steering wheel adjustment YAMAHA WR 450F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: WR 450F, Model: YAMAHA WR 450F 2016Pages: 426, PDF Size: 10.86 MB

Page 107 of 426

PRE-OPERATION INSPECTION AND MAINTENANCE

3-9

EAS2GC1079

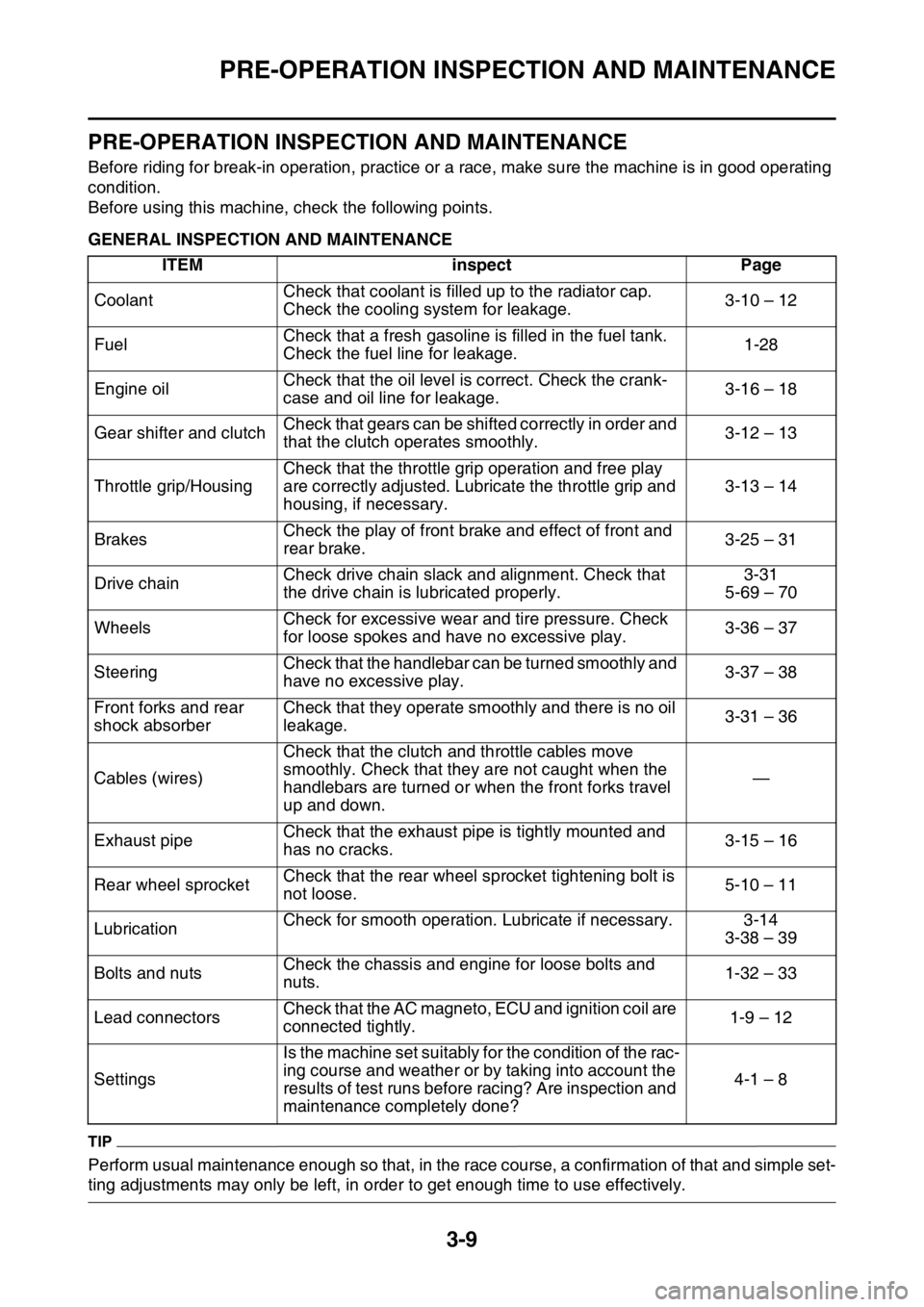

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS2GC1080GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.ITEM inspect Page

Coolant Check that coolant is filled up to the radiator cap.

Check the cooling system for leakage. 3-10 – 12

Fuel Check that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage. 1-28

Engine oil Check that the oil level is correct. Check the crank-

case and oil line for leakage. 3-16 – 18

Gear shifter and clutch Check that gears can be shifted correctly in order and

that the clutch operates smoothly. 3-12 – 13

Throttle grip/Housing Check that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary. 3-13 – 14

Brakes Check the play of front brake and effect of front and

rear brake. 3-25 – 31

Drive chain Check drive chain slack and alignment. Check that

the drive chain is lubricated properly. 3-31

5-69 – 70

Wheels Check for excessive wear and tire pressure. Check

for loose spokes and have no excessive play. 3-36 – 37

Steering Check that the handlebar can be turned smoothly and

have no excessive play. 3-37 – 38

Front forks and rear

shock absorber Check that they operate smoothly and there is no oil

leakage.

3-31 – 36

Cables (wires) Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.

—

Exhaust pipe Check that the exhaust pipe is tightly mounted and

has no cracks. 3-15 – 16

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is

not loose. 5-10 – 11

Lubrication Check for smooth operation. Lubricate if necessary. 3-14

3-38 – 39

Bolts and nuts Check the chassis and engine for loose bolts and

nuts. 1-32 – 33

Lead connectors Check that the AC magneto, ECU and ignition coil are

connected tightly. 1-9 – 12

Settings Is the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?

4-1 – 8