YAMAHA XMAX 400 2014 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2014, Model line: XMAX 400, Model: YAMAHA XMAX 400 2014Pages: 92, PDF Size: 7.3 MB

Page 51 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

6

EAU18772

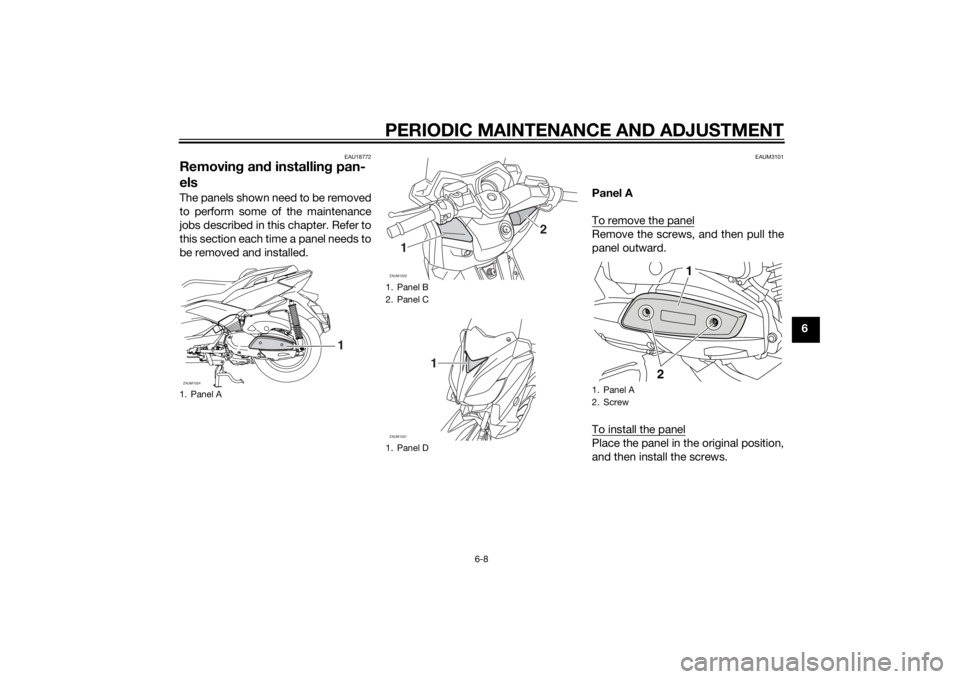

Removing and installing pan-

elsThe panels shown need to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time a panel needs to

be removed and installed.

EAUM3101

Panel A

To remove the panelRemove the screws, and then pull the

panel outward.

To install the panelPlace the panel in the original position,

and then install the screws.

