torque YAMAHA XT1200ZE 2017 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: XT1200ZE, Model: YAMAHA XT1200ZE 2017Pages: 122, PDF Size: 3.36 MB

Page 68 of 122

Periodic maintenance an d a djustment

6-2

6

EAU17303

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replace-

ment, or repair of the emission control

devices and systems may be per-

formed by any repair establishment or

individual that is certified (if applicable).

Yamaha dealers are trained and equipped to perform these particular

services.

EAU49563

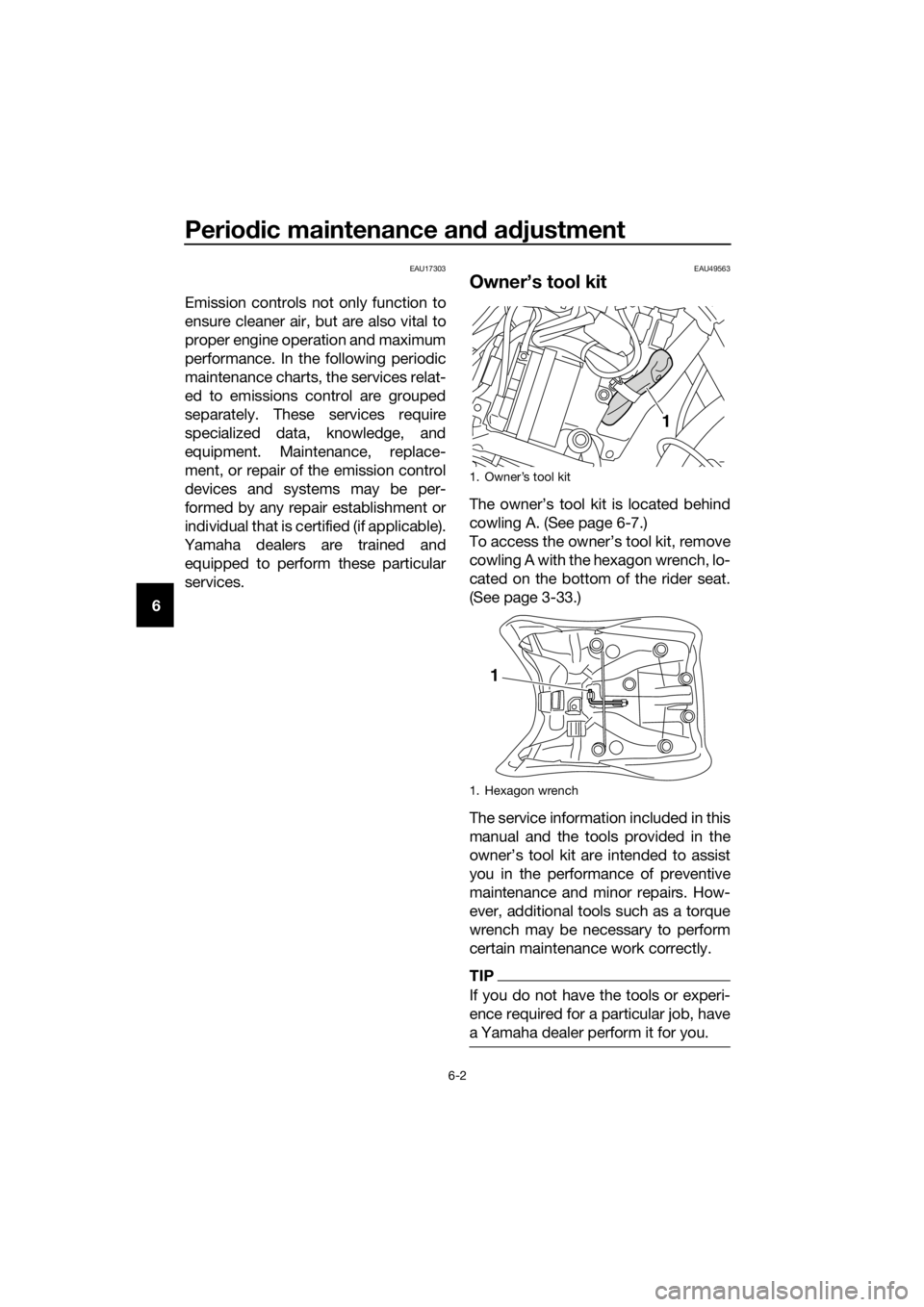

Owner’s tool kit

The owner’s tool kit is located behind

cowling A. (See page 6-7.)

To access the owner’s tool kit, remove

cowling A with the hexagon wrench, lo-

cated on the bottom of the rider seat.

(See page 3-33.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.

TIP

If you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you.

