oil YAMAHA XMAX 400 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: XMAX 400, Model: YAMAHA XMAX 400 2014Pages: 92, PDF Size: 7.3 MB

Page 48 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-5

6

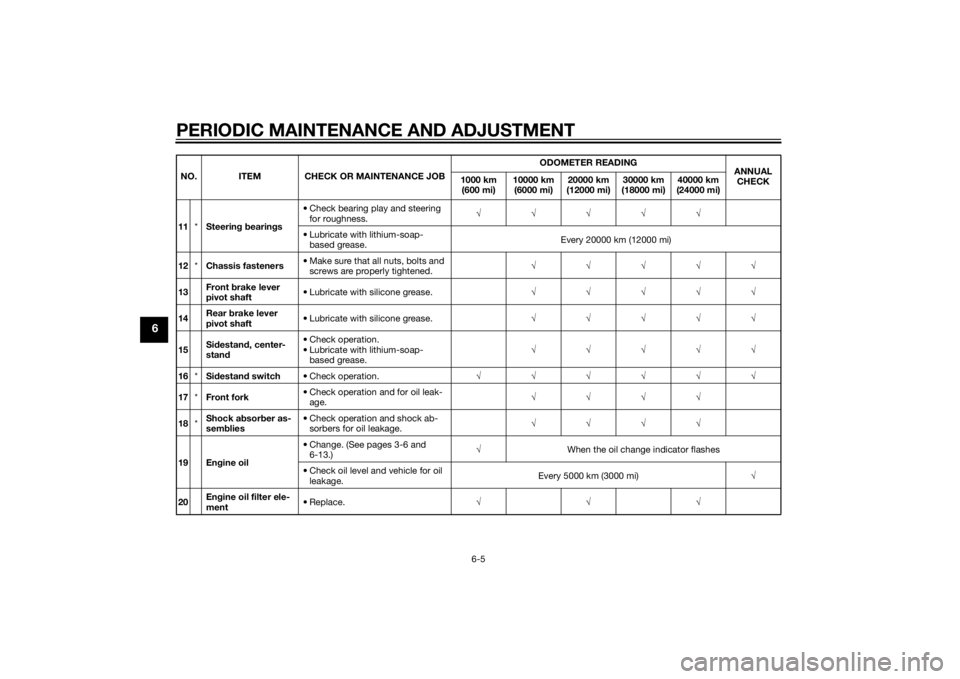

11*Steering bearings• Check bearing play and steering

for roughness.√√√√√

• Lubricate with lithium-soap-

based grease.Every 20000 km (12000 mi)

12*Chassis fasteners• Make sure that all nuts, bolts and

screws are properly tightened.√√√√√

13Front brake lever

pivot shaft• Lubricate with silicone grease.√√√√√

14Rear brake lever

pivot shaft• Lubricate with silicone grease.√√√√√

15Sidestand, center-

stand• Check operation.

• Lubricate with lithium-soap-

based grease.√√√√√

16*Sidestand switch• Check operation.√√√√√√

17*Front fork• Check operation and for oil leak-

age.√√√√

18*Shock absorber as-

semblies• Check operation and shock ab-

sorbers for oil leakage.√√√√

19 Engine oil• Change. (See pages 3-6 and

6-13.)√When the oil change indicator flashes

• Check oil level and vehicle for oil

leakage.Every 5000 km (3000 mi)√

20Engine oil filter ele-

ment• Replace.√√√ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)10000 km

(6000 mi)

20000 km

(12000 mi)30000 km

(18000 mi)40000 km

(24000 mi)

