YAMAHA XJ6-N 2010 Manual PDF

Manufacturer: YAMAHA, Model Year: 2010, Model line: XJ6-N, Model: YAMAHA XJ6-N 2010Pages: 104, PDF Size: 2.86 MB

Page 71 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

●

Clean the filler cap before re-

moving. Use only DOT 4 brake

fluid from a sealed container.

●

Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

●

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

●

Be careful that water does not

enter the brake fluid reservoir

when refilling. Water will signifi-

cantly lower the boiling point of

the fluid and may result in vapor

lock.

NOTICE

ECA17640

Brake fluid may damage painted sur-

faces or plastic parts. Always clean

up spilled fluid immediately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and thebrake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

EAU22731

Changing the brake fluid Have a Yamaha dealer change the

brake fluid at the intervals specified in

the TIP after the periodic maintenance

and lubrication chart. In addition, have

the oil seals of the master cylinders and

calipers as well as the brake hoses re-

placed at the intervals listed below or

whenever they are damaged or leak-

ing.●

Oil seals: Replace every two

years.

●

Brake hoses: Replace every four

years.

U20SE3E0.book Page 26 Monday, April 23, 2012 10:47 AM

Page 72 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

EAU22760

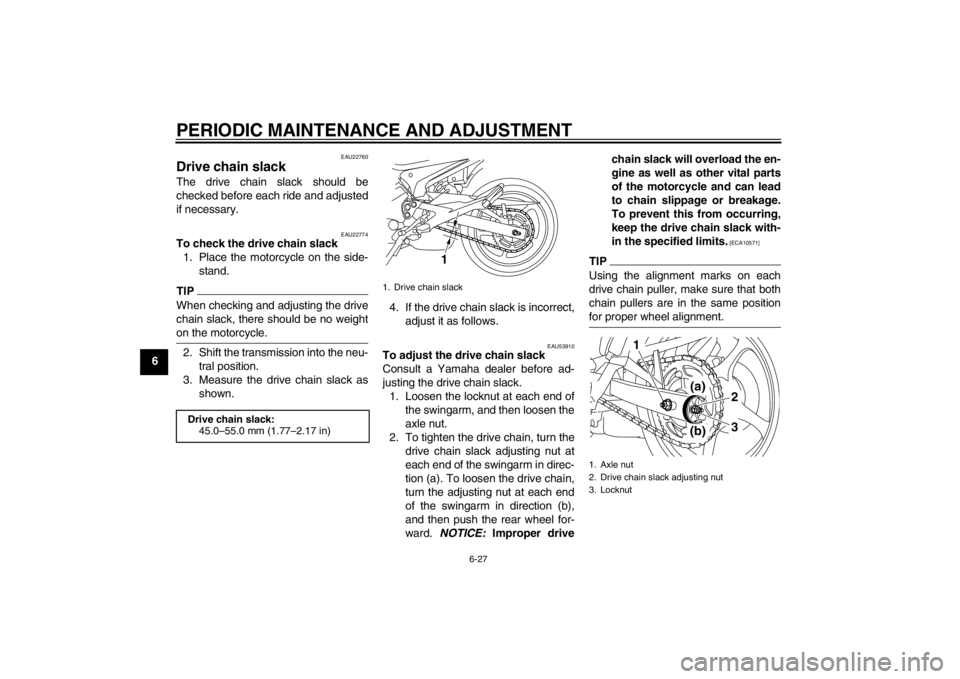

Drive chain slack The drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22774

To check the drive chain slack1. Place the motorcycle on the side- stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into the neu-tral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU53910

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.1. Loosen the locknut at each end of the swingarm, and then loosen the

axle nut.

2. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

[ECA10571]

TIPUsing the alignment marks on each

drive chain puller, make sure that both

chain pullers are in the same position

for proper wheel alignment.

