ABS YAMAHA XJ6-N 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: XJ6-N, Model: YAMAHA XJ6-N 2016Pages: 104, PDF Size: 2.91 MB

Page 28 of 104

Instrument and control functions

3-14

3

EAU51802

ABS (for ABS mo dels)

The Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake ped-

al. In this situation, continue to apply

the brakes and let the ABS work; do

not “pump” the brakes as this will re-

duce braking effectiveness.

WARNING

EWA16051

Always keep a sufficient distance

from the vehicle ahea d to match the

ri din g speed even with ABS.

The ABS performs best with

lon g b rakin g d istances.

On certain surfaces, such as

rou gh or g ravel roa ds, the b rak-

in g d istance may be lon ger with

the ABS than without.

The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

TIP

The ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “click-

ing” noise can be heard from un-

der the seat, and if the brake lever

or brake pedal is even slightly ap-

plied, a vibration can be felt at the

lever and pedal, but these do not

indicate a malfunction.

This ABS has a test mode which

allows the owner to experience

the pulsation at the brake lever or

brake pedal when the ABS is op-

erating. However, special tools are

required, so please consult your

Yamaha dealer.

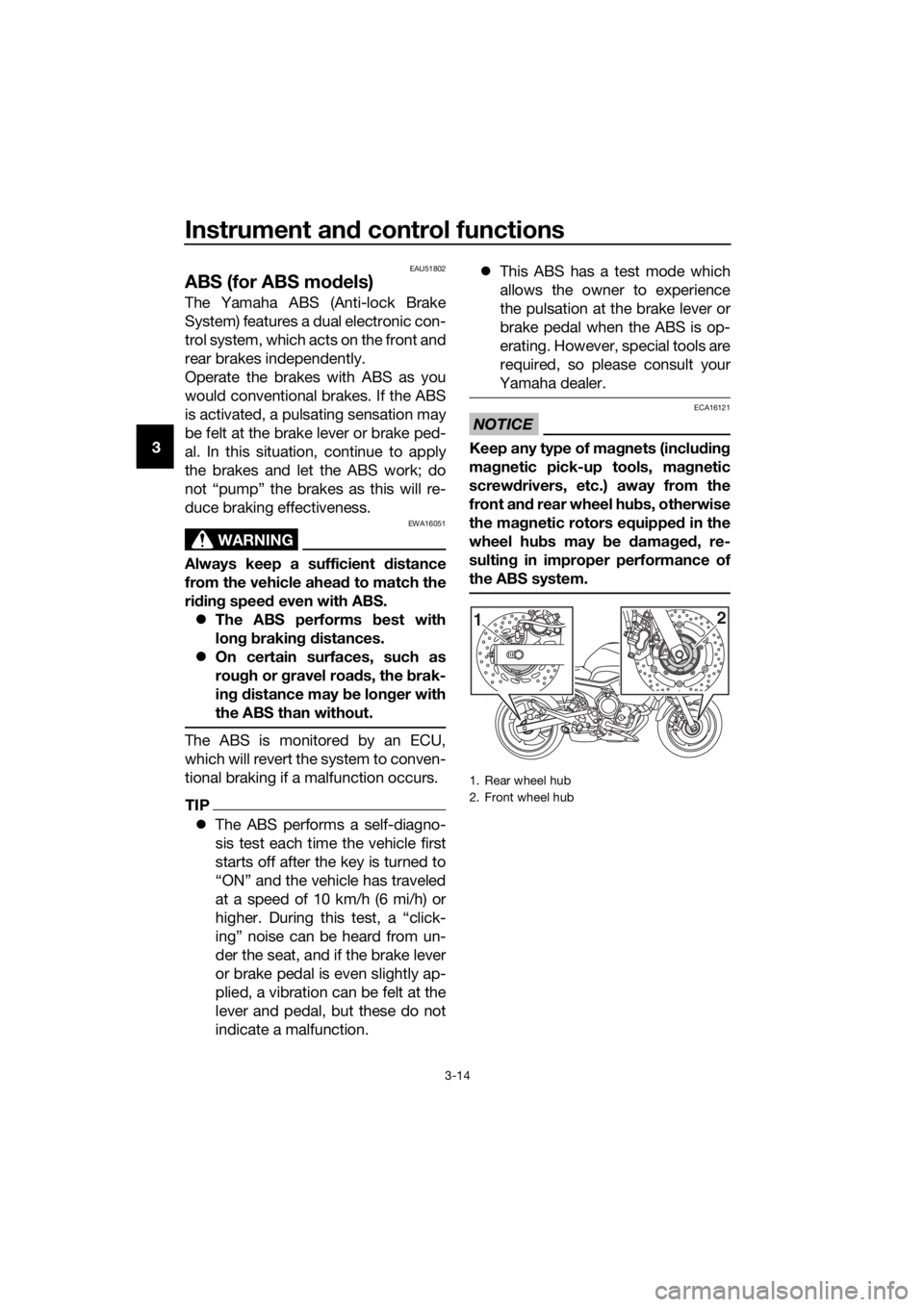

NOTICE

ECA16121

Keep any type of mag nets (includin g

ma gnetic pick-up tools, ma gnetic

screwd rivers, etc.) away from the

front an d rear wheel hu bs, otherwise

the ma gnetic rotors equippe d in the

wheel hu bs may be damag ed , re-

sultin g in improper performance of

the ABS system.

