engine coolant YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 18 of 426

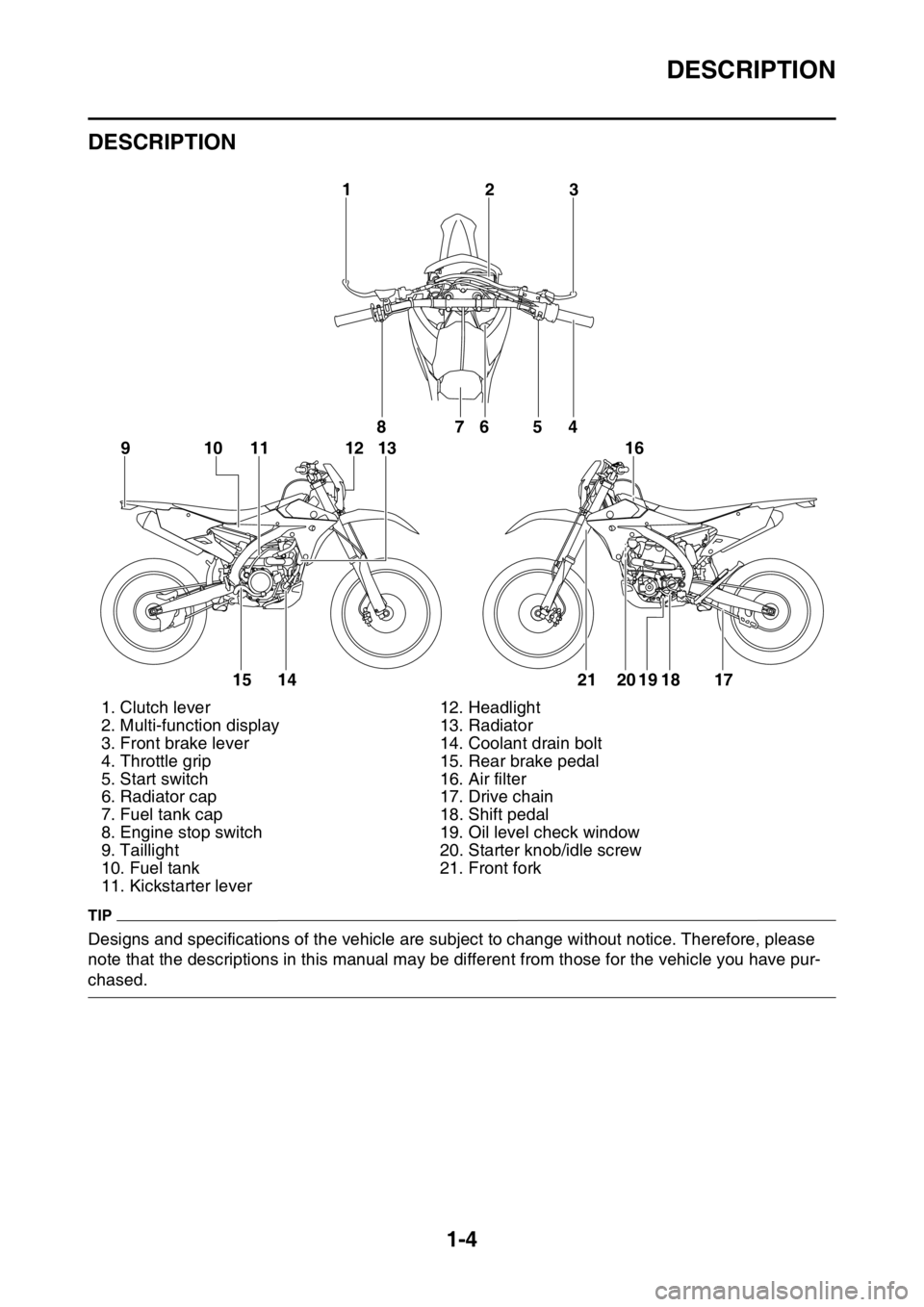

DESCRIPTION

1-4

EAS2GC1009

DESCRIPTION

TIP

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have pur-

chased.1. Clutch lever 12. Headlight

2. Multi-function display 13. Radiator

3. Front brake lever 14. Coolant drain bolt

4. Throttle grip 15. Rear brake pedal

5. Start switch 16. Air filter

6. Radiator cap 17. Drive chain

7. Fuel tank cap 18. Shift pedal

8. Engine stop switch 19. Oil level check window

9. Taillight 20. Starter knob/idle screw

10. Fuel tank 21. Front fork

11. Kickstarter lever

32

1

8

10

91 112 1376

54

15 14 21 20 19 18 17 16

Page 21 of 426

IMPORTANT INFORMATION

1-7

EAS20180

IMPORTANT INFORMATION

EAS2GC1020PREPARATION FOR REMOVAL AND DIS-

ASSEMBLY

1. Before the jobs, completely remove mud, dust, and the like in order to prevent the en-

try of them into the inside during the jobs.

• Before cleaning with high-pressure water of washers, cover the following parts.

Air duct

Silencer exhaust port

Drain hole on the cylinder head (right side)

Hole under the water pump housing

2. Use proper special tools and equipment. See “SPECIAL TOOLS”.

3. During disassembly, check and measure the required parts, and make a record of them

so that you may refer to the record when in-

stalling them. Moreover, arrange gears, cyl-

inders, pistons, and other parts for each

section so as not to confuse or lose them. 4. During disassembly, clean each of the parts,

and store them in trays for each section.

5. Flammable. Keep servicing areas away from any source of fire.

6. During servicing, take special care not to re-

ceive an injury or a burn on the engine, the

exhaust pipe, the silencer, or the like.

7. If coolant is left adhered to the chassis, paint

and plating will be damaged. Therefore,

rinse it out with water in good time.

EWA

WARNING

Coolant is potentially harmful and should

be handled with special care.

• If it enters your eyes, wash it away with wa-ter enough and then get medical attention

• If it splashes on your skin or clothes,

quickly wash it away with water and then

with soapy water.

• If it is swallowed, immediately induce vom-

iting and get medical attention.

