brake pads YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 97 of 426

3

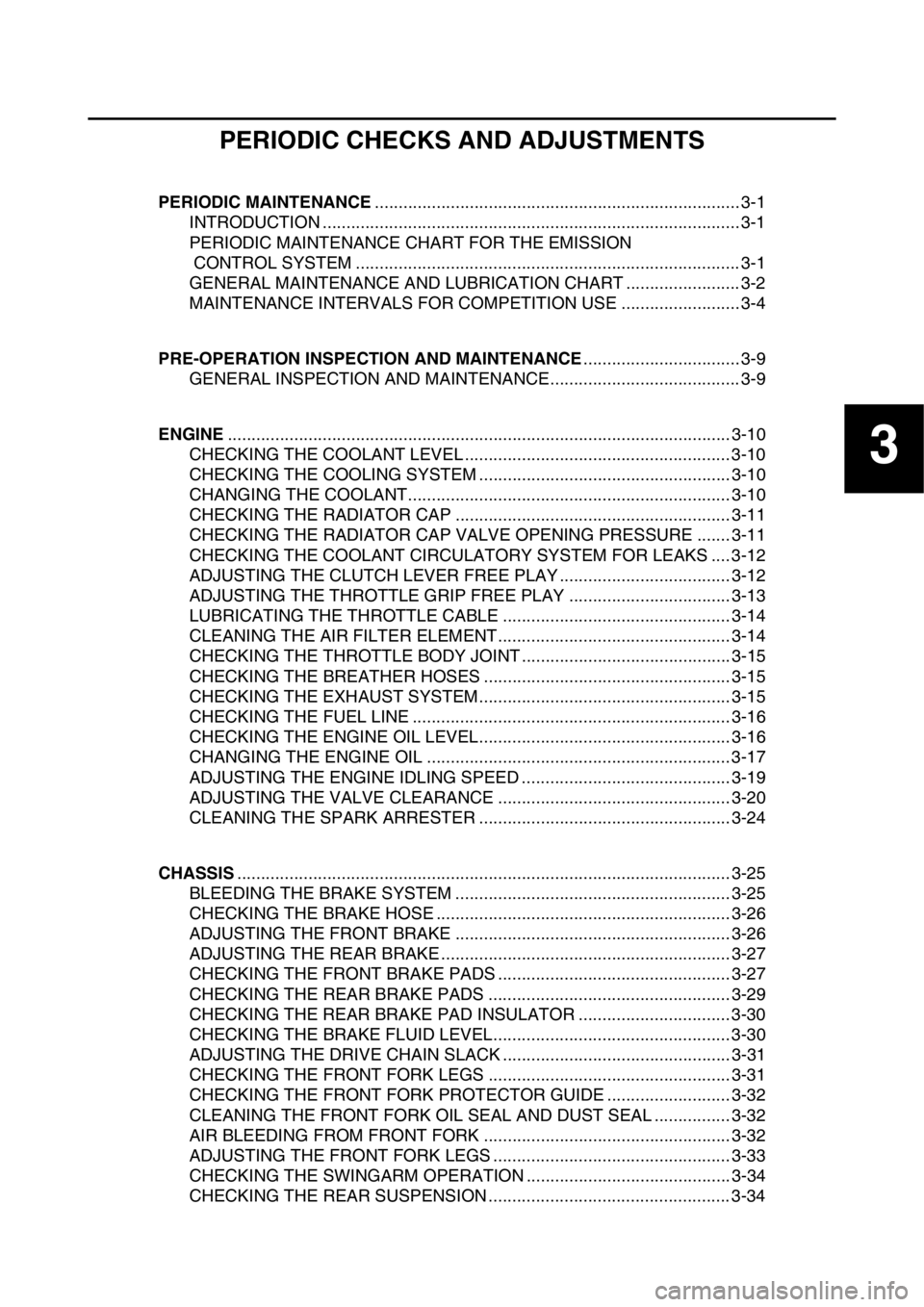

PERIODIC CHECKS AND ADJUSTMENTS

PERIODIC MAINTENANCE............................................................................. 3-1

INTRODUCTION ........................................................................................ 3-1

PERIODIC MAINTENANCE CHART FOR THE EMISSION

CONTROL SYSTEM ....................... .......................................................... 3-1

GENERAL MAINTENANCE AND LUBRICATION CHART ........................ 3-2

MAINTENANCE INTERVALS FOR COMPETITION USE ......................... 3-4

PRE-OPERATION INSPECTION AND MAINTENANCE ................................. 3-9

GENERAL INSPECTION AND MAINTENANCE........................................ 3-9

ENGINE .......................................................................................................... 3-10

CHECKING THE COOLANT LEVEL ........................................................ 3-10

CHECKING THE COOLING SYSTEM ..................................................... 3-10

CHANGING THE COOLANT.................................................................... 3-10

CHECKING THE RADIATOR CAP .......................................................... 3-11

CHECKING THE RADIATOR CAP VALVE OPENING PRESSURE ....... 3-11

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-12

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-12

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-13

LUBRICATING THE THROTTLE CABLE ................................................ 3-14

CLEANING THE AIR FILTER ELEMENT................................................. 3-14

CHECKING THE THROTTLE BODY JOINT ............................................ 3-15

CHECKING THE BREATHER HOSES .................................................... 3-15

CHECKING THE EXHAUST SYSTEM............................. ........................ 3-15

CHECKING THE FUEL LINE ................................................................... 3-16

CHECKING THE ENGINE OIL LEVEL............................. ........................ 3-16

CHANGING THE ENGINE OIL ................................................................ 3-17

ADJUSTING THE ENGINE IDLING SPEED ......... ................................... 3-19

ADJUSTING THE VALVE CLEARANCE ................................................. 3-20

CLEANING THE SPARK ARRESTER ..................................................... 3-24

CHASSIS ........................................................................................................ 3-25

BLEEDING THE BRAKE SYST EM .......................................................... 3-25

CHECKING THE BRAKE HOSE .............................................................. 3-26

