engine oil YAMAHA XT1200Z 2017 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: XT1200Z, Model: YAMAHA XT1200Z 2017Pages: 120, PDF Size: 3.32 MB

Page 5 of 120

Table of contents

Safety information ............................1-1

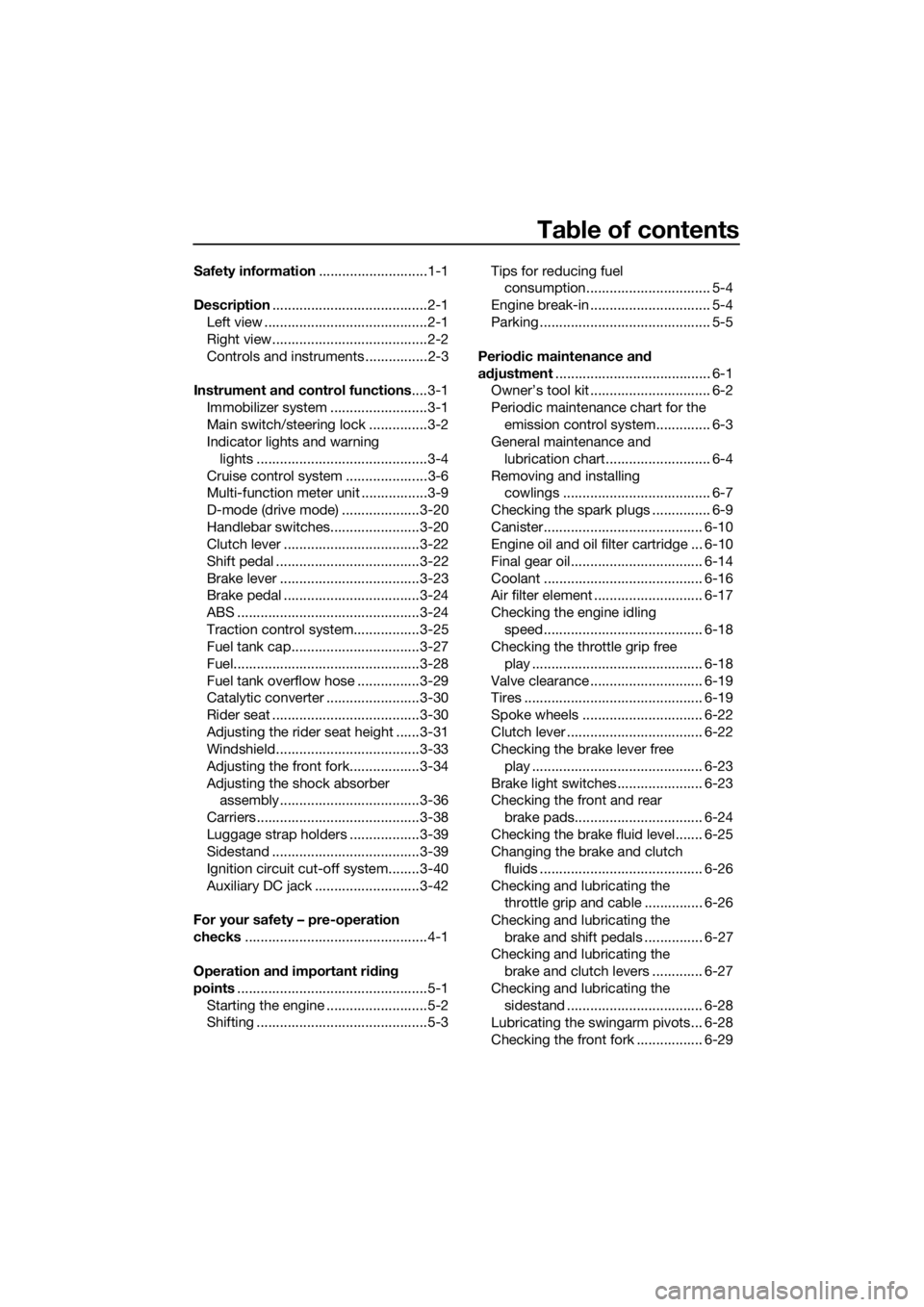

Description ........................................2-1

Left view ..........................................2-1

Right view........................................2-2

Controls and instruments ................2-3

Instrument an d control functions ....3-1

Immobilizer system .........................3-1

Main switch/steering lock ...............3-2

Indicator lights and warning lights ............................................3-4