EAS2GC1021REPLACEMENT PARTS

Make sure that the parts and grease or oil to be

used for repair of the vehicle, including periodic

replacement parts, are new YAMAHA genuine

parts and recommended parts.

Do not use any used parts, because these may

not be genuine though they have similar ap-

pearances or because the quality may be

changed by aging.

Page 45 of 426

MAINTENANCE AFTER BREAK-IN

1-31

EAS2GC1055

MAINTENANCE AFTER BREAK-IN

After a break-in, perform careful maintenance

to get ready for the next practice or race.

Refer to “PRE-OPERATION INSPECTION

AND MAINTENANCE” on page 3-9.

EAS2GC1056MAJOR MAINTENANCE

1. For the engine• Leaks around the engineCheck for pressure l eaks from the cylinder

head or the cylinder, oil leaks from the

crankcase or the case cover, leaks from the

coolant system, and other leaks.

• Check that the valve, the cylinder head, the cylinder, the piston, and the piston ring fit

one another, and that contact between the

valve and the cylinder head, and that be-

tween the cylinder and the piston are cor-

rect.

• Engine oil change Drain the oil, and check for dirt and foreign

materials such as metal chips. (If any foreign

material is mixed, disassemble and check

the crankcase.)

Pour the specified amount of the recom-

mended oil.

• AC magneto

Check for looseness in mounted areas of

the rotor and the stator.

Check that the connector is not being dis-

connected.

• Silencer Check the main body and stay for cracks.

Check for leaks.

• Mounting bolts and nuts Check for looseness in mounted areas of

parts, as well as engine mounting bolts and

engine brackets.

2. For the chassis

• Check welds and mounted areas of the frame, the swingarm, the link, the bracket,

and so on, for looseness and cracks.

• Wheel (s) Check the wheel for runout. Check the

spoke for looseness.

• Brake(s) Check the brake disc mounting bolt for

looseness.

Check that the reservoir contains the speci-

fied amount of brake fluid. Check for leaks. • Cable

Grease and adjust cables.

•Drive chain

Lubricate the drive chain and adjust its ten-

sion.

• Fuel tank

Clean the inside of the fuel tank. Check for

leaks.

• Suspension

Check for oil leaks in the front fork or the rear

shock absorber. Check that the mounted

conditions are good.

• Sprocket Check for looseness in the sprocket mount-

ed on the rear wheel.

• Mounting bolts and nuts

Check mounted areas for looseness.

ECA

NOTICE

After a break-in or before each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to “TORQUE-CHECK

POINTS” on page 1-32.)

• Greasing and oilingAlways grease or oil the specified points.

Page 57 of 426

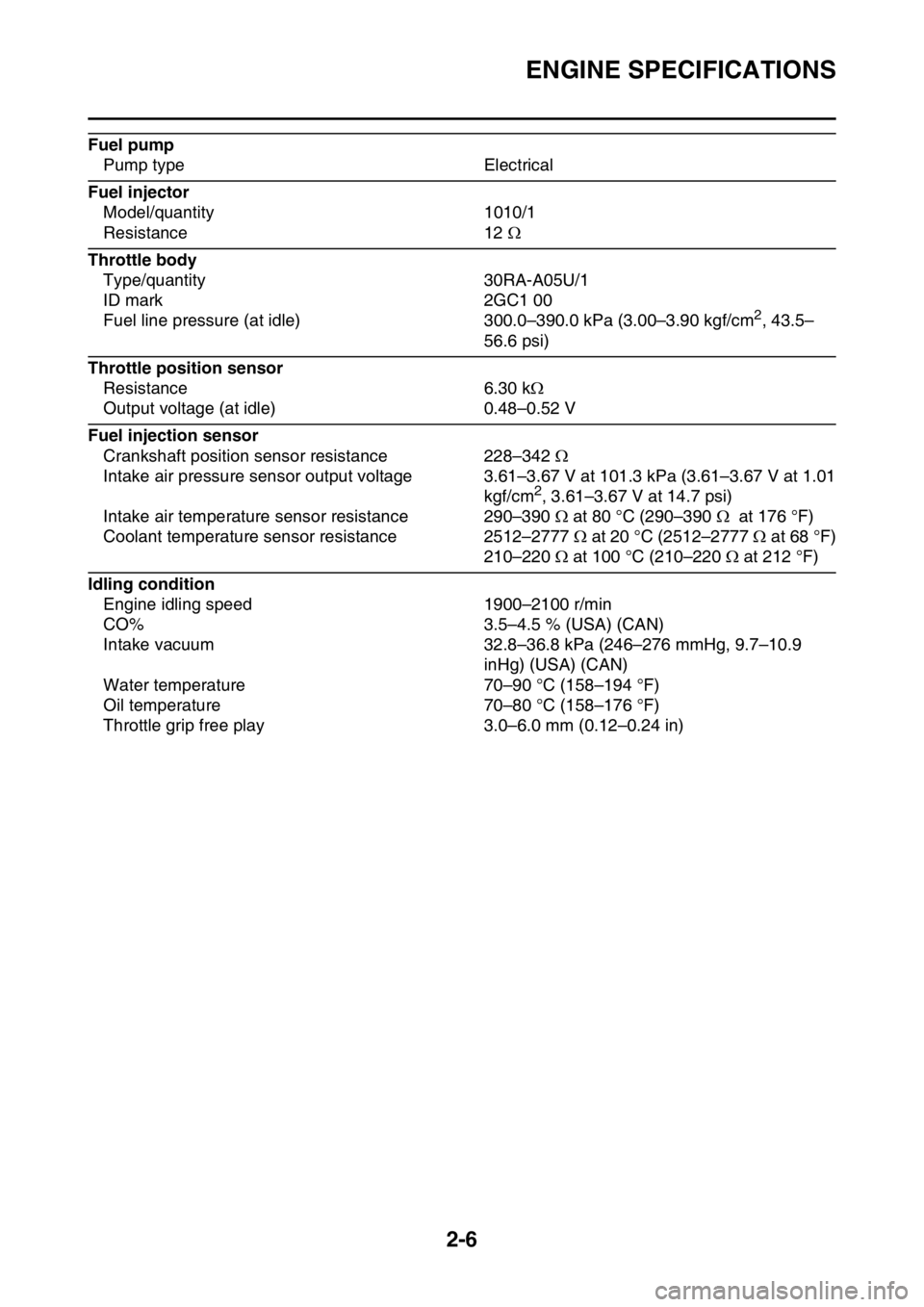

ENGINE SPECIFICATIONS

2-6

Fuel pumpPump type Electrical

Fuel injector

Model/quantity 1010/1

Resistance 12

Throttle body

Type/quantity 30RA-A05U/1

ID mark 2GC1 00

Fuel line pressure (at idle) 300.0–390.0 kPa (3.00–3.90 kgf/cm

2, 43.5–

56.6 psi)