1. Panel AZAUM1024

1

1. Panel B

2. Panel C

1. Panel DZAUM10221

2

ZAUM1021

1

1. Panel A

2. Screw

21

U1SDE1E0.book Page 8 Monday, September 23, 2013 3:55 PM

Page 52 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

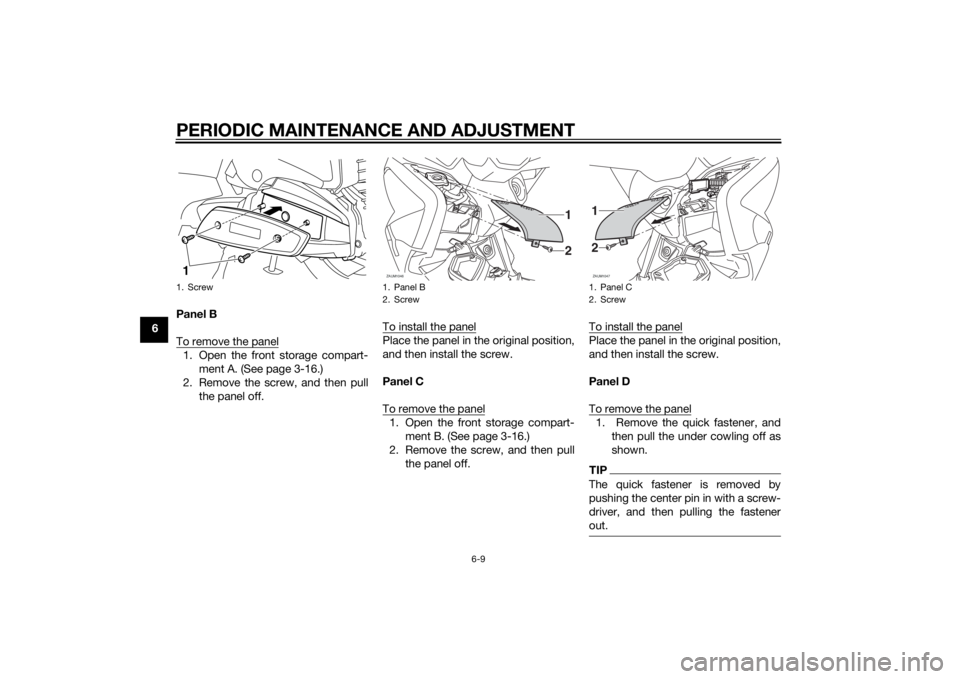

6Panel B

To remove the panel

1. Open the front storage compart-

ment A. (See page 3-16.)

2. Remove the screw, and then pull

the panel off.To install the panel

Place the panel in the original position,

and then install the screw.

Panel C

To remove the panel1. Open the front storage compart-

ment B. (See page 3-16.)

2. Remove the screw, and then pull

the panel off.To install the panel

Place the panel in the original position,

and then install the screw.

Panel D

To remove the panel1. Remove the quick fastener, and

then pull the under cowling off as

shown.TIPThe quick fastener is removed by

pushing the center pin in with a screw-

driver, and then pulling the fastener

out.

1. Screw1

1. Panel B

2. ScrewZAUM1046

12

1. Panel C

2. ScrewZAUM104712

U1SDE1E0.book Page 9 Monday, September 23, 2013 3:55 PM

Page 53 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

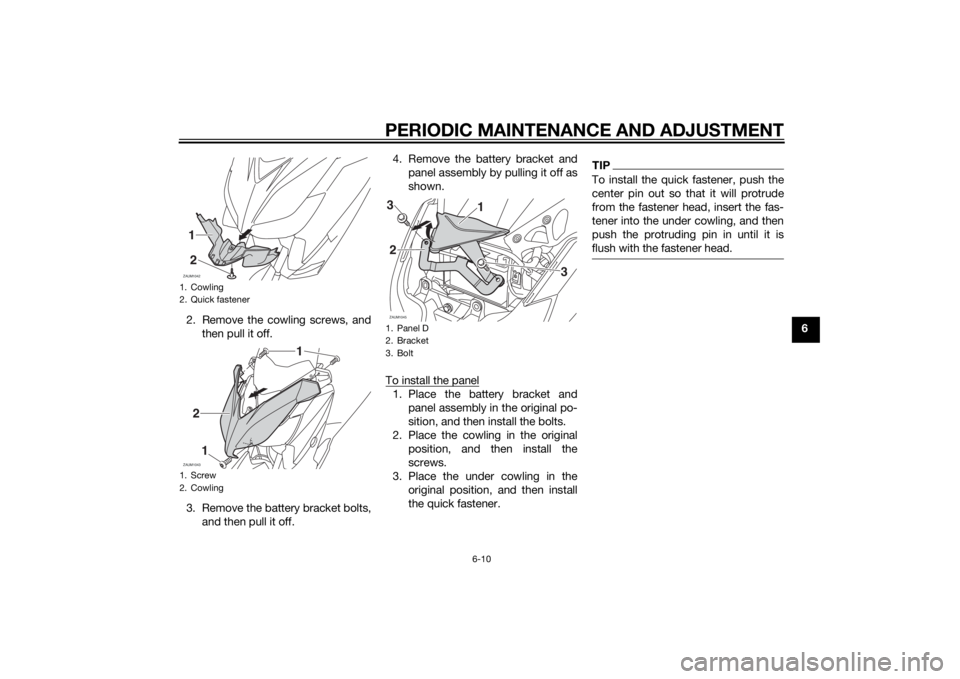

6 2. Remove the cowling screws, and

then pull it off.

3. Remove the battery bracket bolts,

and then pull it off.4. Remove the battery bracket and

panel assembly by pulling it off as

shown.

To install the panel

1. Place the battery bracket and

panel assembly in the original po-

sition, and then install the bolts.

2. Place the cowling in the original

position, and then install the

screws.

3. Place the under cowling in the

original position, and then install

the quick fastener.

TIPTo install the quick fastener, push the

center pin out so that it will protrude

from the fastener head, insert the fas-

tener into the under cowling, and then

push the protruding pin in until it is

flush with the fastener head.