U1SDE1E0.book Page 5 Monday, September 23, 2013 3:55 PM

Page 49 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

6

EAU34492

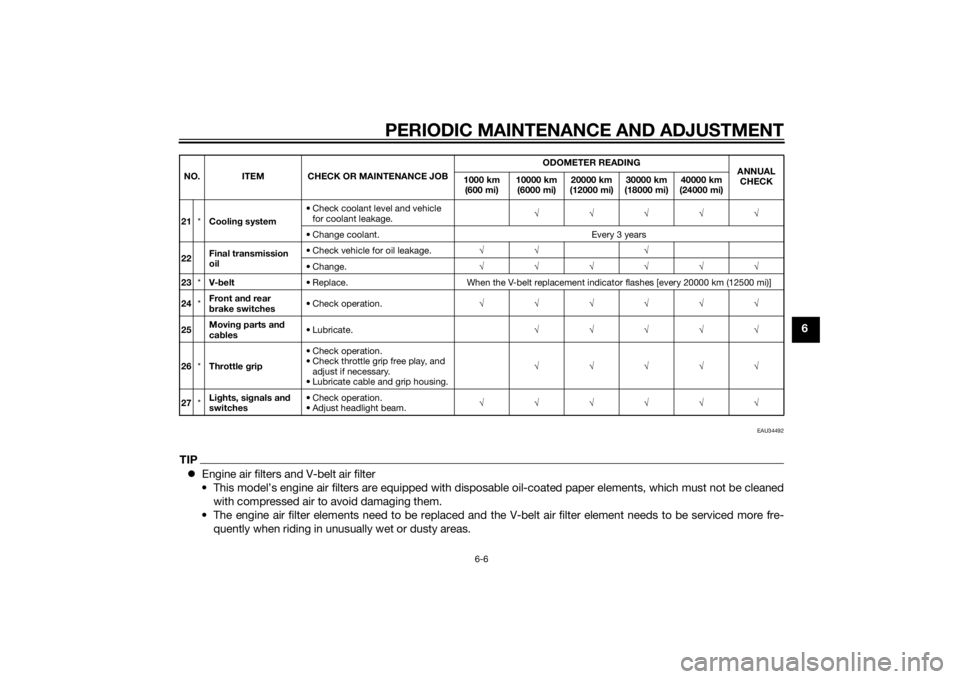

TIPEngine air filters and V-belt air filter

• This model’s engine air filters are equipped with disposable oil-coated paper elements, which must not be cleaned

with compressed air to avoid damaging them.

• The engine air filter elements need to be replaced and the V-belt air filter element needs to be serviced more fre-

quently when riding in unusually wet or dusty areas.21*Cooling system• Check coolant level and vehicle

for coolant leakage.√√√√√

• Change coolant. Every 3 years

22Final transmission

oil• Check vehicle for oil leakage.√√ √

• Change.√√√√√√

23*V-belt• Replace. When the V-belt replacement indicator flashes [every 20000 km (12500 mi)]

24*Front and rear

brake switches• Check operation.√√√√√√

25Moving parts and

cables• Lubricate.√√√√√

26*Throttle grip• Check operation.

• Check throttle grip free play, and

adjust if necessary.

• Lubricate cable and grip housing.√√√√√

27*Lights, signals and

switches• Check operation.

• Adjust headlight beam.√√√√√√ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)10000 km

(6000 mi)20000 km

(12000 mi)30000 km

(18000 mi)40000 km

(24000 mi)

