maintenance YAMAHA XV535 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XV535, Model: YAMAHA XV535 2000Pages: 87, PDF Size: 17.84 MB

Page 46 of 87

R

6-8

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

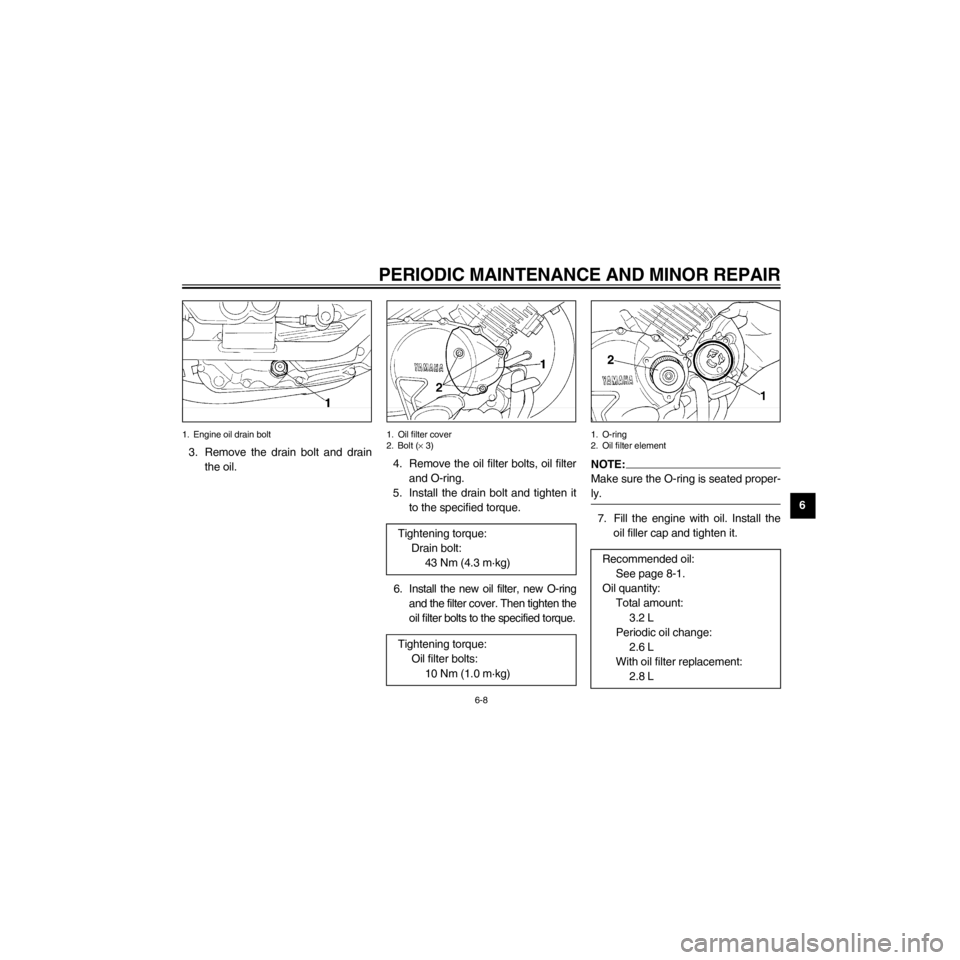

1. Engine oil drain bolt

3. Remove the drain bolt and drain

the oil.

1. Oil filter cover

2. Bolt (´ 3)

4. Remove the oil filter bolts, oil filter

and O-ring.

5. Install the drain bolt and tighten it

to the specified torque.

6. Install the new oil filter, new O-ring

and the filter cover. Then tighten the

oil filter bolts to the specified torque. Tightening torque:

Drain bolt:

43 Nm (4.3 mákg)

Tightening torque:

Oil filter bolts:

10 Nm (1.0 mákg)

1. O-ring

2. Oil filter element

NOTE:

Make sure the O-ring is seated proper-

ly.

7. Fill the engine with oil. Install the

oil filler cap and tighten it.

Recommended oil:

See page 8-1.

Oil quantity:

Total amount:

3.2 L

Periodic oil change:

2.6 L

With oil filter replacement:

2.8 L

Page 47 of 87

L

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

EC000066

CAUTION:

lDo not put in any chemical addi-

tives. Engine oil also lubricates

the clutch and additives could

cause clutch slippage.

lBe sure no foreign material en-

ters the crankcase.