1. Rear wheel hub

2. Front wheel hub

12

UB61E1E0.book Page 14 Wednesday, October 21, 2015 11:19 AM

Page 35 of 104

Instrument and control functions

3-21

3

EAU47001

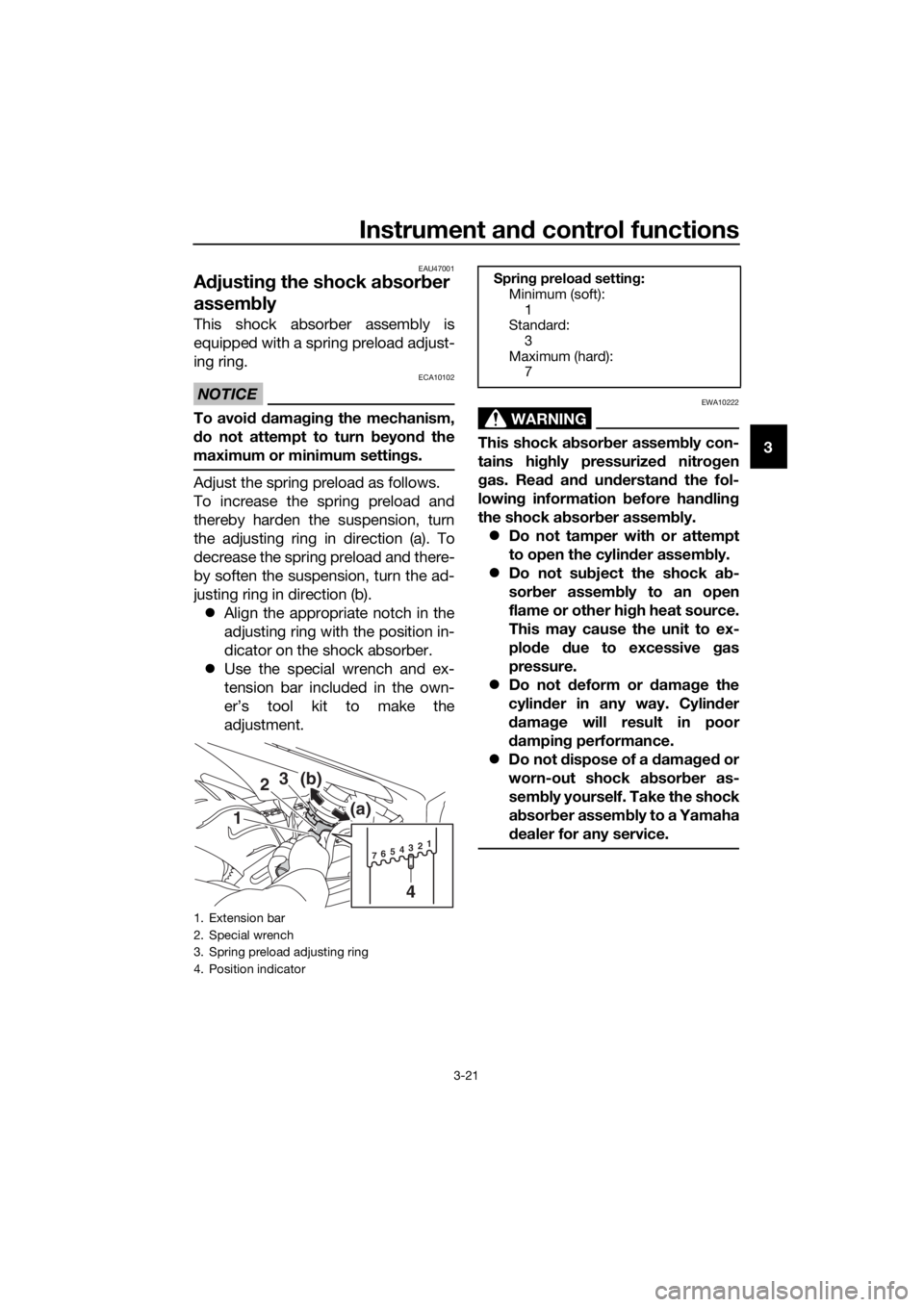

A djustin g the shock a bsor ber

assem bly

This shock absorber assembly is

equipped with a spring preload adjust-

ing ring.

NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn beyon d the

maximum or minimum settin gs.

Adjust the spring preload as follows.

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction (a). To

decrease the spring preload and there-

by soften the suspension, turn the ad-

justing ring in direction (b).

Align the appropriate notch in the

adjusting ring with the position in-

dicator on the shock absorber.

Use the special wrench and ex-

tension bar included in the own-

er’s tool kit to make the

adjustment.

WARNING

EWA10222

This shock ab sorber assem bly con-

tains hig hly pressurize d nitro gen

g as. Rea d an d un derstan d the fol-

lowin g information before han dlin g

the shock a bsor ber assem bly.

Do not tamper with or attempt

to open the cylind er assembly.