ADJUSTING THE FRONT BRAKE .......................................................... 3-26

ADJUSTING THE REAR BRAKE ............................................................. 3-27

CHECKING THE FRONT BR AKE PADS ................................................. 3-27

CHECKING THE REAR BRAKE PADS ........................... ........................ 3-29

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-30

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-30

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-31

CHECKING THE FRONT FORK LEGS ................................................... 3-31

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-32

CLEANING THE FRONT FORK OI L SEAL AND DUST SEAL ................ 3-32

AIR BLEEDING FROM FRONT FORK .................................................... 3-32

ADJUSTING THE FRONT FORK LEGS .................................................. 3-33

CHECKING THE SWINGARM OPERATION ........................................... 3-34

CHECKING THE REAR SUSPENSION ................................................... 3-34

Page 100 of 426

PERIODIC MAINTENANCE

3-2

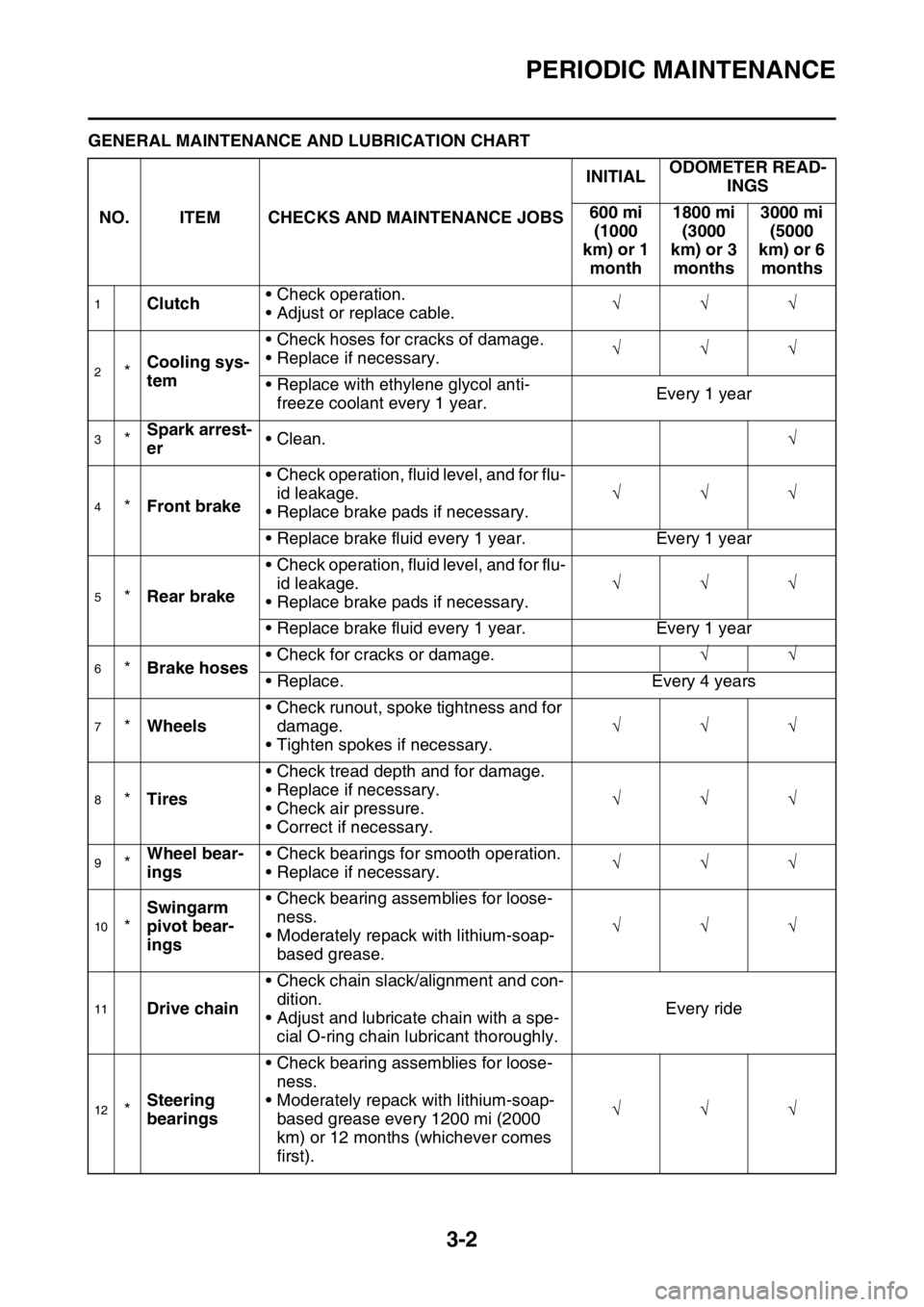

EAS2GC1077GENERAL MAINTENANCE AND LUBRICATION CHARTNO. ITEM CHECKS AND MAINTENANCE JOBS INITIAL

ODOMETER READ-

INGS

600 mi (1000

km) or 1 month 1800 mi

(3000

km) or 3 months 3000 mi

(5000

km) or 6 months

1Clutch • Check operation.

• Adjust or replace cable.

2*Cooling sys-

tem • Check hoses for cracks of damage.

• Replace if necessary.

• Replace with ethylene glycol anti- freeze coolant every 1 year. Every 1 year

3*Spark arrest-

er • Clean.

4*Front brake • Check operation, fluid level, and for flu-

id leakage.

• Replace brake pads if necessary.

• Replace brake fluid every 1 year. Every 1 year

5* Rear brake • Check operation, fluid level, and for flu-

id leakage.

• Replace brake pads if necessary.

• Replace brake fluid every 1 year. Every 1 year

6* Brake hoses • Check for cracks or damage.

• Replace. Every 4 years

7*Wheels • Check runout, spoke tightness and for

damage.

• Tighten spokes if necessary.

8*

Tires • Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.

9*

Wheel bear-

ings • Check bearings for smooth operation.

• Replace if necessary.

10*Swingarm

pivot bear-

ings • Check bearing assemblies for loose-

ness.

• Moderately repack with lithium-soap- based grease.

11Drive chain• Check chain slack/alignment and con-

dition.

• Adjust and lubricate chain with a spe- cial O-ring chain lubricant thoroughly. Every ride

12*

Steering

bearings • Check bearing assemblies for loose-

ness.

• Moderately repack with lithium-soap- based grease every 1200 mi (2000

km) or 12 months (whichever comes

first).