Drive chain slack:

45.0–55.0 mm (1.77–2.17 in)

1. Drive chain slack

1

1. Axle nut

2. Drive chain slack adjusting nut

3. Locknut

3

1

2

(a)(b)

U20SE3E0.book Page 27 Monday, April 23, 2012 10:47 AM

Page 73 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

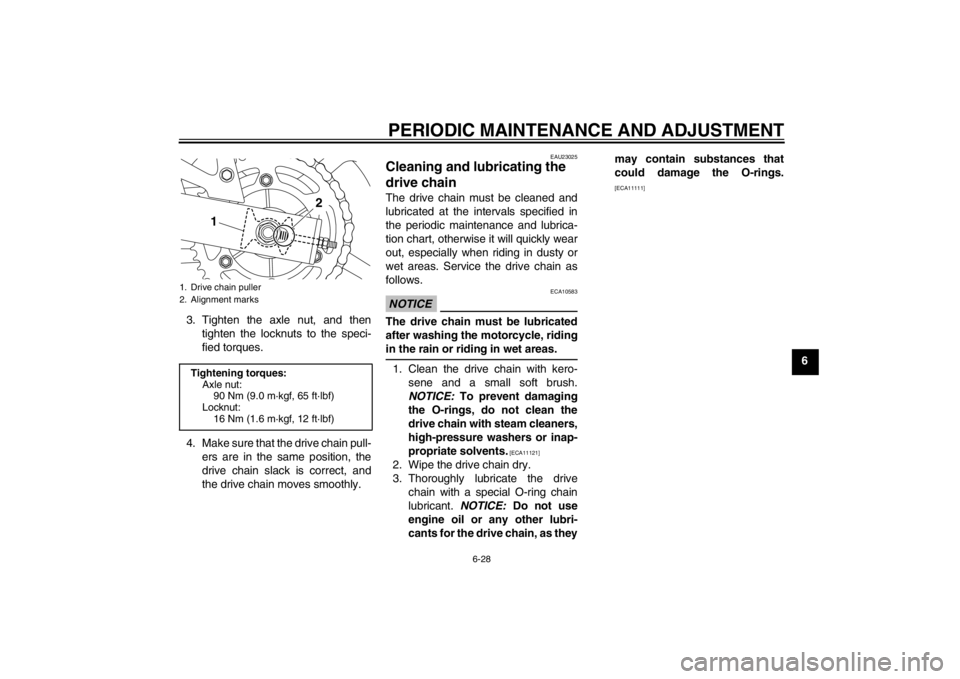

3. Tighten the axle nut, and then

tighten the locknuts to the speci-

fied torques.

4. Make sure that the drive chain pull- ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

EAU23025

Cleaning and lubricating the

drive chain The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10583

The drive chain must be lubricated

after washing the motorcycle, riding

in the rain or riding in wet areas.1. Clean the drive chain with kero-sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11121]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they may contain substances that

could damage the O-rings.

[ECA11111]

1. Drive chain puller

2. Alignment marksTightening torques:

Axle nut:90 Nm (9.0 m·kgf, 65 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