Cruise control system .....................3-6

Multi-function meter unit .................3-9

D-mode (drive mode) ....................3-20

Handlebar switches.......................3-20

Clutch lever ...................................3-22

Shift pedal .....................................3-22

Brake lever ....................................3-23

Brake pedal ...................................3-24

ABS ...............................................3-24

Traction control system.................3-25

Fuel tank cap.................................3-27

Fuel................................................3-28

Fuel tank overflow hose ................3-29

Catalytic converter ........................3-30

Rider seat ......................................3-30

Adjusting the rider seat height ......3-31

Windshield.....................................3-33

Adjusting the front fork..................3-34

Adjusting the shock absorber assembly....................................3-36

Carriers..........................................3-38

Luggage strap holders ..................3-39

Sidestand ......................................3-39

Ignition circuit cut-off system........3-40

Auxiliary DC jack ...........................3-42

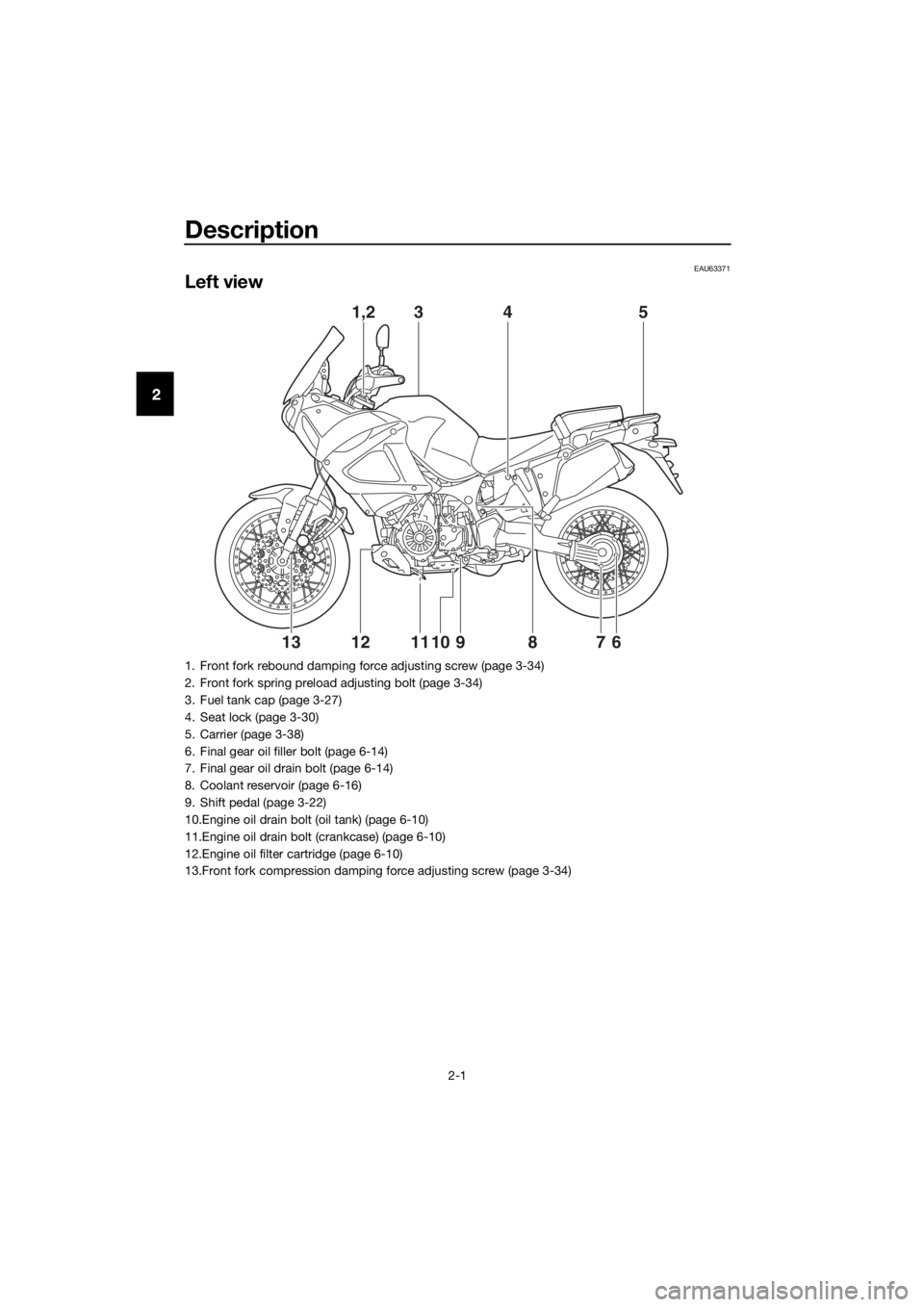

For your safety – pre-operation

checks ...............................................4-1

Operation an d important ri din g

points .................................................5-1

Starting the engine ..........................5-2

Shifting ............................................5-3 Tips for reducing fuel

consumption................................ 5-4

Engine break-in ............................... 5-4

Parking ............................................ 5-5

Perio dic maintenance an d

a d justment ........................................ 6-1

Owner’s tool kit ............................... 6-2

Periodic maintenance chart for the

emission control system.............. 6-3

General maintenance and

lubrication chart........................... 6-4

Removing and installing cowlings ...................................... 6-7

Checking the spark plugs ............... 6-9

Canister......................................... 6-10

Engine oil and oil filter cartridge ... 6-10

Final gear oil.................................. 6-14

Coolant ......................................... 6-16

Air filter element ............................ 6-17

Checking the engine idling speed......................................... 6-18

Checking the throttle grip free

play ............................................ 6-18

Valve clearance ............................. 6-19

Tires .............................................. 6-19

Spoke wheels ............................... 6-22

Clutch lever ................................... 6-22

Checking the brake lever free play ............................................ 6-23

Brake light switches ...................... 6-23

Checking the front and rear brake pads................................. 6-24

Checking the brake fluid level....... 6-25

Changing the brake and clutch fluids .......................................... 6-26

Checking and lubricating the throttle grip and cable ............... 6-26