Throttle position sensor Resistance 6.30 k

Output voltage (at idle) 0.48–0.52 V

Fuel injection sensor Crankshaft position sensor resistance 228–342

Intake air pressure sensor output voltage 3.61–3.67 V at 101.3 kPa (3.61–3.67 V at 1.01 kgf/cm

2, 3.61–3.67 V at 14.7 psi)

Intake air temperature sensor resistance 290–390 at 80 °C (290–390 at 176 °F)

Coolant temperature sensor resistance 2512–2777 at 20 °C (2512–2777 at 68 °F)

210–220 at 100 °C (210–220 at 212 °F)

Idling condition

Engine idling speed 1900–2100 r/min

CO% 3.5–4.5 % (USA) (CAN)

Intake vacuum 32.8–36.8 kPa (246–276 mmHg, 9.7–10.9 inHg) (USA) (CAN)

Water temperature 70–90 °C (158–194 °F)

Oil temperature 70–80 °C (158–176 °F)

Throttle grip free play 3.0–6.0 mm (0.12–0.24 in)

Page 64 of 426

TIGHTENING TORQUES

2-13

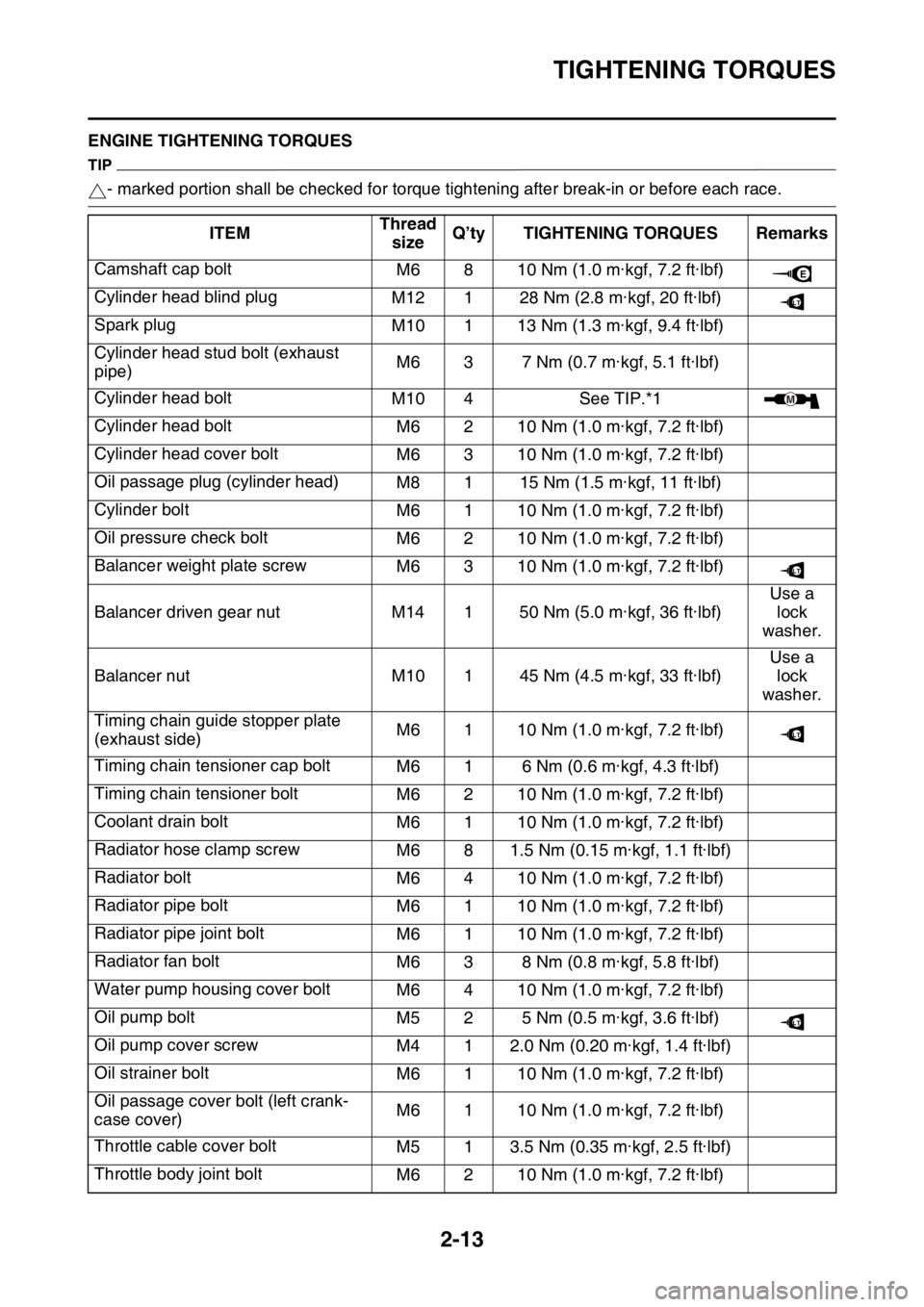

EAS2GC1066ENGINE TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEM Thread

size Q’ty TIGHTENING TORQUES Remarks

Camshaft cap bolt M6 8 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head blind plug M12 1 28 Nm (2.8 m·kgf, 20 ft·lbf)

Spark plug M10 1 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Cylinder head stud bolt (exhaust

pipe) M6 3 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Cylinder head bolt M10 4See TIP.*1

Cylinder head bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head cover bolt M6 3 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil passage plug (cylinder head) M8 1 15 Nm (1.5 m·kgf, 11 ft·lbf)

Cylinder bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pressure check bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer weight plate screw M6 3 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer driven gear nut M14 1 50 Nm (5.0 m·kgf, 36 ft·lbf) Use a

lock

washer.

