light YAMAHA XV1600A 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: XV1600A, Model: YAMAHA XV1600A 2001Pages: 104, PDF Size: 20.37 MB

Page 40 of 104

OPERATION AND IMPORTANT RIDING POINTS

5-3

5

EAU01258

Starting a warm engine Follow the same procedure as for start-

ing a cold engine with the exception

that the starter (choke) is not required

when the engine is warm.

EAU00423

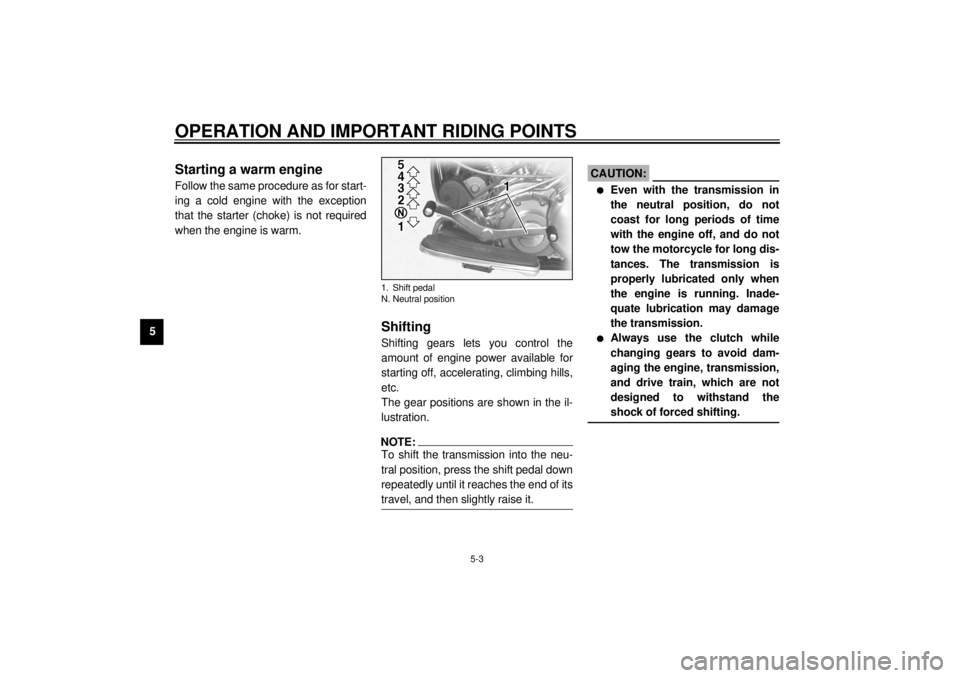

Shifting Shifting gears lets you control the

amount of engine power available for

starting off, accelerating, climbing hills,

etc.

The gear positions are shown in the il-

lustration.NOTE:@ To shift the transmission into the neu-

tral position, press the shift pedal down

repeatedly until it reaches the end of its

travel, and then slightly raise it. @

EC000048

CAUTION:@ l

Even with the transmission in

the neutral position, do not

coast for long periods of time

with the engine off, and do not

tow the motorcycle for long dis-

tances. The transmission is

properly lubricated only when

the engine is running. Inade-

quate lubrication may damage

the transmission.

l

Always use the clutch while

changing gears to avoid dam-

aging the engine, transmission,

and drive train, which are not

designed to withstand the

shock of forced shifting.