Page 105 of 426

PERIODIC MAINTENANCE

3-7

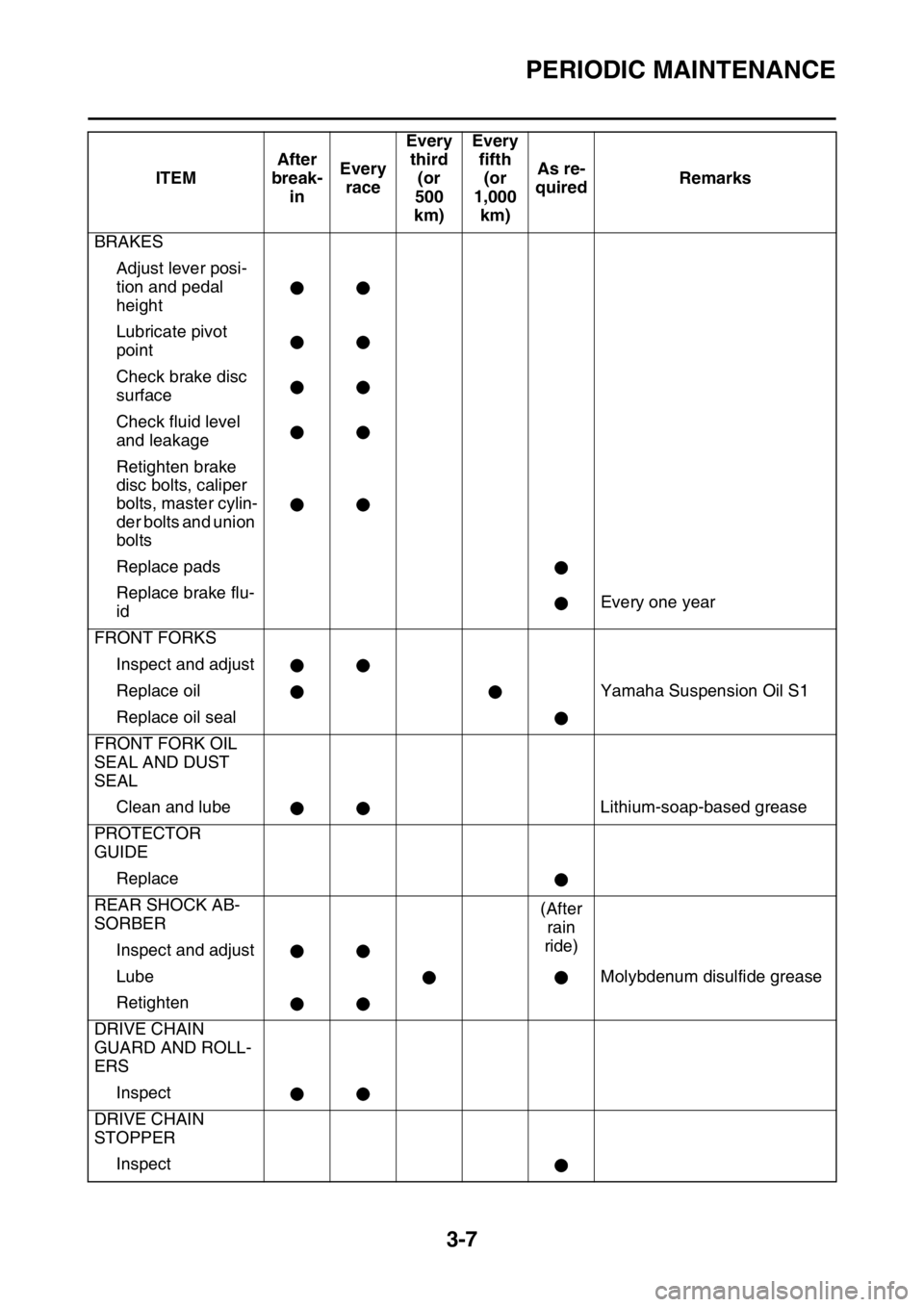

BRAKESAdjust lever posi-

tion and pedal

height

Lubricate pivot

point

Check brake disc

surface

Check fluid level

and leakage

Retighten brake

disc bolts, caliper

bolts, master cylin-

der bolts and union

bolts

Replace pads

Replace brake flu-

id Every one year

FRONT FORKS Inspect and adjust

Replace oil Yamaha Suspension Oil S1

Replace oil seal

FRONT FORK OIL

SEAL AND DUST

SEAL Clean and lube Lithium-soap-based grease

PROTECTOR

GUIDE

Replace

REAR SHOCK AB-

SORBER (After

rain

ride)