1. Cowling

2. Quick fastener

1. Screw

2. CowlingZAUM104212ZAUM10432

1

1

1. Panel D

2. Bracket

3. BoltZAUM1045

1

32

3

U1SDE1E0.book Page 10 Monday, September 23, 2013 3:55 PM

Page 54 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

6

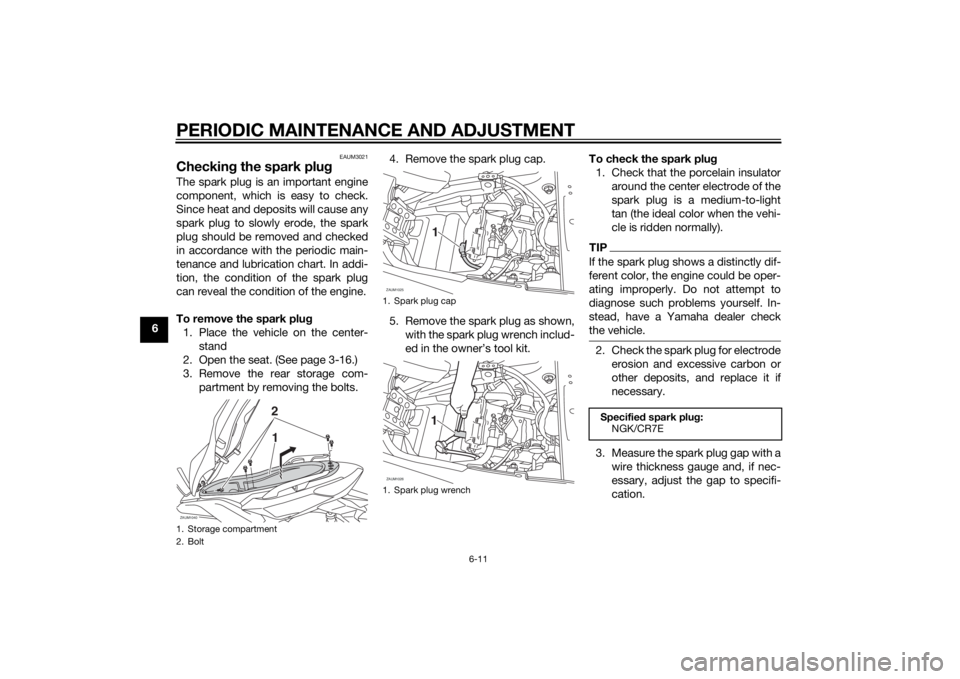

EAUM3021

Checking the spark plugThe spark plug is an important engine

component, which is easy to check.

Since heat and deposits will cause any

spark plug to slowly erode, the spark

plug should be removed and checked

in accordance with the periodic main-

tenance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

To remove the spark plug

1. Place the vehicle on the center-

stand

2. Open the seat. (See page 3-16.)

3. Remove the rear storage com-

partment by removing the bolts.4. Remove the spark plug cap.

5. Remove the spark plug as shown,

with the spark plug wrench includ-

ed in the owner’s tool kit.To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the vehi-

cle is ridden normally).

TIPIf the spark plug shows a distinctly dif-

ferent color, the engine could be oper-

ating improperly. Do not attempt to

diagnose such problems yourself. In-

stead, have a Yamaha dealer check

the vehicle.2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.