@

1. Shift pedal

N. Neutral position

E_5JA.book Page 3 Wednesday, September 13, 2000 6:06 PM

Page 41 of 104

OPERATION AND IMPORTANT RIDING POINTS

5-4

5

EAU02941

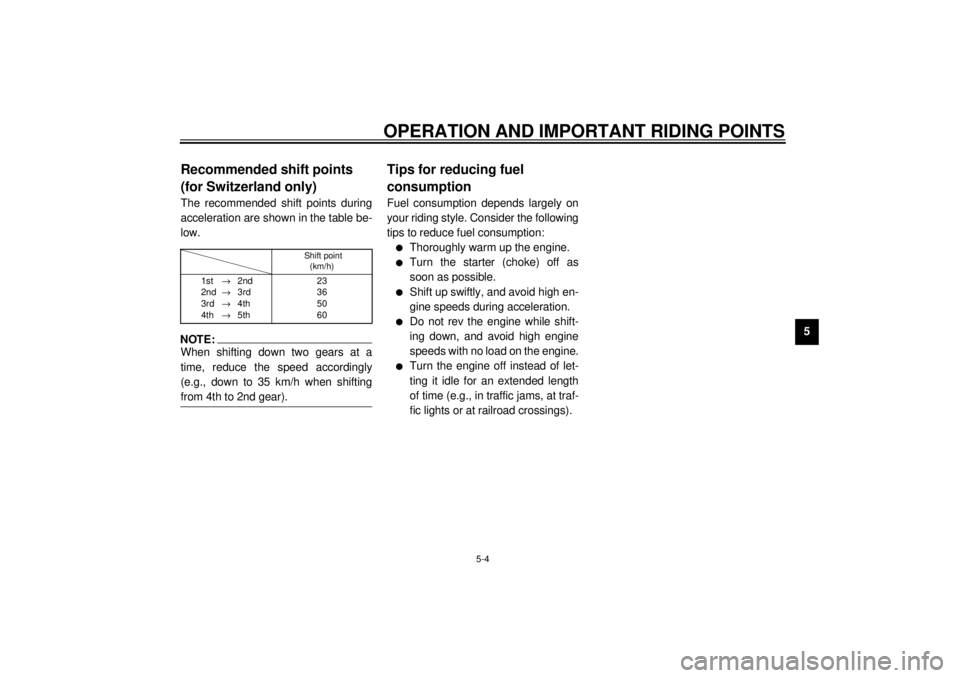

Recommended shift points

(for Switzerland only) The recommended shift points during

acceleration are shown in the table be-

low.CF-01ENOTE:@ When shifting down two gears at a

time, reduce the speed accordingly

(e.g., down to 35 km/h when shifting

from 4th to 2nd gear). @

EAU00424

Tips for reducing fuel

consumption Fuel consumption depends largely on

your riding style. Consider the following

tips to reduce fuel consumption:l

Thoroughly warm up the engine.

l

Turn the starter (choke) off as

soon as possible.

l

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

l

Do not rev the engine while shift-

ing down, and avoid high engine

speeds with no load on the engine.

l

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

Shift point

(km/h)