1. Owner’s tool kit

1. Hexagon wrench

1

1

UBP9E0E0.book Page 2 Wedne sday, February 8, 2017 8:34 AM

Page 75 of 122

Periodic maintenance an d a djustment

6-9

6

EAU19653

Checkin g the spark plu gs

The spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

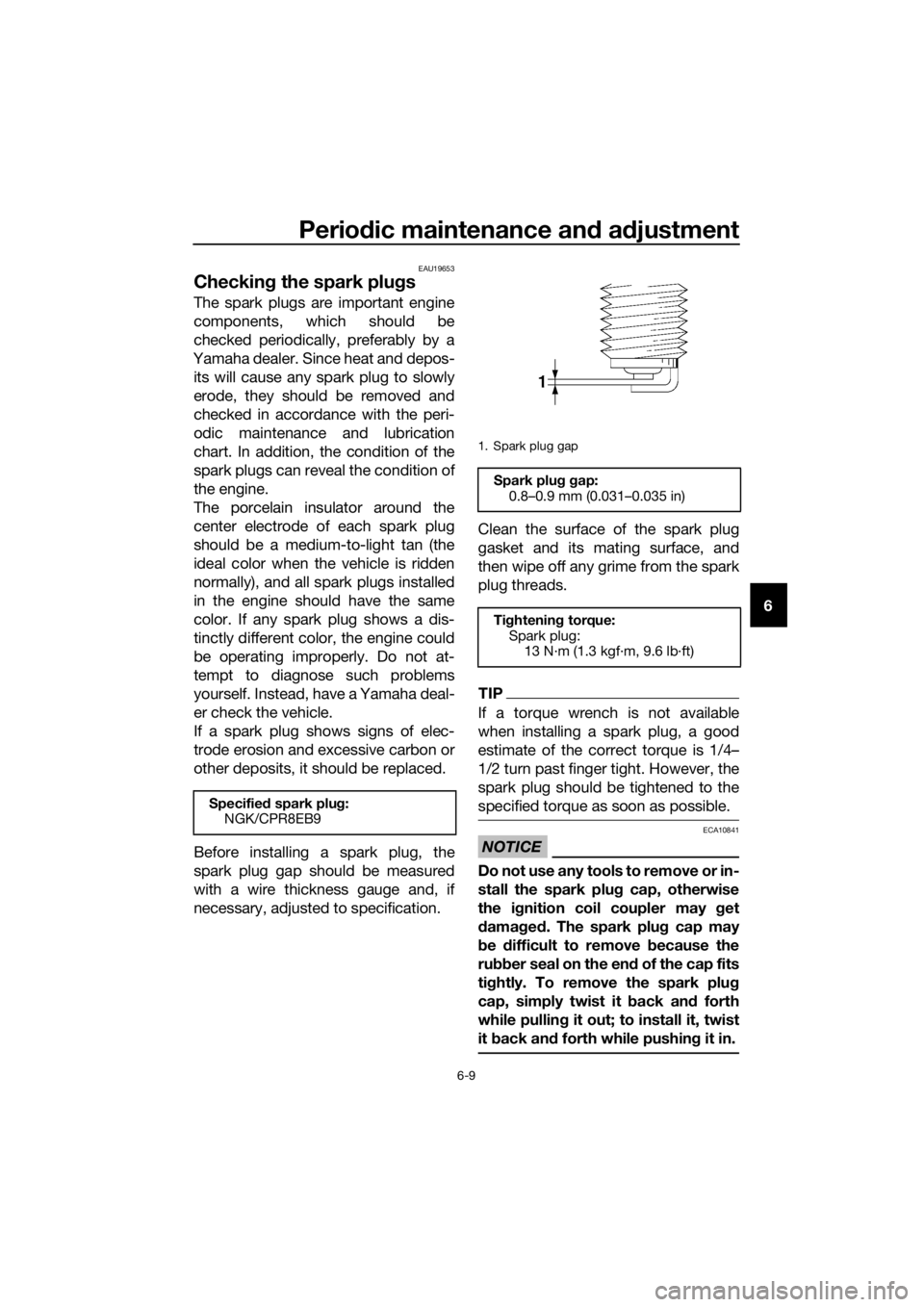

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification. Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

Specified spark plu g:

NGK/CPR8EB9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.6 lb·ft)

