light YAMAHA XMAX 250 2009 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: XMAX 250, Model: YAMAHA XMAX 250 2009Pages: 92, PDF Size: 4.7 MB

Page 24 of 92

EAU12331

Anti-theft alarm (optional)

This model can be equipped with an

optional anti-theft alarm by a Yamaha

dealer. Contact a Yamaha dealer for

more information.

EAU12347

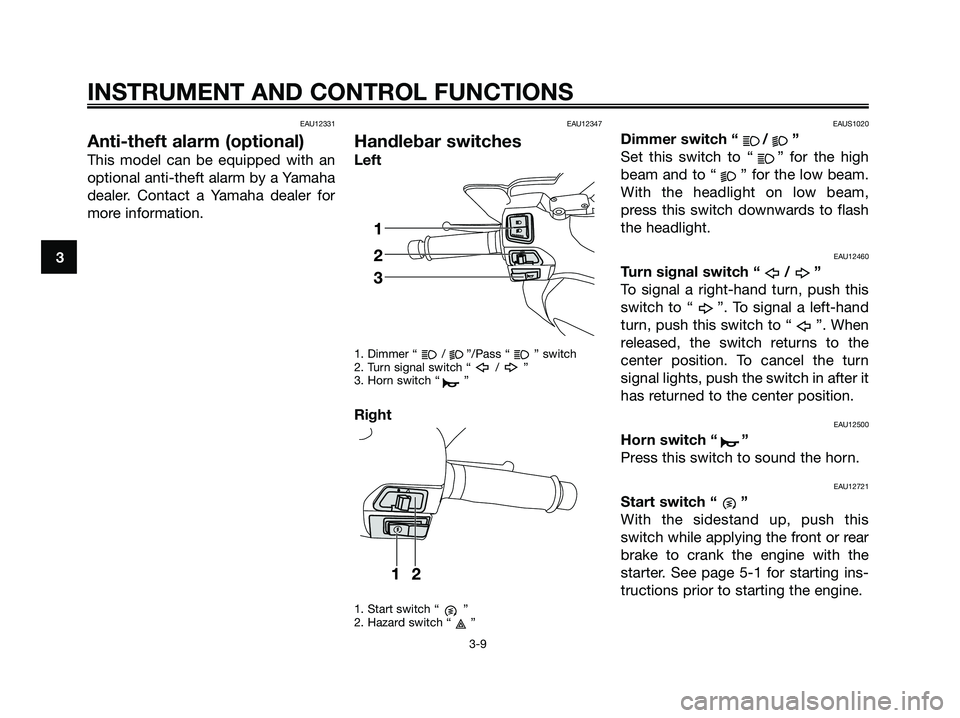

Handlebar switches

Left

1. Dimmer “ / ”/Pass “ ” switch

2. Turn signal switch “ / ”

3. Horn switch “ ”

Right

1. Start switch “ ”

2. Hazard switch “ ”

EAUS1020

Dimmer switch “ / ”

Set this switch to “ ” for the high

beam and to “ ” for the low beam.

With the headlight on low beam,

press this switch downwards to flash

the headlight.

EAU12460

Turn signal switch “ / ”

To signal a right-hand turn, push this

switch to “ ”. To signal a left-hand

turn, push this switch to “ ”. When

released, the switch returns to the

center position. To cancel the turn

signal lights, push the switch in after it

has returned to the center position.

EAU12500

Horn switch “ ”

Press this switch to sound the horn.

EAU12721

Start switch “ ”

With the sidestand up, push this

switch while applying the front or rear

brake to crank the engine with the

starter. See page 5-1 for starting ins-

tructions prior to starting the engine.

INSTRUMENT AND CONTROL FUNCTIONS

3-9

3

1C0-F8199-E5.QXD 3/10/08 05:56 Página 24

Page 25 of 92

EAUM1990

Hazard switch “h”, “ ”

With the key in the “ON” position, set

this switch to “ ” to turn on the

hazard lighting (simultaneous flashing

of all turn signal lights). To turn off the

hazard lighting, set this switch to “h”

and, then turn the key to “OFF”.