Checking and lubricating the brake and shift pedals ............... 6-27

Checking and lubricating the

brake and clutch levers ............. 6-27

Checking and lubricating the sidestand ................................... 6-28

Lubricating the swingarm pivots... 6-28

Checking the front fork ................. 6-29

UBP8E0E0.book Page 1 Thursday, December 8, 2016 7:25 PM

Page 12 of 120

Description

2-1

2

EAU63371

Left view

356

7891011

41,2

1213

1. Front fork rebound damping force adjusting screw (page 3-34)

2. Front fork spring preload adjusting bolt (page 3-34)

3. Fuel tank cap (page 3-27)

4. Seat lock (page 3-30)

5. Carrier (page 3-38)

6. Final gear oil filler bolt (page 6-14)

7. Final gear oil drain bolt (page 6-14)

8. Coolant reservoir (page 6-16)

9. Shift pedal (page 3-22)

10.Engine oil drain bolt (oil tank) (page 6-10)

11.Engine oil drain bolt (crankcase) (page 6-10)

12.Engine oil filter cartridge (page 6-10)

13.Front fork compression damping force adjusting screw (page 3-34)

UBP8E0E0.book Page 1 Thursday, December 8, 2016 7:25 PM

Page 13 of 120

Description

2-2

2

EAU63391

Right view

1

7

681112910

23,45

1. Rear brake fluid reservoir (page 6-25)

2. Shock absorber assembly spring preload adjusting knob (page 3-36)

3. Front fork rebound damping force adjusting screw (page 3-34)

4. Front fork spring preload adjusting bolt (page 3-34)

5. Fuses (page 6-32)

6. Front fork compression damping force adjusting screw (page 3-34)

7. Owner’s tool kit (page 6-2)

8. Battery (page 6-30)

9. Engine oil filler cap (page 6-10)

10.Engine oil level check window (page 6-10)

11.Brake pedal (page 3-24)

12.Shock absorber assembly rebound damping force adjusting knob (page 3-36)

UBP8E0E0.book Page 2 Thursday, December 8, 2016 7:25 PM

Page 18 of 120

Instrument and control functions

3-4

3

EAU4939C

In dicator li ghts and warning

li g hts

EAU11032Turn si gnal in dicator li ghts “ ”

an d“”

Each indicator light will flash when its

corresponding turn signal lights are

flashing.

EAU11061Neutral in dicator li ght “ ”

This indicator light comes on when the

transmission is in the neutral position.

EAU11081Hi gh beam in dicator li ght “ ”

This indicator light comes on when the

high beam of the headlight is switched

on.

EAU11256Oil level warnin g li ght “ ”

This warning light comes on if the en-

gine oil level is low.

The electrical circuit of the warning

light can be checked by turning the key

to “ON”. The warning light should

come on for a few seconds and then

go off.

If the warning light does not come on

initially when the key is turned to “ON”,

or if the warning light remains on after

confirming that the oil level is correct

(see page 6-10), have a Yamaha dealer

check the vehicle.

TIP

Even if the oil level is sufficient, the

warning light may flicker when rid-

ing on a slope or during sudden

acceleration or deceleration, but

this is not a malfunction.

This model is equipped with a self-

diagnosis device for the oil level

detection circuit. If a problem is

detected in the oil level detection

circuit, the oil level warning light

will flash repeatedly. If this occurs,

have a Yamaha dealer check the

vehicle.