Inspect and adjust

Lube Molybdenum disulfide grease

Retighten

DRIVE CHAIN

GUARD AND ROLL-

ERS

Inspect

DRIVE CHAIN

STOPPER Inspect ITEM

After

break- in Every

race Every

third (or

500

km) Every

fifth (or

1,000 km) As re-

quired Remarks

Page 125 of 426

CHASSIS

3-27

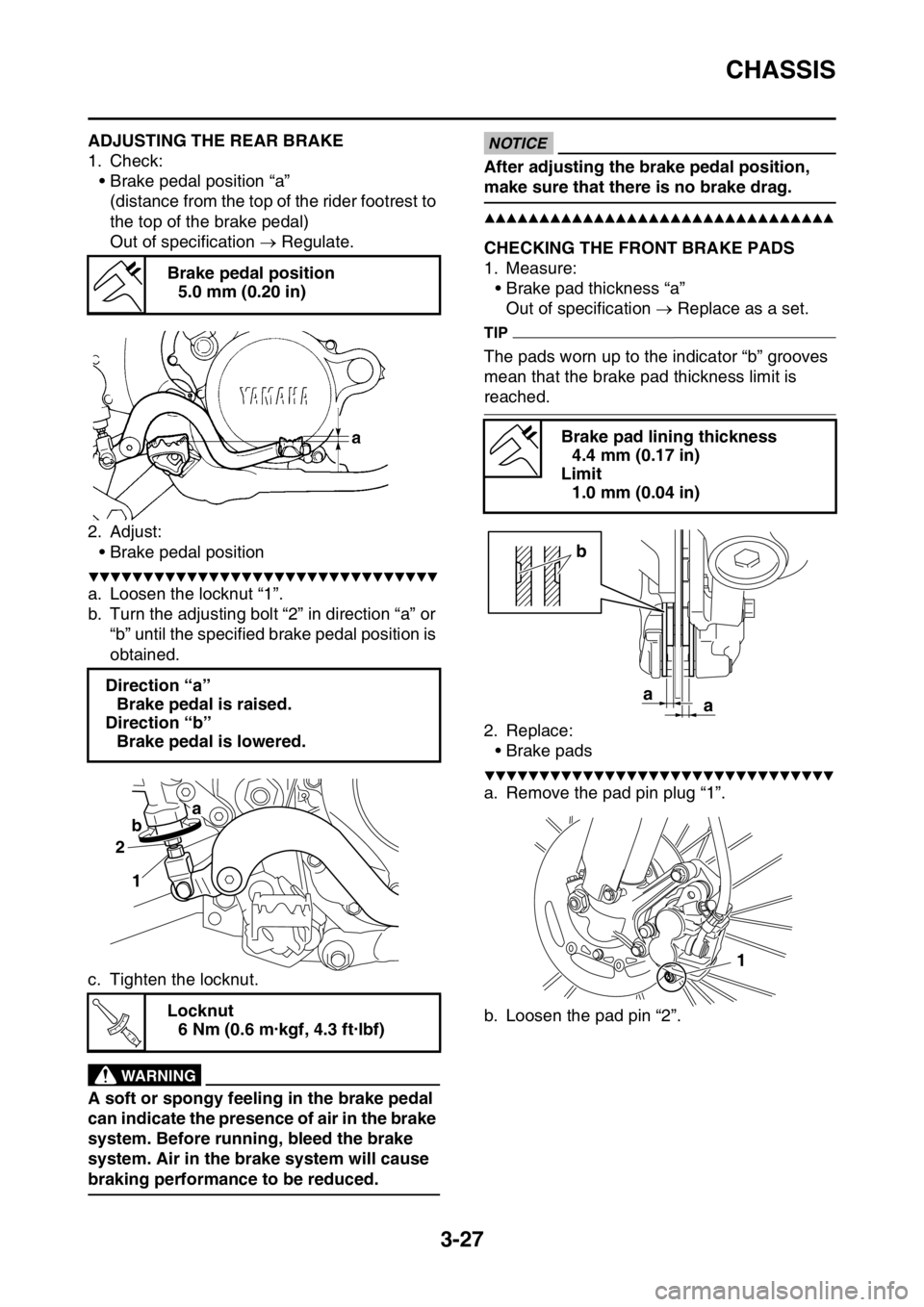

EAS2GC1105ADJUSTING THE REAR BRAKE

1. Check:• Brake pedal position “a”(distance from the top of the rider footrest to

the top of the brake pedal)

Out of specification Regulate.

2. Adjust: • Brake pedal position

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting bolt “2” in direction “a” or “b” until the specified brake pedal position is

obtained.

c. Tighten the locknut.

EWA

WARNING

A soft or spongy feeling in the brake pedal

can indicate the presence of air in the brake

system. Before running, bleed the brake

system. Air in the brake system will cause

braking performance to be reduced.

ECA

NOTICE

After adjusting the brake pedal position,

make sure that there is no brake drag.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS2GC1106CHECKING THE FRONT BRAKE PADS

1. Measure: • Brake pad thickness “a”Out of specification Replace as a set.

TIP

The pads worn up to the indicator “b” grooves

mean that the brake pad thickness limit is

reached.

2. Replace:

• Brake pads

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the pad pin plug “1”.

b. Loosen the pad pin “2”.

Brake pedal position

5.0 mm (0.20 in)

Direction “a” Brake pedal is raised.

Direction “b”

Brake pedal is lowered.

Locknut6 Nm (0.6 m·kgf, 4.3 ft·lbf)

1

2

a

b

T R..

Brake pad lining thickness

4.4 mm (0.17 in)

Limit 1.0 mm (0.04 in)

a

b

a

1

Page 126 of 426

CHASSIS

3-28

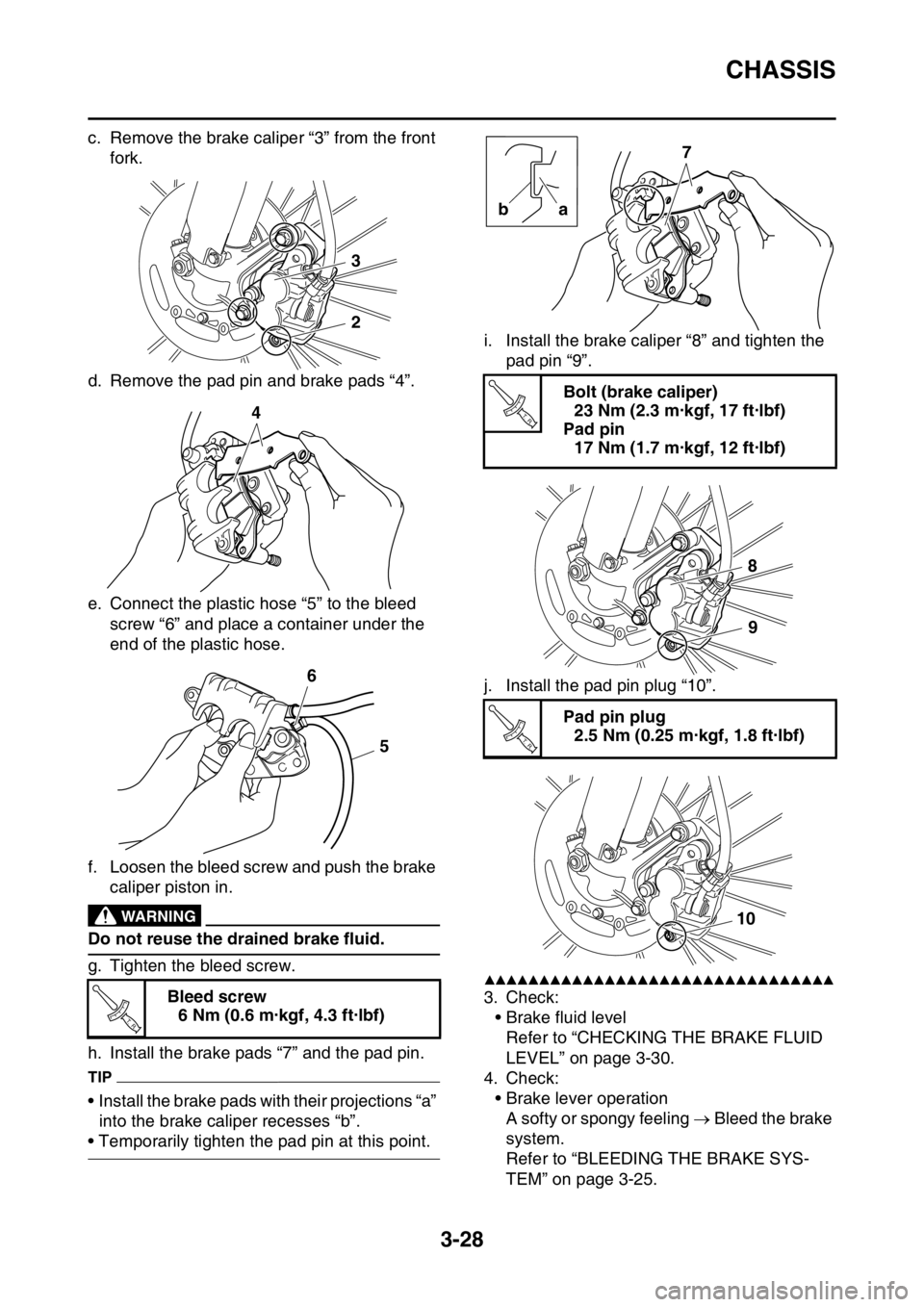

c. Remove the brake caliper “3” from the front fork.

d. Remove the pad pin and brake pads “4”.

e. Connect the plastic hose “5” to the bleed screw “6” and place a container under the

end of the plastic hose.

f. Loosen the bleed screw and push the brake caliper piston in.