UBP9E0E0.book Page 9 Wedne sday, February 8, 2017 8:34 AM

Page 78 of 122

Periodic maintenance an d a djustment

6-12

6

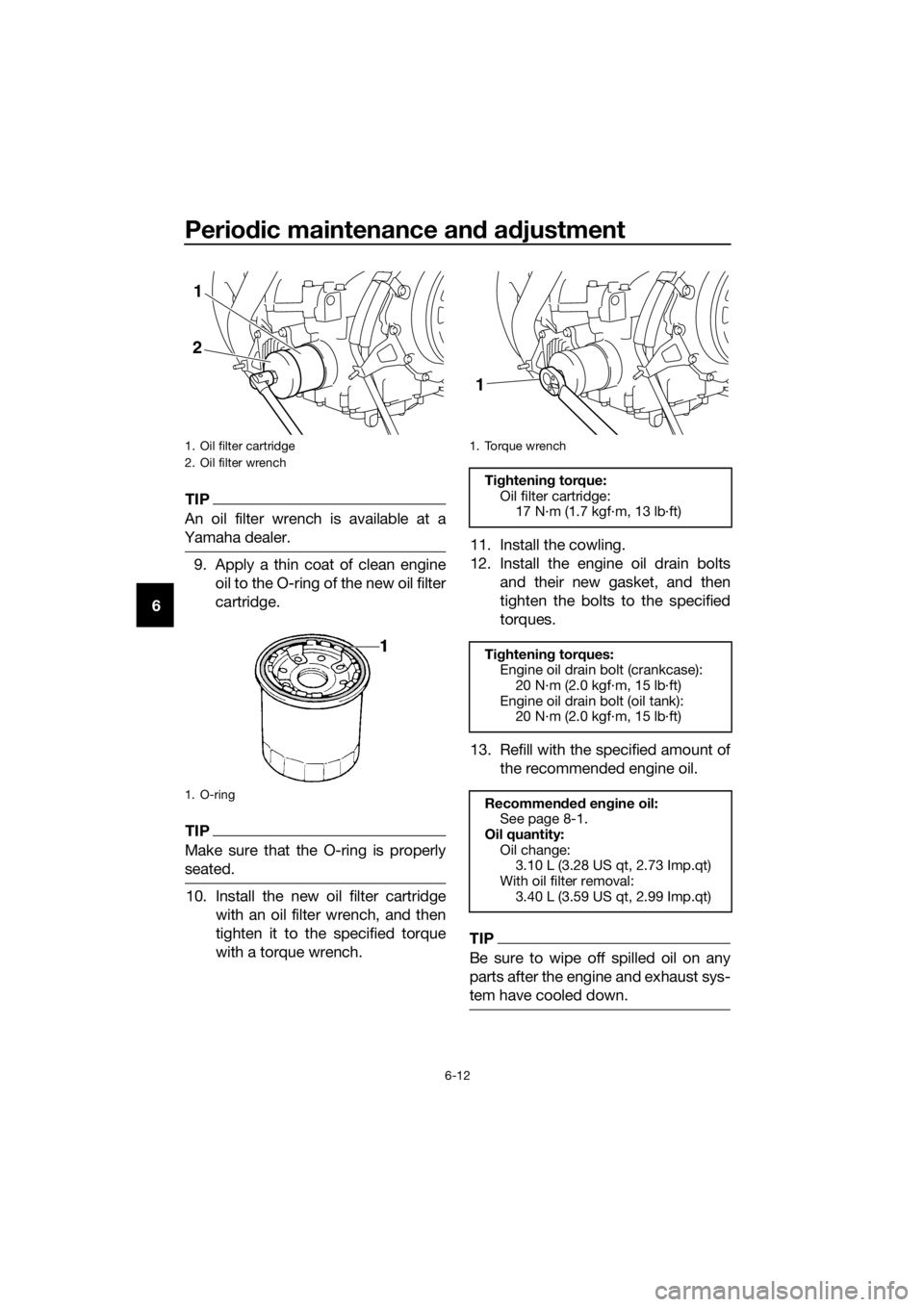

TIP

An oil filter wrench is available at a

Yamaha dealer.

9. Apply a thin coat of clean engine oil to the O-ring of the new oil filter

cartridge.

TIP

Make sure that the O-ring is properly

seated.

10. Install the new oil filter cartridge with an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench. 11. Install the cowling.

12. Install the engine oil drain bolts

and their new gasket, and then

tighten the bolts to the specified

torques.

13. Refill with the specified amount of the recommended engine oil.

TIP

Be sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.

1. Oil filter cartridge

2. Oil filter wrench

1. O-ring

2

1

1. Torque wrench

Tightening torque:

Oil filter cartridge: 17 N·m (1.7 kgf·m, 13 lb·ft)

Ti ghtening torques:

Engine oil drain bolt (crankcase):

20 N·m (2.0 kgf·m, 15 lb·ft)

Engine oil drain bolt (oil tank): 20 N·m (2.0 kgf·m, 15 lb·ft)

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:3.10 L (3.28 US qt, 2.73 Imp.qt)

With oil filter removal: 3.40 L (3.59 US qt, 2.99 Imp.qt)