EAU58401Cruise control in dicator

li g hts “ ”/“SET”

These indicator lights come on when

the cruise control system is activated.

See page 3-6 for a detailed explanation

of the function of these indicator lights.

The electrical circuit of these indicator

lights can be checked by turning the

key to “ON”. These indicator lights

should come on for a few seconds, and

then go off.

1. Left turn signal indicator light “ ”

2. Right turn signal indicator light “ ”

3. Oil level warning light “ ”

4. Engine trouble warning light “ ”

5. Anti-lock Brake System (ABS) warning light “ ”

6. Traction control system indicator light “ ”

7. Cruise control indicator lights “ ”/“SET”

8. High beam indicator light “ ”

9. Neutral indicator light “ ”

10.Immobilizer system indicator light “ ”

GEARN25A.TEMP ˚C

LoC.TEMP˚C

0:00TIME TRIP

345687910

12

ABS

UBP8E0E0.book Page 4 Thursday, December 8, 2016 7:25 PM

Page 57 of 120

For your safety – pre-operation checks

4-1

4

EAU63440

Inspect your vehicle each time you use it to make sure the vehicle is in safe oper-

ating condition. Always follow the inspection and maintenance procedures and

schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility

of an acci dent or equipment d amage. Do not operate the vehicle if you fin d

any prob lem. If a pro blem cannot be corrected b y the proce dures provi ded

in this manual, have the vehicle inspecte d b y a Yamaha d ealer.

Before using this vehicle, check the following points:

ITEM CHECKSPAGE

Fuel • Check fuel level in fuel tank.

• Refuel if necessary.

• Check fuel line for leakage.

• Check fuel tank breather hose and overflow hose for

obstructions, cracks or damage, and check hose con-

nections. 3-28,

3-29

En gine oil • Check oil level in engine.

• If necessary, add recommended oil to specified level.

• Check vehicle for oil leakage. 6-10

Final gear oil • Check vehicle for oil leakage. 6-14

Coolant • Check coolant level in reservoir.

• If necessary, add recommended coolant to specified

level.

• Check cooling system for leakage. 6-16

Front brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-24,

6-25

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-24,

6-25

Clutch • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check hydraulic system for leakage. 6-22

