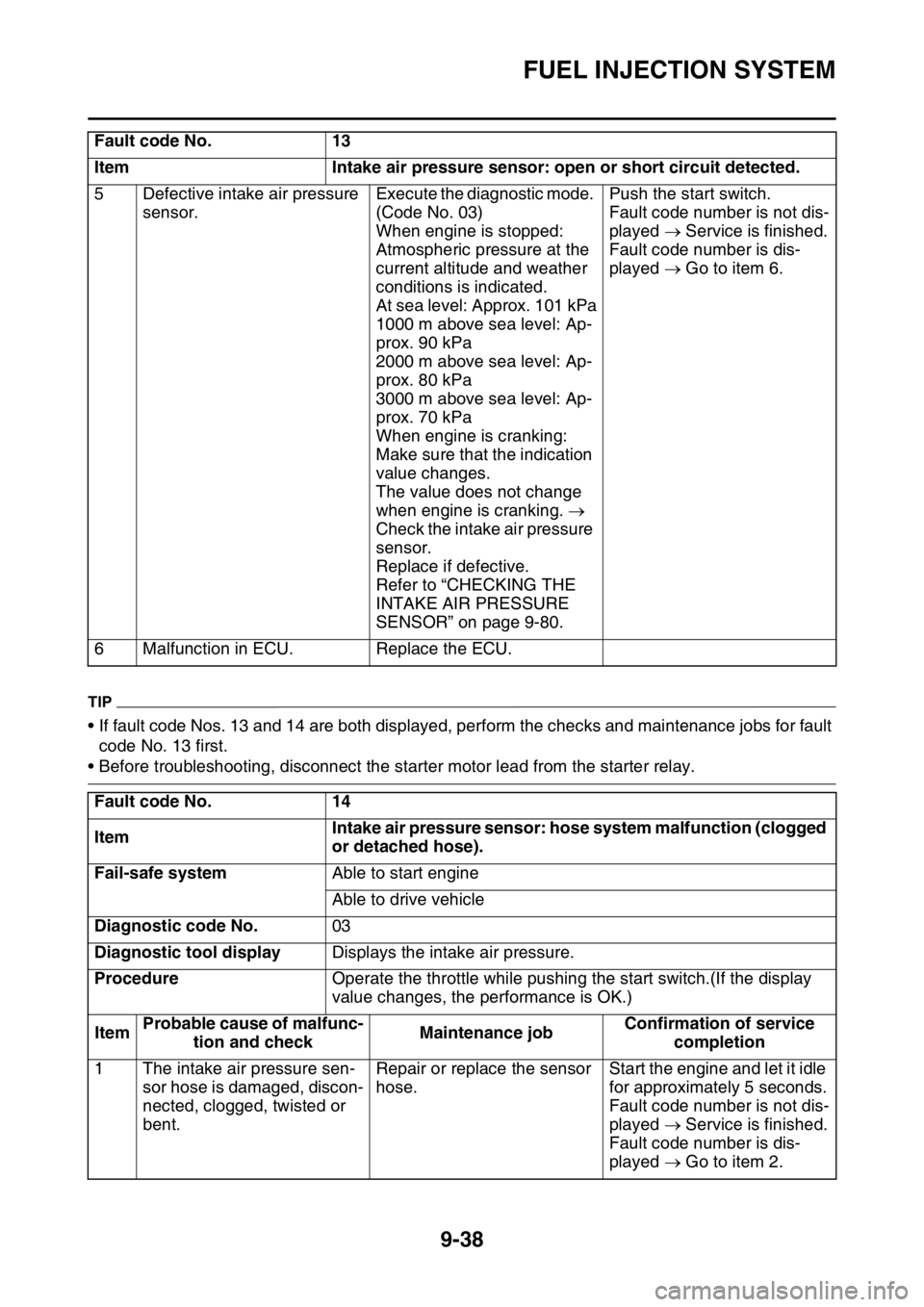

TIP

• If fault code Nos. 13 and 14 are both displayed, perform the checks and maintenance jobs for fault

code No. 13 first.

• Before troubleshooting, disconnect the star ter motor lead from the starter relay.

5 Defective intake air pressure

sensor. Execute the diagnostic mode.