1

UBP9E0E0.book Page 12 Wednesday, February 8, 2017 8:34 AM

Page 80 of 122

Periodic maintenance an d a djustment

6-14

6

EAU20017

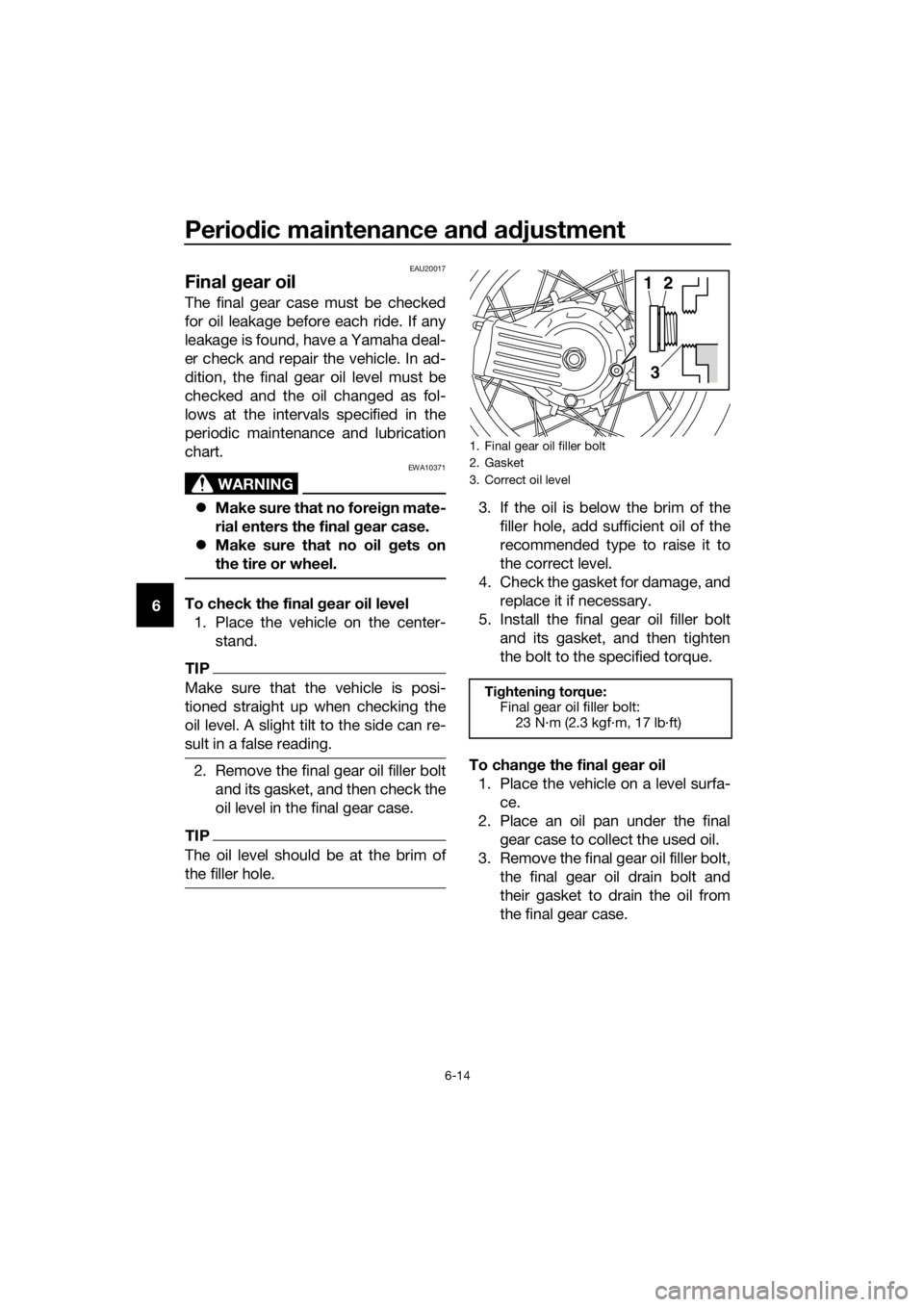

Final g ear oil

The final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the vehicle. In ad-

dition, the final gear oil level must be

checked and the oil changed as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

WARNING

EWA10371

Make sure that no forei gn mate-

rial enters the final g ear case.

Make sure that no oil g ets on

the tire or wheel.

To check the final gear oil level

1. Place the vehicle on the center- stand.

TIP

Make sure that the vehicle is posi-

tioned straight up when checking the

oil level. A slight tilt to the side can re-

sult in a false reading.

2. Remove the final gear oil filler boltand its gasket, and then check the

oil level in the final gear case.

TIP

The oil level should be at the brim of

the filler hole.

3. If the oil is below the brim of thefiller hole, add sufficient oil of the

recommended type to raise it to

the correct level.

4. Check the gasket for damage, and replace it if necessary.

5. Install the final gear oil filler bolt and its gasket, and then tighten

the bolt to the specified torque.

To chan ge the final gear oil

1. Place the vehicle on a level surfa- ce.

2. Place an oil pan under the final gear case to collect the used oil.

3. Remove the final gear oil filler bolt, the final gear oil drain bolt and

their gasket to drain the oil from

the final gear case.