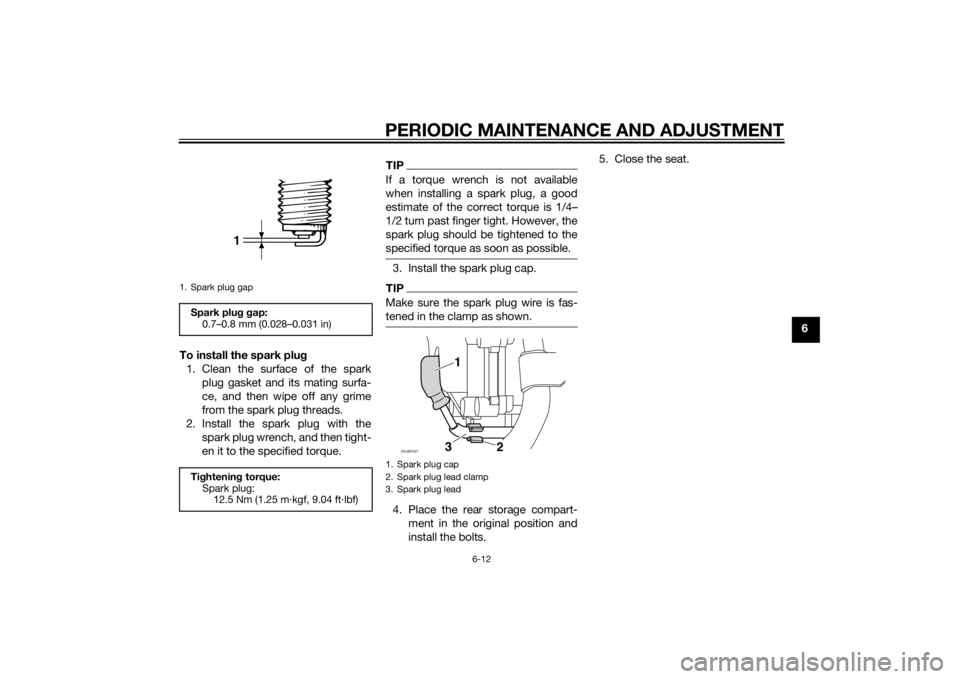

3. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.

1. Storage compartment

2. BoltZAUM1040

2

1

1. Spark plug cap

1. Spark plug wrenchZAUM1025

1

ZAUM1026

1

Specified spark plug:

NGK/CR7E

U1SDE1E0.book Page 11 Monday, September 23, 2013 3:55 PM

Page 55 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

6

To install the spark plug

1. Clean the surface of the spark

plug gasket and its mating surfa-

ce, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the

spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.3. Install the spark plug cap.TIPMake sure the spark plug wire is fas-

tened in the clamp as shown.4. Place the rear storage compart-

ment in the original position and

install the bolts.5. Close the seat.

1. Spark plug gapSpark plug gap:

0.7–0.8 mm (0.028–0.031 in)

Tightening torque:

Spark plug:

12.5 Nm (1.25 m·kgf, 9.04 ft·lbf)

1

1. Spark plug cap

2. Spark plug lead clamp

3. Spark plug lead

ZAUM1027

1

2 3

U1SDE1E0.book Page 12 Monday, September 23, 2013 3:55 PM

Page 56 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

6

EAUM3031

Engine oil and oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart and when the oil change

indicator comes on.

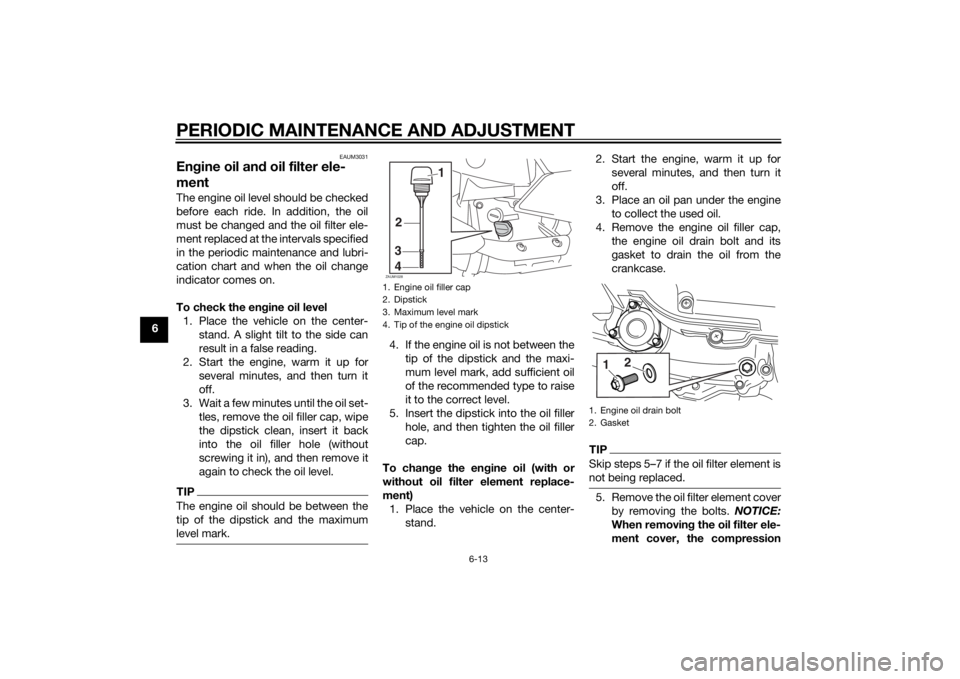

To check the engine oil level

1. Place the vehicle on the center-

stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.TIPThe engine oil should be between the

tip of the dipstick and the maximum

level mark.