UBP8E0E0.book Page 1 Thursday, December 8, 2016 7:25 PM

Page 60 of 120

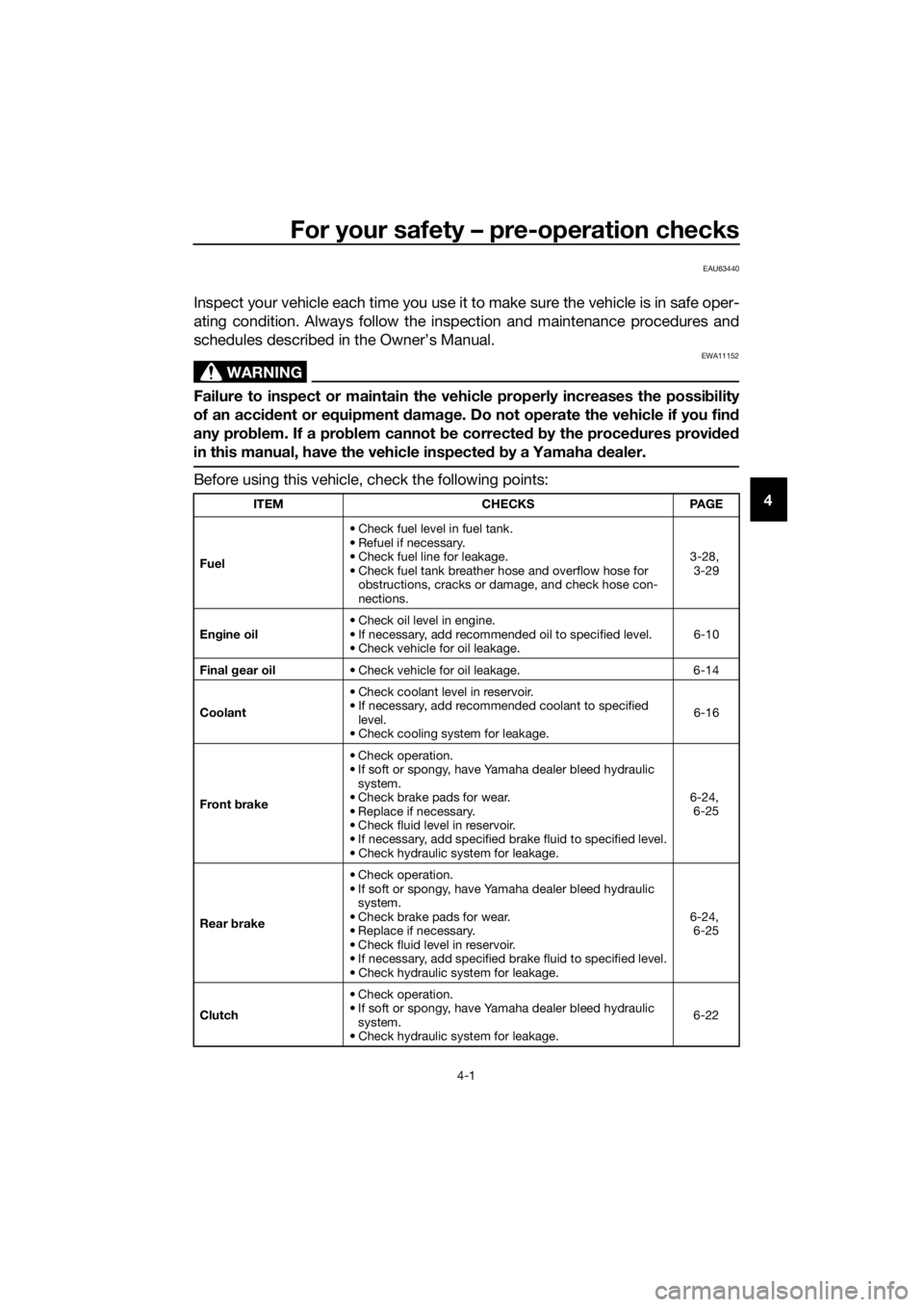

Operation and important rid ing points

5-2

5

EAU54172

Startin g the en gine

In order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:

The transmission is in the neutral

position.

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

See page 3-40 for more informa-

tion.

1. Turn the key to “ON” and make sure that the start/engine stop

switch is set to “ ”.

The following warning lights and

indicator lights should come on for

a few seconds, then go off. Oil level warning light

Engine trouble warning light

Traction control system indi-

cator light

Cruise control indicator lights

Immobilizer system indicator

light

NOTICE

ECA11834

If a warnin g or in dicator li ght does

not come on initially when the key is

turne d to “ON”, or if a warnin g or in-

d icator li ght remains on, see pag e

3-4 for the correspon din g warnin g

an d in dicator li ght circuit check.

The ABS warning light should

come on when the key is turned to

“ON”, and then go off after travel-

ing at a speed of 10 km/h (6 mi/h)

or higher.

NOTICE

ECA17682

If the ABS warnin g li ght does not

come on an d then g o off as ex-

plained above, see pag e 3-4 for the

warnin g lig ht circuit check.

2. Shift the transmission into the

neutral position. The neutral indi-

cator light should come on. If not,

ask a Yamaha dealer to check the

electrical circuit.

3. Start the engine by pushing the “ ” side of the start/engine

stop switch.

If the engine fails to start, release

the start/engine stop switch, wait

a few seconds, and then try again.

Each starting attempt should be

as short as possible to preserve

the battery. Do not crank the en-

gine more than 10 seconds on any

one attempt.

NOTICE

ECA11043

For maximum eng ine life, never ac-

celerate har d when the en gine is

col d!

UBP8E0E0.book Page 2 Thursday, December 8, 2016 7:25 PM

Page 62 of 120

Operation and important rid ing points

5-4

5

EAU16811

Tips for re ducin g fuel con-

sumption

Fuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

Do not rev the engine while shift-

ing down, and avoid high engine

speeds with no load on the en-

gine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

EAU16842

Engine break-in

There is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the fol-

lowing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that

might result in engine overheating

must be avoided.

EAU58991

0–1000 km (0–600 mi)

Avoid prolonged operation above 3900

r/min. NOTICE: After 1000 km (600

mi) of operation, the en gine oil an d

final gear oil must be chan ged , an d

the oil filter cartri dge or element re-

placed .

[ECA10333]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 4700

r/min.

1600 km (1000 mi) an d b eyon d

The vehicle can now be operated nor-

mally.

NOTICE

ECA23060

Keep the en gine spee d out of

the tachometer hi gh-r/min zo-

ne.