EWA

WARNING

Do not reuse the drained brake fluid.

g. Tighten the bleed screw.

h. Install the brake pads “7” and the pad pin.

TIP

• Install the brake pads with their projections “a” into the brake caliper recesses “b”.

• Temporarily tighten the pad pin at this point. i. Install the brake caliper “8” and tighten the

pad pin “9”.

j. Install the pad pin plug “10”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Check: • Brake fluid levelRefer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30.

4. Check: • Brake lever operation

A softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

Bleed screw

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

3

2

4

6

5

T R..

Bolt (brake caliper)23 Nm (2.3 m·kgf, 17 ft·lbf)

Pad pin 17 Nm (1.7 m·kgf, 12 ft·lbf)

Pad pin plug 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

7

a

b

T R..

8

9

T R..

10

Page 127 of 426

CHASSIS

3-29

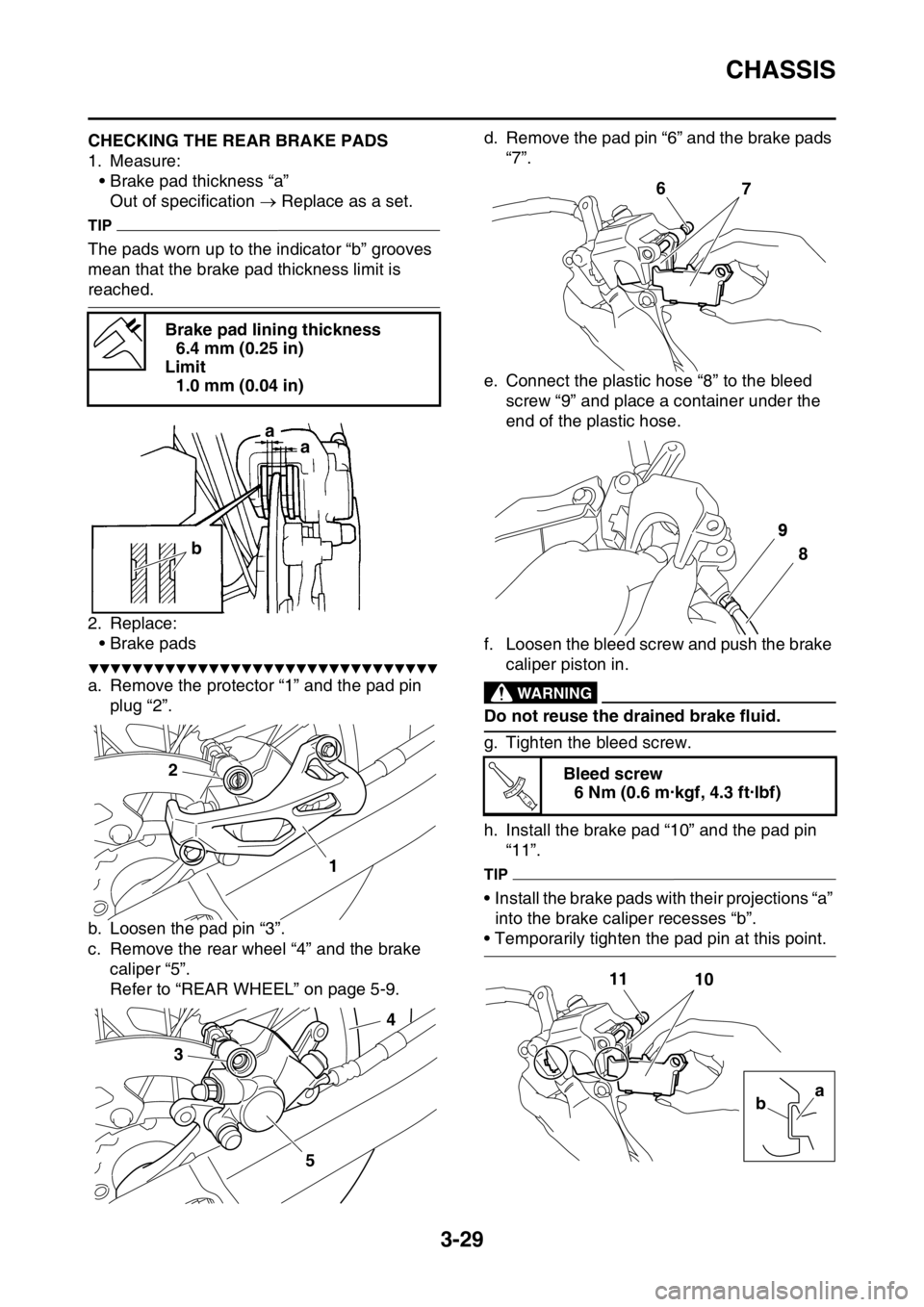

EAS2GC1107CHECKING THE REAR BRAKE PADS

1. Measure:• Brake pad thickness “a”Out of specification Replace as a set.

TIP

The pads worn up to the indicator “b” grooves

mean that the brake pad thickness limit is

reached.

2. Replace:

• Brake pads

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the protector “1” and the pad pin

plug “2”.

b. Loosen the pad pin “3”.

c. Remove the rear wheel “4” and the brake caliper “5”.

Refer to “REAR WHEEL” on page 5-9. d. Remove the pad pin “6” and the brake pads

“7”.

e. Connect the plastic hose “8” to the bleed screw “9” and place a container under the

end of the plastic hose.

f. Loosen the bleed screw and push the brake caliper piston in.EWA

WARNING

Do not reuse the drained brake fluid.

g. Tighten the bleed screw.

h. Install the brake pad “10” and the pad pin “11”.

TIP

• Install the brake pads with their projections “a” into the brake caliper recesses “b”.

• Temporarily tighten the pad pin at this point.

Brake pad lining thickness

6.4 mm (0.25 in)

Limit 1.0 mm (0.04 in)

b a

a

1

2

3

4

5

Bleed screw 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

7

6

9

8

T R..

