warning YAMAHA XT1200Z 2013 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: XT1200Z, Model: YAMAHA XT1200Z 2013Pages: 108, PDF Size: 2.86 MB

Page 70 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6

EAU20016

Final gear oil The final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the vehicle. In addi-

tion, the final gear oil level must be

checked and the oil changed as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

WARNING

EWA10370

●

Make sure that no foreign mate-

rial enters the final gear case.

●

Make sure that no oil gets on the

tire or wheel.

To check the final gear oil level1. Place the vehicle on the center- stand.TIPMake sure that the vehicle is positioned

straight up when checking the oil level.

A slight tilt to the side can result in a

false reading.2. Remove the final gear oil filler boltand its gasket, and then check the

oil level in the final gear case.

TIPThe oil level should be at the brim of the

filler hole.3. If the oil is below the brim of the fill-er hole, add sufficient oil of the rec-

ommended type to raise it to the

correct level.

4. Check the gasket for damage, and replace it if necessary.

5. Install the final gear oil filler bolt and its gasket, and then tighten the

bolt to the specified torque. To change the final gear oil

1. Place the vehicle on a level sur- face.

2. Place an oil pan under the final gear case to collect the used oil.

3. Remove the final gear oil filler bolt, the final gear oil drain bolt and their

gasket to drain the oil from the final

gear case.

4. Install the final gear oil drain bolt and its new gasket, and then tight-

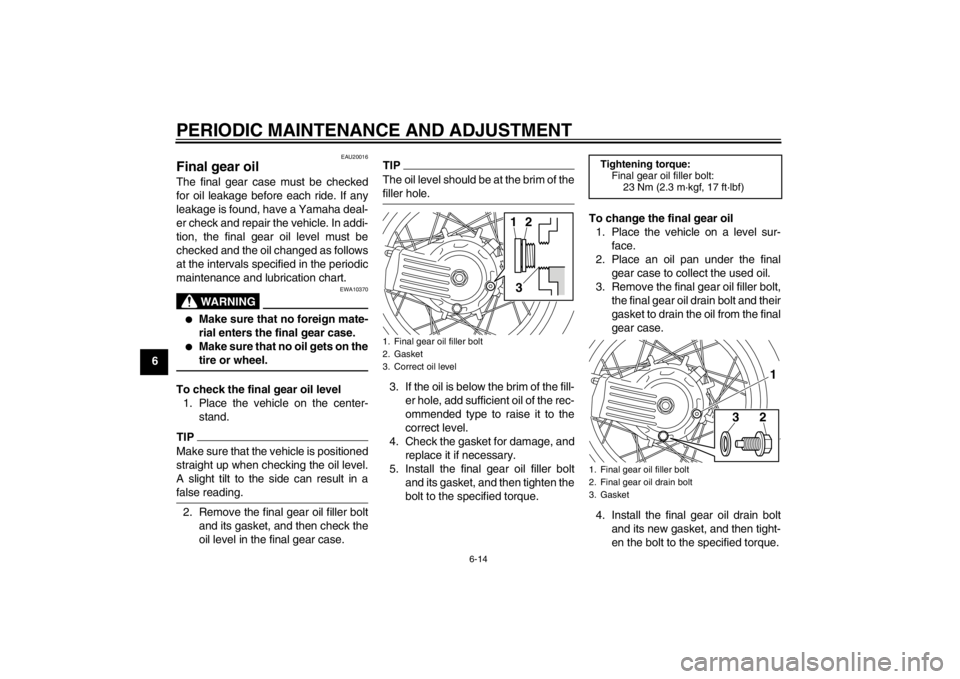

en the bolt to the specified torque.1. Final gear oil filler bolt

2. Gasket

3. Correct oil level

1

2

3

Tightening torque: Final gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)1. Final gear oil filler bolt

2. Final gear oil drain bolt

3. Gasket

2

3

1

U23PE3E0.book Page 14 Monday, July 30, 2012 8:44 AM

Page 72 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-16

64. Add coolant or distilled water to

raise the coolant to the maximum

level mark, install the coolant res-

ervoir cap. WARNING! Remove

only the coolant reservoir cap.