UBP8E0E0.book Page 4 Thursday, December 8, 2016 7:25 PM

Page 68 of 120

Periodic maintenance an d a djustment

6-5

6

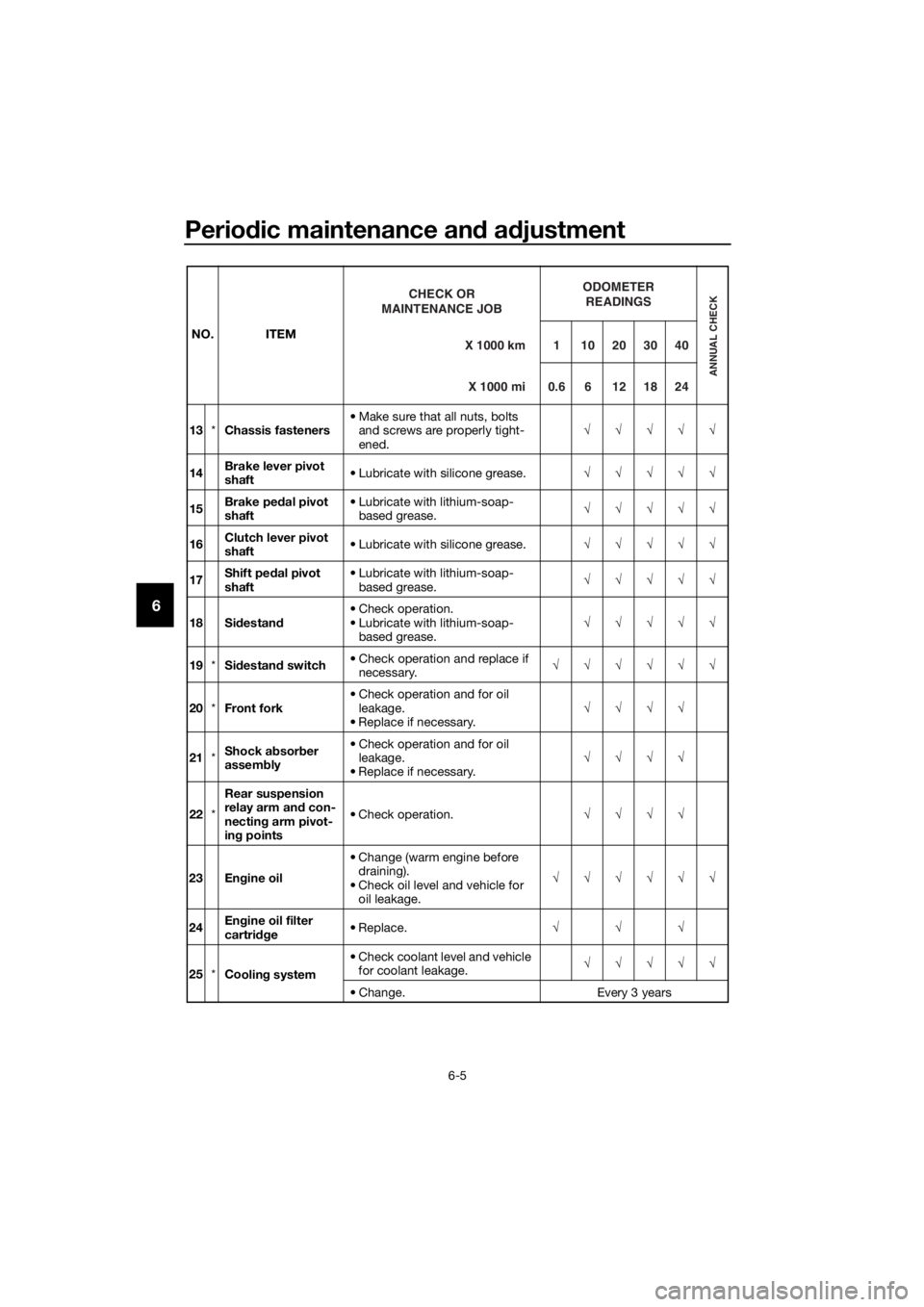

13 *Chassis fasteners • Make sure that all nuts, bolts

and screws are properly tight-

ened. √√√√√

14 Brake lever pivot

shaft

• Lubricate with silicone grease.

√√√√√

15 Brake pe

dal pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

16 Clutch lever pivot

shaft • Lubricate with silicone grease.

√√√√√

17 Shift pe

dal pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

18 Si destan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

19 *Sidestan d switch • Check operation and replace if

necessary. √√√√√√

20 *Front fork • Check operation and for oil

leakage.

• Replace if necessary. √√√√

21 *Shock ab

sorber

assem bly • Check operation and for oil

leakage.

• Replace if necessary. √√√√

22 *Rear suspension

relay arm an

d con-

nectin g arm pivot-

in g points • Check operation.

√√√√

23 En gine oil • Change (warm engine before

draining).

• Check oil level and vehicle for oil leakage. √√√√√√

24 En

gine oil filter

cartri dge • Replace.