1. Final gear oil filler bolt

2. Gasket

3. Correct oil level

Tightening torque:

Final gear oil filler bolt:

23 N·m (2.3 kgf·m, 17 lb·ft)

12

3

UBP9E0E0.book Page 14 Wednesday, February 8, 2017 8:34 AM

Page 81 of 122

Periodic maintenance an d a djustment

6-15

6

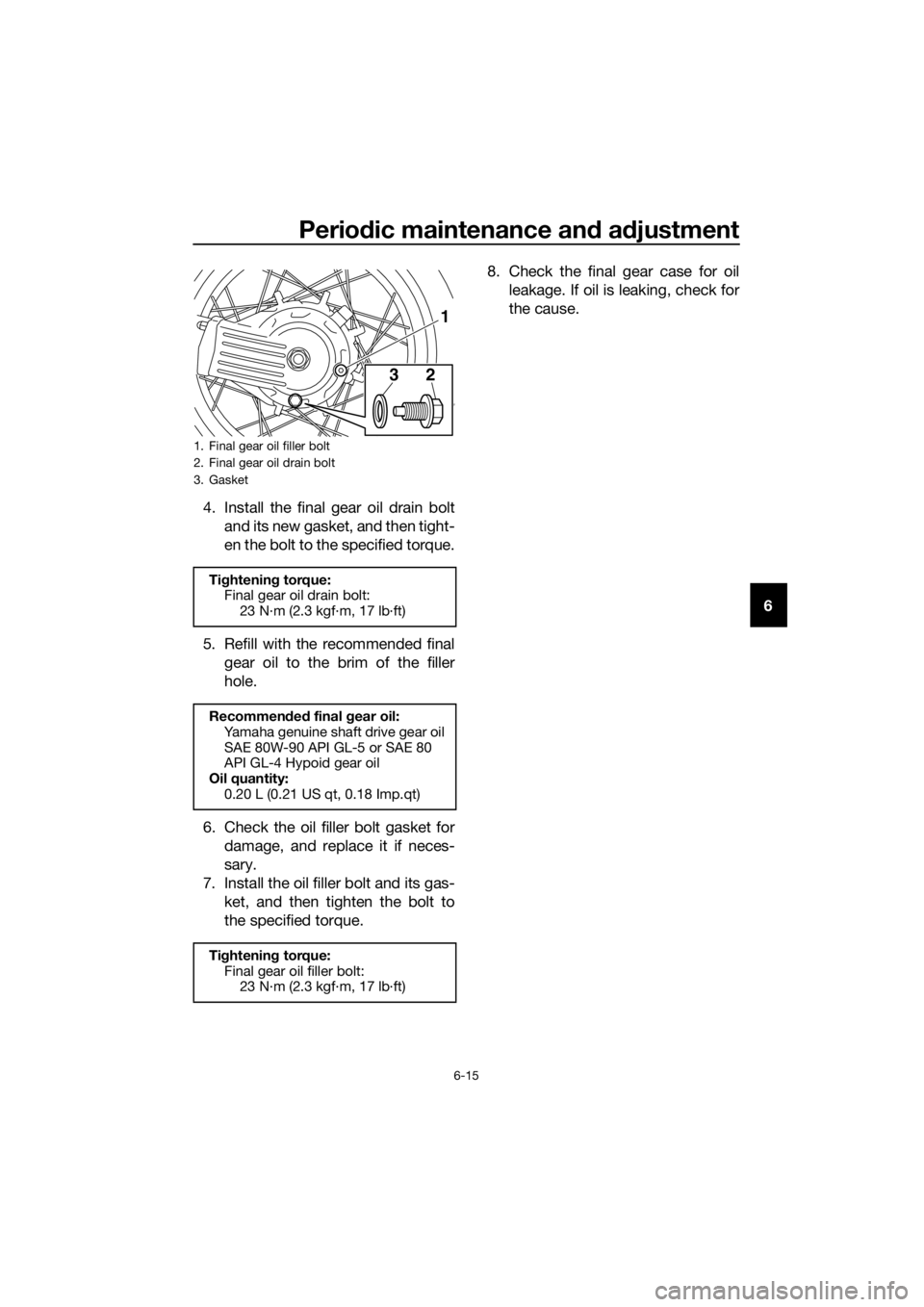

4. Install the final gear oil drain bolt

and its new gasket, and then tight-

en the bolt to the specified torque.