1

2

U20SE3E0.book Page 28 Monday, April 23, 2012 10:47 AM

Page 74 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-29

6

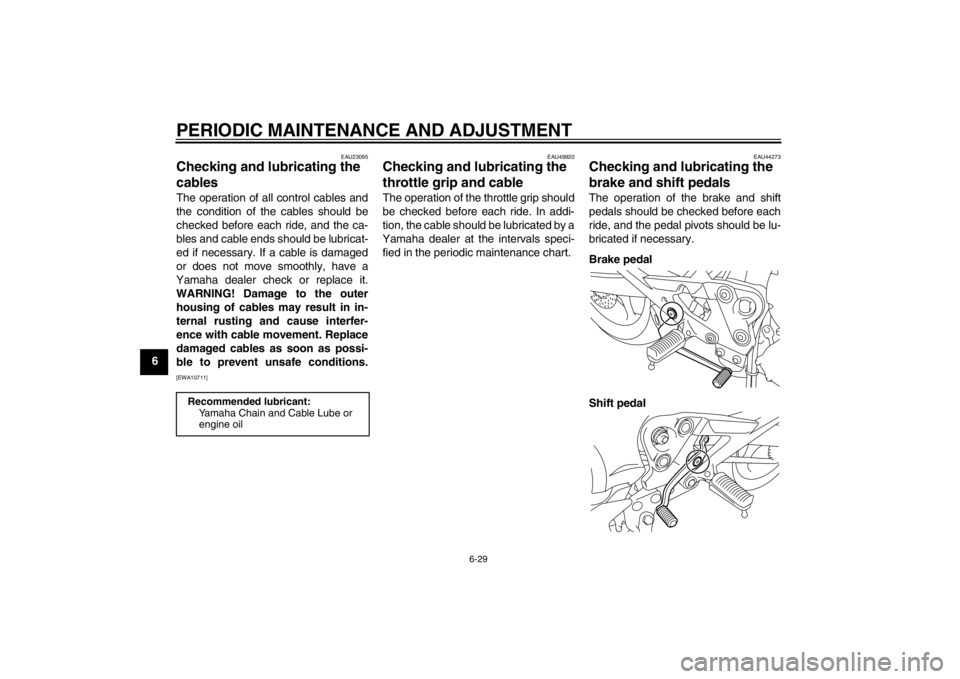

EAU23095

Checking and lubricating the

cables The operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubricat-

ed if necessary. If a cable is damaged

or does not move smoothly, have a

Yamaha dealer check or replace it.

WARNING! Damage to the outer housing of cables may result in in-

ternal rusting and cause interfer-

ence with cable movement. Replace

damaged cables as soon as possi-

ble to prevent unsafe conditions.[EWA10711] EAU49920

Checking and lubricating the

throttle grip and cable The operation of the throttle grip should

be checked before each ride. In addi-

tion, the cable should be lubricated by a

Yamaha dealer at the intervals speci- fied in the periodic maintenance chart.

EAU44273

Checking and lubricating the

brake and sh ift pedals The operation of the brake and shift

pedals should be checked before each

ride, and the pedal pivots should be lu-

bricated if necessary.

Brake pedal

Shift pedal

Recommended lubricant:

Yamaha Chain and Cable Lube or

engine oil

U20SE3E0.book Page 29 Monday, April 23, 2012 10:47 AM

Page 75 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-30

6

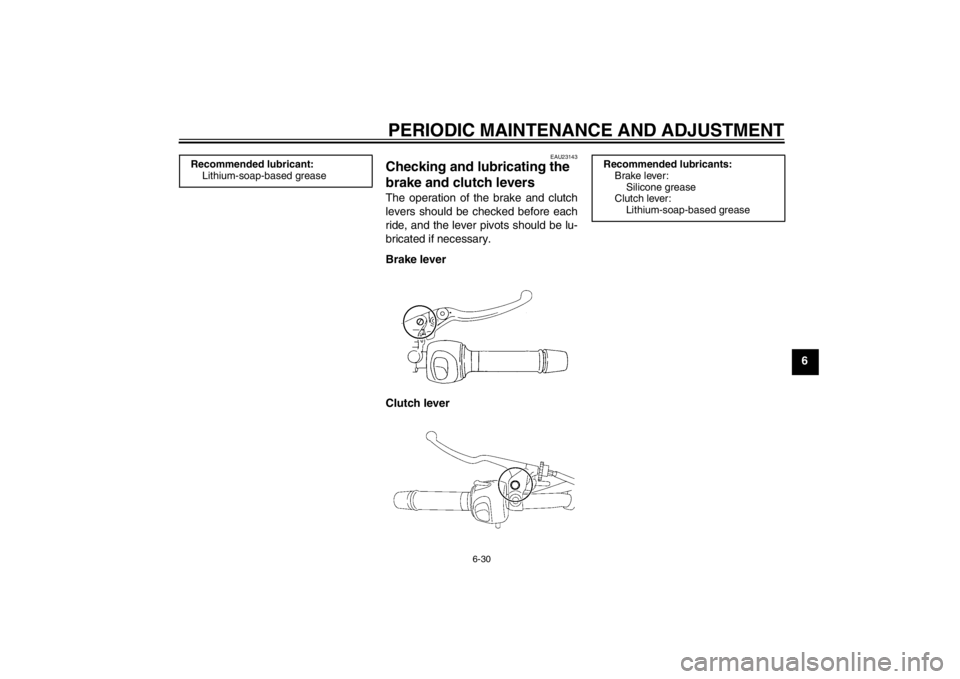

EAU23143

Checking and lubricating the

brake and clutch levers The operation of the brake and clutch

levers should be checked before each

ride, and the lever pivots should be lu-

bricated if necessary.