(Code No. 03)

When engine is stopped:

Atmospheric pressure at the

current altitude and weather

conditions is indicated.

At sea level: Approx. 101 kPa

1000 m above sea level: Ap-

prox. 90 kPa

2000 m above sea level: Ap-

prox. 80 kPa

3000 m above sea level: Ap-

prox. 70 kPa

When engine is cranking:

Make sure that the indication

value changes.

The value does not change

when engine is cranking.

Check the intake air pressure

sensor.

Replace if defective.

Refer to “CHECKING THE

INTAKE AIR PRESSURE

SENSOR” on page 9-80. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 6.

6 Malfunction in ECU. Replace the ECU.

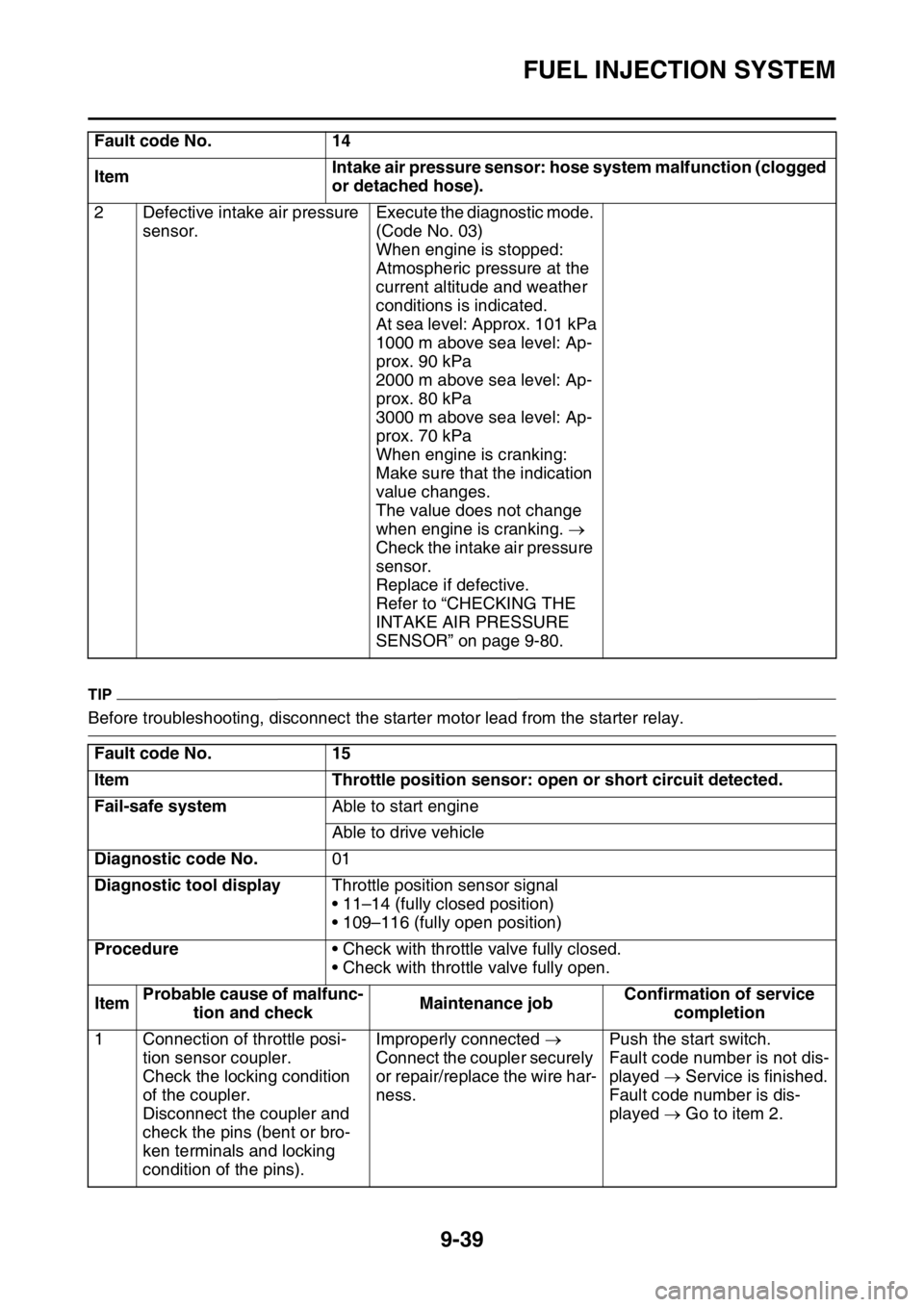

Fault code No. 14

Item Intake air pressure sensor: hose system malfunction (clogged

or detached hose).