1st®2nd

2nd®3rd

3rd®4th

4th®5th23

36

50

60

E_5JA.book Page 4 Wednesday, September 13, 2000 6:06 PM

Page 45 of 104

6

PERIODIC MAINTENANCE AND MINOR REPAIR

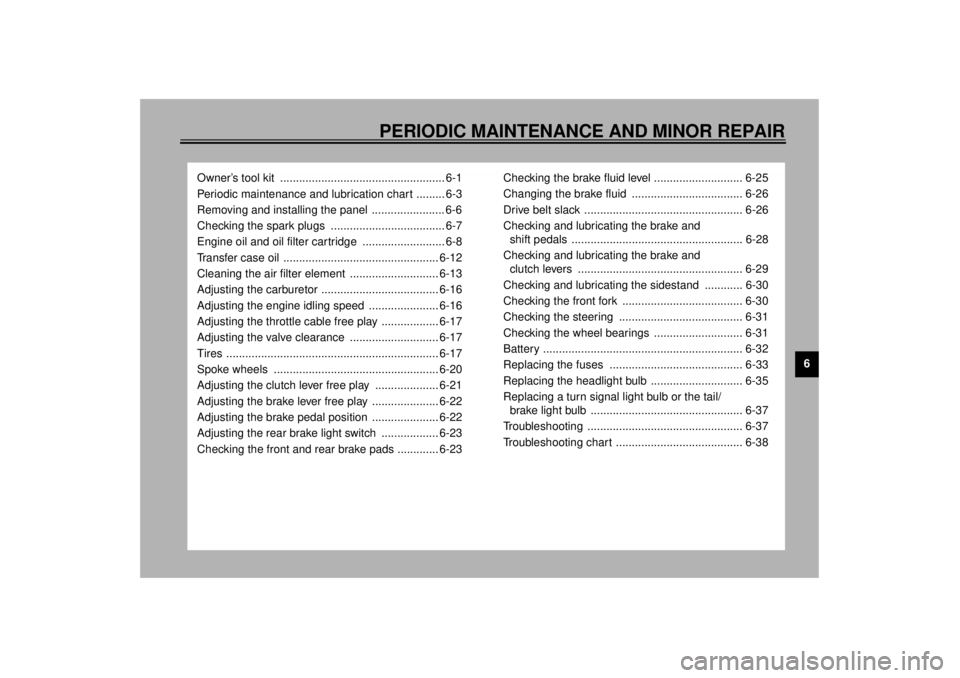

Owner’s tool kit .................................................... 6-1

Periodic maintenance and lubrication chart ......... 6-3

Removing and installing the panel ....................... 6-6

Checking the spark plugs .................................... 6-7

Engine oil and oil filter cartridge .......................... 6-8

Transfer case oil ................................................. 6-12

Cleaning the air filter element ............................ 6-13

Adjusting the carburetor ..................................... 6-16

Adjusting the engine idling speed ...................... 6-16

Adjusting the throttle cable free play .................. 6-17

Adjusting the valve clearance ............................ 6-17

Tires ................................................................... 6-17

Spoke wheels .................................................... 6-20

Adjusting the clutch lever free play .................... 6-21

Adjusting the brake lever free play ..................... 6-22

Adjusting the brake pedal position ..................... 6-22

Adjusting the rear brake light switch .................. 6-23

Checking the front and rear brake pads ............. 6-23Checking the brake fluid level ............................ 6-25

Changing the brake fluid ................................... 6-26

Drive belt slack .................................................. 6-26

Checking and lubricating the brake and

shift pedals ...................................................... 6-28

Checking and lubricating the brake and

clutch levers .................................................... 6-29

Checking and lubricating the sidestand ............ 6-30

Checking the front fork ...................................... 6-30

Checking the steering ....................................... 6-31

Checking the wheel bearings ............................ 6-31

Battery ............................................................... 6-32

Replacing the fuses .......................................... 6-33

Replacing the headlight bulb ............................. 6-35

Replacing a turn signal light bulb or the tail/

brake light bulb ................................................ 6-37

Troubleshooting ................................................. 6-37

Troubleshooting chart ........................................ 6-38

E_5JA.book Page 1 Wednesday, September 13, 2000 6:06 PM

Page 50 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-5

6

EAU03541

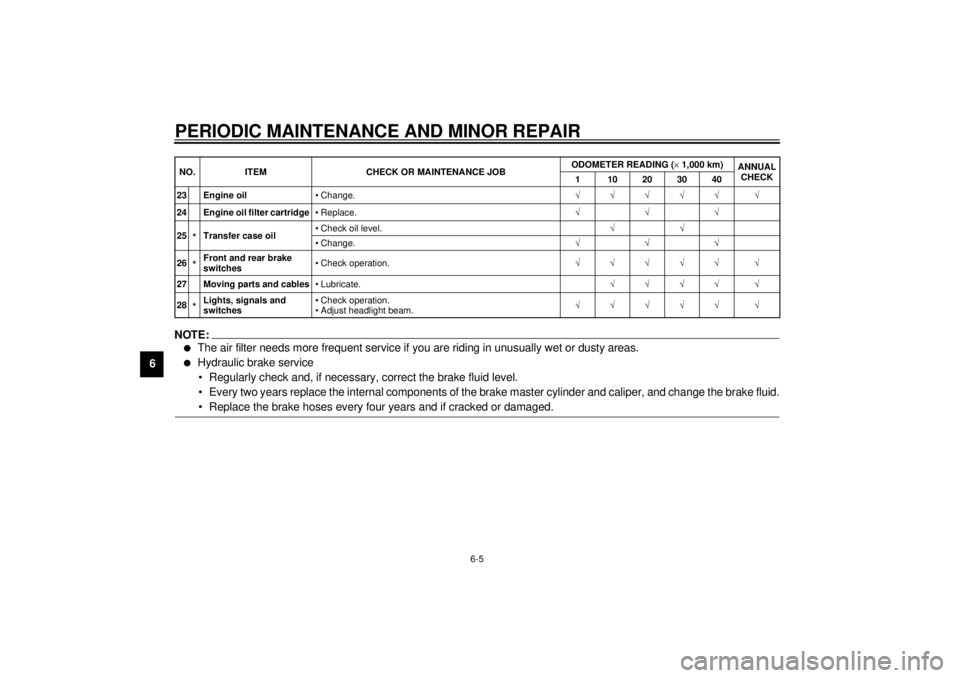

NOTE:@l

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

l

Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinder and caliper, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

@23 Engine oil• Change.ÖÖÖÖÖ Ö

24 Engine oil filter cartridge•Replace.ÖÖÖ

25

*Transfer case oil• Check oil level.ÖÖ

• Change.ÖÖÖ

26*Front and rear brake

switches• Check operation.ÖÖÖÖÖ Ö

27 Moving parts and cables• Lubricate.ÖÖÖÖ Ö

28*Lights, signals and

switches• Check operation.