Never attempt to remove the ra-

diator cap when the engine is

hot.

[EWA15161]

NOTICE: If coolant is

not available, use distilled water

or soft tap water instead. Do not

use hard water or salt water

since it is harmful to the engine.

If water has been used instead

of coolant, replace it with cool-

ant as soon as possible, other-

wise the cooling system will not

be protected against frost and

corrosion. If water has been

added to the coolant, have a

Yamaha dealer check the anti-

freeze content of the coolant as

soon as possible, otherwise the

effectiveness of the coolant will

be reduced. [ECA10472] EAU33031

Changing the coolant

The coolant must be changed at the in-

tervals specified in the periodic mainte-

nance and lubrication chart. Have a

Yamaha dealer change the coolant.

WARNING! Never attempt to remove the radiator cap when the engine is

hot.

[EWA10381] EAU36764

Air filter element The air filter element must be replaced

at the intervals specified in the periodic

maintenance and lubrication chart.

Have a Yamaha dealer replace the air

filter element.

Coolant reservoir capacity (up to

the maximum level mark):

0.26 L (0.27 US qt, 0.23 Imp.qt)

U23PE3E0.book Page 16 Monday, July 30, 2012 8:44 AM

Page 74 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-18

6

EAU49675

Tires Tires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be checked

and, if necessary, adjusted before each

ride.

WARNING

EWA10503

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control.●

The tire air pressure must be

checked and adjusted on cold

tires (i.e., when the temperature

of the tires equals the ambient

temperature).

●

The tire air pressure must be ad-

justed in accordance with the

riding speed and with the totalweight of rider, passenger, car-

go, and accessories approved

for this model.

WARNING

EWA10511

Never overload your vehicle. Opera-

tion of an overloaded vehicle could

cause an accident.

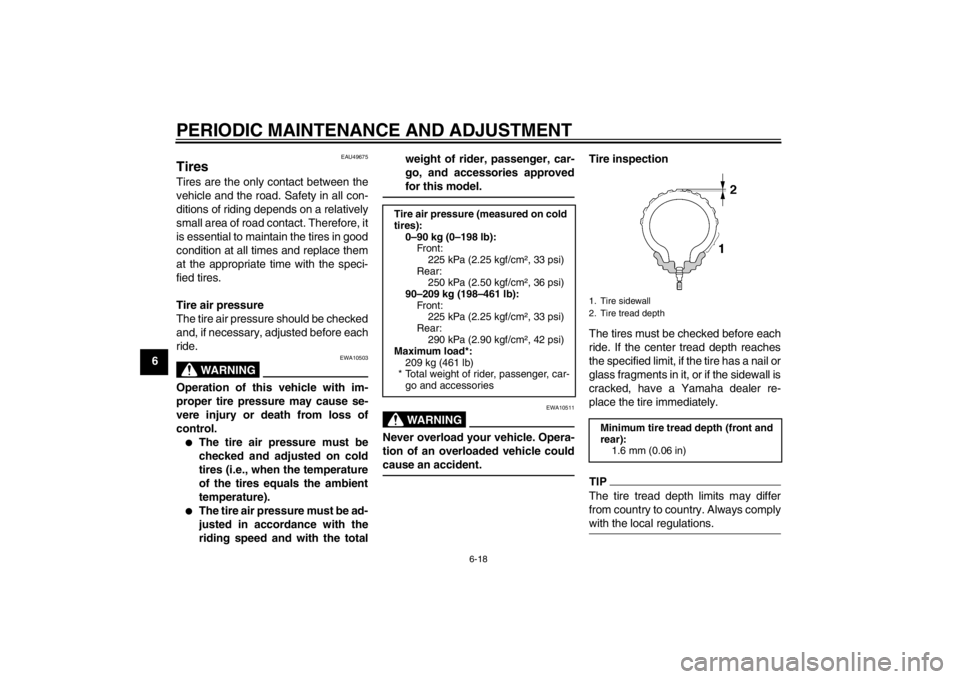

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail or

glass fragments in it, or if the sidewall is

cracked, have a Yamaha dealer re-

place the tire immediately.TIPThe tire tread depth limits may differ

from country to country. Always comply

with the local regulations.