Fail-safe system Able to start engine

Able to drive vehicle

Diagnostic code No. 03

Diagnostic tool display Displays the intake air pressure.

Procedure Operate the throttle while pushing the start switch.(If the display

value changes, the performance is OK.)

Item Probable cause of malfunc-

tion and check Maintenance jobConfirmation of service

completion

1 The intake air pressure sen- sor hose is damaged, discon-

nected, clogged, twisted or

bent. Repair or replace the sensor

hose.

Start the engine and let it idle

for approximately 5 seconds.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 2.

Fault code No. 13

Item Intake air pressure sensor: open or short circuit detected.

Page 369 of 426

FUEL INJECTION SYSTEM

9-39

TIP

Before troubleshooting, disconnect the starter motor lead from the starter relay.

2 Defective intake air pressure

sensor. Execute the diagnostic mode.

(Code No. 03)

When engine is stopped:

Atmospheric pressure at the

current altitude and weather

conditions is indicated.

At sea level: Approx. 101 kPa

1000 m above sea level: Ap-

prox. 90 kPa

2000 m above sea level: Ap-

prox. 80 kPa

3000 m above sea level: Ap-

prox. 70 kPa

When engine is cranking:

Make sure that the indication

value changes.

The value does not change

when engine is cranking.

Check the intake air pressure

sensor.

Replace if defective.

Refer to “CHECKING THE

INTAKE AIR PRESSURE

SENSOR” on page 9-80.

Fault code No. 15

Item Throttle position sensor: open or short circuit detected.

Fail-safe system Able to start engine

Able to drive vehicle

Diagnostic code No. 01

Diagnostic tool display Throttle position sensor signal

• 11–14 (fully closed position)

• 109–116 (fully open position)

Procedure • Check with throttle valve fully closed.

• Check with throttle valve fully open.

Item Probable cause of malfunc-

tion and check Maintenance jobConfirmation of service

completion

1 Connection of throttle posi- tion sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 2.

Fault code No.

14

Item Intake air pressure sensor: hose system malfunction (clogged

or detached hose).