TIP

Even if the key is turned from “ON” to

“OFF” with the hazard lighting on, the

hazard lighting will continue to flash

regardless of the hazard switch posi-

tion. To cancel the hazard lighting, the

key must be turned to “ON” and the

hazard switch must be set to the “h”

position.

The hazard lighting is used in case of

an emergency or to warn other drivers

when your scooter is stopped where

it might be a traffic hazard.

ECA10060

NOTICE

Do not use the hazard light for an

extended length of time, otherwise

the battery may discharge.

EAU12900

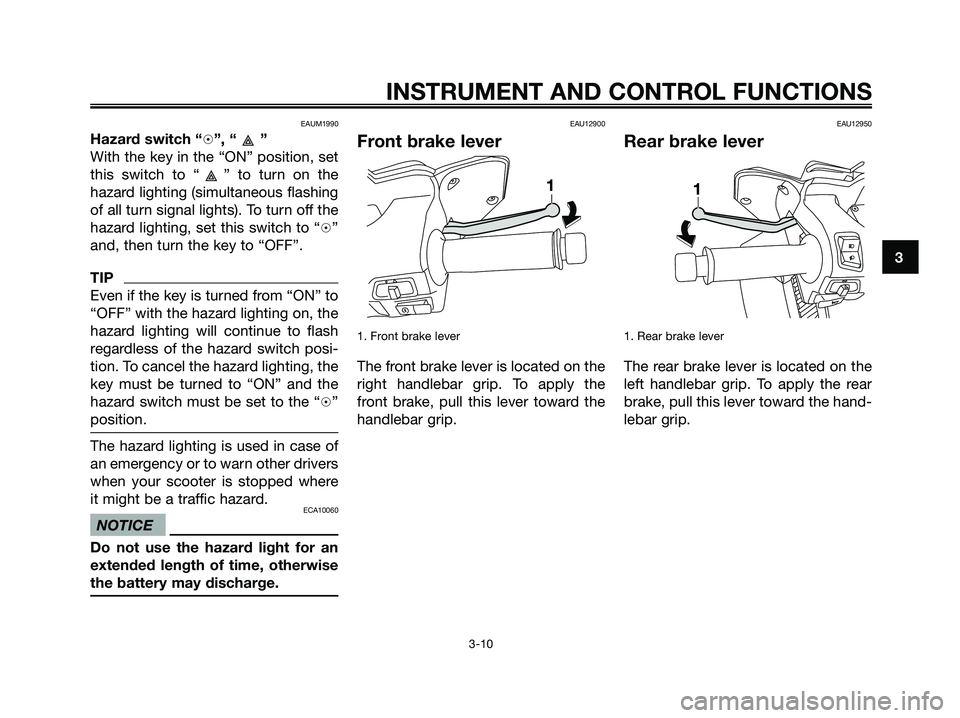

Front brake lever

1. Front brake lever

The front brake lever is located on the

right handlebar grip. To apply the

front brake, pull this lever toward the

handlebar grip.

EAU12950

Rear brake lever

1. Rear brake lever

The rear brake lever is located on the

left handlebar grip. To apply the rear

brake, pull this lever toward the hand-

lebar grip.