U1SDE1E0.book Page 6 Monday, September 23, 2013 3:55 PM

Page 56 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

6

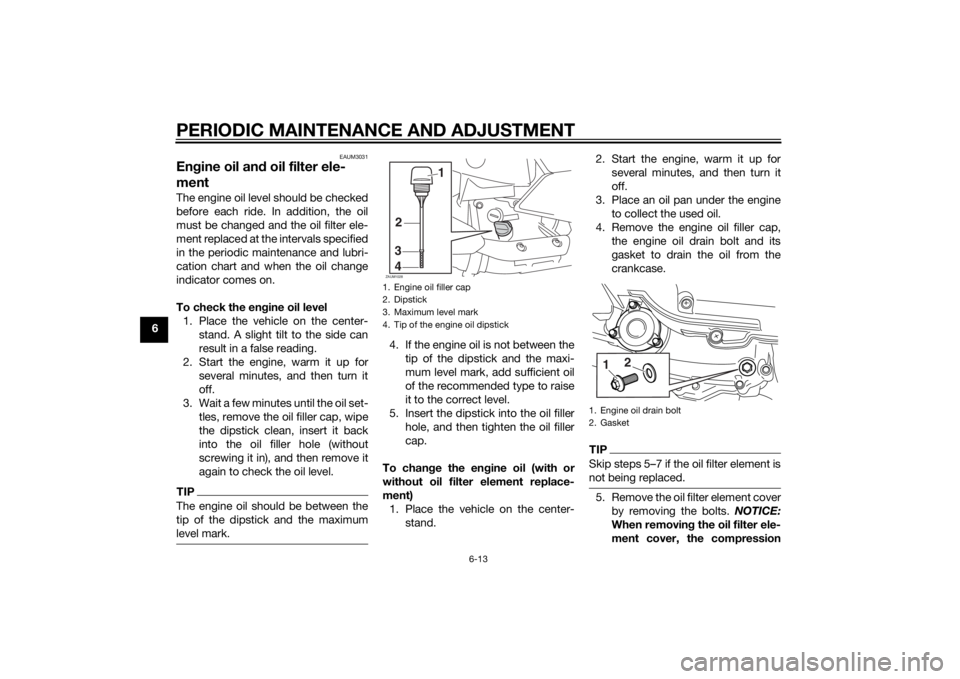

EAUM3031

Engine oil and oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart and when the oil change

indicator comes on.

To check the engine oil level

1. Place the vehicle on the center-

stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.TIPThe engine oil should be between the

tip of the dipstick and the maximum

level mark.

4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler

hole, and then tighten the oil filler

cap.

To change the engine oil (with or

without oil filter element replace-

ment)

1. Place the vehicle on the center-

stand.2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Place an oil pan under the engine

to collect the used oil.

4. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5…7 if the oil filter element is

not being replaced.5. Remove the oil filter element cover

by removing the bolts. NOTICE:

When removing the oil filter ele-

ment cover, the compression

1. Engine oil filler cap

2. Dipstick

3. Maximum level mark

4. Tip of the engine oil dipstickZAUM102834

1

2

1. Engine oil drain bolt

2. Gasket

12

U1SDE1E0.book Page 13 Monday, September 23, 2013 3:55 PM

Page 57 of 92

![YAMAHA XMAX 400 2014 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6 spring will fall out. Take care not

to lose the compression spring.

[ECA12912]

6. Remove and replace the oil filter

element and O-rings.7. Install the compre YAMAHA XMAX 400 2014 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6 spring will fall out. Take care not

to lose the compression spring.

[ECA12912]

6. Remove and replace the oil filter

element and O-rings.7. Install the compre](/img/51/53001/w960_53001-56.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6 spring will fall out. Take care not

to lose the compression spring.

[ECA12912]

6. Remove and replace the oil filter

element and O-rings.7. Install the compression spring and

oil filter element cover by installing

the bolts, then tightening them to

the specified torque.

TIPMake sure that the O-rings are properly

seated.8. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.9. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11671

Do not use oils with a diesel

specification of “CD” or oils of a

higher quality than specified. In

1. Bolt

2. Oil filter element cover

21

1. Oil filter element cover

2. O-ring

3. Compression spring

4. Oil filter element

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1

24

3

Tightening torque:

Engine oil drain bolt:

20 Nm (2.0 m·kgf, 14 ft·lbf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element replace-

ment:

1.50 L (1.59 US qt, 1.32 Imp.qt)

With oil filter element replacement:

1.70 L (1.80 US qt, 1.50 Imp.qt)

U1SDE1E0.book Page 14 Monday, September 23, 2013 3:55 PM

Page 58 of 92

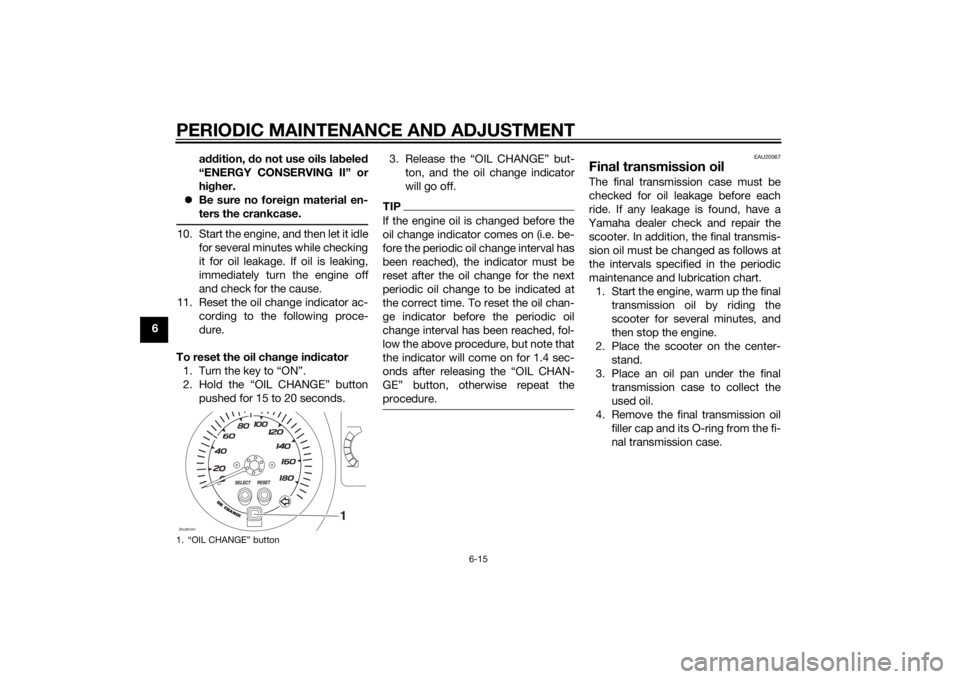

PERIODIC MAINTENANCE AND ADJUSTMENT

6-15

6addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Be sure no foreign material en-

ters the crankcase.

10. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

11. Reset the oil change indicator ac-

cording to the following proce-

dure.

To reset the oil change indicator

1. Turn the key to “ON”.

2. Hold the “OIL CHANGE” button

pushed for 15 to 20 seconds.3. Release the “OIL CHANGE” but-

ton, and the oil change indicator

will go off.

TIPIf the engine oil is changed before the

oil change indicator comes on (i.e. be-

fore the periodic oil change interval has

been reached), the indicator must be

reset after the oil change for the next

periodic oil change to be indicated at

the correct time. To reset the oil chan-

ge indicator before the periodic oil

change interval has been reached, fol-

low the above procedure, but note that

the indicator will come on for 1.4 sec-

GEŽ button, otherwise repeat the

procedure.

EAU20067

Final transmission oilThe final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the

scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Start the engine, warm up the final

transmission oil by riding the

scooter for several minutes, and

then stop the engine.

2. Place the scooter on the center-

stand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

4. Remove the final transmission oil

filler cap and its O-ring from the fi-

nal transmission case.