• Adjust headlight beam.ÖÖÖÖÖ Ö NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (´1,000 km)

ANNUAL

CHECK

1 10203040

E_5JA_Periodic.fm Page 5 Monday, December 18, 2000 7:28 PM

Page 52 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-7

6

EAU01639

Checking the spark plugs The spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal col-

or when the motorcycle is ridden nor-

mally), and all spark plugs installed inthe engine should have the same color.

If any spark plug shows a distinctly dif-

ferent color, the engine could be defec-

tive. Do not attempt to diagnose such

problems yourself. Instead, have a

Yamaha dealer check the motorcycle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced.

Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

NOTE:@ If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible. @

a. Spark plug gap

Specified spark plug:

DPR7EA-9/NGK or

X22EPR-U9/DENSO

Spark plug gap:

0.8–0.9 mm

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kg)

E_5JA.book Page 7 Wednesday, September 13, 2000 6:06 PM

Page 53 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-8

6

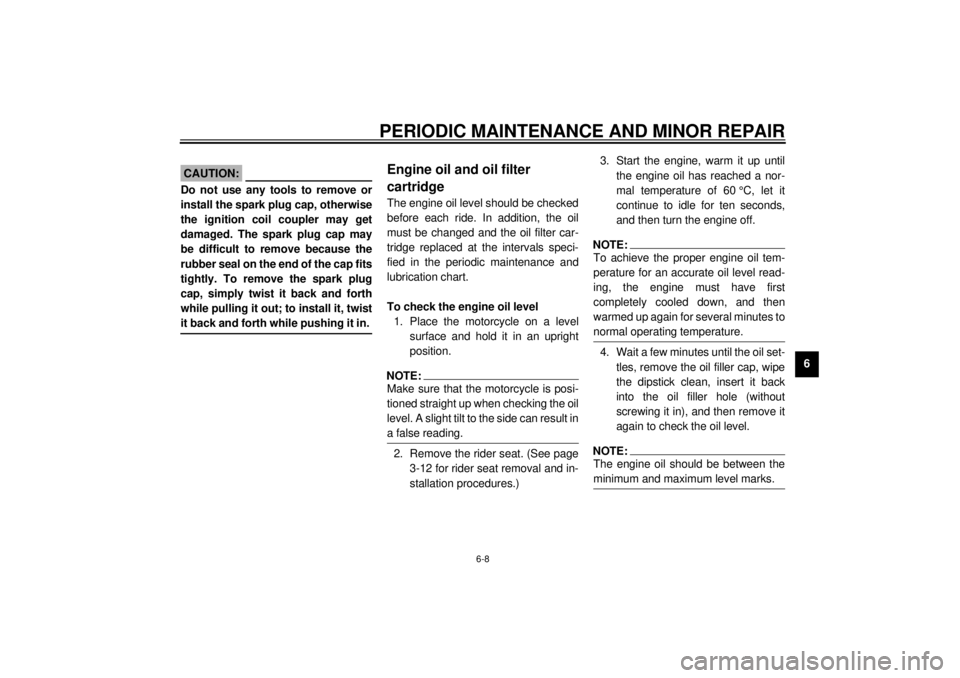

ECA00021

CAUTION:@ Do not use any tools to remove or

install the spark plug cap, otherwise

the ignition coil coupler may get

damaged. The spark plug cap may

be difficult to remove because the

rubber seal on the end of the cap fits

tightly. To remove the spark plug

cap, simply twist it back and forth

while pulling it out; to install it, twist

it back and forth while pushing it in. @

EAU03679

Engine oil and oil filter

cartridge The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:@ Make sure that the motorcycle is posi-

tioned straight up when checking the oil

level. A slight tilt to the side can result in

a false reading. @2. Remove the rider seat. (See page

3-12 for rider seat removal and in-

stallation procedures.)3. Start the engine, warm it up until

the engine oil has reached a nor-

mal temperature of 60 °C, let it

continue to idle for ten seconds,

and then turn the engine off.