4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler

hole, and then tighten the oil filler

cap.

To change the engine oil (with or

without oil filter element replace-

ment)

1. Place the vehicle on the center-

stand.2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Place an oil pan under the engine

to collect the used oil.

4. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5…7 if the oil filter element is

not being replaced.5. Remove the oil filter element cover

by removing the bolts. NOTICE:

When removing the oil filter ele-

ment cover, the compression

1. Engine oil filler cap

2. Dipstick

3. Maximum level mark

4. Tip of the engine oil dipstickZAUM102834

1

2

1. Engine oil drain bolt

2. Gasket

12

U1SDE1E0.book Page 13 Monday, September 23, 2013 3:55 PM

Page 57 of 92

![YAMAHA XMAX 400 2014 Workshop Manual PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6 spring will fall out. Take care not

to lose the compression spring.

[ECA12912]

6. Remove and replace the oil filter

element and O-rings.7. Install the compre YAMAHA XMAX 400 2014 Workshop Manual PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6 spring will fall out. Take care not

to lose the compression spring.

[ECA12912]

6. Remove and replace the oil filter

element and O-rings.7. Install the compre](/img/51/53001/w960_53001-56.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6 spring will fall out. Take care not

to lose the compression spring.

[ECA12912]

6. Remove and replace the oil filter

element and O-rings.7. Install the compression spring and

oil filter element cover by installing

the bolts, then tightening them to

the specified torque.

TIPMake sure that the O-rings are properly

seated.8. Install the engine oil drain bolt and

its new gasket, and then tighten

the bolt to the specified torque.9. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11671

Do not use oils with a diesel

specification of “CD” or oils of a

higher quality than specified. In

1. Bolt

2. Oil filter element cover

21

1. Oil filter element cover

2. O-ring

3. Compression spring

4. Oil filter element

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1

24

3

Tightening torque:

Engine oil drain bolt:

20 Nm (2.0 m·kgf, 14 ft·lbf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element replace-

ment:

1.50 L (1.59 US qt, 1.32 Imp.qt)

With oil filter element replacement:

1.70 L (1.80 US qt, 1.50 Imp.qt)

U1SDE1E0.book Page 14 Monday, September 23, 2013 3:55 PM

Page 58 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-15

6addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Be sure no foreign material en-

ters the crankcase.

10. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

11. Reset the oil change indicator ac-

cording to the following proce-

dure.