1. “OIL CHANGE” buttonZAUM1051

OIL CHANGE

1

U1SDE1E0.book Page 15 Monday, September 23, 2013 3:55 PM

Page 59 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-16

6

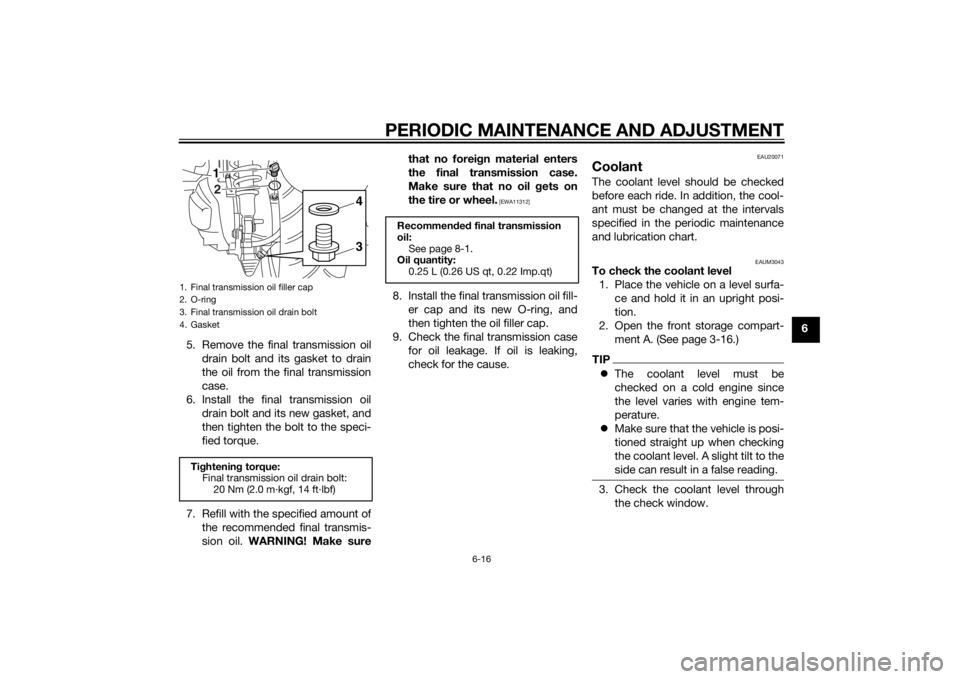

5. Remove the final transmission oil

drain bolt and its gasket to drain

the oil from the final transmission

case.

6. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fied torque.

7. Refill with the specified amount of

the recommended final transmis-

sion oil. WARNING! Make surethat no foreign material enters

the final transmission case.

Make sure that no oil gets on

the tire or wheel.

[EWA11312]

8. Install the final transmission oil fill-

er cap and its new O-ring, and

then tighten the oil filler cap.

9. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM3043

To check the coolant level

1. Place the vehicle on a level surfa-

ce and hold it in an upright posi-

tion.

2. Open the front storage compart-

ment A. (See page 3-16.)TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.3. Check the coolant level through

the check window.

1. Final transmission oil filler cap

2. O-ring

3. Final transmission oil drain bolt

4. GasketTightening torque:

Final transmission oil drain bolt:

20 Nm (2.0 m·kgf, 14 ft·lbf)

21

34

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.25 L (0.26 US qt, 0.22 Imp.qt)