10

11

a

b

Page 128 of 426

CHASSIS

3-30

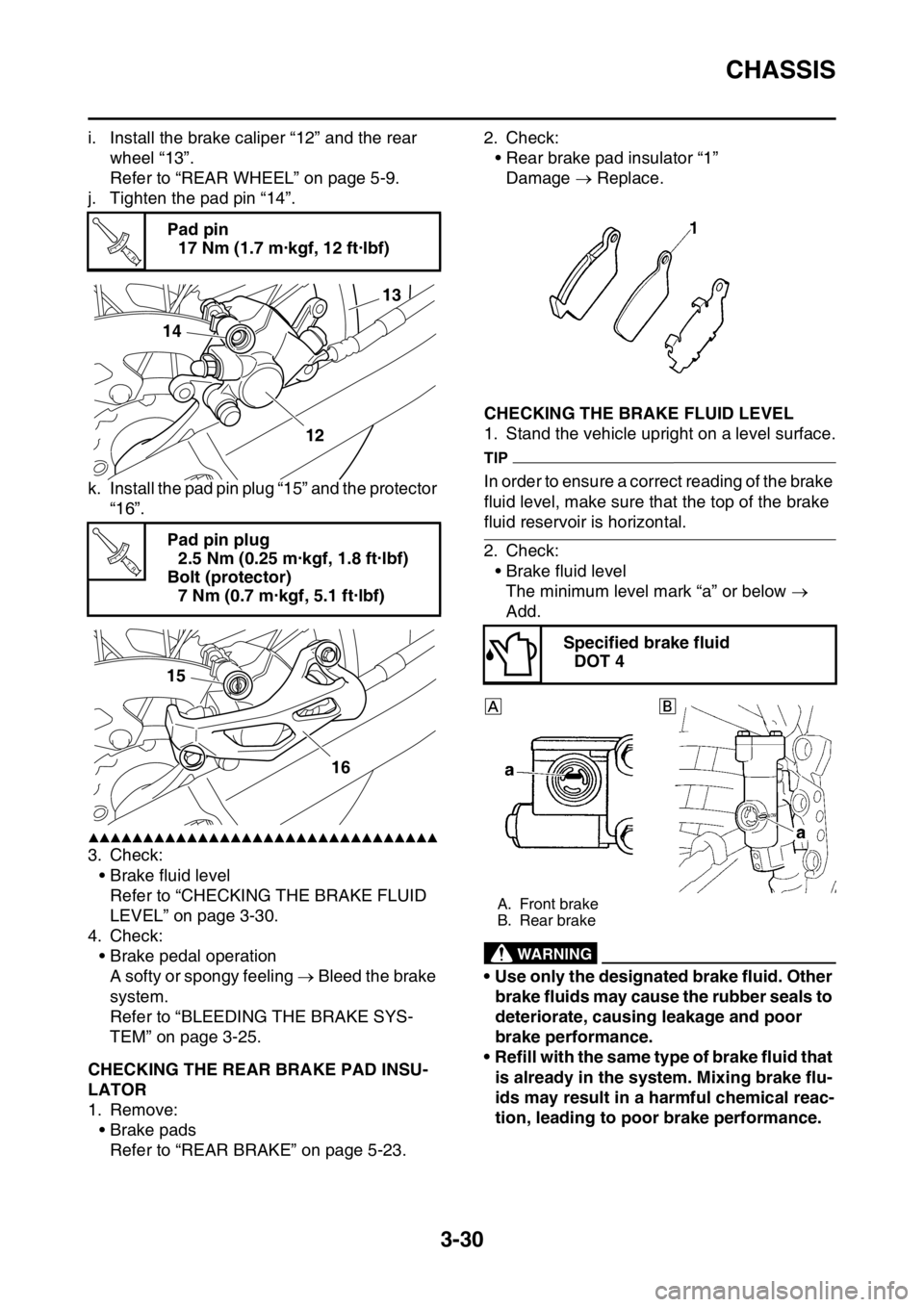

i. Install the brake caliper “12” and the rear wheel “13”.

Refer to “REAR WHEEL” on page 5-9.

j. Tighten the pad pin “14”.

k. Install the pad pin plug “15” and the protector “16”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Check:• Brake fluid levelRefer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-30.

4. Check: • Brake pedal operationA softy or spongy feeling Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-25.

EAS2GC1108CHECKING THE REAR BRAKE PAD INSU-

LATOR

1. Remove: • Brake padsRefer to “REAR BRAKE” on page 5-23. 2. Check:

• Rear brake pad insulator “1”Damage Replace.

EAS2GC1109CHECKING THE BRAKE FLUID LEVEL

1. Stand the vehicle upright on a level surface.

TIP

In order to ensure a correct reading of the brake

fluid level, make sure that the top of the brake

fluid reservoir is horizontal.

2. Check:

• Brake fluid levelThe minimum level mark “a” or below

Add.

EWA

WARNING

• Use only the designated brake fluid. Other brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

Pad pin

17 Nm (1.7 m·kgf, 12 ft·lbf)

Pad pin plug 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Bolt (protector) 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

T R..

13

14

12

T R..