INSTRUMENT AND CONTROL FUNCTIONS

3-10

3

1C0-F8199-E5.QXD 3/10/08 05:56 Página 25

Page 27 of 92

EAU13212

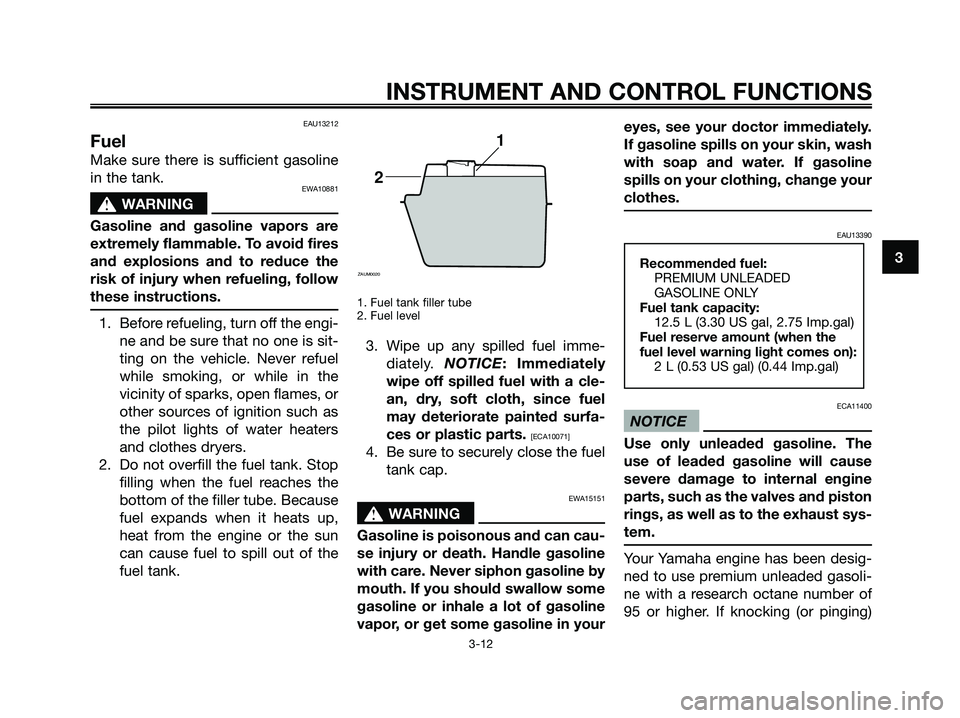

Fuel

Make sure there is sufficient gasoline

in the tank.

EWA10881

s s

WARNING

Gasoline and gasoline vapors are

extremely flammable. To avoid fires

and explosions and to reduce the

risk of injury when refueling, follow

these instructions.

1. Before refueling, turn off the engi-

ne and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the

vicinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. Stop

filling when the fuel reaches the

bottom of the filler tube. Because

fuel expands when it heats up,

heat from the engine or the sun

can cause fuel to spill out of the

fuel tank.

1. Fuel tank filler tube

2. Fuel level

3. Wipe up any spilled fuel imme-

diately. NOTICE: Immediately

wipe off spilled fuel with a cle-

an, dry, soft cloth, since fuel

may deteriorate painted surfa-

ces or plastic parts.

[ECA10071]

4. Be sure to securely close the fuel

tank cap.

EWA15151

s s

WARNING

Gasoline is poisonous and can cau-

se injury or death. Handle gasoline

with care. Never siphon gasoline by

mouth. If you should swallow some

gasoline or inhale a lot of gasoline

vapor, or get some gasoline in youreyes, see your doctor immediately.

If gasoline spills on your skin, wash

with soap and water. If gasoline

spills on your clothing, change your

clothes.

EAU13390

ECA11400

NOTICE

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to internal engine

parts, such as the valves and piston

rings, as well as to the exhaust sys-

tem.

Your Yamaha engine has been desig-

ned to use premium unleaded gasoli-

ne with a research octane number of

95 or higher. If knocking (or pinging)

Recommended fuel:

PREMIUM UNLEADED

GASOLINE ONLY

Fuel tank capacity:

12.5 L (3.30 US gal, 2.75 Imp.gal)

Fuel reserve amount (when the

fuel level warning light comes on):

2 L (0.53 US gal) (0.44 Imp.gal)

1

2

ZAUM0020

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

1C0-F8199-E5.QXD 3/10/08 05:56 Página 27

Page 34 of 92

EWA10240

s s

WARNING

The vehicle must not be ridden with

the sidestand down, or if the sides-

tand cannot be properly moved up

(or does not stay up), otherwise the

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control. Yama-

ha’s ignition circuit cut-off system

has been designed to assist the

operator in fulfilling the responsibi-

lity of raising the sidestand before

starting off. Therefore, check this

system regularly as described

below and have a Yamaha dealer

repair it if it does not function pro-

perly.

EAU45051

Ignition circuit cut-off

system

The ignition circuit cut-off system

(comprising the sidestand switch and

brake light switches) has the following

functions.

●It prevents starting when the

sidestand is up, but neither brake

is applied.

●It prevents starting when either

brake is applied, but the sides-

tand is still down.