5. Refill with the recommended final gear oil to the brim of the filler

hole.

6. Check the oil filler bolt gasket for damage, and replace it if neces-

sary.

7. Install the oil filler bolt and its gas- ket, and then tighten the bolt to

the specified torque. 8. Check the final gear case for oil

leakage. If oil is leaking, check for

the cause.

1. Final gear oil filler bolt

2. Final gear oil drain bolt

3. Gasket

Tightening torque:

Final gear oil drain bolt:

23 N·m (2.3 kgf·m, 17 lb·ft)

Recommen ded final gear oil:

Yamaha genuine shaft drive gear oil

SAE 80W-90 API GL-5 or SAE 80

API GL-4 Hypoid gear oil

Oil quantity: 0.20 L (0.21 US qt, 0.18 Imp.qt)

Ti ghtening torque:

Final gear oil filler bolt: 23 N·m (2.3 kgf·m, 17 lb·ft)

23

1

UBP9E0E0.book Page 15 Wednesday, February 8, 2017 8:34 AM

Page 102 of 122

Periodic maintenance an d a djustment

6-36

6

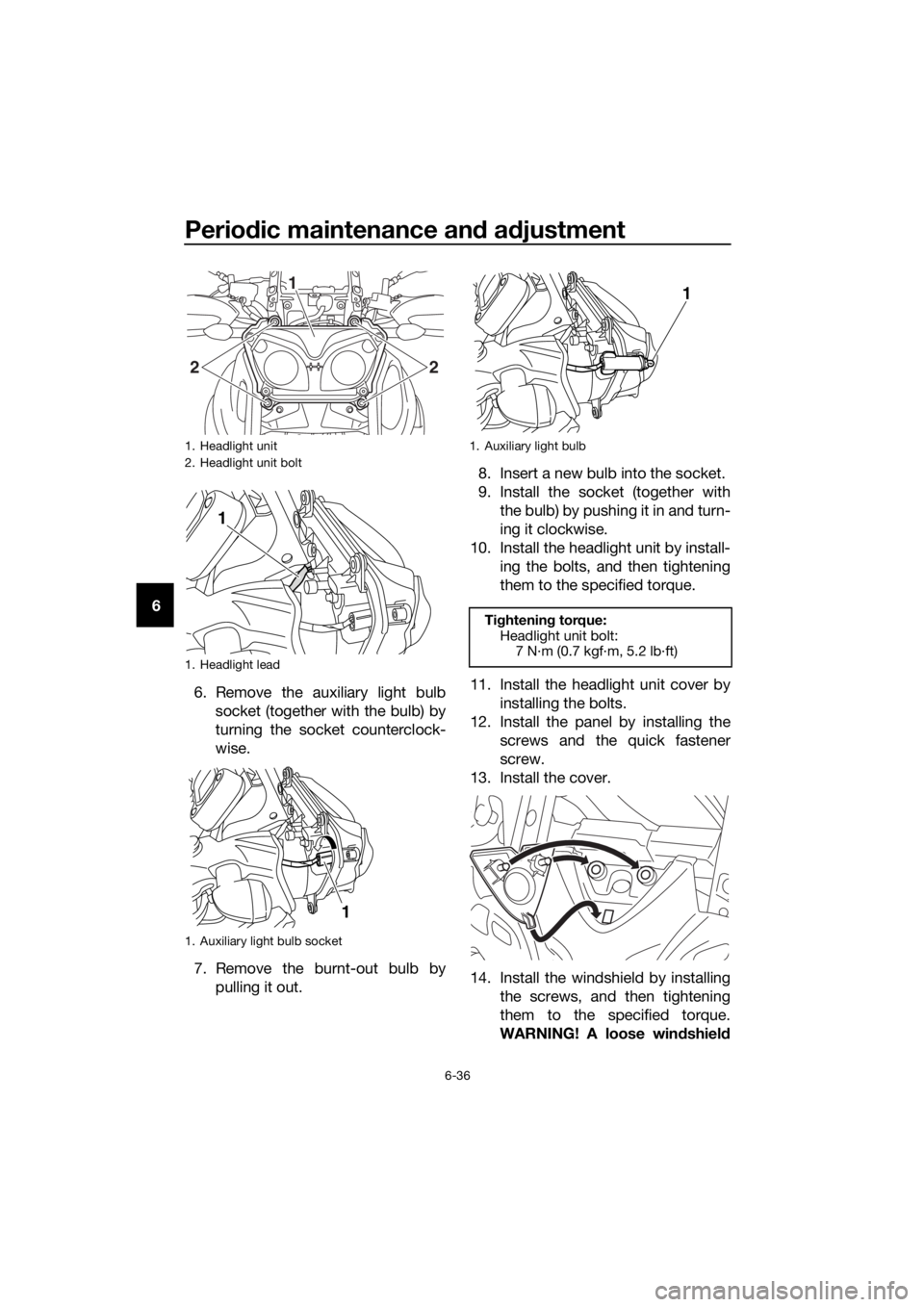

6. Remove the auxiliary light bulbsocket (together with the bulb) by

turning the socket counterclock-

wise.

7. Remove the burnt-out bulb by pulling it out. 8. Insert a new bulb into the socket.

9. Install the socket (together with

the bulb) by pushing it in and turn-

ing it clockwise.

10. Install the headlight unit by install- ing the bolts, and then tightening

them to the specified torque.

11. Install the headlight unit cover by installing the bolts.

12. Install the panel by installing the screws and the quick fastener

screw.