U1SDE1E0.book Page 16 Monday, September 23, 2013 3:55 PM

Page 68 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-25

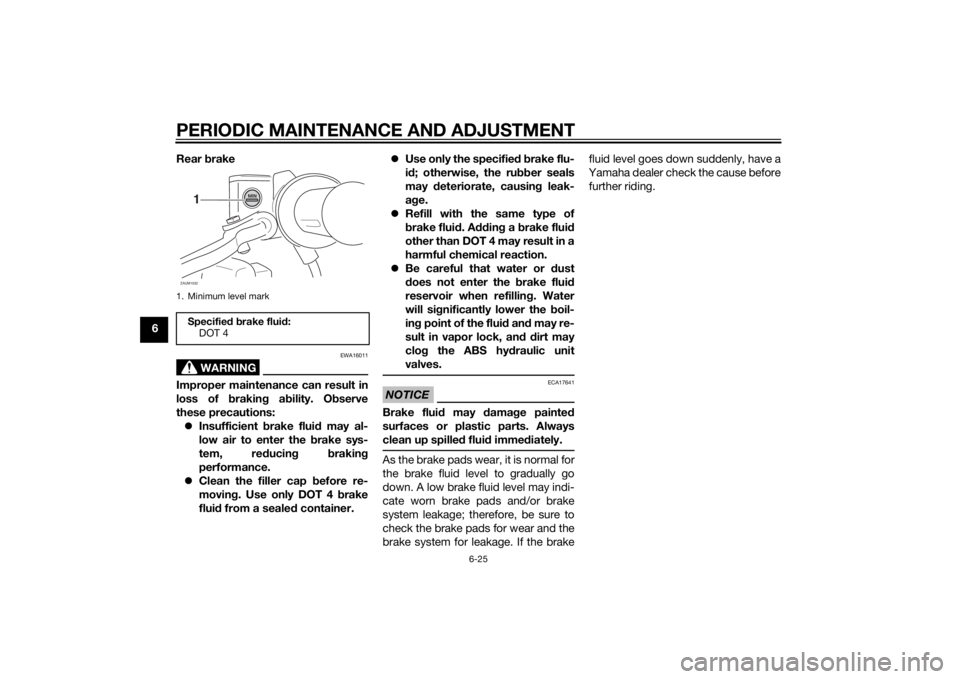

6Rear brake

WARNING

EWA16011

Improper maintenance can result in

loss of braking ability. Observe

these precautions:

Insufficient brake fluid may al-

low air to enter the brake sys-

tem, reducing braking

performance.

Clean the filler cap before re-

moving. Use only DOT 4 brake

fluid from a sealed container.Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

does not enter the brake fluid

reservoir when refilling. Water

will significantly lower the boil-

ing point of the fluid and may re-

sult in vapor lock, an

d dirt may

clog the ABS hydraulic unit

valves.

NOTICE

ECA17641

Brake fluid may damage painted

surfaces or plastic parts. Always

clean up spilled fluid immediately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brakefluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

1. Minimum level markSpecified brake fluid:

DOT 4ZAUM1032

1

U1SDE1E0.book Page 25 Monday, September 23, 2013 3:55 PM

Page 69 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

EAU22733

Changing the brake fluidHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

EAU23098

Checking and lubricating the

cablesThe operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubri-

cated if necessary. If a cable is

damaged or does not move smoothly,

have a Yamaha dealer check or re-

place it. WARNING! Damage to the

outer housing of cables may result

in internal rusting and cause inter-

ference with cable movement. Re-

place damaged cables as soon as

possible to prevent unsafe condi-

tions.

[EWA10712]EAU23115

Checking and lubricating the

throttle grip and cableThe operation of the throttle grip

should be checked before each ride. In

addition, the cable should be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

chart.

The throttle cable is equipped with a

rubber cover. Make sure that the cover

is securely installed. Even though the

cover is installed correctly, it does not

completely protect the cable from wa-

ter entry. Therefore, use care not to

pour water directly onto the cover or

cable when washing the vehicle. If the

cable or cover becomes dirty, wipe

clean with a moist cloth.

Recommended lubricant:

Yamaha cable lubricant or other

suitable cable lubricant

U1SDE1E0.book Page 26 Monday, September 23, 2013 3:55 PM

Page 71 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

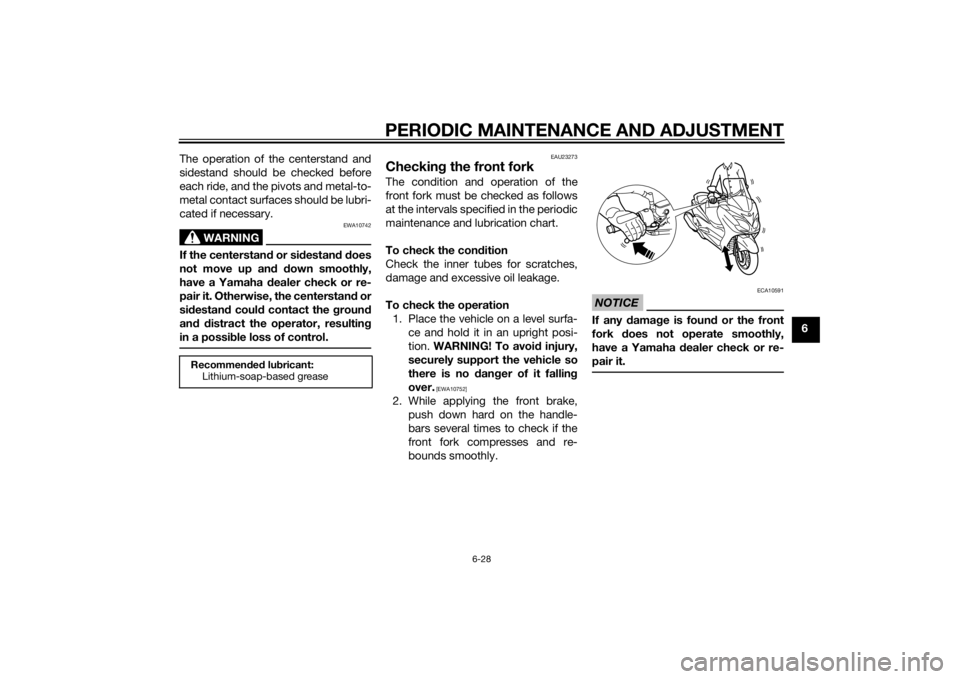

6 The operation of the centerstand and

sidestand should be checked before

each ride, and the pivots and metal-to-

metal contact surfaces should be lubri-

cated if necessary.

WARNING

EWA10742

If the centerstand or sidestand does

not move up and down smoothly,

have a Yamaha dealer check or re-

pair it. Otherwise, the centerstand or

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control.

EAU23273

Checking the front forkThe condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the condition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation

1. Place the vehicle on a level surfa-

ce and hold it in an upright posi-

tion. WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10752]

2. While applying the front brake,

push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

Recommended lubricant:

Lithium-soap-based grease

U1SDE1E0.book Page 28 Monday, September 23, 2013 3:55 PM

Page 81 of 92

SCOOTER CARE AND STORAGE

7-1

7

EAU37834

Matte color cautionNOTICE

ECA15193

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

advice on what products to use be-

fore cleaning the vehicle. Using a

brush, harsh chemical products or

cleaning compounds when cleaning

these parts will scratch or damage

their surface. Wax also should not

be applied to any matte colored fin-

ished parts.

EAU26096

CareWhile the open design of a scooter re-

veals the attractiveness of the technol-

ogy, it also makes it more vulnerable.

Rust and corrosion can develop even if

high-quality components are used. A

rusty exhaust pipe may go unnoticed

on a car, however, it detracts from the

overall appearance of a scooter. Fre-

quent and proper care does not only

comply with the terms of the warranty,

but it will also keep your scooter look-

ing good, extend its life and optimize

its performance.

Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov-

ers as well as all electrical cou-

plers and connectors, including

the spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-ucts onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.

Cleaning

NOTICE

ECA10784

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are

used on hard-to-remove dirt, do

not leave the cleaner on the af-

fected area any longer than in-

structed. Also, thoroughly rinse

the area off with water, immedi-

ately dry it, and then apply a cor-

rosion protection spray.

Improper cleaning can damage

plastic parts (such as cowlings,

panels, windshields, headlight

lenses, meter lenses, etc.) and

the mufflers. Use only a soft,

clean cloth or sponge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

oughly cleaned with water, di-

luted mild detergent with water

may be used. Be sure to rinse

U1SDE1E0.book Page 1 Monday, September 23, 2013 3:55 PM