Balancer nut M10 1 45 Nm (4.5 m·kgf, 33 ft·lbf) Use a

lock

washer.

Timing chain guide stopper plate

(exhaust side) M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing chain tensioner cap bolt M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Timing chain tensioner bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Coolant drain bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator hose clamp screw M6 8 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Radiator bolt M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe joint bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator fan bolt M6 3 8 Nm (0.8 m·kgf, 5.8 ft·lbf)

Water pump housing cover bolt M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pump bolt M5 2 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Oil pump cover screw M4 1 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Oil strainer bolt M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil passage cover bolt (left crank-

case cover) M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Throttle cable cover bolt M5 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Throttle body joint bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

E

LT

M

LT

LT

LT

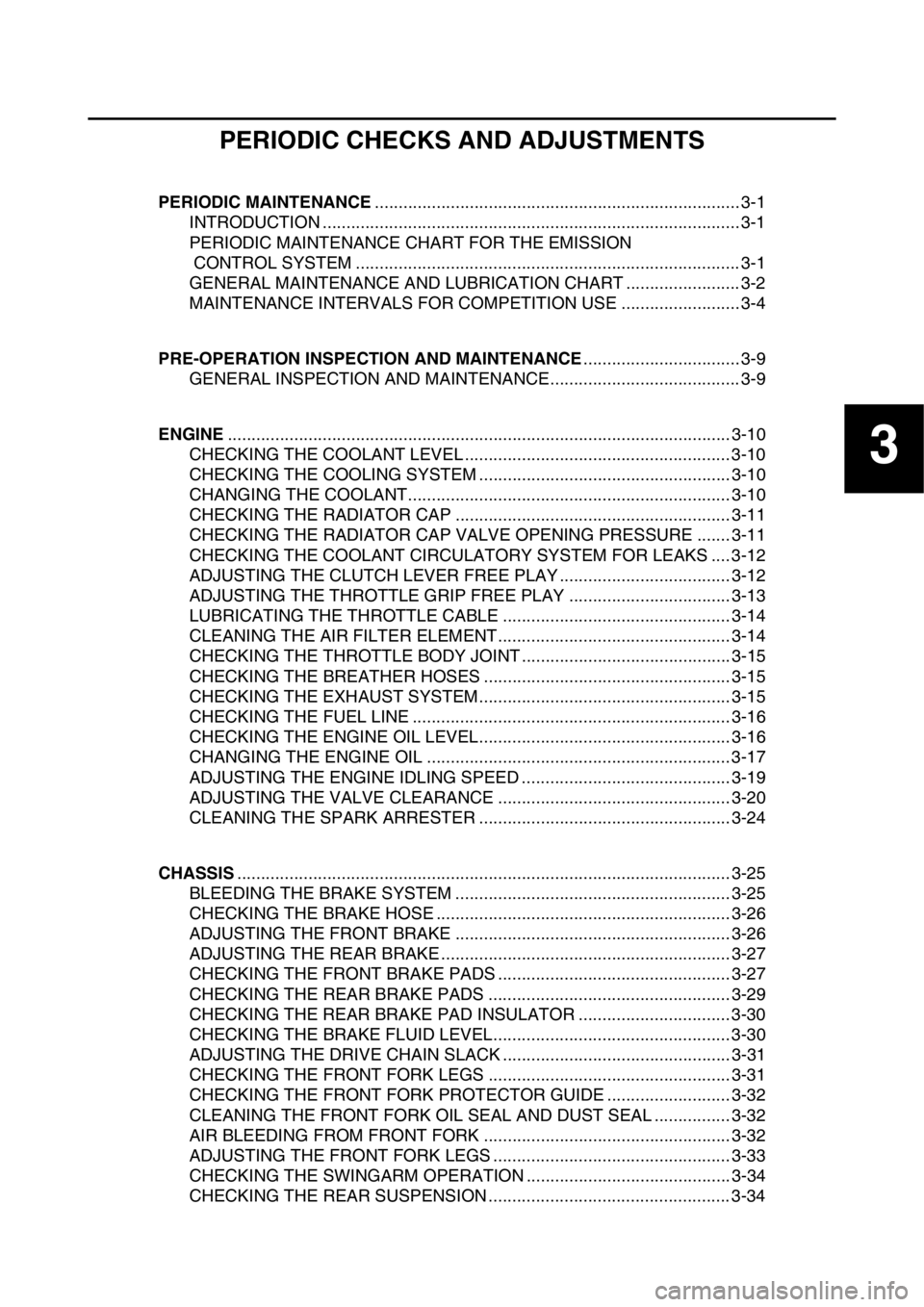

Page 97 of 426

3

PERIODIC CHECKS AND ADJUSTMENTS

PERIODIC MAINTENANCE............................................................................. 3-1

INTRODUCTION ........................................................................................ 3-1

PERIODIC MAINTENANCE CHART FOR THE EMISSION

CONTROL SYSTEM ....................... .......................................................... 3-1

GENERAL MAINTENANCE AND LUBRICATION CHART ........................ 3-2

MAINTENANCE INTERVALS FOR COMPETITION USE ......................... 3-4

PRE-OPERATION INSPECTION AND MAINTENANCE ................................. 3-9

GENERAL INSPECTION AND MAINTENANCE........................................ 3-9

ENGINE .......................................................................................................... 3-10

CHECKING THE COOLANT LEVEL ........................................................ 3-10

CHECKING THE COOLING SYSTEM ..................................................... 3-10

CHANGING THE COOLANT.................................................................... 3-10

CHECKING THE RADIATOR CAP .......................................................... 3-11

CHECKING THE RADIATOR CAP VALVE OPENING PRESSURE ....... 3-11

CHECKING THE COOLANT CIRCULATORY SYSTEM FOR LEAKS .... 3-12

ADJUSTING THE CLUTCH LEVER FREE PLAY .................................... 3-12

ADJUSTING THE THROTTLE GRIP FREE PLAY .................................. 3-13