13. Install the cover.

14. Install the windshield by installing the screws, and then tightening

them to the specified torque.

WARNING! A loose win dshield

1. Headlight unit

2. Headlight unit bolt

1. Headlight lead

1. Auxiliary light bulb socket

1

2

2

1

1

1. Auxiliary light bulb

Tightening torque:

Headlight unit bolt: 7 N·m (0.7 kgf·m, 5.2 lb·ft)

1

UBP9E0E0.book Page 36 Wednesday, February 8, 2017 8:34 AM

Page 103 of 122

![YAMAHA XT1200ZE 2017 Owners Manual Periodic maintenance an d a djustment

6-37

6

coul

d cause an acci dent. Be

sure to tig hten the screws to the

specified torque.

[EWA15511] EAU70570

Turn si

gnal li ght and b rake/tail

lig ht

This YAMAHA XT1200ZE 2017 Owners Manual Periodic maintenance an d a djustment

6-37

6

coul

d cause an acci dent. Be

sure to tig hten the screws to the

specified torque.

[EWA15511] EAU70570

Turn si

gnal li ght and b rake/tail

lig ht

This](/img/51/53169/w960_53169-102.png)

Periodic maintenance an d a djustment

6-37

6

coul

d cause an acci dent. Be

sure to tig hten the screws to the

specified torque.

[EWA15511] EAU70570

Turn si

gnal li ght and b rake/tail

lig ht

This model is equipped with LED-type

turn signal lights and an LED-type

brake/tail light.

If a turn signal light or the brake/tail

light does not come on, have a

Yamaha dealer check it.

Ti ghtening torque:

Windshield screw: 0.5 N·m (0.05 kgf·m, 0.37 lb·ft)

UBP9E0E0.book Page 37 Wednesday, February 8, 2017 8:34 AM