NOTE:@ To achieve the proper engine oil tem-

perature for an accurate oil level read-

ing, the engine must have first

completely cooled down, and then

warmed up again for several minutes to

normal operating temperature. @4. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.NOTE:@ The engine oil should be between the

minimum and maximum level marks. @

E_5JA.book Page 8 Wednesday, September 13, 2000 6:06 PM

Page 57 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-12

6

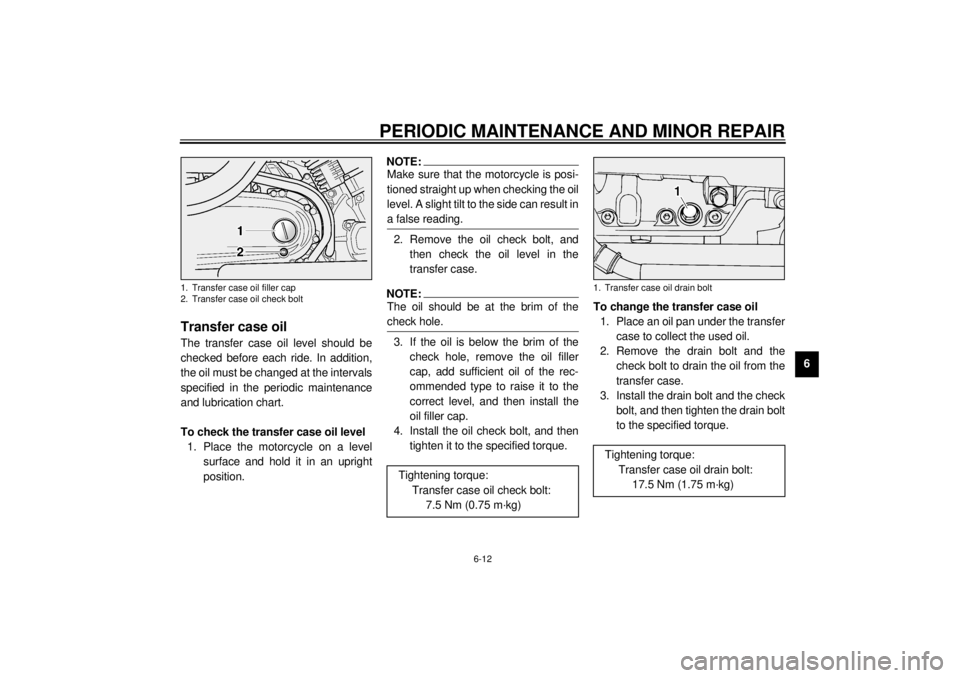

EAU03395

Transfer case oil The transfer case oil level should be

checked before each ride. In addition,

the oil must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

To check the transfer case oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.

NOTE:@ Make sure that the motorcycle is posi-

tioned straight up when checking the oil

level. A slight tilt to the side can result in

a false reading. @2. Remove the oil check bolt, and

then check the oil level in the

transfer case.NOTE:@ The oil should be at the brim of the

check hole. @3. If the oil is below the brim of the

check hole, remove the oil filler

cap, add sufficient oil of the rec-

ommended type to raise it to the

correct level, and then install the

oil filler cap.

4. Install the oil check bolt, and then

tighten it to the specified torque.To change the transfer case oil

1. Place an oil pan under the transfer

case to collect the used oil.

2. Remove the drain bolt and the

check bolt to drain the oil from the

transfer case.

3. Install the drain bolt and the check

bolt, and then tighten the drain bolt

to the specified torque.