15 16

Specified brake fluidDOT 4

A. Front brake

B. Rear brake

Page 159 of 426

FRONT WHEEL

5-7

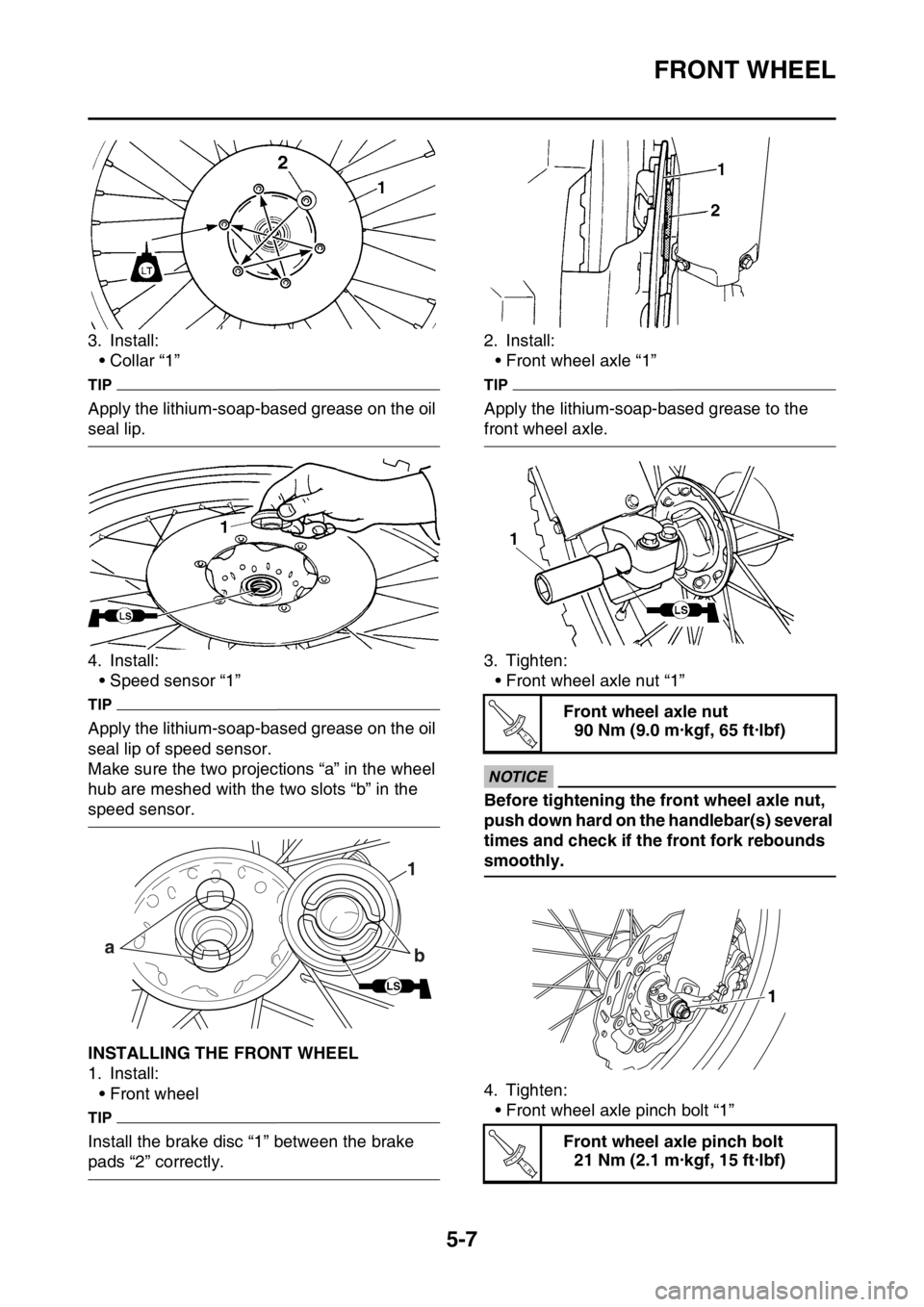

3. Install:• Collar “1”

TIP

Apply the lithium-soap-based grease on the oil

seal lip.

4. Install:

• Speed sensor “1”

TIP

Apply the lithium-soap-based grease on the oil

seal lip of speed sensor.

Make sure the two projections “a” in the wheel

hub are meshed with the two slots “b” in the

speed sensor.

EAS2GC1159INSTALLING THE FRONT WHEEL

1. Install:• Front wheel

TIP

Install the brake disc “1” between the brake

pads “2” correctly. 2. Install:

• Front wheel axle “1”

TIP

Apply the lithium-soap-based grease to the

front wheel axle.

3. Tighten:

• Front wheel axle nut “1”

ECA

NOTICE

Before tightening the front wheel axle nut,

push down hard on the handlebar(s) several

times and check if the front fork rebounds

smoothly.

4. Tighten:• Front wheel axle pinch bolt “1”1

a b

LS

Front wheel axle nut

90 Nm (9.0 m·kgf, 65 ft·lbf)

Front wheel axle pinch bolt 21 Nm (2.1 m·kgf, 15 ft·lbf)

T R..

1

T R..

Page 164 of 426

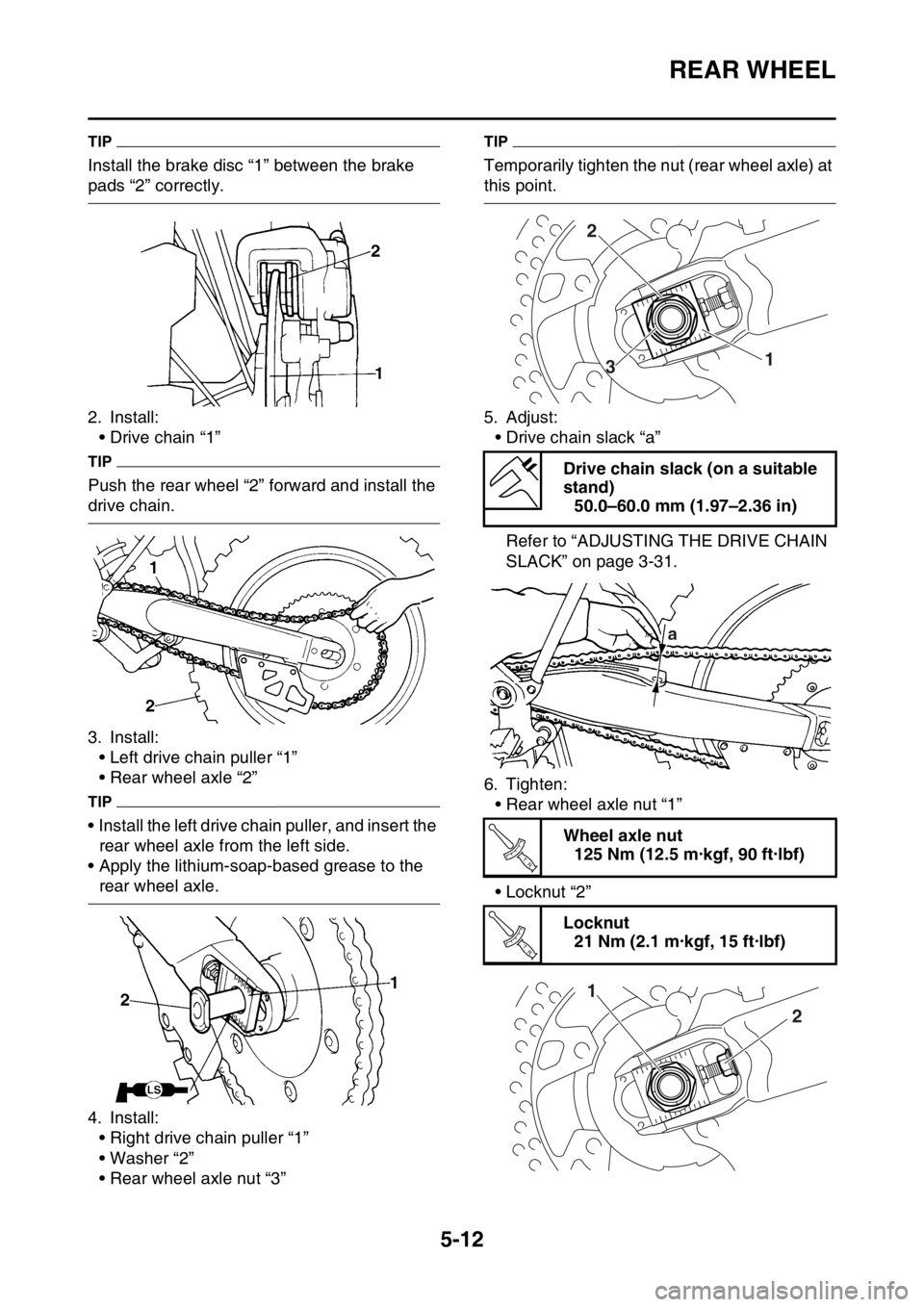

REAR WHEEL

5-12

TIP

Install the brake disc “1” between the brake

pads “2” correctly.