8. Start the engine and warm it up for

a few minutes. While warming up,

check for oil leakage. If oil leakage

is found, stop the engine immedi-

ately and check for the cause.

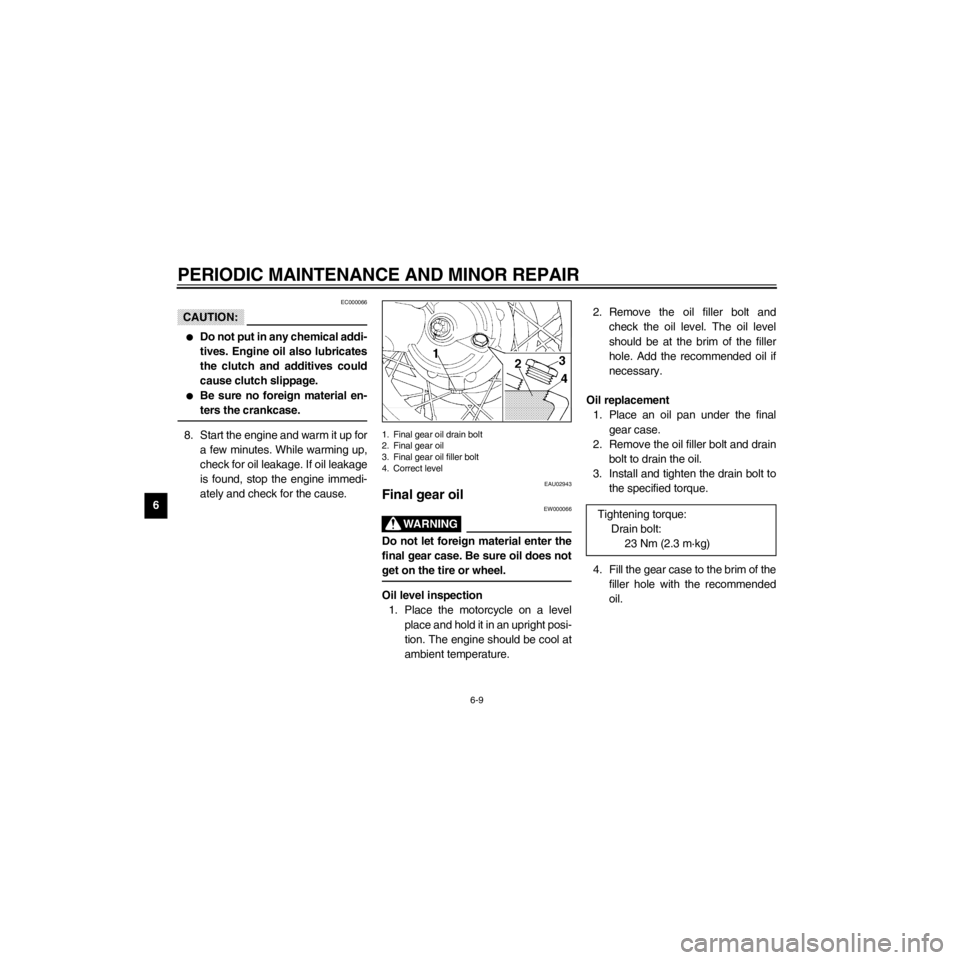

1. Final gear oil drain bolt

2. Final gear oil

3. Final gear oil filler bolt

4. Correct level

EAU02943

Final gear oil

EW000066

Do not let foreign material enter the

final gear case. Be sure oil does not

get on the tire or wheel.

Oil level inspection

1. Place the motorcycle on a level

place and hold it in an upright posi-

tion. The engine should be cool at

ambient temperature.2. Remove the oil filler bolt and

check the oil level. The oil level

should be at the brim of the filler

hole. Add the recommended oil if

necessary.

Oil replacement

1. Place an oil pan under the final

gear case.

2. Remove the oil filler bolt and drain

bolt to drain the oil.

3. Install and tighten the drain bolt to

the specified torque.

4. Fill the gear case to the brim of the

filler hole with the recommended

oil. Tightening torque:

Drain bolt:

23 Nm (2.3 mákg)

Page 48 of 87

R

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

NOTE:

ÒGL-4Ó is a quality and additive rating.