Tire air pressure (measured on cold

tires):

0–90 kg (0–198 lb):Front:

225 kPa (2.25 kgf/cm², 33 psi)

Rear: 250 kPa (2.50 kgf/cm², 36 psi)

90–209 kg (198–461 lb): Front:225 kPa (2.25 kgf/cm², 33 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

Maximum load*:

209 kg (461 lb)

* Total weight of rider, passenger, car- go and accessories

1. Tire sidewall

2. Tire tread depthMinimum tire tread depth (front and

rear): 1.6 mm (0.06 in)

U23PE3E0.book Page 18 Monday, July 30, 2012 8:44 AM

Page 75 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-19

6

WARNING

EWA10471

●

Have a Yamaha dealer replace

excessively worn tires. Besides

being illegal, operating the vehi-

cle with excessively worn tires

decreases riding stability and

can lead to loss of control.

●

The replacement of all wheel

and brake-related parts, includ-

ing the tires, should be left to a

Yamaha dealer, who has the necessary professional knowl-

edge and experience to do so.

●

Ride at moderate speeds after

changing a tire since the tire

surface must first be “broken

in” for it to develop its optimal

characteristics.

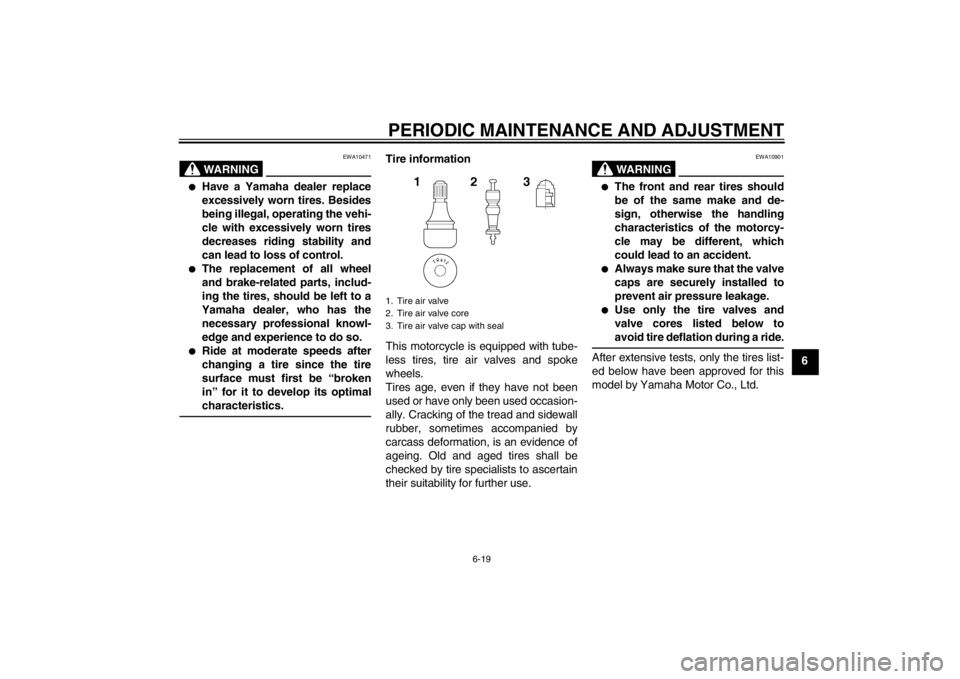

Tire information

This motorcycle is equipped with tube-

less tires, tire air valves and spoke

wheels.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10901

●

The front and rear tires should

be of the same make and de-

sign, otherwise the handling

characteristics of the motorcy-

cle may be different, which

could lead to an accident.

●

Always make sure that the valve

caps are securely installed to

prevent air pressure leakage.

●

Use only the tire valves and

valve cores listed below to

avoid tire deflation during a ride.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha Motor Co., Ltd.