LUBRICATING THE THROTTLE CABLE ................................................ 3-14

CLEANING THE AIR FILTER ELEMENT................................................. 3-14

CHECKING THE THROTTLE BODY JOINT ............................................ 3-15

CHECKING THE BREATHER HOSES .................................................... 3-15

CHECKING THE EXHAUST SYSTEM............................. ........................ 3-15

CHECKING THE FUEL LINE ................................................................... 3-16

CHECKING THE ENGINE OIL LEVEL............................. ........................ 3-16

CHANGING THE ENGINE OIL ................................................................ 3-17

ADJUSTING THE ENGINE IDLING SPEED ......... ................................... 3-19

ADJUSTING THE VALVE CLEARANCE ................................................. 3-20

CLEANING THE SPARK ARRESTER ..................................................... 3-24

CHASSIS ........................................................................................................ 3-25

BLEEDING THE BRAKE SYST EM .......................................................... 3-25

CHECKING THE BRAKE HOSE .............................................................. 3-26

ADJUSTING THE FRONT BRAKE .......................................................... 3-26

ADJUSTING THE REAR BRAKE ............................................................. 3-27

CHECKING THE FRONT BR AKE PADS ................................................. 3-27

CHECKING THE REAR BRAKE PADS ........................... ........................ 3-29

CHECKING THE REAR BRAKE PAD INSULATOR ................................ 3-30

CHECKING THE BRAKE FLUID LEVEL.................................................. 3-30

ADJUSTING THE DRIVE CHAIN SLACK ................................................ 3-31

CHECKING THE FRONT FORK LEGS ................................................... 3-31

CHECKING THE FRONT FORK PROTECTOR GUIDE .......................... 3-32

CLEANING THE FRONT FORK OI L SEAL AND DUST SEAL ................ 3-32

AIR BLEEDING FROM FRONT FORK .................................................... 3-32

ADJUSTING THE FRONT FORK LEGS .................................................. 3-33

CHECKING THE SWINGARM OPERATION ........................................... 3-34

CHECKING THE REAR SUSPENSION ................................................... 3-34

Page 104 of 426

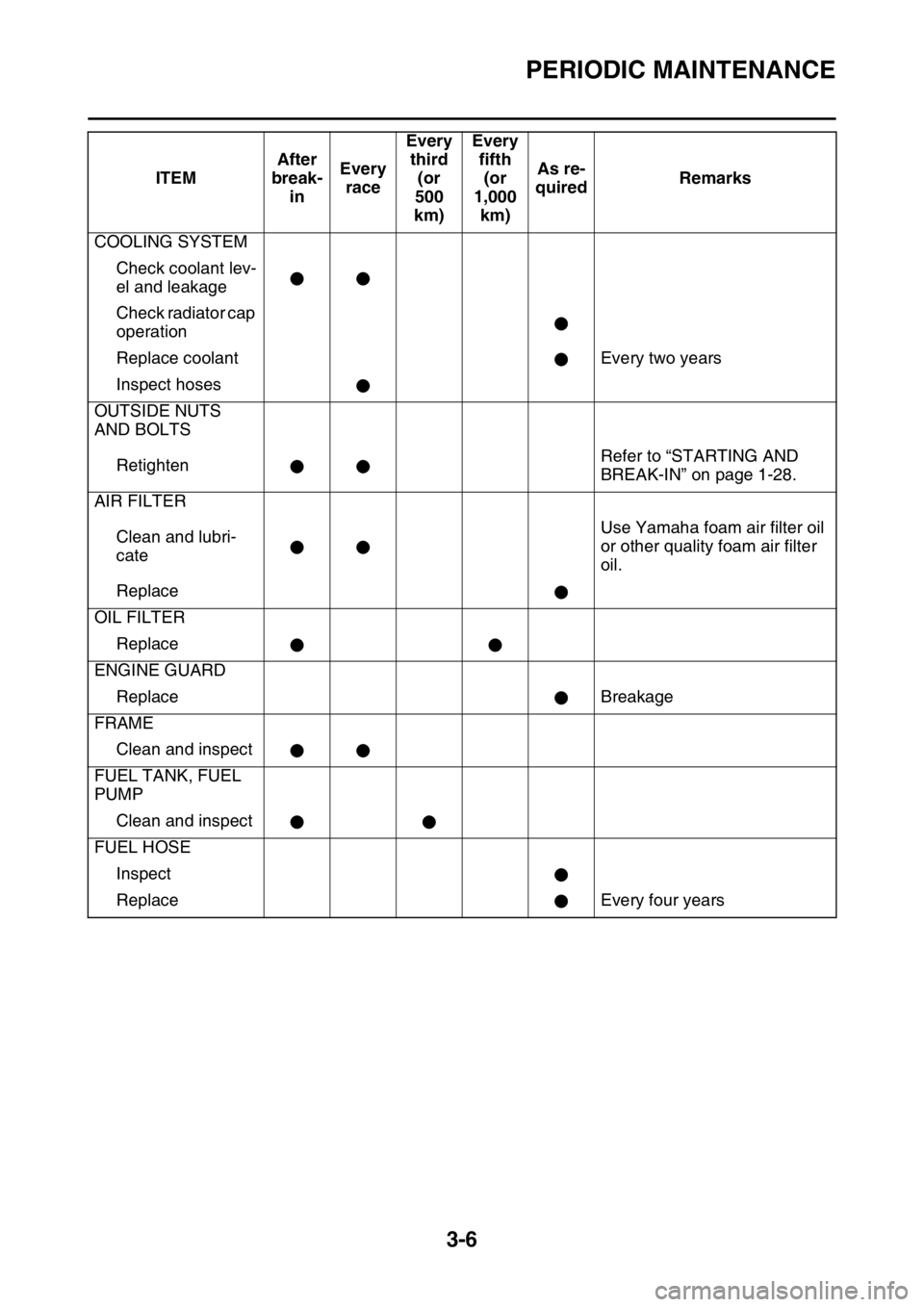

PERIODIC MAINTENANCE

3-6

COOLING SYSTEMCheck coolant lev-

el and leakage

Check radiator cap

operation

Replace coolant Every two years

Inspect hoses

OUTSIDE NUTS

AND BOLTS

Retighten Refer to “STARTING AND

BREAK-IN” on page 1-28.