Page 371 of 426

FUEL INJECTION SYSTEM

9-41

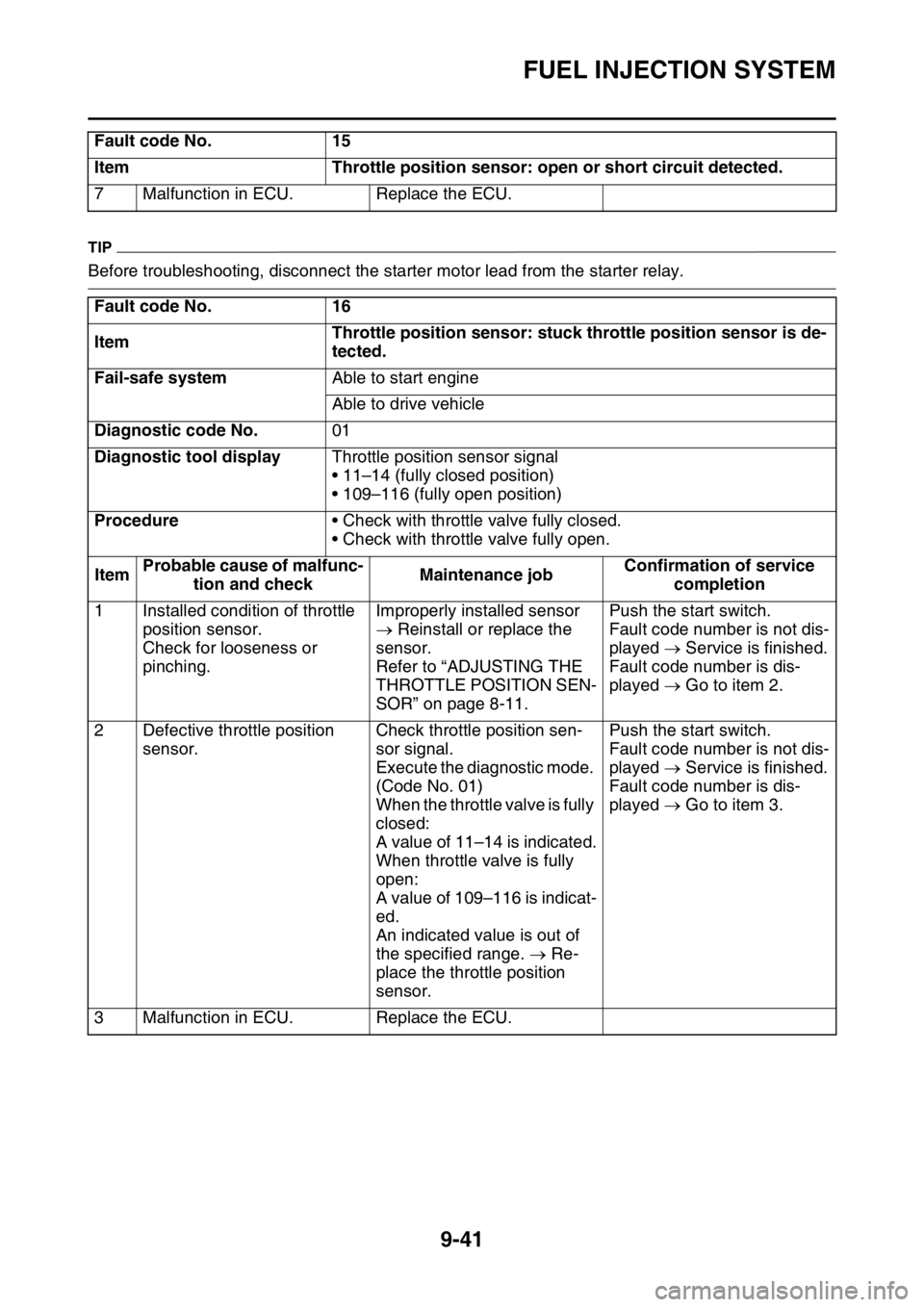

TIP

Before troubleshooting, disconnect the starter motor lead from the starter relay.

7 Malfunction in ECU. Replace the ECU.

Fault code No. 16

Item

Throttle position sensor: stuck throttle position sensor is de-

tected.

Fail-safe system Able to start engine

Able to drive vehicle

Diagnostic code No. 01

Diagnostic tool display Throttle position sensor signal

• 11–14 (fully closed position)

• 109–116 (fully open position)

Procedure • Check with throttle valve fully closed.

• Check with throttle valve fully open.

Item Probable cause of malfunc-

tion and check Maintenance jobConfirmation of service

completion

1 Installed condition of throttle position sensor.

Check for looseness or

pinching. Improperly installed sensor

Reinstall or replace the

sensor.

Refer to “ADJUSTING THE

THROTTLE POSITION SEN-

SOR” on page 8-11. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 2.

2 Defective throttle position sensor. Check throttle position sen-

sor signal.

Execute the diagnostic mode.

(Code No. 01)

When the throttle valve is fully

closed:

A value of 11–14 is indicated.

When throttle valve is fully

open:

A value of 109–116 is indicat-

ed.

An indicated value is out of

the specified range.

Re-

place the throttle position

sensor. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 3.

3 Malfunction in ECU. Replace the ECU. Fault code No. 15

Item Throttle position sensor: open or short circuit detected.