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

U23PE3E0.book Page 19 Monday, July 30, 2012 8:44 AM

Page 77 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6

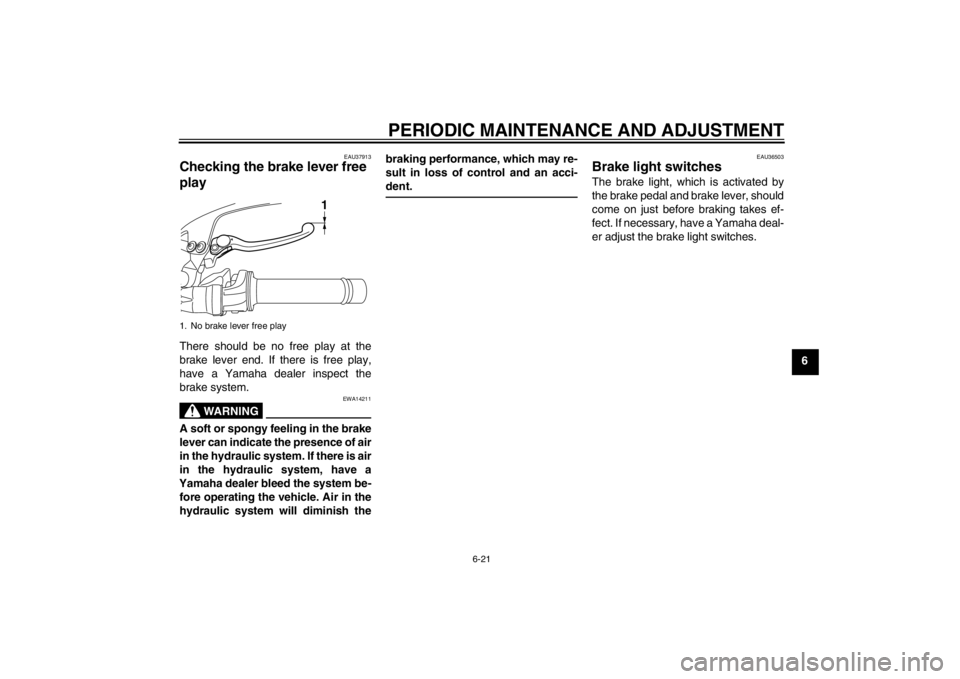

EAU37913

Checking the brake lever free

play There should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14211

A soft or spongy feeling in the brake

lever can indicate the presence of air

in the hydraulic system. If there is air

in the hydraulic system, have a

Yamaha dealer bleed the system be- fore operating the vehicle. Air in the

hydraulic system will diminish the braking performance, which may re-

sult in loss of control and an acci-

dent.

EAU36503

Brake light switches The brake light, which is activated by

the brake pedal and brake lever, should

come on just before braking takes ef-

fect. If necessary, have a Yamaha deal-

er adjust the brake light switches.