2. Install:• Drive chain “1”

TIP

Push the rear wheel “2” forward and install the

drive chain.

3. Install:• Left drive chain puller “1”

• Rear wheel axle “2”

TIP

• Install the left drive chain puller, and insert the rear wheel axle from the left side.

• Apply the lithium-soap-based grease to the

rear wheel axle.

4. Install: • Right drive chain puller “1”

• Washer “2”

• Rear wheel axle nut “3”

TIP

Temporarily tighten the nut (rear wheel axle) at

this point.

5. Adjust:

• Drive chain slack “a”

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” on page 3-31.

6. Tighten: • Rear wheel axle nut “1”

• Locknut “2”

Drive chain slack (on a suitable

stand) 50.0–60.0 mm (1.97–2.36 in)

Wheel axle nut 125 Nm (12.5 m·kgf, 90 ft·lbf)

Locknut 21 Nm (2.1 m·kgf, 15 ft·lbf)

2

1

3

a

T R..

T R..

1

2

Page 165 of 426

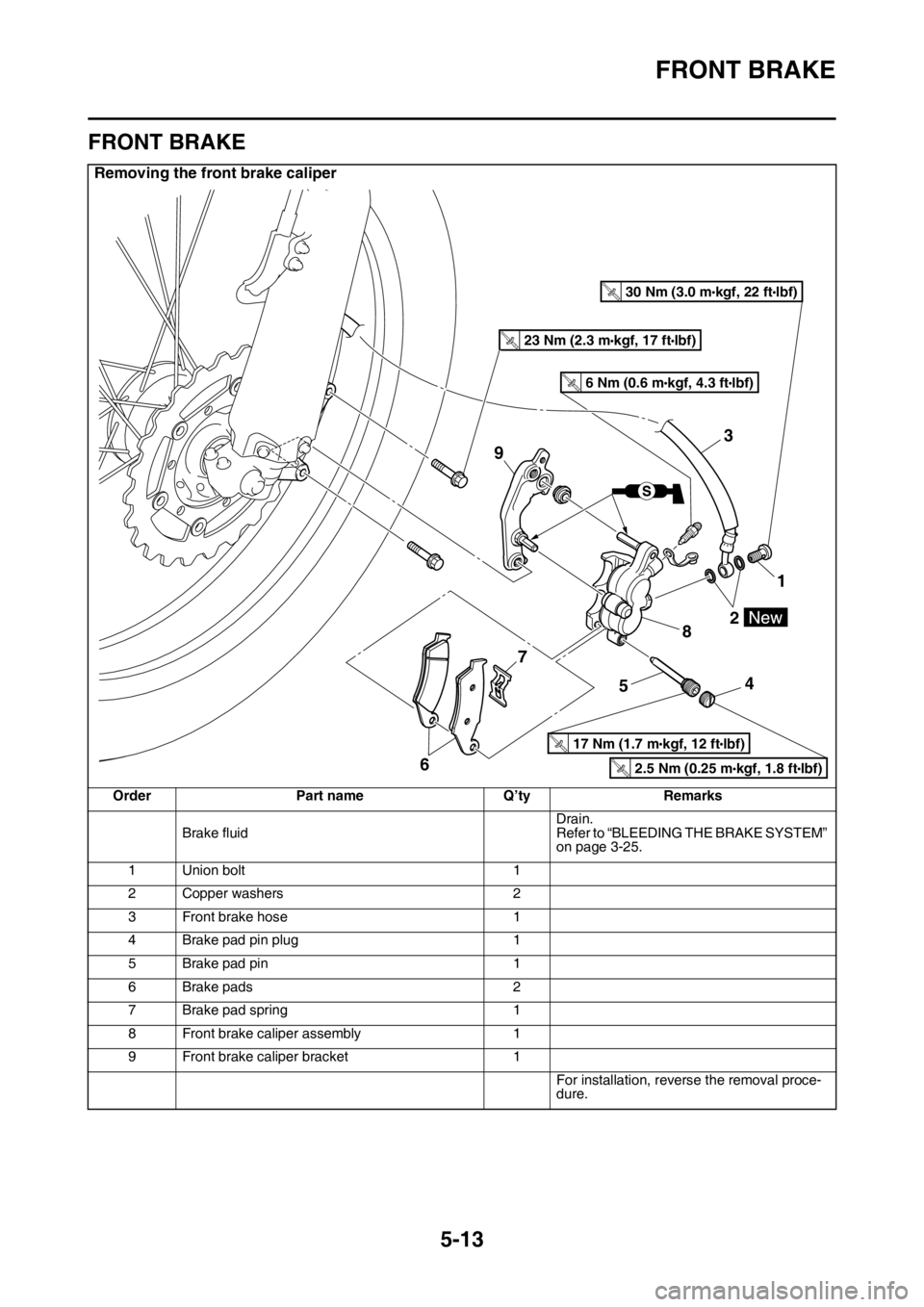

FRONT BRAKE

5-13

EAS2GC1167

FRONT BRAKE

Removing the front brake caliper

OrderPart name Q’tyRemarks

Brake fluid Drain.

Refer to “BLEEDING THE BRAKE SYSTEM”

on page 3-25.

1 Union bolt 1

2 Copper washers 2

3 Front brake hose 1

4 Brake pad pin plug 1

5 Brake pad pin 1

6 Brake pads 2

7 Brake pad spring 1

8 Front brake caliper assembly 1

9 Front brake caliper bracket 1

For installation, reverse the removal proce-

dure.

3

9

1

2

8

4

5

7

6

T.R.30 Nm (3.0 mlbf)

kgf, 22 ft

T.R.23 Nm (2.3 mlbf)

kgf, 17 ft

T.R.17 Nm (1.7 mlbf)

kgf, 12 ft

T.R.2.5 Nm (0.25 mlbf)

kgf, 1.8 ft

T.R.6 Nm (0.6 mlbf)

kgf, 4.3 ft