1. Transfer case oil filler cap

2. Transfer case oil check bolt

Tightening torque:

Transfer case oil check bolt:

7.5 Nm (0.75 m·kg)

1. Transfer case oil drain boltTightening torque:

Transfer case oil drain bolt:

17.5 Nm (1.75 m·kg)

E_5JA.book Page 12 Wednesday, September 13, 2000 6:06 PM

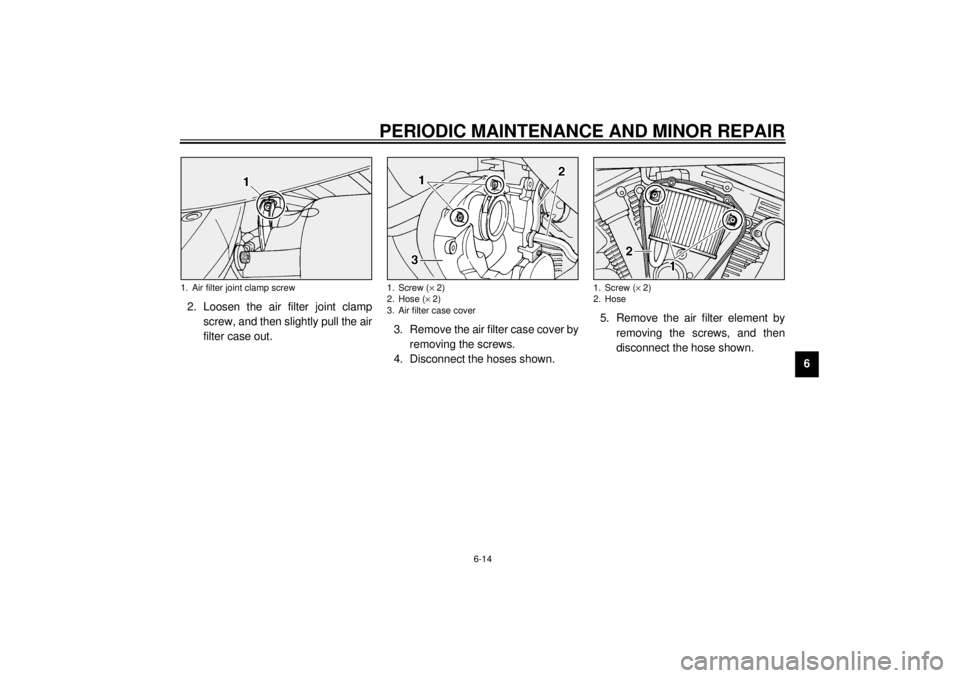

Page 59 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-14

6 2. Loosen the air filter joint clamp

screw, and then slightly pull the air

filter case out.3. Remove the air filter case cover by

removing the screws.

4. Disconnect the hoses shown.5. Remove the air filter element by

removing the screws, and then

disconnect the hose shown.

1. Air filter joint clamp screw

1. Screw (´ 2)

2. Hose (´ 2)

3. Air filter case cover

1. Screw (´ 2)

2. Hose

E_5JA.book Page 14 Wednesday, September 13, 2000 6:06 PM

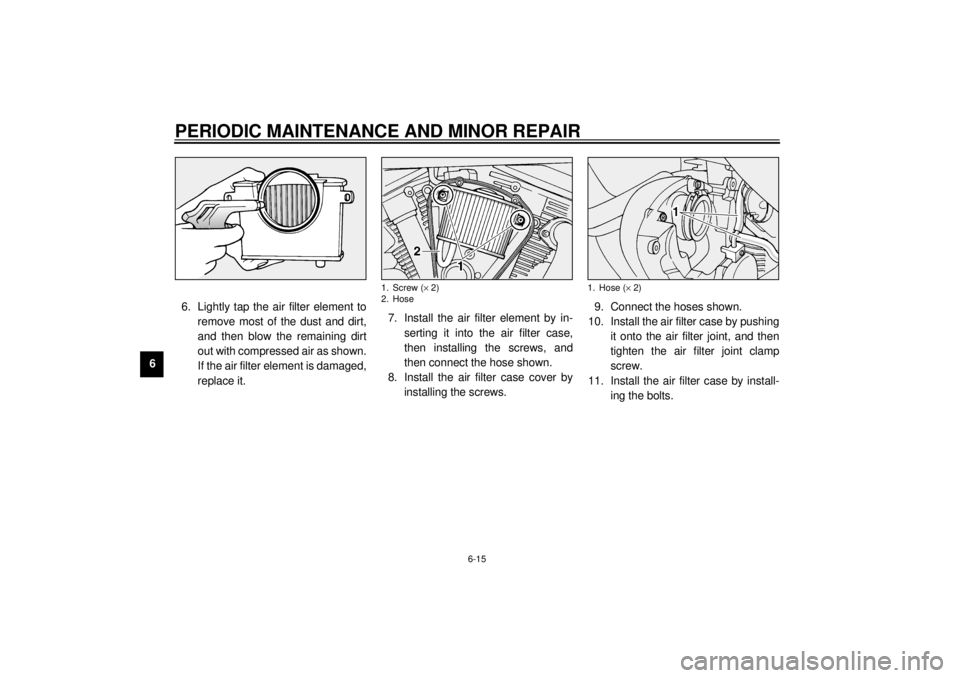

Page 60 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-15

66. Lightly tap the air filter element to

remove most of the dust and dirt,

and then blow the remaining dirt

out with compressed air as shown.