1. No brake lever free play

1

U23PE3E0.book Page 21 Monday, July 30, 2012 8:44 AM

Page 79 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6

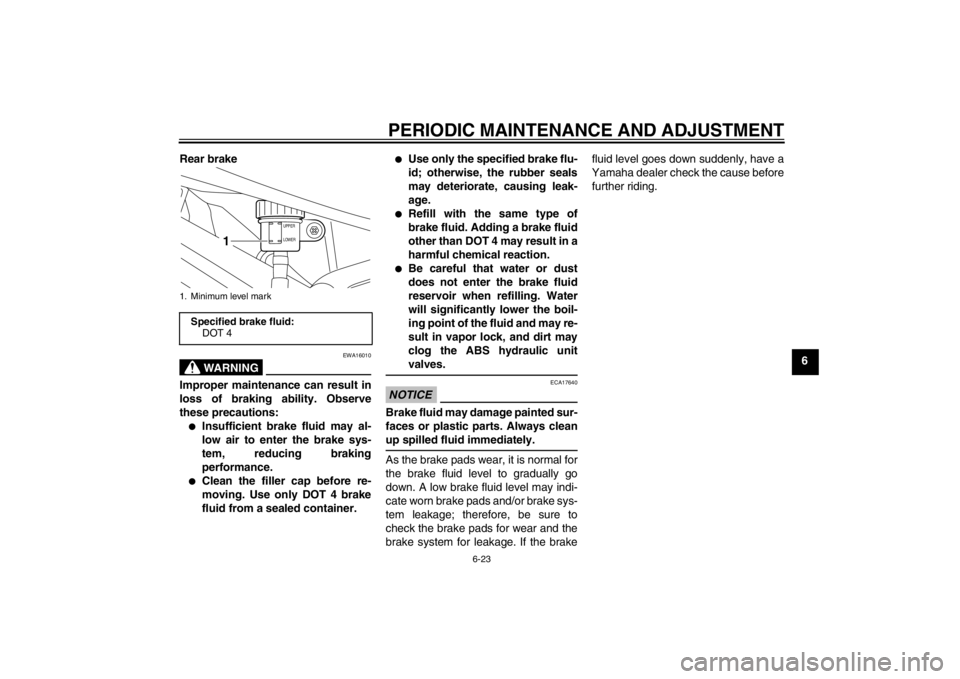

Rear brake

WARNING

EWA16010

Improper maintenance can result in

loss of braking ability. Observe

these precautions:●

Insufficient brake fluid may al-

low air to enter the brake sys-

tem, reducing braking

performance.

●

Clean the filler cap before re-

moving. Use only DOT 4 brake

fluid from a sealed container.

●

Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

●

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

●

Be careful that water or dust

does not enter the brake fluid

reservoir when refilling. Water

will significantly lower the boil-

ing point of the fluid and may re-

sult in vapor lock, and dirt may

clog the ABS hydraulic unit

valves.

NOTICE

ECA17640

Brake fluid may damage painted sur-

faces or plastic parts. Always clean

up spilled fluid immediately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

1. Minimum level markSpecified brake fluid:

DOT 4

UPPER

LOWER

1

U23PE3E0.book Page 23 Monday, July 30, 2012 8:44 AM

Page 82 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

EAU23213

Checking and lubricating the

centerstand and sidestand The operation of the centerstand and

sidestand should be checked before

each ride, and the pivots and metal-to-

metal contact surfaces should be lubri-

cated if necessary.

WARNING

EWA10741

If the centerstand or sidestand does

not move up and down smoothly,

have a Yamaha dealer check or re-

pair it. Otherwise, the centerstand or

sidestand could contact the ground

and distract the operator, resulting

in a possible loss of control.

EAUM1652

Lubricating the swingarm piv-

ots The swingarm pivots must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

and lubrication chart.

Recommended lubricant:

Lithium-soap-based grease

Recommended lubricant:Lithium-soap-based grease

U23PE3E0.book Page 26 Monday, July 30, 2012 8:44 AM

Page 83 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

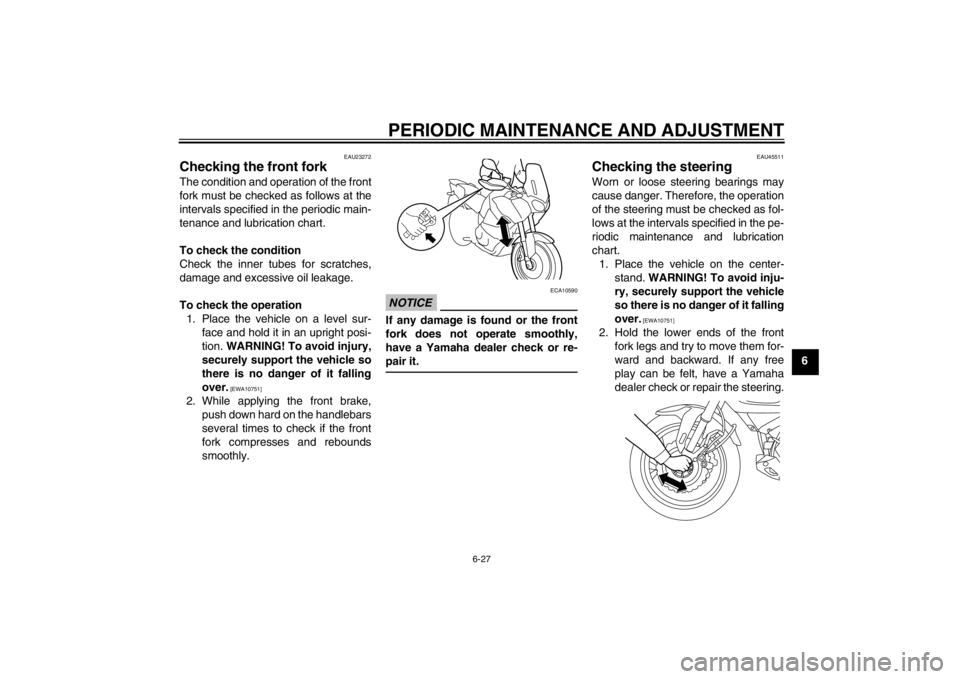

EAU23272

Checking the front fork The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10751]

2. While applying the front brake, push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

NOTICE

ECA10590

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

EAU45511

Checking the steering Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.1. Place the vehicle on the center- stand. WARNING! To avoid inju-

ry, securely support the vehicle

so there is no danger of it falling

over.

[EWA10751]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steering.

U23PE3E0.book Page 27 Monday, July 30, 2012 8:44 AM

Page 84 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

EAU23291

Checking the wheel bearings The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings.

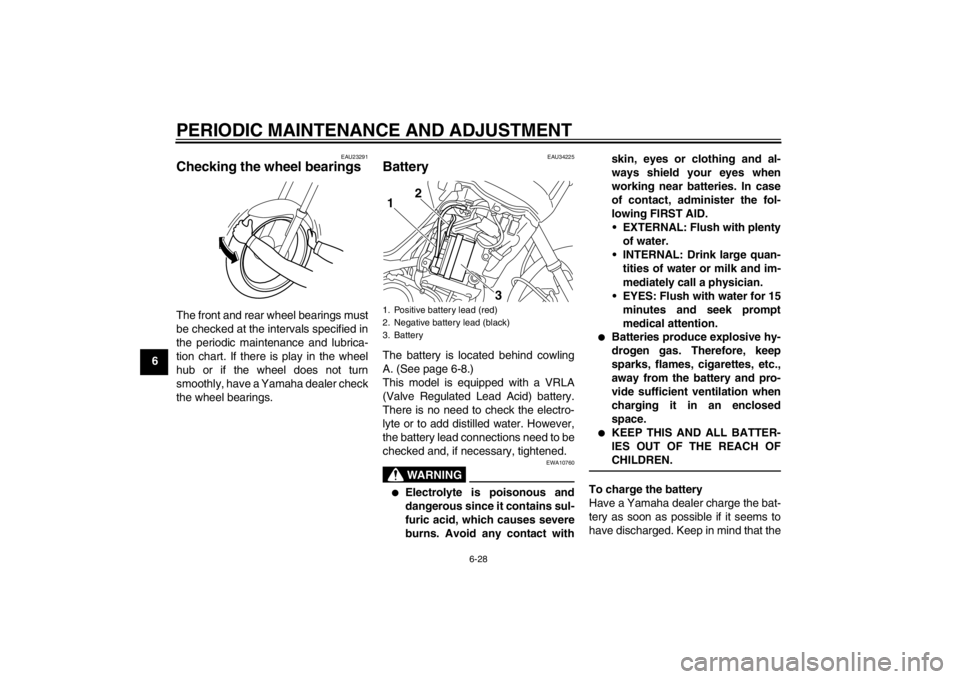

EAU34225

Battery The battery is located behind cowling

A. (See page 6-8.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to be

checked and, if necessary, tightened.

WARNING

EWA10760

●

Electrolyte is poisonous and

dangerous since it contains sul-

furic acid, which causes severe

burns. Avoid any contact withskin, eyes or clothing and al-

ways shield your eyes when

working near batteries. In case

of contact, administer the fol-

lowing FIRST AID.

EXTERNAL: Flush with plenty of water.

INTERNAL: Drink large quan- tities of water or milk and im-

mediately call a physician.

EYES: Flush with water for 15 minutes and seek prompt

medical attention.