AIR FILTER

Clean and lubri-

cate Use Yamaha foam air filter oil

or other quality foam air filter

oil.

Replace

OIL FILTER

Replace

ENGINE GUARD Replace Breakage

FRAME Clean and inspect

FUEL TANK, FUEL

PUMP

Clean and inspect

FUEL HOSE Inspect

Replace Every four years

ITEM

After

break- in Every

race Every

third (or

500

km) Every

fifth (or

1,000 km) As re-

quired Remarks

Page 107 of 426

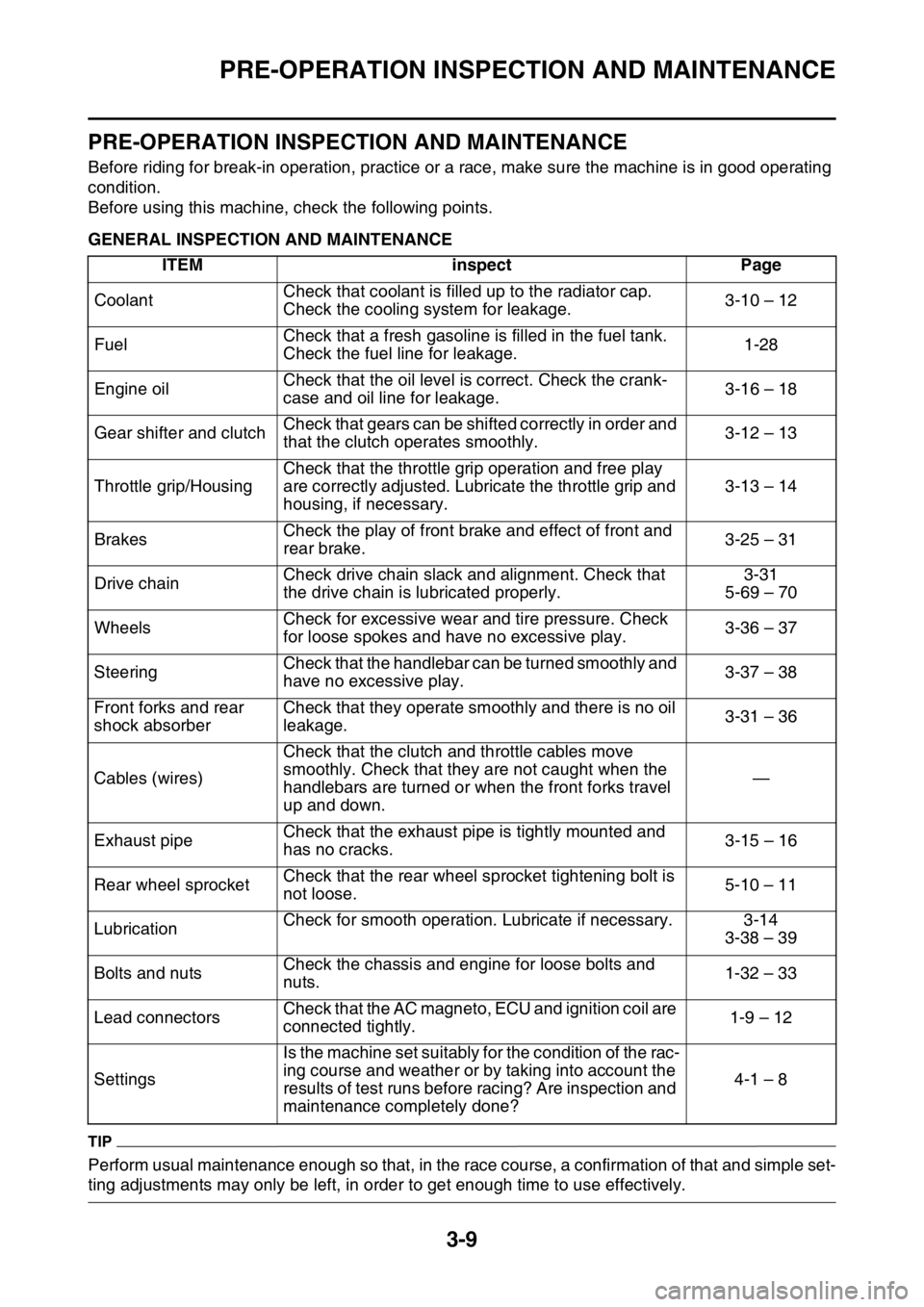

PRE-OPERATION INSPECTION AND MAINTENANCE

3-9

EAS2GC1079

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS2GC1080GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.ITEM inspect Page

Coolant Check that coolant is filled up to the radiator cap.

Check the cooling system for leakage. 3-10 – 12

Fuel Check that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage. 1-28

Engine oil Check that the oil level is correct. Check the crank-

case and oil line for leakage. 3-16 – 18

Gear shifter and clutch Check that gears can be shifted correctly in order and

that the clutch operates smoothly. 3-12 – 13

Throttle grip/Housing Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary. 3-13 – 14

Brakes Check the play of front brake and effect of front and

rear brake. 3-25 – 31

Drive chain Check drive chain slack and alignment. Check that

the drive chain is lubricated properly. 3-31

5-69 – 70

Wheels Check for excessive wear and tire pressure. Check

for loose spokes and have no excessive play. 3-36 – 37

Steering Check that the handlebar can be turned smoothly and

have no excessive play. 3-37 – 38

Front forks and rear

shock absorber Check that they operate smoothly and there is no oil

leakage.

3-31 – 36

Cables (wires) Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.

—

Exhaust pipe Check that the exhaust pipe is tightly mounted and

has no cracks. 3-15 – 16

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is

not loose. 5-10 – 11

Lubrication Check for smooth operation. Lubricate if necessary. 3-14

3-38 – 39

Bolts and nuts Check the chassis and engine for loose bolts and

nuts. 1-32 – 33

Lead connectors Check that the AC magneto, ECU and ignition coil are

connected tightly. 1-9 – 12

Settings Is the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?