●It cuts the running engine when

the sidestand is moved down.

Periodically check the operation of

the ignition circuit cut-off system

according to the following procedure.

INSTRUMENT AND CONTROL FUNCTIONS

3-19

3

1C0-F8199-E5.QXD 3/10/08 05:56 Página 34

Page 38 of 92

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-3

4

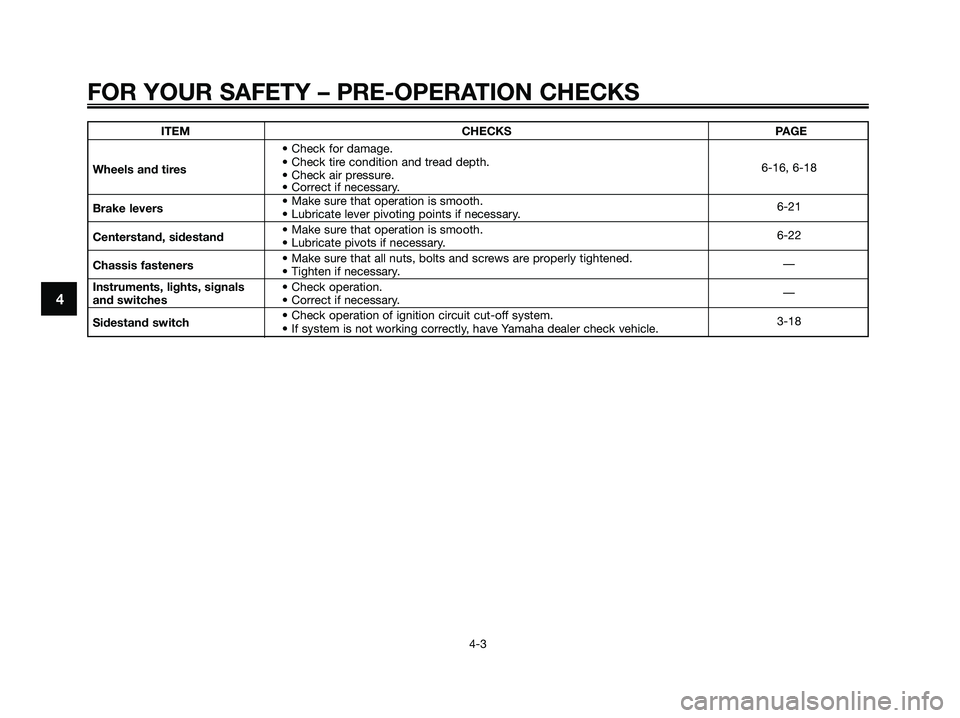

ITEM CHECKS PAGE

• Check for damage.

Wheels and tires• Check tire condition and tread depth.

• Check air pressure.6-16, 6-18

• Correct if necessary.

Brake levers• Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.6-21

Centerstand, sidestand• Make sure that operation is smooth.

• Lubricate pivots if necessary.6-22

Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.

• Tighten if necessary.—

Instruments, lights, signals • Check operation.

and switches• Correct if necessary.—

Sidestand switch • Check operation of ignition circuit cut-off system.

• If system is not working correctly, have Yamaha dealer check vehicle.3-18

1C0-F8199-E5.QXD 3/10/08 05:56 Página 38

Page 39 of 92

EAU15951

Read the Owner’s Manual carefully to

become familiar with all controls. If

there is a control or function you do

not understand, ask your Yamaha

dealer.

EWA10271

s s

WARNING

Failure to familiarize yourself with

the controls can lead to loss of

control, which could cause an acci-

dent or injury.

EAU45310

TIP

This model is equipped with a lean

angle sensor to stop the engine in

case of a turnover. To start the engine

after a turnover, be sure to turn the

main switch to “OFF” and then to

“ON”. Failing to do so will prevent the

engine from starting even though the

engine will crank when pushing the

start switch.