If the air filter element is damaged,

replace it.7. Install the air filter element by in-

serting it into the air filter case,

then installing the screws, and

then connect the hose shown.

8. Install the air filter case cover by

installing the screws.9. Connect the hoses shown.

10. Install the air filter case by pushing

it onto the air filter joint, and then

tighten the air filter joint clamp

screw.

11. Install the air filter case by install-

ing the bolts.

1. Screw (´ 2)

2. Hose

1. Hose (´ 2)

E_5JA.book Page 15 Wednesday, September 13, 2000 6:06 PM

Page 68 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

6

EW000109

WARNING

@ A soft or spongy feeling in the brake

pedal can indicate the presence of

air in the hydraulic system. If there

is air in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the motorcycle. Air in

the hydraulic system will diminish

the braking performance, which

may result in loss of control and an

accident. @

EAU00713

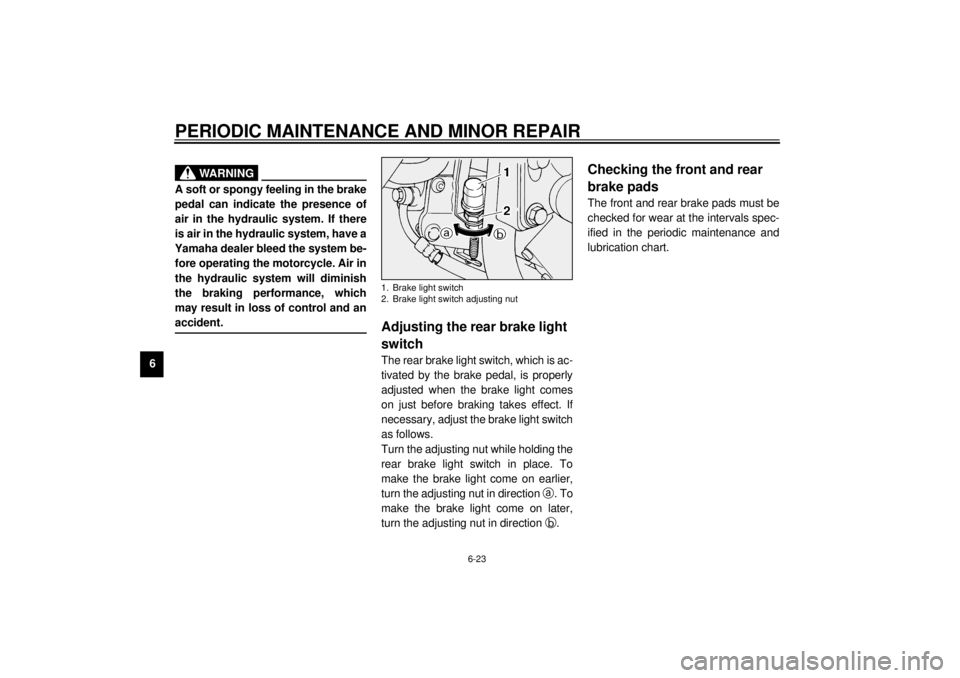

Adjusting the rear brake light

switch The rear brake light switch, which is ac-

tivated by the brake pedal, is properly

adjusted when the brake light comes

on just before braking takes effect. If

necessary, adjust the brake light switch

as follows.

Turn the adjusting nut while holding the

rear brake light switch in place. To

make the brake light come on earlier,

turn the adjusting nut in direction

a. To

make the brake light come on later,

turn the adjusting nut in direction

b.

EAU00721

Checking the front and rear

brake pads The front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

1. Brake light switch

2. Brake light switch adjusting nut

E_5JA.book Page 23 Wednesday, September 13, 2000 6:06 PM