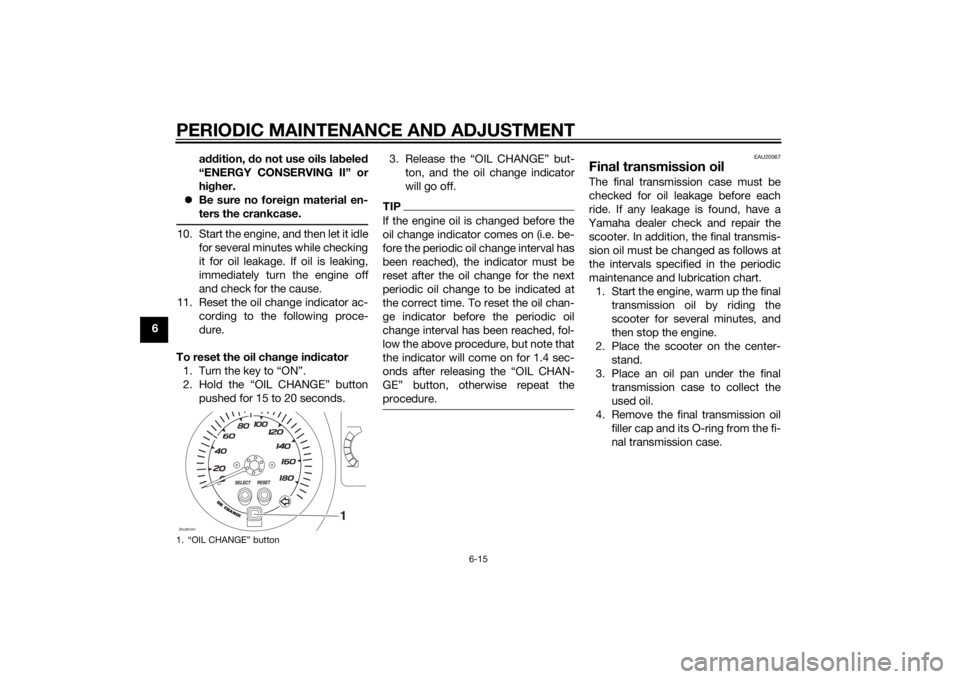

To reset the oil change indicator

1. Turn the key to “ON”.

2. Hold the “OIL CHANGE” button

pushed for 15 to 20 seconds.3. Release the “OIL CHANGE” but-

ton, and the oil change indicator

will go off.

TIPIf the engine oil is changed before the

oil change indicator comes on (i.e. be-

fore the periodic oil change interval has

been reached), the indicator must be

reset after the oil change for the next

periodic oil change to be indicated at

the correct time. To reset the oil chan-

ge indicator before the periodic oil

change interval has been reached, fol-

low the above procedure, but note that

the indicator will come on for 1.4 sec-

GEŽ button, otherwise repeat the

procedure.

EAU20067

Final transmission oilThe final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the

scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Start the engine, warm up the final

transmission oil by riding the

scooter for several minutes, and

then stop the engine.

2. Place the scooter on the center-

stand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

4. Remove the final transmission oil

filler cap and its O-ring from the fi-

nal transmission case.

1. “OIL CHANGE” buttonZAUM1051

OIL CHANGE

1

U1SDE1E0.book Page 15 Monday, September 23, 2013 3:55 PM

Page 59 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-16

6

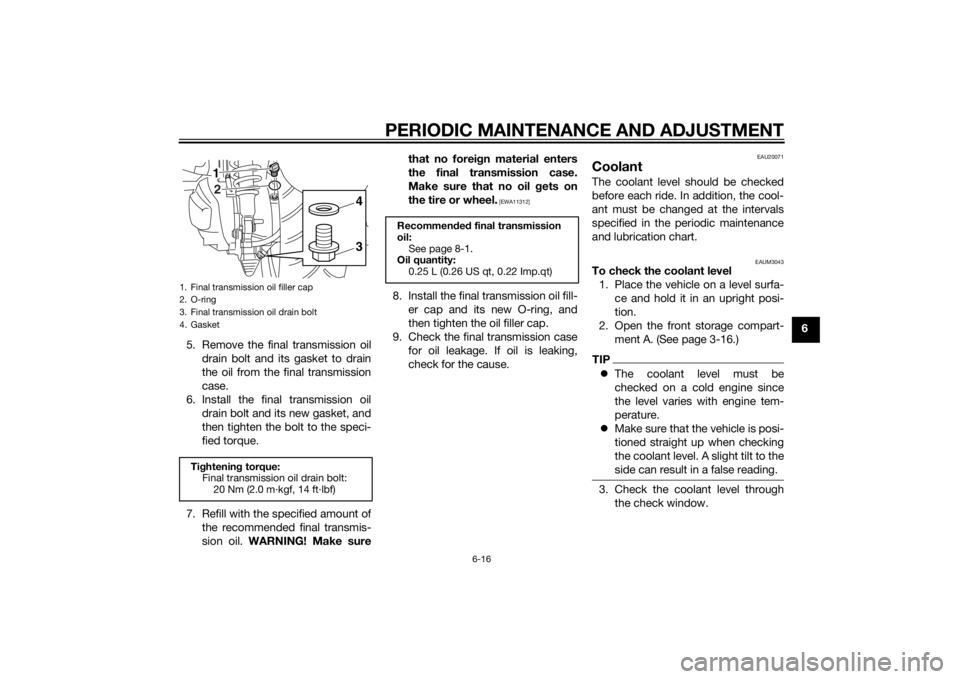

5. Remove the final transmission oil

drain bolt and its gasket to drain

the oil from the final transmission

case.

6. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fied torque.

7. Refill with the specified amount of

the recommended final transmis-

sion oil. WARNING! Make surethat no foreign material enters

the final transmission case.

Make sure that no oil gets on

the tire or wheel.

[EWA11312]

8. Install the final transmission oil fill-

er cap and its new O-ring, and

then tighten the oil filler cap.

9. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUM3043

To check the coolant level

1. Place the vehicle on a level surfa-

ce and hold it in an upright posi-

tion.