Do not su bject the shock a b-

sor ber assem bly to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plo de due to excessive gas

pressure.

Do not deform or damag e the

cylin der in any way. Cylin der

d amag e will result in poor

d ampin g performance.

Do not dispose of a d amaged or

worn-out shock a bsor ber as-

sem bly

yourself. Take the shock

a b sor ber assem bly to a Yamaha

d ealer for any service.

1. Extension bar

2. Special wrench

3. Spring preload adjusting ring

4. Position indicator

1

2

3

4

5

6

7

1 2

3(a)

(b)

4

Sprin

g preloa d settin g:

Minimum (soft): 1

Standard:

3

Maximum (hard): 7

UB61E1E0.book Page 21 Wednesday, October 21, 2015 11:19 AM

Page 41 of 104

Operation and important ri din g points

5-2

5

EAU51792

Startin g the eng ine

In order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:

The transmission is in the neutral

position.

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

See page 3-22 for more informa-

tion.

1. Turn the key to “ON” and make sure that the engine stop switch is

set to “ ”.

The following warning lights and

indicator light should come on for

a few seconds, then go off. Oil level warning light

Coolant temperature warning

light

Engine trouble warning light

Immobilizer system indicator

light

NOTICE

ECA17671

If the ab ove warnin g li ghts or in dica-

tor li ght do not come on initially

when the key is turned to “ON”, or if

a warnin g or in dicator li ght remains

on, see pa ge 3-4 for the correspon d-

in g warnin g an d in dicator li ght cir-

cuit check.

For ABS models:

The ABS warning light should

come on when the main switch is

turned to “ON” and then go off af-

ter traveling at a speed of 10 km/h

(6 mi/h) or higher.

NOTICE

ECA17682

If the ABS warnin g li ght does not

come on an d then go off as ex-

plained above, see pa ge 3-4 for the

warnin g li ght circuit check.

2. Shift the transmission into the

neutral position. The neutral indi-

cator light should come on. If not,

ask a Yamaha dealer to check the

electrical circuit.

3. Start the engine by pushing the start switch.

If the engine fails to start, release

the start switch, wait a few sec-

onds, and then try again. Each

starting attempt should be as

short as possible to preserve the

battery. Do not crank the engine

more than 10 seconds on any one

attempt.

NOTICE

ECA11043

For maximum en gine life, never ac-

celerate har d when the en gine is

col d!

UB61E1E0.book Page 2 Wednesday, October 21, 2015 11:19 AM

Page 67 of 104

Periodic maintenance an d a djustment

6-23

6

EAU37914

Checkin g the brake lever free

play

There should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spon gy feelin g in the b rake

lever can in dicate the presence of

air in the hy draulic system. If there is

air in the hy draulic system, have a

Yamaha dealer blee d the system be-

fore operatin g the vehicle. Air in the

hy draulic system will diminish the

b rakin g performance, which may re-

sult in loss of control an d an acci-

d ent.