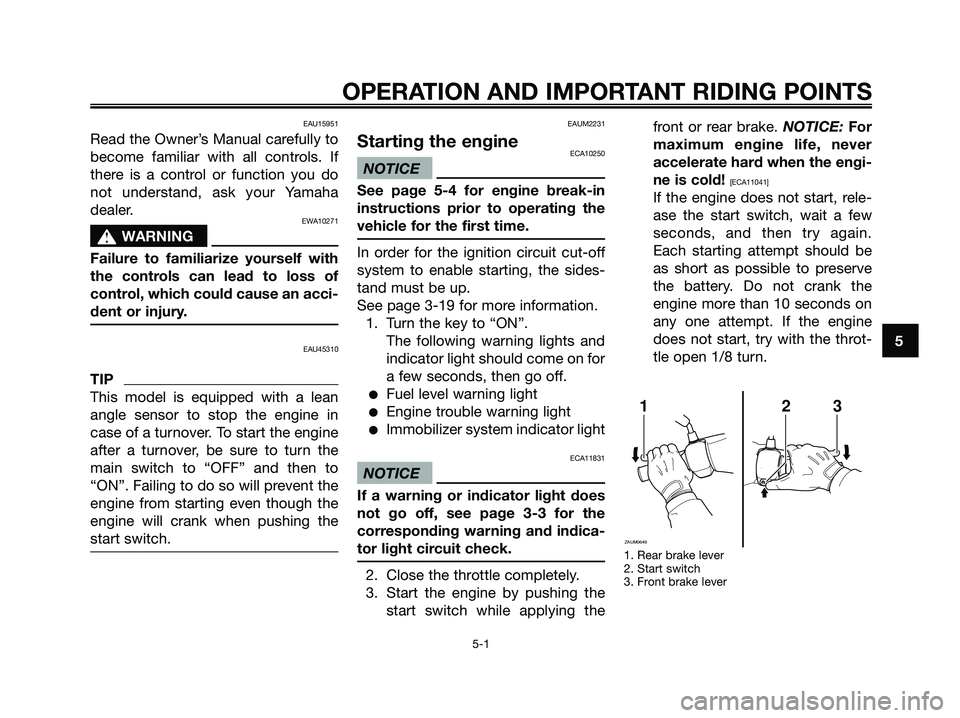

EAUM2231

Starting the engineECA10250

NOTICE

See page 5-4 for engine break-in

instructions prior to operating the

vehicle for the first time.

In order for the ignition circuit cut-off

system to enable starting, the sides-

tand must be up.

See page 3-19 for more information.

1. Turn the key to “ON”.

The following warning lights and

indicator light should come on for

a few seconds, then go off.

●Fuel level warning light

●Engine trouble warning light

●Immobilizer system indicator light

ECA11831

NOTICE

If a warning or indicator light does

not go off, see page 3-3 for the

corresponding warning and indica-

tor light circuit check.

2. Close the throttle completely.

3. Start the engine by pushing the

start switch while applying thefront or rear brake. NOTICE: For

maximum engine life, never

accelerate hard when the engi-

ne is cold!

[ECA11041]

If the engine does not start, rele-

ase the start switch, wait a few

seconds, and then try again.

Each starting attempt should be

as short as possible to preserve

the battery. Do not crank the

engine more than 10 seconds on

any one attempt. If the engine

does not start, try with the throt-

tle open 1/8 turn.