4-1 – 8

Page 108 of 426

ENGINE

3-10

EAS2GC1081

ENGINE

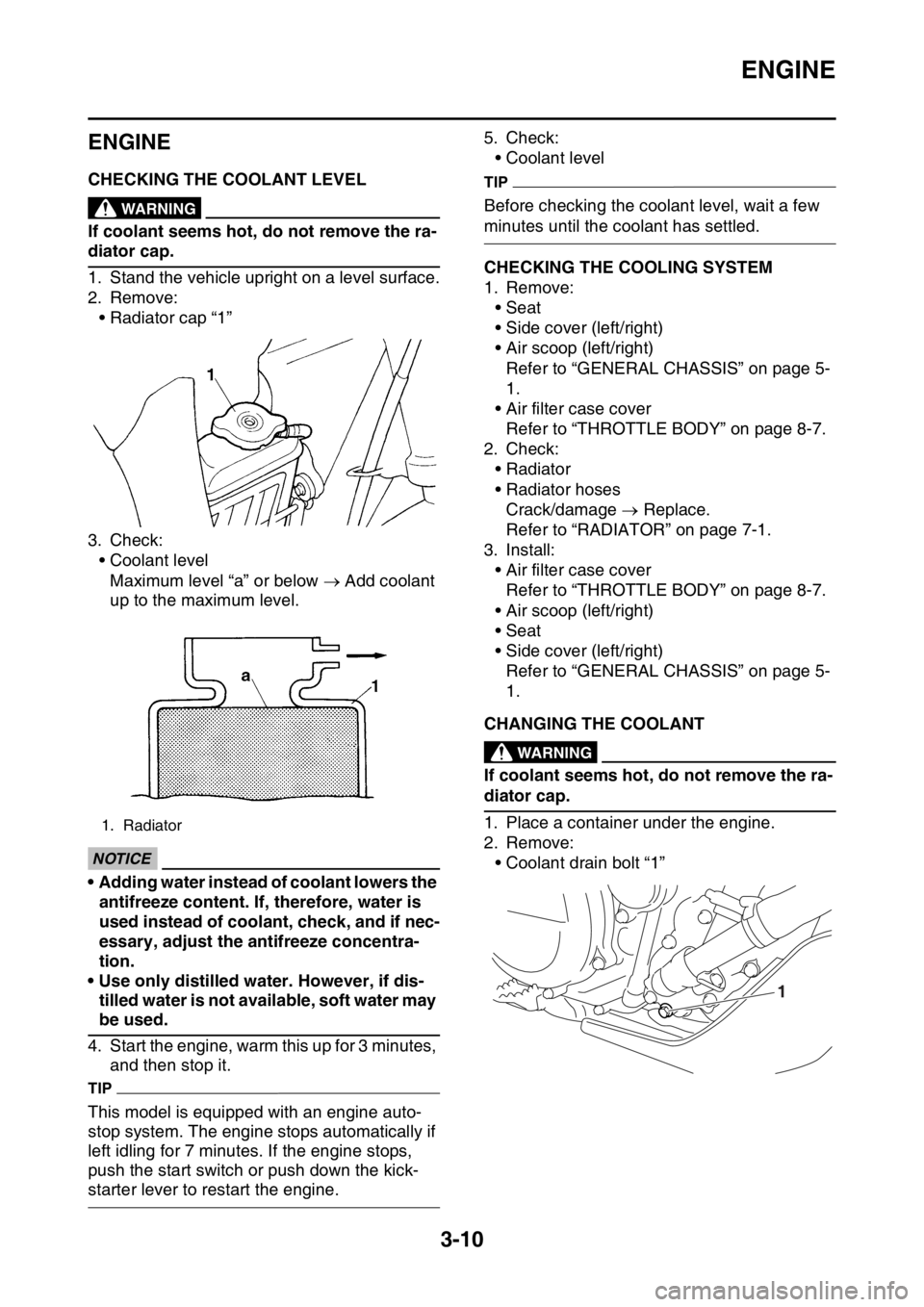

EAS2GC1082CHECKING THE COOLANT LEVELEWA

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Stand the vehicle upright on a level surface.

2. Remove:• Radiator cap “1”

3. Check: • Coolant levelMaximum level “a” or below Add coolant

up to the maximum level.

ECA

NOTICE

• Adding water instead of coolant lowers the

antifreeze content. If, therefore, water is

used instead of coolant, check, and if nec-

essary, adjust the antifreeze concentra-

tion.

• Use only distilled water. However, if dis- tilled water is not available, soft water may

be used.

4. Start the engine, warm this up for 3 minutes, and then stop it.

TIP

This model is equipped with an engine auto-

stop system. The engine stops automatically if

left idling for 7 minutes. If the engine stops,

push the start switch or push down the kick-

starter lever to restart the engine. 5. Check:

• Coolant level

TIP

Before checking the coolant level, wait a few

minutes until the coolant has settled.

EAS2GC1083CHECKING THE COOLING SYSTEM

1. Remove:• Seat

• Side cover (left/right)

• Air scoop (left/right)Refer to “GENERAL CHASSIS” on page 5-

1.

• Air filter case cover Refer to “THROTTLE BODY” on page 8-7.

2. Check:

• Radiator

• Radiator hosesCrack/damage Replace.

Refer to “RADIATOR” on page 7-1.

3. Install: • Air filter case cover

Refer to “THROTTLE BODY” on page 8-7.

• Air scoop (left/right)

• Seat

• Side cover (left/right) Refer to “GENERAL CHASSIS” on page 5-

1.

EAS2GC1084CHANGING THE COOLANTEWA

WARNING

If coolant seems hot, do not remove the ra-

diator cap.

1. Place a container under the engine.

2. Remove:• Coolant drain bolt “1”

1. Radiator

1

Page 109 of 426

ENGINE

3-11

3. Remove:• Radiator capSlowly loosen the radiator cap to drain cool-

ant.

TIP

When the radiator cap is loosened, coolant will

gush out transversely; therefore, bring the con-

tainer near to the outlet.

4. Thoroughly flush the cooling system with

clean tap water.