Brake lever

Clutch lever

Recommended lubricant:Lithium-soap-based grease

Recommended lubricants:Brake lever:

Silicone grease

Clutch lever:

Lithium-soap-based grease

U20SE3E0.book Page 30 Monday, April 23, 2012 10:47 AM

Page 76 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-31

6

EAU23202

Checking and lubricating the

sidestand The operation of the sidestand should

be checked before each ride, and the

sidestand pivot and metal-to-metal

contact surfaces should be lubricated if

necessary.

WARNING

EWA10731

If the sidestand does not move up

and down smoothly, have a Yamaha

dealer check or repair it. Otherwise,

the sidestand could contact the

ground and distract the operator, re-

sulting in a possible loss of control.

EAUM1652

Lubricating the swingarm piv-

ots The swingarm pivots must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU23272

Checking the front fork The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10751]

2. While applying the front brake, push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

Recommended lubricant:Lithium-soap-based grease

Recommended lubricant:Lithium-soap-based grease

U20SE3E0.book Page 31 Monday, April 23, 2012 10:47 AM

Page 77 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

6

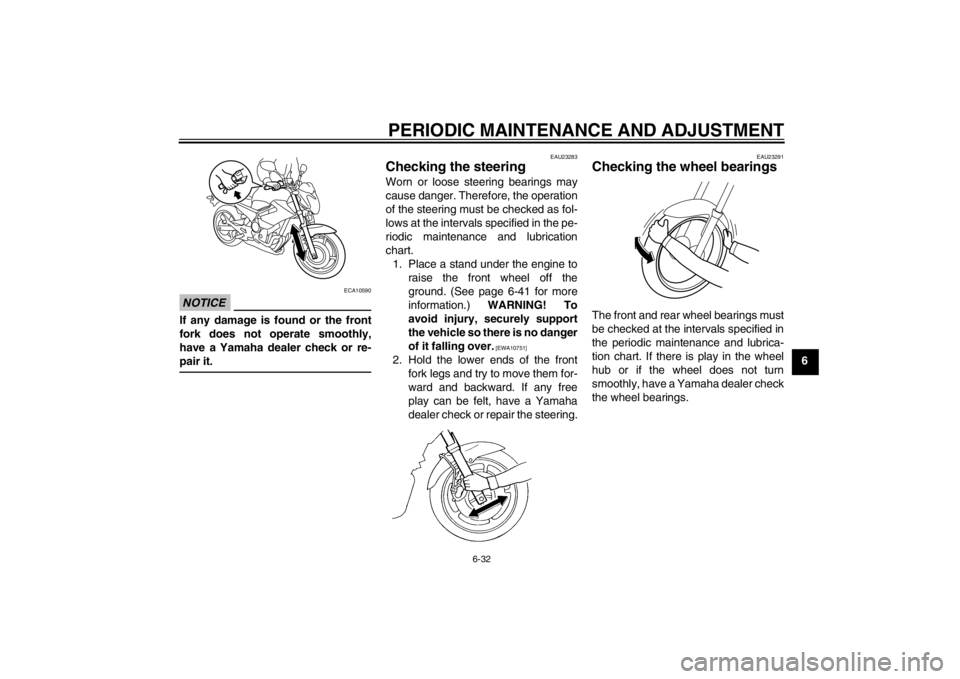

NOTICE

ECA10590

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

EAU23283

Checking the steering Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.1. Place a stand under the engine to raise the front wheel off the

ground. (See page 6-41 for more

information.) WARNING! To

avoid injury, securely support

the vehicle so there is no danger

of it falling over.

[EWA10751]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steering.

EAU23291

Checking the wheel bearings The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings.