√√√

25 *Co

o

lin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change. Every 3 years

NO. ITEM

X 1000 km

CHECK OR

MAINTENANCE JOB

X 1000 mi ODOMETER

READINGS

ANNUAL CHECK

110203040

0.6 6 12 18 24

UBP8E0E0.book Page 5 Thursday, December 8, 2016 7:25 PM

Page 72 of 120

Periodic maintenance an d a djustment

6-9

6

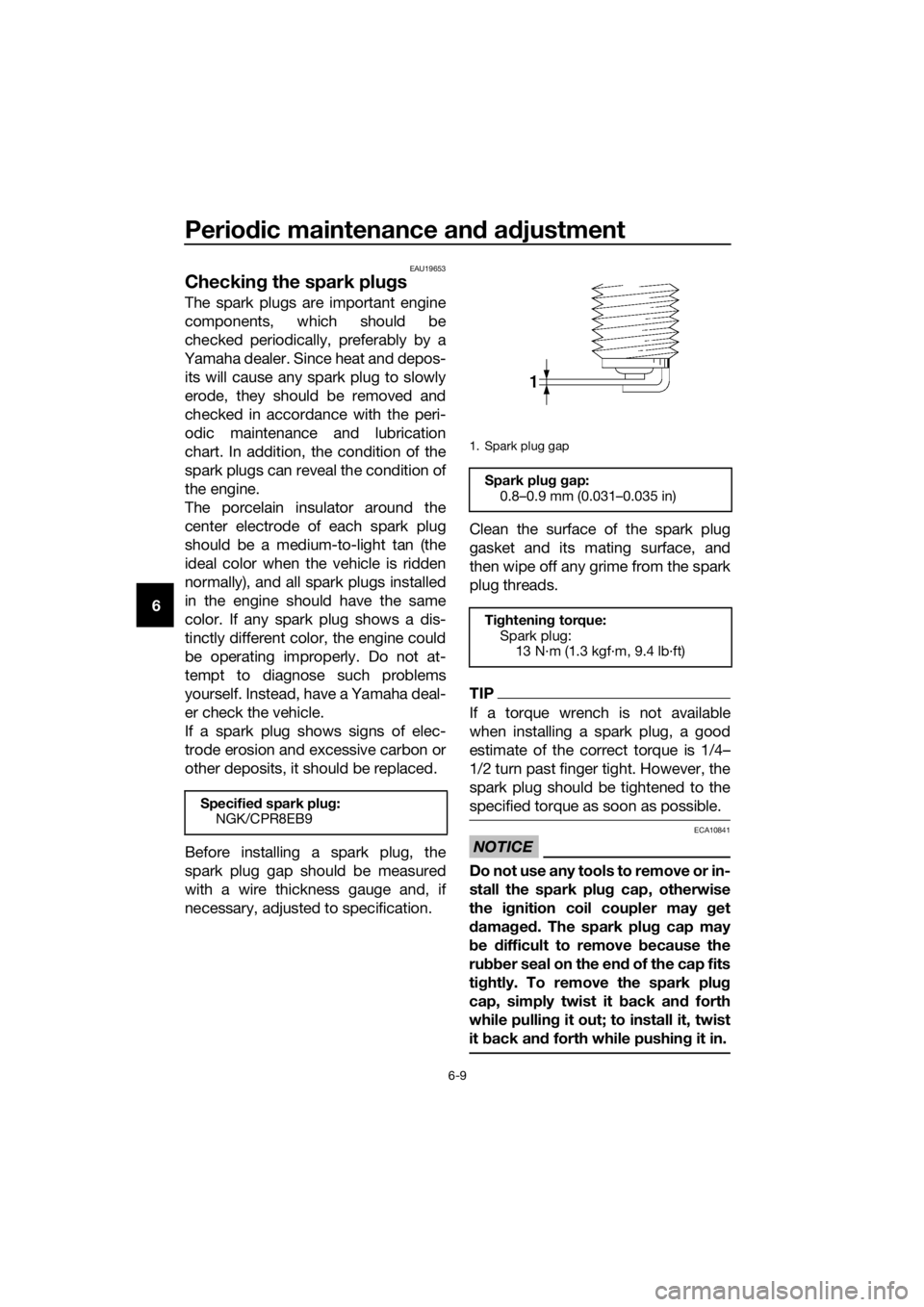

EAU19653

Checkin g the spark plu gs

The spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification. Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

Specifie d spark plu g:

NGK/CPR8EB9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtening torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.4 lb·ft)