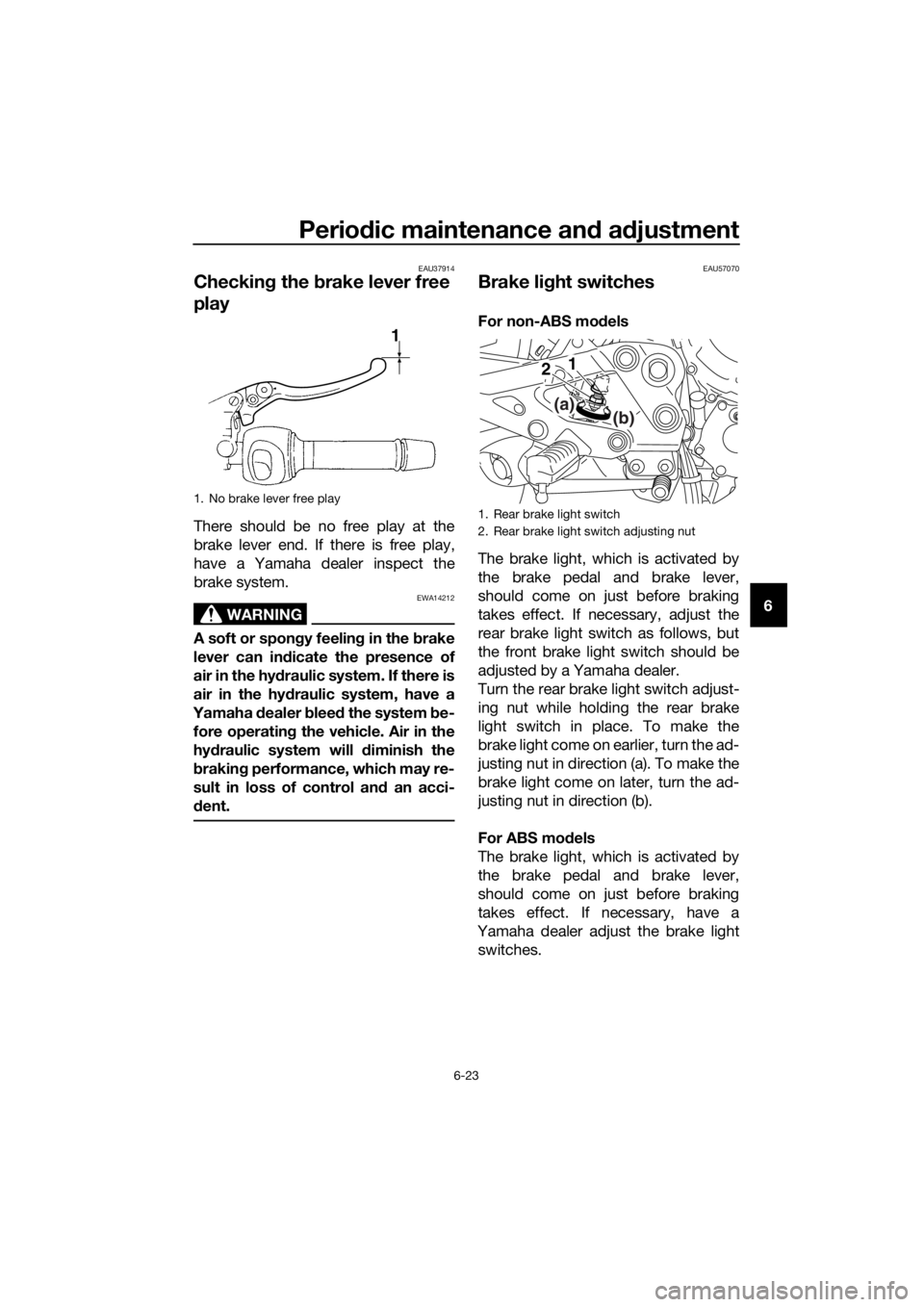

EAU57070

Brake li ght switches

For non-ABS mo dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad-

justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

For ABS mo dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, have a

Yamaha dealer adjust the brake light switches.

1. No brake lever free play

1

1. Rear brake light switch

2. Rear brake light switch adjusting nut

1

2

(a)

(b)