Page 372 of 426

FUEL INJECTION SYSTEM

9-42

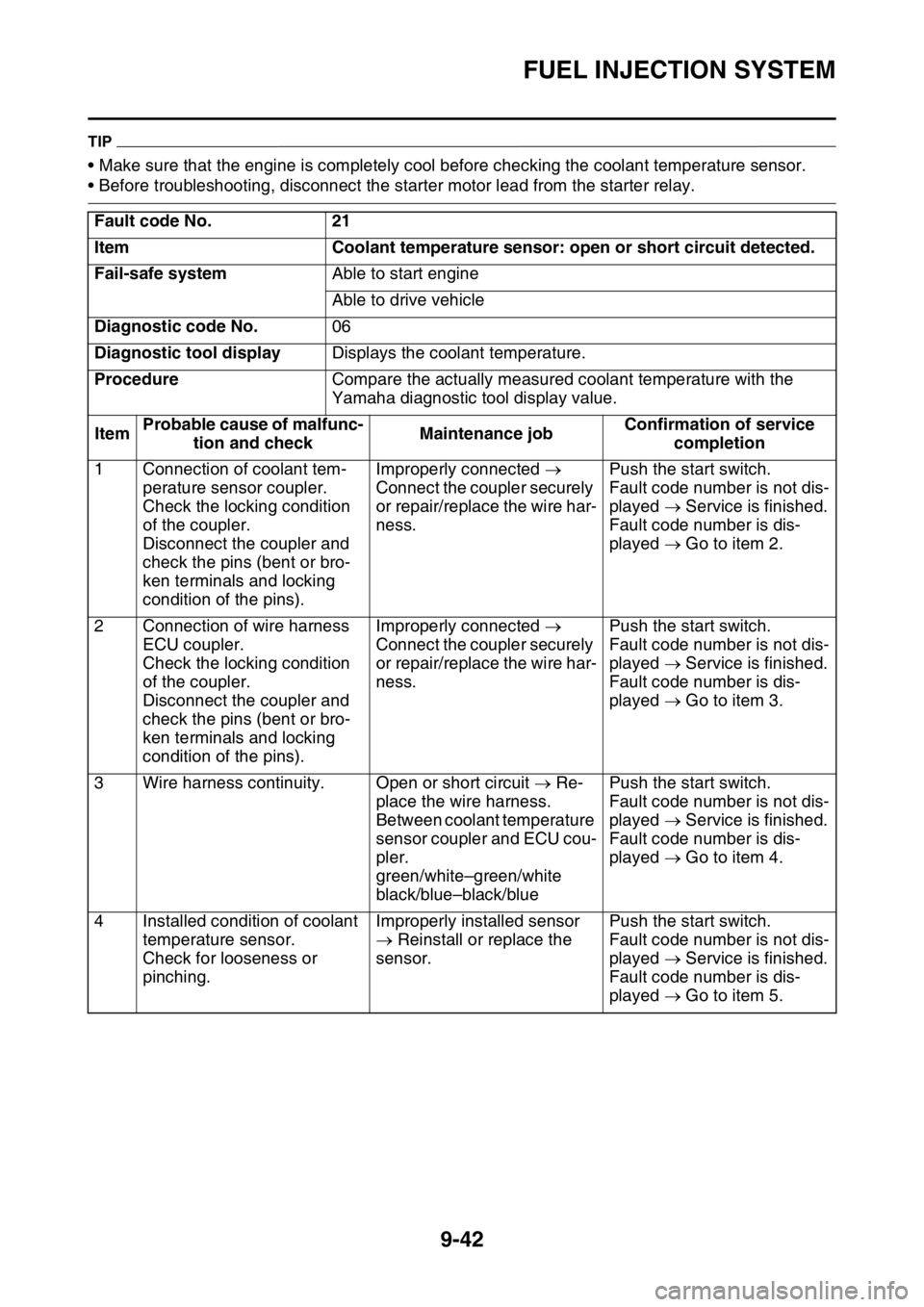

TIP

• Make sure that the engine is completely cool before checking the coolant temperature sensor.

• Before troubleshooting, disconnect the starter motor lead from the starter relay.

Fault code No. 21

Item Coolant temperature sensor: open or short circuit detected.

Fail-safe system Able to start engine

Able to drive vehicle

Diagnostic code No. 06

Diagnostic tool display Displays the coolant temperature.

Procedure Compare the actually measured coolant temperature with the

Yamaha diagnostic tool display value.

Item Probable cause of malfunc-

tion and check Maintenance jobConfirmation of service

completion

1 Connection of coolant tem- perature sensor coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 2.

2 Connection of wire harness ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins). Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 3.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between coolant temperature

sensor coupler and ECU cou-

pler.

green/white–green/white

black/blue–black/blue Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 4.

4 Installed condition of coolant temperature sensor.

Check for looseness or

pinching. Improperly installed sensor

Reinstall or replace the

sensor. Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played Go to item 5.