UBP8E0E0.book Page 9 Thursday, December 8, 2016 7:25 PM

Page 73 of 120

Periodic maintenance an d a djustment

6-10

6

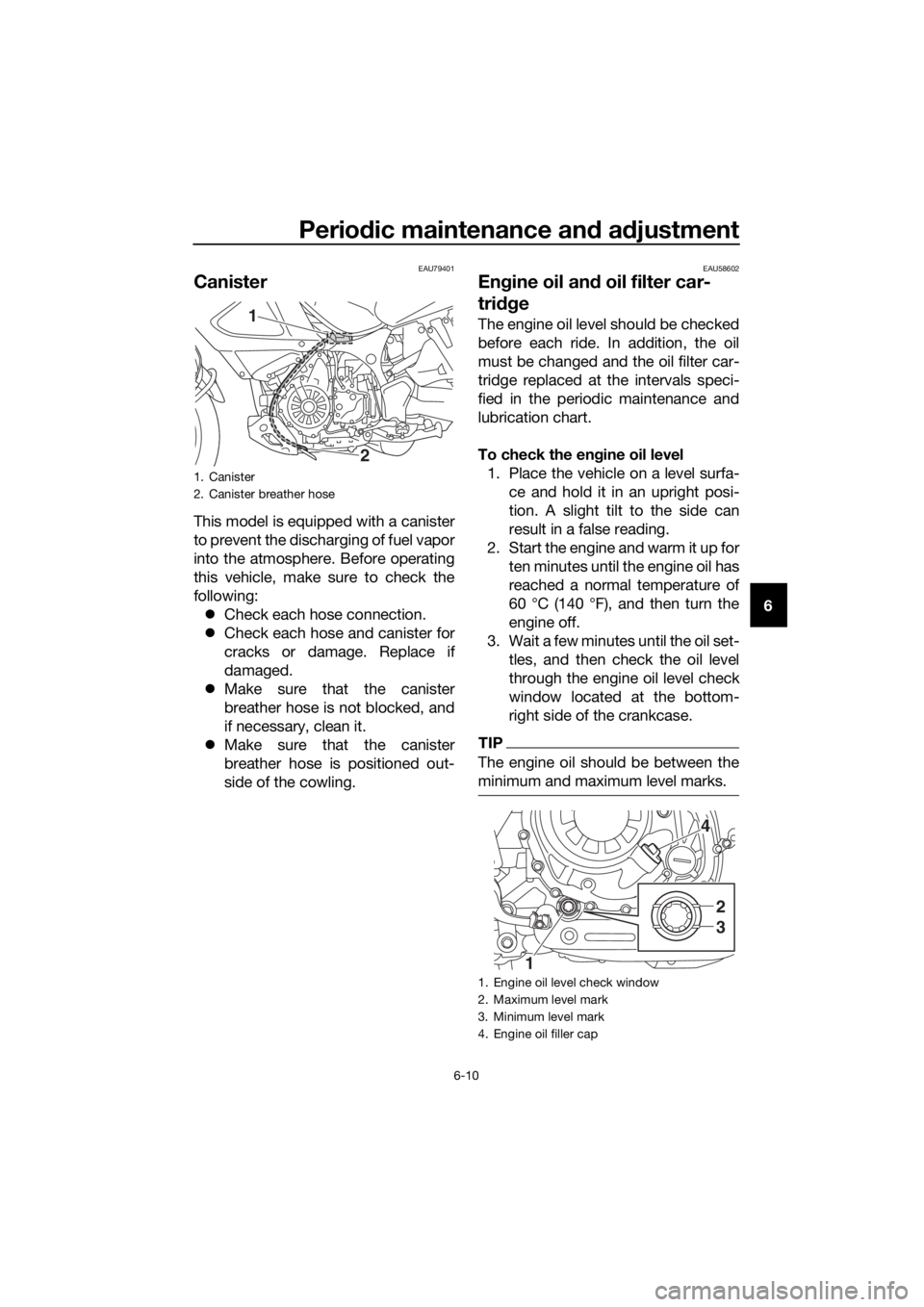

EAU79401

Canister

This model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather hose is not blocked, and

if necessary, clean it.

Make sure that the canister

breather hose is positioned out-

side of the cowling.

EAU58602

Engine oil an d oil filter car-

tri dge

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the en gine oil level

1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine and warm it up for ten minutes until the engine oil has

reached a normal temperature of

60 °C (140 °F), and then turn the

engine off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the engine oil level check

window located at the bottom-

right side of the crankcase.

TIP

The engine oil should be between the

minimum and maximum level marks.

1. Canister

2. Canister breather hose

2

1

1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

4. Engine oil filler cap

4

2

3

1

UBP8E0E0.book Page 10 Thursday, December 8, 2016 7:25 PM