1. Rear brake lever

2. Start switch

3. Front brake lever

123

ZAUM0649

OPERATION AND IMPORTANT RIDING POINTS

5-1

5

1C0-F8199-E5.QXD 3/10/08 05:56 Página 39

Page 41 of 92

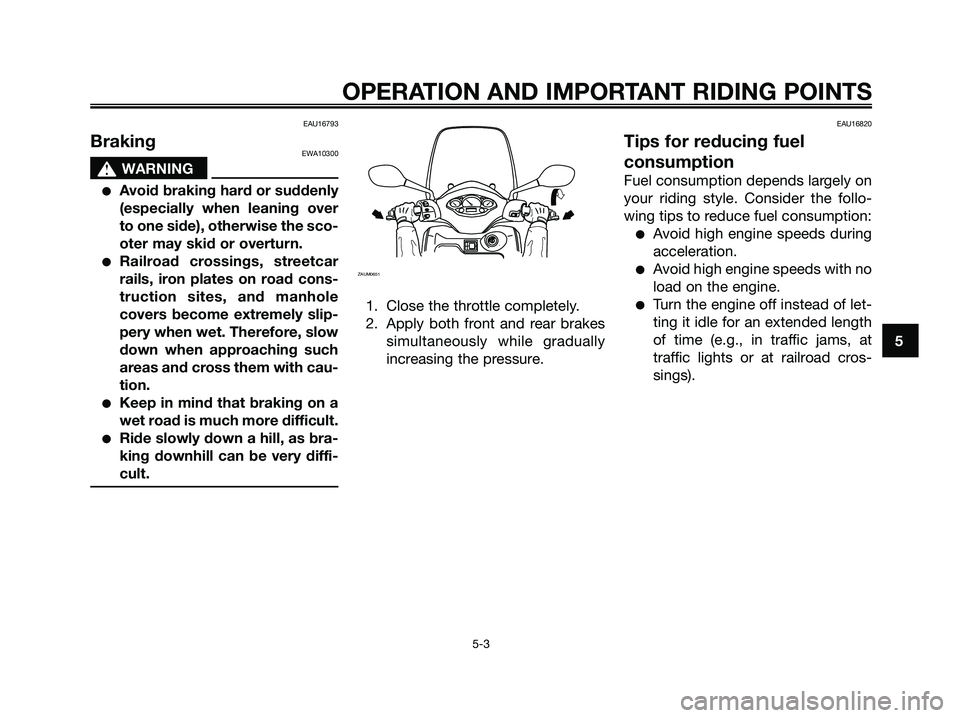

EAU16793

BrakingEWA10300

s s

WARNING

●Avoid braking hard or suddenly

(especially when leaning over

to one side), otherwise the sco-

oter may skid or overturn.

●Railroad crossings, streetcar

rails, iron plates on road cons-

truction sites, and manhole

covers become extremely slip-

pery when wet. Therefore, slow

down when approaching such

areas and cross them with cau-

tion.

●Keep in mind that braking on a

wet road is much more difficult.

●Ride slowly down a hill, as bra-

king downhill can be very diffi-

cult.

1. Close the throttle completely.

2. Apply both front and rear brakes

simultaneously while gradually

increasing the pressure.

EAU16820

Tips for reducing fuel

consumption

Fuel consumption depends largely on

your riding style. Consider the follo-

wing tips to reduce fuel consumption:

●Avoid high engine speeds during

acceleration.

●Avoid high engine speeds with no

load on the engine.

●Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at

traffic lights or at railroad cros-

sings).