U20SE3E0.book Page 32 Monday, April 23, 2012 10:47 AM

Page 78 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

6

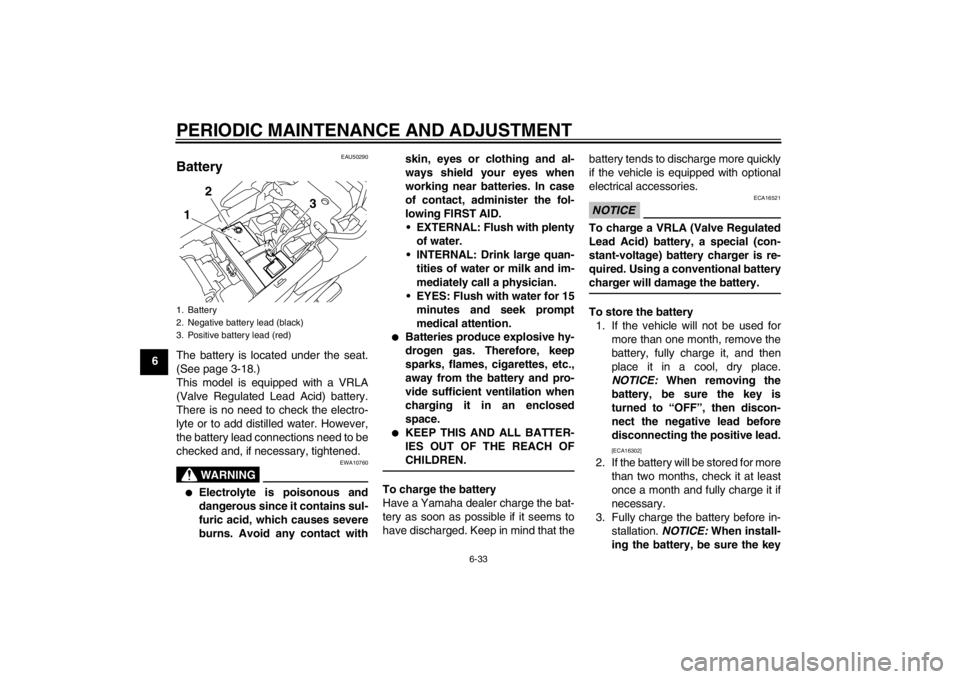

EAU50290

Battery The battery is located under the seat.

(See page 3-18.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to be

checked and, if necessary, tightened.

WARNING

EWA10760

●

Electrolyte is poisonous and

dangerous since it contains sul-

furic acid, which causes severe

burns. Avoid any contact withskin, eyes or clothing and al-

ways shield your eyes when

working near batteries. In case

of contact, administer the fol-

lowing FIRST AID.

EXTERNAL: Flush with plenty of water.

INTERNAL: Drink large quan- tities of water or milk and im-

mediately call a physician.

EYES: Flush with water for 15 minutes and seek prompt

medical attention.

●

Batteries produce explosive hy-

drogen gas. Therefore, keep

sparks, flames, cigarettes, etc.,

away from the battery and pro-

vide sufficient ventilation when

charging it in an enclosed

space.

●

KEEP THIS AND ALL BATTER-

IES OUT OF THE REACH OF

CHILDREN.

To charge the battery

Have a Yamaha dealer charge the bat-

tery as soon as possible if it seems to

have discharged. Keep in mind that the battery tends to discharge more quickly

if the vehicle is equipped with optional

electrical accessories.

NOTICE

ECA16521

To charge a VRLA (Valve Regulated

Lead Acid) battery, a special (con-

stant-voltage) battery charger is re-

quired. Using a conventional battery

charger will damage the battery.To store the battery

1. If the vehicle will not be used for more than one month, remove the

battery, fully charge it, and then

place it in a cool, dry place.

NOTICE: When removing the

battery, be sure the key is

turned to “OFF”, then discon-

nect the negative lead before

disconnecting the positive lead.

[ECA16302]

2. If the battery will be stored for more than two months, check it at least

once a month and fully charge it if

necessary.

3. Fully charge the battery before in- stallation. NOTICE: When install-

ing the battery, be sure the key

1. Battery

2. Negative battery lead (black)

3. Positive battery lead (red)1 2

3

U20SE3E0.book Page 33 Monday, April 23, 2012 10:47 AM

Page 79 of 104

![YAMAHA XJ6-N 2010 Manual PDF PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6

is turned to “OFF”, then con-

nect the positive lead before

connecting the negative lead.

[ECA16840]

4. After installation, make sure that

the battery le YAMAHA XJ6-N 2010 Manual PDF PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6

is turned to “OFF”, then con-

nect the positive lead before

connecting the negative lead.

[ECA16840]

4. After installation, make sure that

the battery le](/img/51/52587/w960_52587-78.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6

is turned to “OFF”, then con-

nect the positive lead before

connecting the negative lead.

[ECA16840]

4. After installation, make sure that

the battery leads are properly con-

nected to the battery terminals.NOTICE

ECA16530

Always keep the battery charged.