UB61E1E0.book Page 23 Wednesday, October 21, 2015 11:19 AM

Page 69 of 104

Periodic maintenance an d a djustment

6-25

6

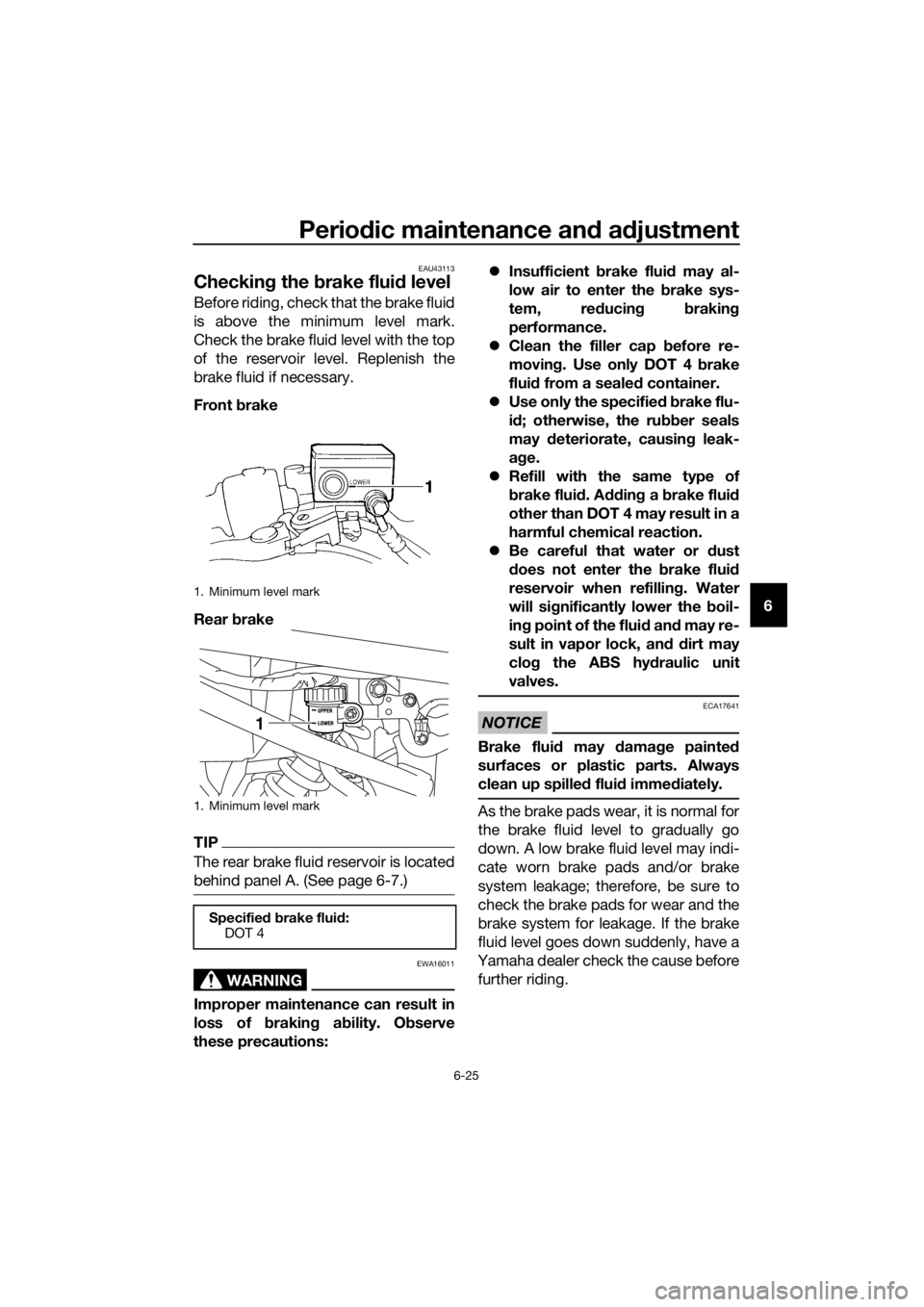

EAU43113

Checkin g the brake flui d level

Before riding, check that the brake fluid

is above the minimum level mark.

Check the brake fluid level with the top

of the reservoir level. Replenish the

brake fluid if necessary.

Front brake

Rear brake

TIP

The rear brake fluid reservoir is located

behind panel A. (See page 6-7.)

WARNING

EWA16011

Improper maintenance can result in

loss of brakin g a bility. O bserve

these precautions:

Insufficient brake flui d may al-

low air to enter the brake sys-

tem, re ducin g brakin g

performance.

Clean the filler cap before re-

moving . Use only DOT 4 b rake

flui d from a seale d container.

Use only the specifie d b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

d oes not enter the brake flui d

reservoir when refilling . Water

will si gnificantly lower the boil-

in g point of the flui d an d may re-

sult in vapor lock, an d d ir t may

clo g th

e ABS hy draulic unit

valves.

NOTICE

ECA17641

Brake flui d may d amage painte d

surfaces or plastic parts. Always

clean up spille d flui d imme diately.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before further riding.

1. Minimum level mark

1. Minimum level mark

Specified b rake flui d:

DOT 4

1

UB61E1E0.book Page 25 Wednesday, October 21, 2015 11:19 AM

Page 79 of 104

Periodic maintenance an d a djustment

6-35

6

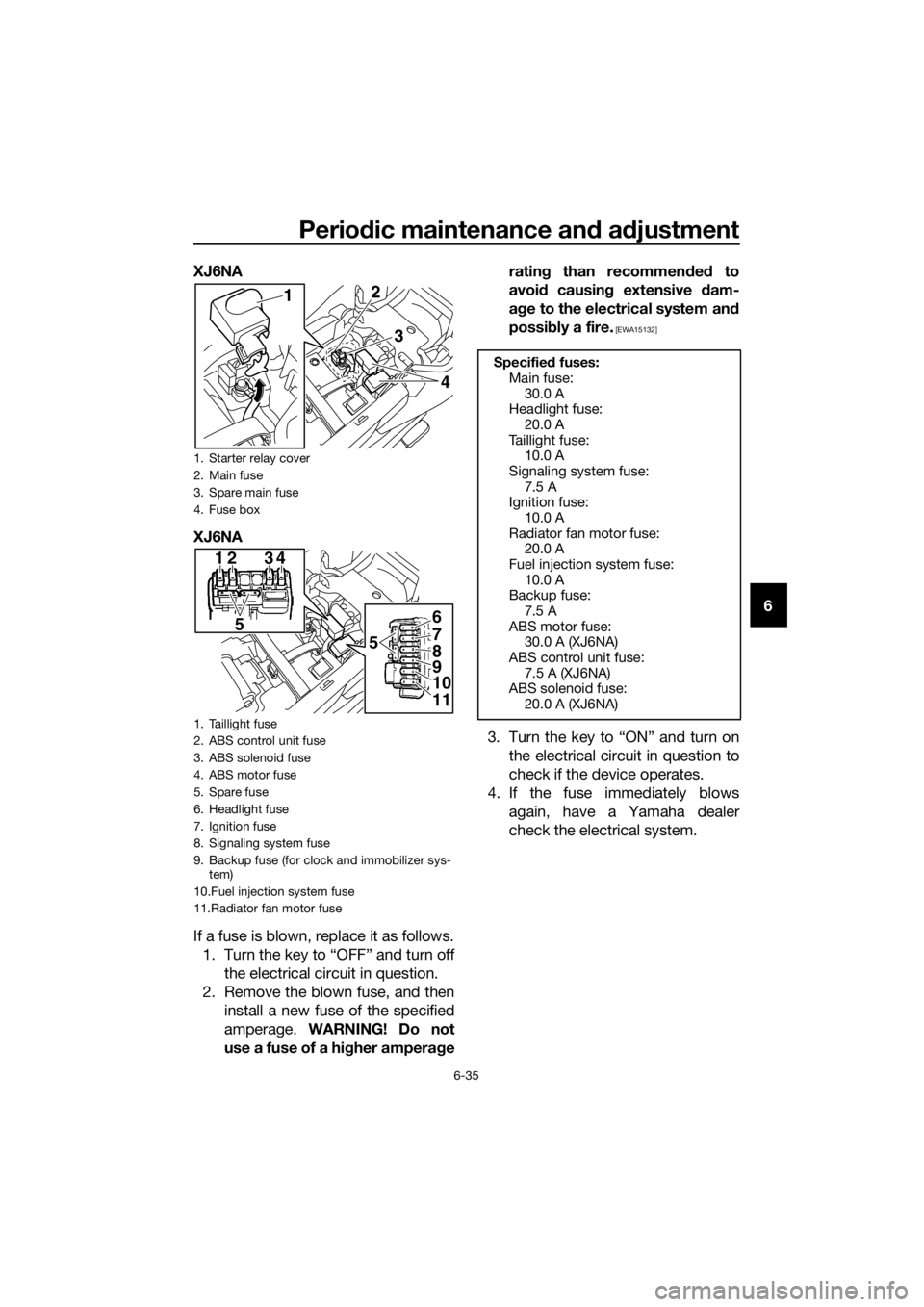

XJ6NA

XJ6NA

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a hi gher ampera ge ratin

g than recommen ded to

avoi d causin g extensive dam-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

1. Starter relay cover

2. Main fuse

3. Spare main fuse

4. Fuse box

1. Taillight fuse

2. ABS control unit fuse

3. ABS solenoid fuse

4. ABS motor fuse

5. Spare fuse

6. Headlight fuse

7. Ignition fuse

8. Signaling system fuse

9. Backup fuse (for clock and immobilizer sys-tem)

10.Fuel injection system fuse

11.Radiator fan motor fuse

2

4

3

1

1

5 56

7

8

9

10

11

234

Specified

fuses:

Main fuse: 30.0 A

Headlight fuse:

20.0 A

Taillight fuse: 10.0 A

Signaling system fuse: 7.5 A

Ignition fuse:

10.0 A

Radiator fan motor fuse: 20.0 A

Fuel injection system fuse: 10.0 A

Backup fuse:

7.5 A

ABS motor fuse: 30.0 A (XJ6NA)

ABS control unit fuse: 7.5 A (XJ6NA)

ABS solenoid fuse:

20.0 A (XJ6NA)

UB61E1E0.book Page 35 Wednesday, October 21, 2015 11:19 AM

Page 85 of 104

Periodic maintenance an d a djustment

6-41

6

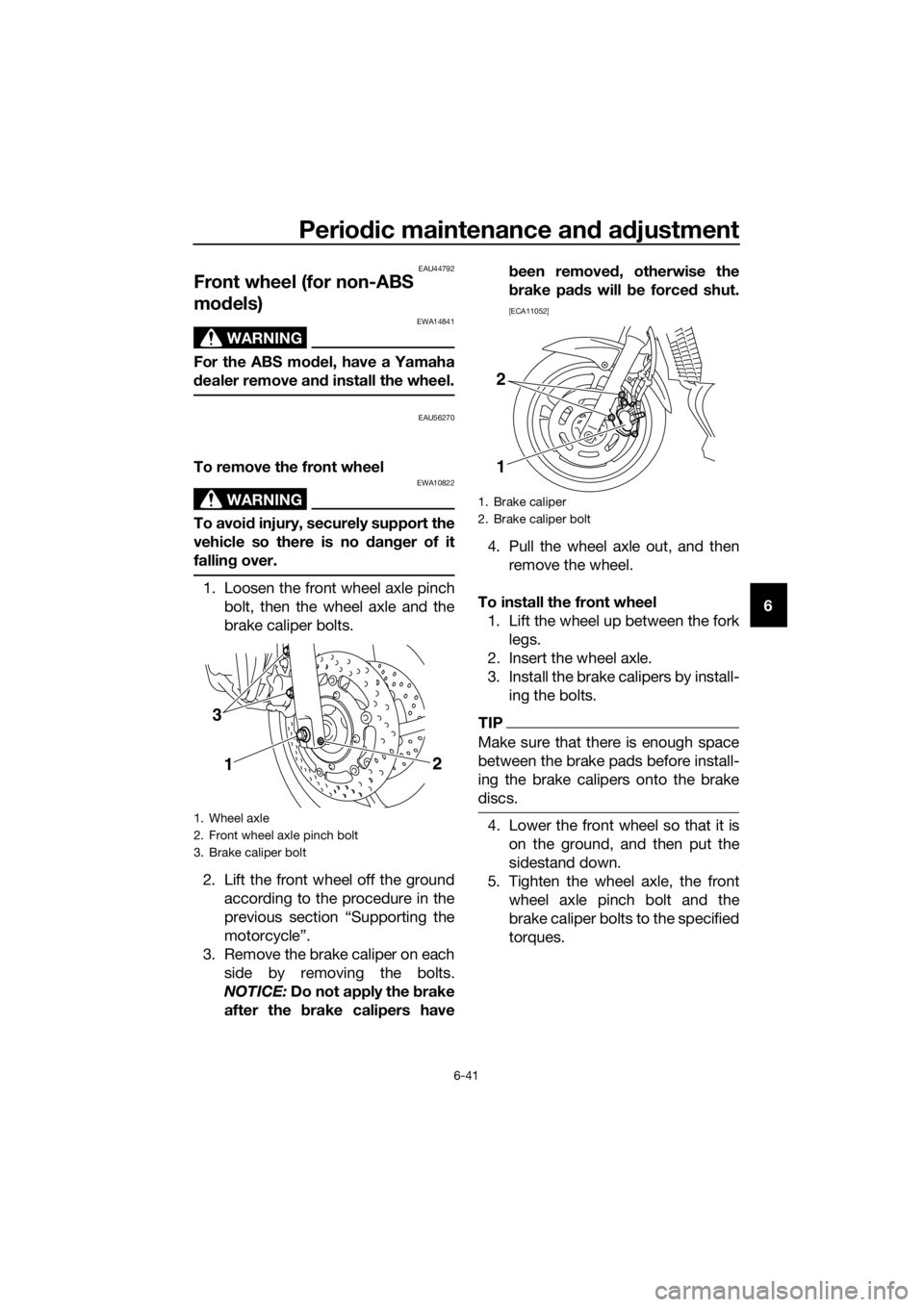

EAU44792

Front wheel (for non-ABS

mo dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56270

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no d anger of it

fallin g over.

1. Loosen the front wheel axle pinch

bolt, then the wheel axle and the

brake caliper bolts.

2. Lift the front wheel off the ground according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the brake caliper on each side by removing the bolts.

NOTICE: Do not apply the b rake

after the b rake calipers have b

een removed , otherwise the

b rake pa ds will be forced shut.

[ECA11052]

4. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Install the brake calipers by install- ing the bolts.

TIP

Make sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.

4. Lower the front wheel so that it ison the ground, and then put the

sidestand down.

5. Tighten the wheel axle, the front wheel axle pinch bolt and the

brake caliper bolts to the specified

torques.1. Wheel axle

2. Front wheel axle pinch bolt

3. Brake caliper bolt

1

3

2

1. Brake caliper

2. Brake caliper bolt

1 2

UB61E1E0.book Page 41 Wednesday, October 21, 2015 11:19 AM

Page 86 of 104

Periodic maintenance an d a djustment

6-42

6 6. Push down hard on the handlebar

several times to check for proper

fork operation.