2. Open the front storage compart-

ment A. (See page 3-16.)TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.3. Check the coolant level through

the check window.

1. Final transmission oil filler cap

2. O-ring

3. Final transmission oil drain bolt

4. GasketTightening torque:

Final transmission oil drain bolt:

20 Nm (2.0 m·kgf, 14 ft·lbf)

21

34

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.25 L (0.26 US qt, 0.22 Imp.qt)

U1SDE1E0.book Page 16 Monday, September 23, 2013 3:55 PM

Page 60 of 92

PERIODIC MAINTENANCE AND ADJUSTMENT

6-17

6

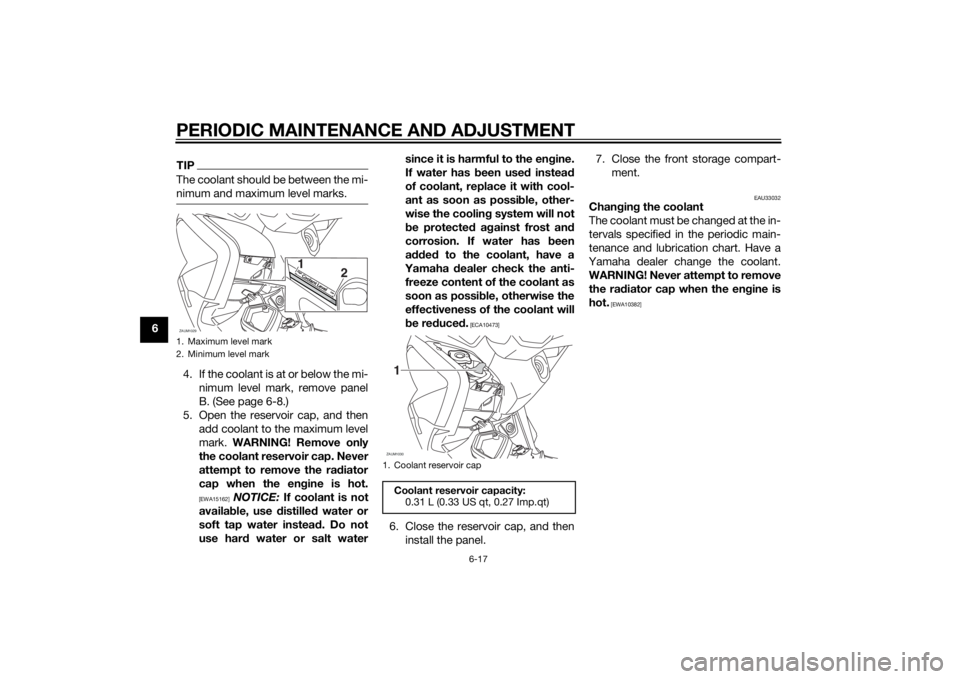

TIPThe coolant should be between the mi-

nimum and maximum level marks.4. If the coolant is at or below the mi-

nimum level mark, remove panel

B. (See page 6-8.)

5. Open the reservoir cap, and then

add coolant to the maximum level

mark. WARNING! Remove only

the coolant reservoir cap. Never

attempt to remove the radiator

cap when the engine is hot.

[EWA15162]

NOTICE: If coolant is not

available, use distilled water or

soft tap water instead. Do not

use hard water or salt watersince it is harmful to the engine.

If water has been used instead

of coolant, replace it with cool-

ant as soon as possible, other-

wise the cooling system will not

be protected against frost and

corrosion. If water has been

added to the coolant, have a

Yamaha dealer check the anti-

freeze content of the coolant as

soon as possible, otherwise the

effectiveness of the coolant will

be reduced.

[ECA10473]

6. Close the reservoir cap, and then

install the panel.7. Close the front storage compart-

ment.

EAU33032

Changing the coolant

The coolant must be changed at the in-

tervals specified in the periodic main-

tenance and lubrication chart. Have a

Yamaha dealer change the coolant.

WARNING! Never attempt to remove

the radiator cap when the engine is

hot.

[EWA10382]

1. Maximum level mark

2. Minimum level markZAUM1029

2 1

Coolant LevelCoolant L

evelH

ighH

igh

LowLo

w

1. Coolant reservoir capCoolant reservoir capacity:

0.31 L (0.33 US qt, 0.27 Imp.qt)ZAUM10301

U1SDE1E0.book Page 17 Monday, September 23, 2013 3:55 PM