5. Install:

• Copper washer

• Coolant drain bolt

6. Pour coolant.

EWA

WARNING

• If coolant splashes in your eyes, thorough- ly wash them with water and consult a

doctor.

• If coolant splashes on your clothes, quick-

ly wash it away with water and then with

soap and water.

• If coolant is swallowed, induce vomiting

and get immediate medical attention.

ECA

NOTICE

• Adding water instead of coolant lowers the

antifreeze content of the coolant. If water

is used instead of coolant check, and if

necessary, correct the antifreeze concen-

tration of the coolant.

• Use only distilled water. However, if dis-

tilled water is not available, soft water may

be used.

• If coolant comes into contact with painted

surfaces, immediately wash them with wa-

ter.

• Do not mix different types of antifreeze.

7. Install:• Radiator cap 8. Start the engine, warm this up for 3 minutes,

stop it, and then wait for it to cool down.

TIP

This model is equipped with an engine auto-

stop system. The engine stops automatically if

left idling for 7 minutes. If the engine stops,

push the start switch or push down the kick-

starter lever to restart the engine.

9. Check:• Coolant levelRefer to “CHECKING THE COOLANT LEV-

EL” on page 3-10.

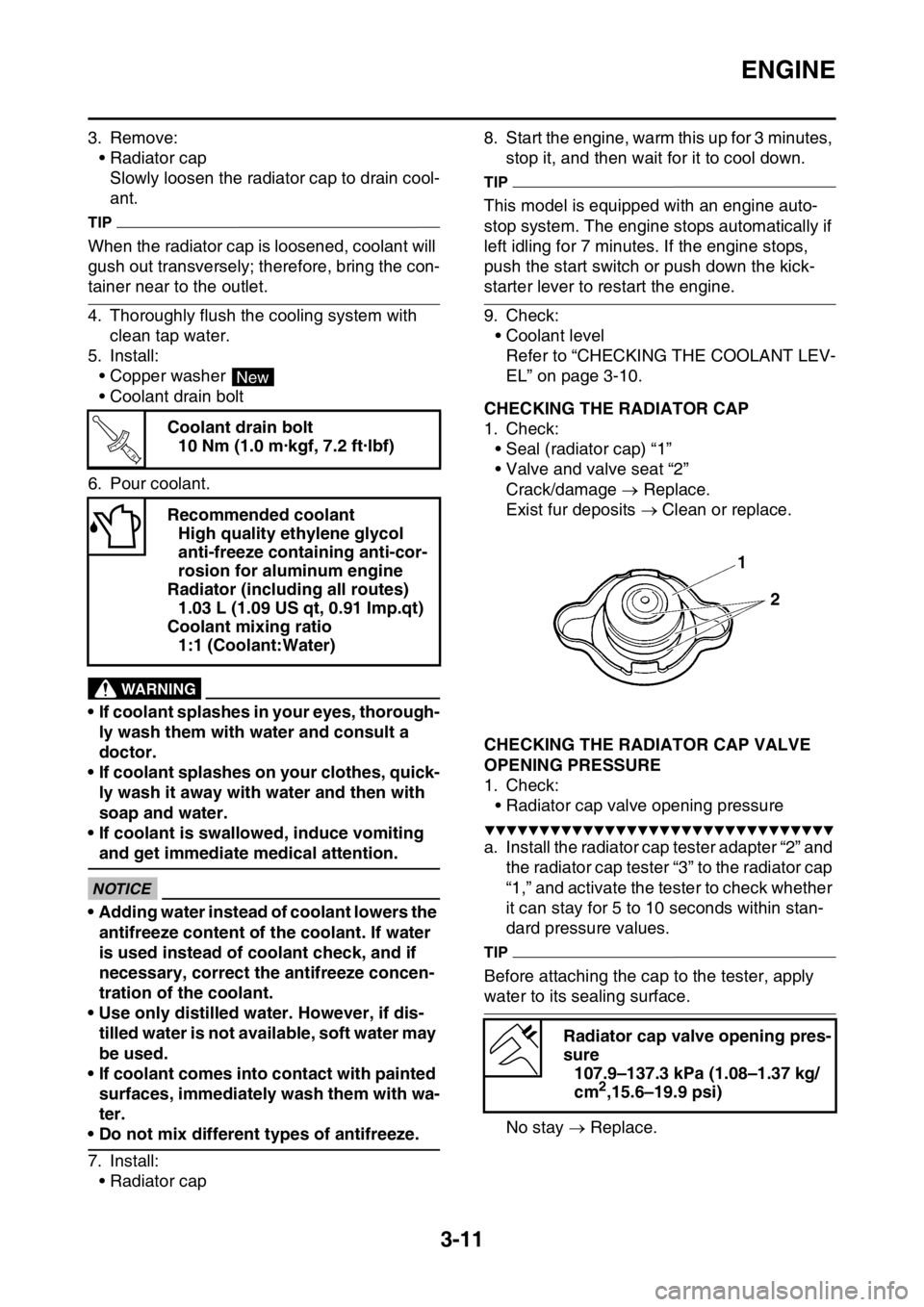

EAS2GC1085CHECKING THE RADIATOR CAP

1. Check:• Seal (radiator cap) “1”

• Valve and valve seat “2”

Crack/damage Replace.

Exist fur deposits Clean or replace.

EAS2GC1086CHECKING THE RADIATOR CAP VALVE

OPENING PRESSURE

1. Check:

• Radiator cap valve opening pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Install the radiator cap tester adapter “2” and the radiator cap tester “3” to the radiator cap

“1,” and activate the tester to check whether

it can stay for 5 to 10 seconds within stan-

dard pressure values.

TIP

Before attaching the cap to the tester, apply

water to its sealing surface.

No stay Replace.

Coolant drain bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Recommended coolant High quality ethylene glycol

anti-freeze containing anti-cor-

rosion for aluminum engine

Radiator (including all routes) 1.03 L (1.09 US qt, 0.91 Imp.qt)

Coolant mixing ratio 1:1 (Coolant:Water)

New

T R..

Radiator cap valve opening pres-

sure 107.9–137.3 kPa (1.08–1.37 kg/

cm

2,15.6–19.9 psi)