PUSHOPEN

ZAUM0651

OPERATION AND IMPORTANT RIDING POINTS

5-3

5

1C0-F8199-E5.QXD 3/10/08 05:56 Página 41

Page 46 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-4

6

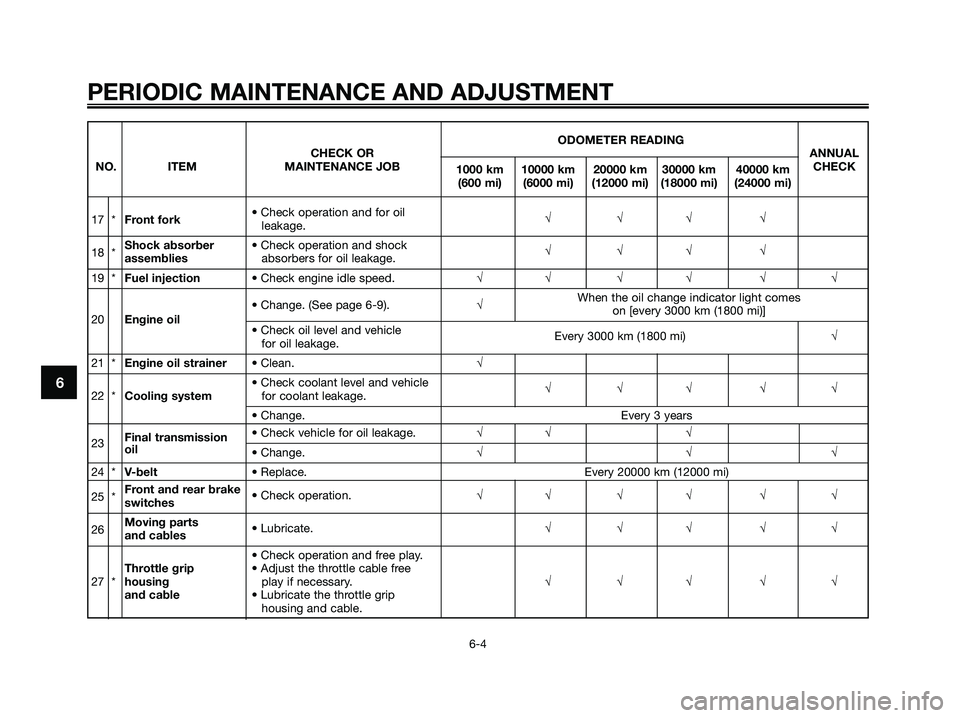

ODOMETER READING

CHECK OR ANNUAL

NO. ITEM MAINTENANCE JOB

1000 km 10000 km 20000 km 30000 km 40000 kmCHECK

(600 mi) (6000 mi) (12000 mi) (18000 mi) (24000 mi)

17 *Front fork• Check operation and for oil

leakage.√√√ √

18 *Shock absorber • Check operation and shock

assembliesabsorbers for oil leakage.√√√ √

19 *Fuel injection• Check engine idle speed.√√ √√ √ √

20Engine oil• Change. (See page 6-9). √When the oil change indicator light comes

on [every 3000 km (1800 mi)]

• Check oil level and vehicle

for oil leakage.Every 3000 km (1800 mi)√

21 *Engine oil strainer• Clean.√

• Check coolant level and vehicle

22 *Cooling systemfor coolant leakage.√√√ √√

• Change. Every 3 years

23Final transmission • Check vehicle for oil leakage.√√ √oil

• Change.√√√

24 *V-belt• Replace. Every 20000 km (12000 mi)

25 *Front and rear brake

switches• Check operation.√√ √√ √ √

26Moving parts

and cables• Lubricate.√√√ √√

• Check operation and free play.

Throttle grip • Adjust the throttle cable free

27 *housingplay if necessary.√√√ √√

and cable• Lubricate the throttle grip

housing and cable.