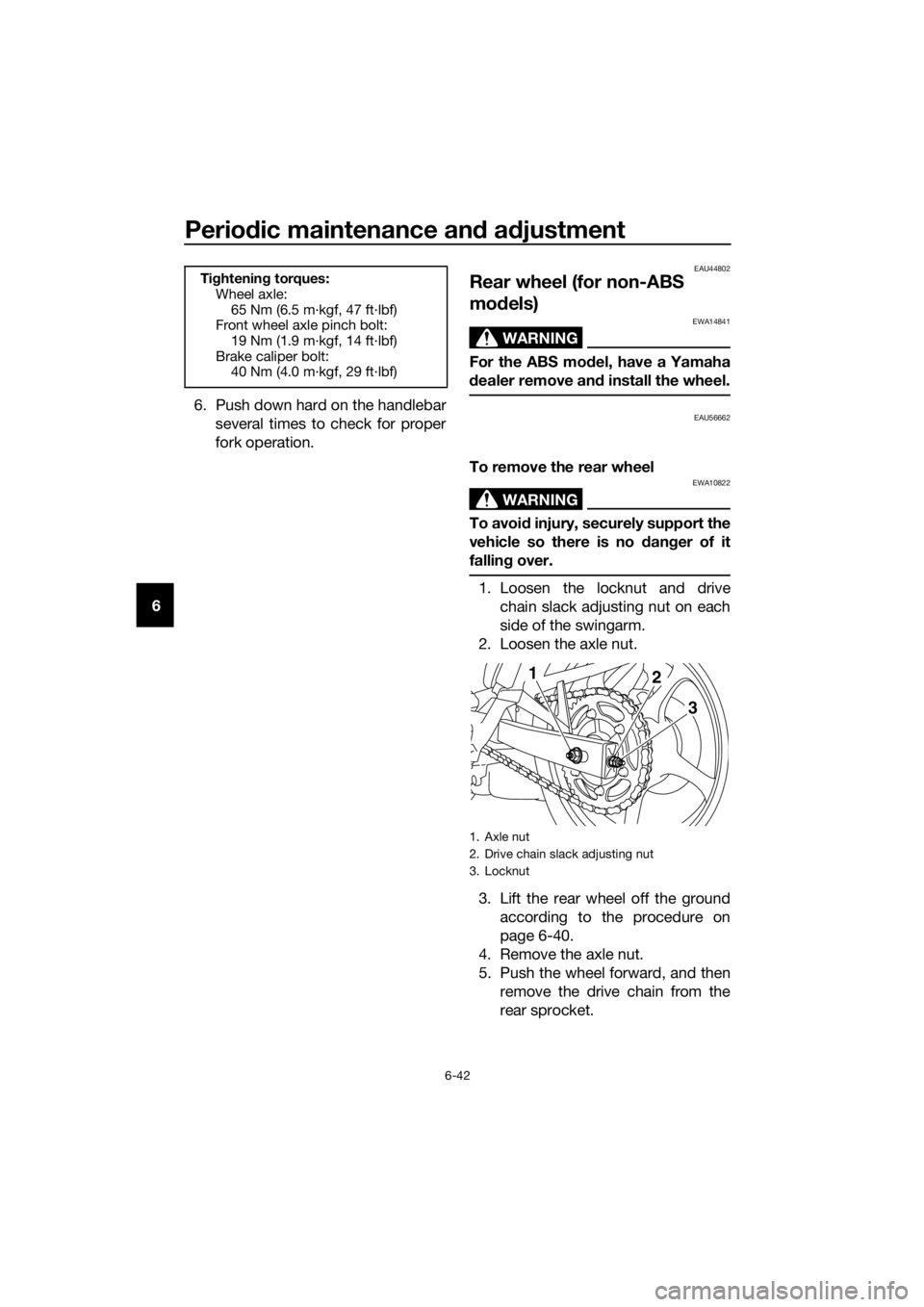

EAU44802

Rear wheel (for non-ABS

mo dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56662

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.

1. Loosen the locknut and drive

chain slack adjusting nut on each

side of the swingarm.

2. Loosen the axle nut.

3. Lift the rear wheel off the ground according to the procedure on

page 6-40.

4. Remove the axle nut.

5. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

Tightenin g torques:

Wheel axle: 65 Nm (6.5 m·kgf, 47 ft·lbf)

Front wheel axle pinch bolt:

19 Nm (1.9 m·kgf, 14 ft·lbf)

Brake caliper bolt: 40 Nm (4.0 m·kgf, 29 ft·lbf)

1. Axle nut

2. Drive chain slack adjusting nut

3. Locknut

1

3

2

UB61E1E0.book Page 42 Wednesday, October 21, 2015 11:19 AM

Page 93 of 104

Motorcycle care and stora ge

7-3

7

2. Apply a corrosion protection spray

on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleaning 1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

4. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

5. Use spray oil as a universal clean- er to remove any remaining dirt.

6. Touch up minor paint damage caused by stones, etc.

7. Wax all painted surfaces.

8. Let the motorcycle dry completely before storing or covering it.

WARNING

EWA11132

Contaminants on the brakes or tires

can cause loss of control. Make sure that there is no oil or

wax on the brakes or tires.

If necessary, clean the b rake

d iscs an d b rake linin gs with a

re gular brake disc cleaner or

acetone, an d wash the tires with

warm water an d a mil d d eter-

g ent. Before ri din g at hi gher speed

s, test the motorcycle’s

b rakin g performance an d cor-

nering b ehavior.

NOTICE

ECA10801

Apply spray oil an d wax spar-

in gly an d make sure to wipe off

any excess.

Never apply oil or wax to any

rubber an d plastic parts, b ut

treat them with a suita ble care

prod uct.

Avoi d using abrasive polishin g

compoun ds as they will wear

away the paint.

TIP

Consult a Yamaha dealer for ad-

vice on what products to use.

Washing, rainy weather or humid

climates can cause the headlight

lens to fog. Turning the headlight

on for a short period of time will

help remove the moisture from the

lens.

UB61E1E0.book Page 3 Wednesday, October 21, 2015 11:19 AM

Page 97 of 104

Specifications

8-2

8

2nd:1.947 (37/19)

3rd: 1.556 (28/18)

4th:

1.333 (32/24)

5th: 1.190 (25/21)

6th: 1.083 (26/24)

Chassis:

Frame type:Diamond

Caster angle: 26.0 °

Trail: 103 mm (4.1 in)

Front tire:

Type:Tubeless

Size: 120/70 ZR17M/C (58W)

Manufacturer/model:

BRIDGESTONE/BT021F

Manufacturer/model: DUNLOP/SPORTMAX-ROADSMART

Rear tire:

Type:

Tubeless

Size: 160/60 ZR17M/C (69W)

Manufacturer/model: BRIDGESTONE/BT021R

Manufacturer/model:

DUNLOP/SPORTMAX-ROADSMART

Loa din g:

Maximum load:

190 kg (419 lb) (XJ6NA)

195 kg (430 lb) (XJ6N)

(Total weight of rider, passenger, cargo

and accessories)

Tire air pressure (measure d on col d

tires):

Up to 90 kg (198 lb) load:

Front: 225 kPa (2.25 kgf/cm², 33 psi)

Rear: 250 kPa (2.50 kgf/cm², 36 psi) 90 kg (198 lb) load - maximum load:

Front:

250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

Front wheel:

Wheel type:

Cast wheel

Rim size: 17M/C x MT3.50

Rear wheel:

Wheel type:

Cast wheel

Rim size:

17M/C x MT4.50

Front brake:

Type:

Hydraulic dual disc brake

Specified brake fluid:

DOT 4

Rear brake:

Type:

Hydraulic single disc brake

Specified brake fluid:

DOT 4

Front suspension:

Type:Telescopic fork

Spring:

Coil spring

Shock absorber: Hydraulic damper

Wheel travel: 130 mm (5.1 in)

Rear suspension:

Type:Swingarm

Spring: Coil spring

Shock absorber:

Gas-hydraulic damper

Wheel travel: 130 mm (5.1 in)

Electrical system:

System voltage:

12 V

Ignition system: TCI

Charging system: AC magneto

UB61E1E0.book Page 2 Wednesday, October 21, 2015 11:19 AM