●

Batteries produce explosive hy-

drogen gas. Therefore, keep

sparks, flames, cigarettes, etc.,

away from the battery and pro-

vide sufficient ventilation when

charging it in an enclosed

space.

●

KEEP THIS AND ALL BATTER-

IES OUT OF THE REACH OF

CHILDREN.

To charge the battery

Have a Yamaha dealer charge the bat-

tery as soon as possible if it seems to

have discharged. Keep in mind that the

1. Positive battery lead (red)

2. Negative battery lead (black)

3. Battery1

3

2

U23PE3E0.book Page 28 Monday, July 30, 2012 8:44 AM

Page 86 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

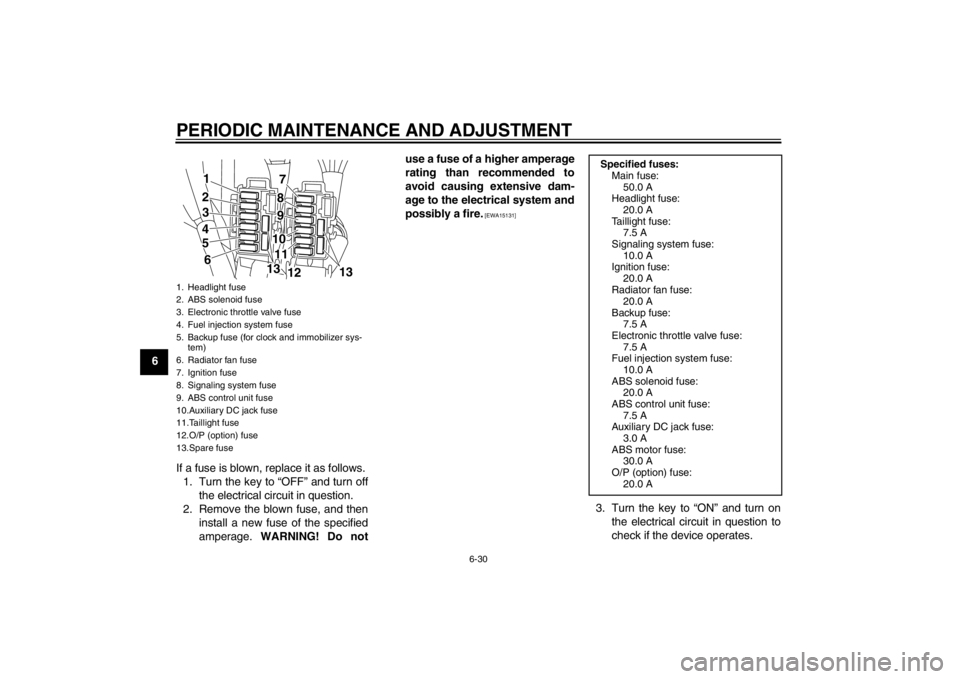

6-30

6If a fuse is blown, replace it as follows.1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15131]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

1. Headlight fuse

2. ABS solenoid fuse

3. Electronic throttle valve fuse

4. Fuel injection system fuse

5. Backup fuse (for clock and immobilizer sys-tem)

6. Radiator fan fuse

7. Ignition fuse

8. Signaling system fuse

9. ABS control unit fuse

10.Auxiliary DC jack fuse

11.Taillight fuse

12.O/P (option) fuse

13.Spare fuse

78912

13

13

1110

124563

Specified fuses: Main fuse:

50.0 A

Headlight fuse:

20.0 A

Taillight fuse: 7.5 A

Signaling system fuse: 10.0 A

Ignition fuse:

20.0 A

Radiator fan fuse: 20.0 A

Backup fuse: 7.5 A

Electronic throttle valve fuse:

7.5 A

Fuel injection system fuse: 10.0 A

ABS solenoid fuse: 20.0 A

ABS control unit fuse:

7.5 A

Auxiliary DC jack fuse: 3.0 A

ABS motor fuse: 30.0 A

O/P (option) fuse:

20.0 A

U23PE3E0.book Page 30 Monday, July 30, 2012 8:44 AM