1C0-F8199-E5.QXD 3/10/08 05:56 Página 46

Page 47 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-5

6

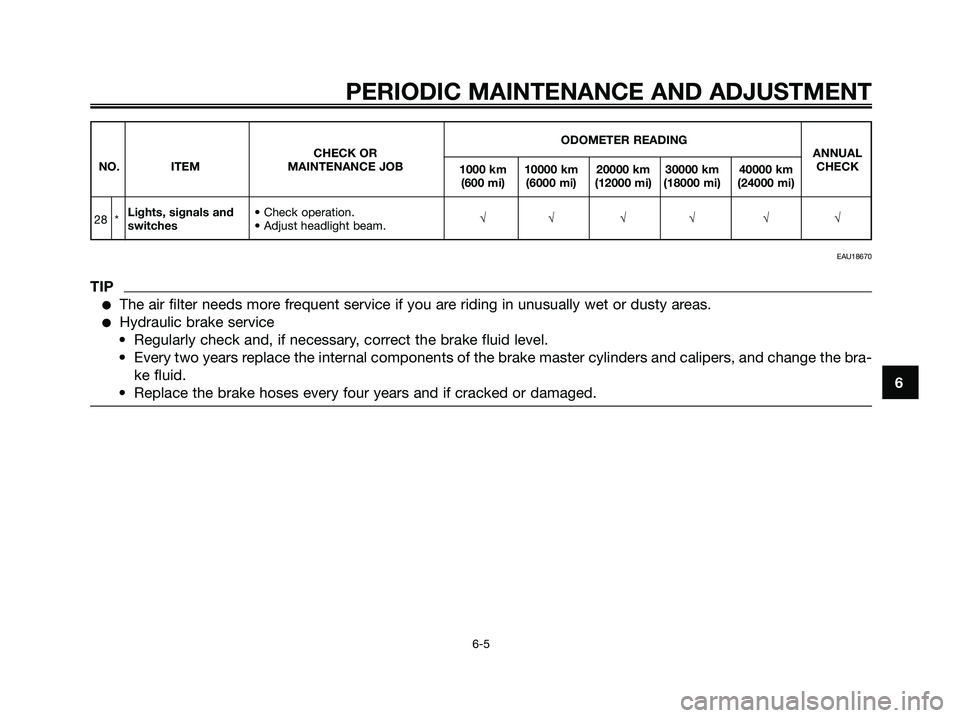

ODOMETER READING

CHECK OR ANNUAL

NO. ITEM MAINTENANCE JOB

1000 km 10000 km 20000 km 30000 km 40000 kmCHECK

(600 mi) (6000 mi) (12000 mi) (18000 mi) (24000 mi)

28 *Lights, signals and • Check operation.

switches• Adjust headlight beam.√√ √√ √ √

EAU18670

TIP

●The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

●Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinders and calipers, and change the bra-

ke fluid.

• Replace the brake hoses every four years and if cracked or damaged.

1C0-F8199-E5.QXD 3/10/08 05:56 Página 47

Page 48 of 92

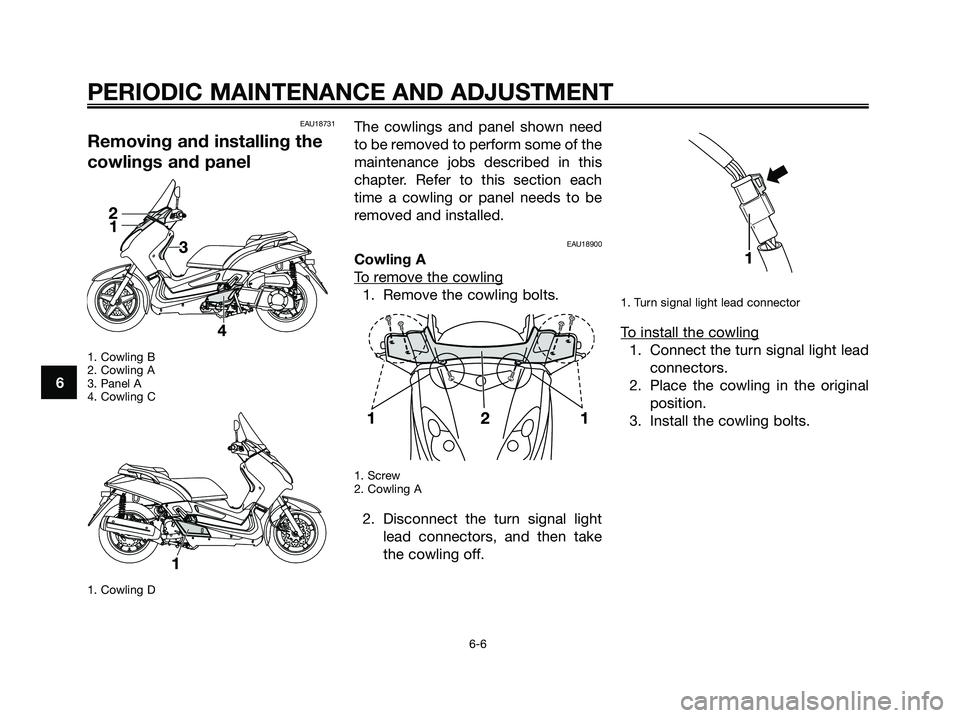

EAU18731

Removing and installing the

cowlings and panel

1. Cowling B

2. Cowling A

3. Panel A

4. Cowling C

1. Cowling D

The cowlings and panel shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each

time a cowling or panel needs to be

removed and installed.

EAU18900

Cowling A

T

o remove the cowling

1. Remove the cowling bolts.

1. Screw

2. Cowling A

2. Disconnect the turn signal light

lead connectors, and then take

the cowling off.

1. Turn signal light lead connector

To install the cowling

1. Connect the turn signal light lead

connectors.

2. Place the cowling in the original

position.

3. Install the cowling bolts.

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

6

1C0-F8199-E5.QXD 3/10/08 05:56 Página 48