Storing a discharged battery can

cause permanent battery damage.

EAU47172

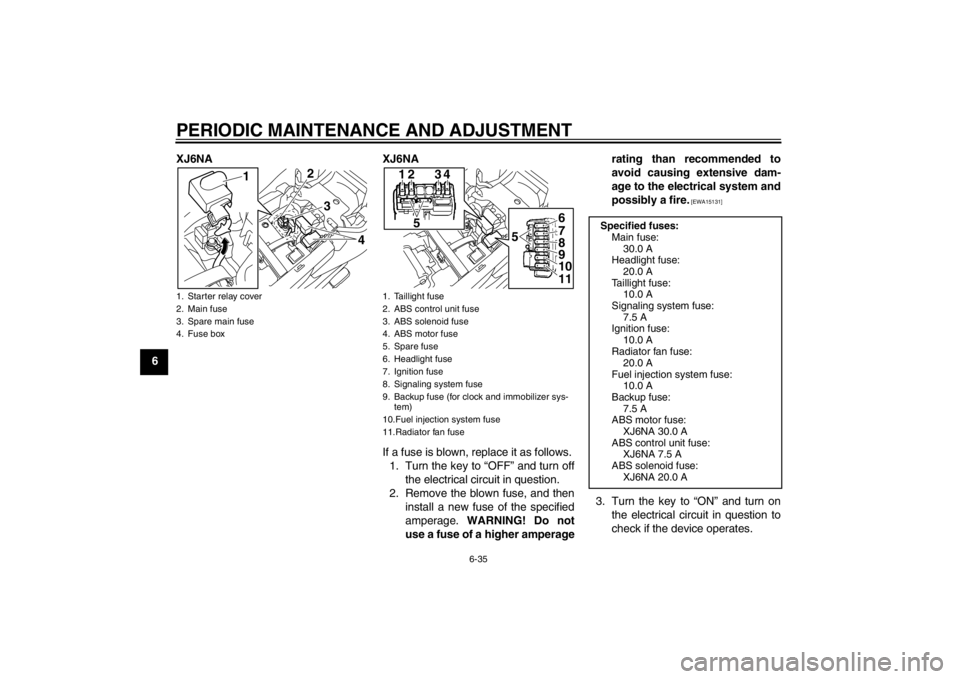

Replacing the fuses The main fuse and the fuse boxes,

which contain the fuses for the individu-

al circuits, are located under the seat.

(See page 3-18.)TIPTo access the main fuse, remove the

starter relay cover as shown.XJ6N XJ6N1. Starter relay cover

2. Main fuse

3. Spare main fuse

4. Fuse box

2

4

3

1

1. Taillight fuse

2. Spare fuse

3. Headlight fuse

4. Ignition fuse

5. Signaling system fuse

6. Backup fuse (for clock and immobilizer sys-

tem)

7. Fuel injection system fuse

8. Radiator fan fuse

1 2

3

4

5

6

7

8

U20SE3E0.book Page 34 Monday, April 23, 2012 10:47 AM

Page 80 of 104

PERIODIC MAINTENANCE AND ADJUSTMENT

6-35

6XJ6NA XJ6NA

If a fuse is blown, replace it as follows.1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15131]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

1. Starter relay cover

2. Main fuse

3. Spare main fuse

4. Fuse box

2

4

3

1

1. Taillight fuse

2. ABS control unit fuse

3. ABS solenoid fuse

4. ABS motor fuse

5. Spare fuse

6. Headlight fuse

7. Ignition fuse

8. Signaling system fuse

9. Backup fuse (for clock and immobilizer sys-

tem)

10.Fuel injection system fuse

11.Radiator fan fuse

1

5 56

7

8

9

10

11

234

Specified fuses:

Main fuse:30.0 A

Headlight fuse:

20.0 A

Taillight fuse: 10.0 A

Signaling system fuse: 7.5 A

Ignition fuse:

10.0 A

Radiator fan fuse: 20.0 A

Fuel injection system fuse: 10.0 A

Backup fuse:

7.5 A

ABS motor fuse: XJ6NA 30.0 A

ABS control unit fuse: XJ6NA 7.5 A

ABS solenoid fuse:

XJ6NA 20.0 A

U20SE3E0.book Page 35 Monday, April 23, 2012 10:47 AM