Hypoid gear oils rated ÒGL-5Ó or ÒGL-6Ó

may also be used.

5. Install and tighten the filler bolt to

the specified torque.

6. After replacing the final gear oil, be

sure to check for oil leakage. Final gear case capacity:

0.19 L

Recommended oil:

SAE 80 API GL-4 Hypoid gear oil

If desired, an SAE 80W90 hypoid

gear oil may be used for all

conditions.

Tightening torque:

Oil filler bolt:

23 Nm (2.3 mákg)

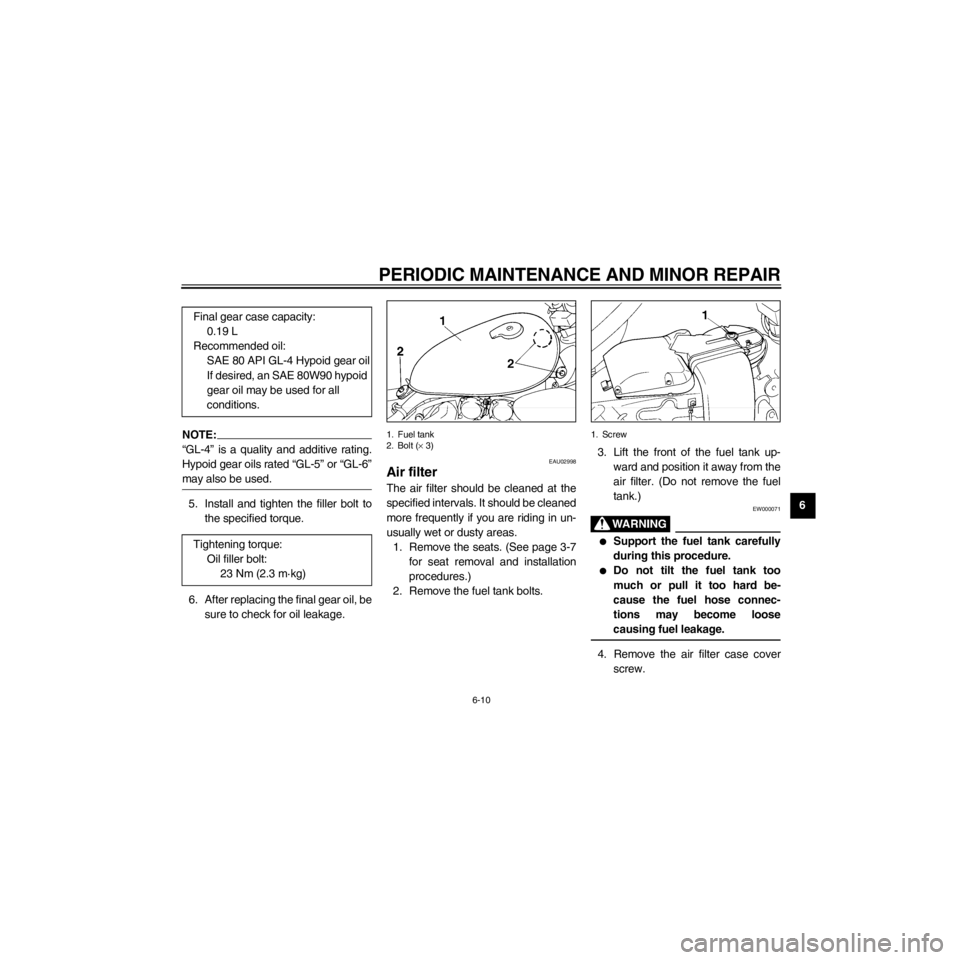

1. Fuel tank

2. Bolt (´ 3)

EAU02998

Air filter

The air filter should be cleaned at the

specified intervals. It should be cleaned

more frequently if you are riding in un-

usually wet or dusty areas.

1. Remove the seats. (See page 3-7

for seat removal and installation

procedures.)

2. Remove the fuel tank bolts.

1. Screw

3. Lift the front of the fuel tank up-

ward and position it away from the

air filter. (Do not remove the fuel

tank.)

EW000071

lSupport the fuel tank carefully

during this procedure.

lDo not tilt the fuel tank too

much or pull it too hard be-

cause the fuel hose connec-

tions may become loose

causing fuel leakage.

4. Remove the air filter case cover

screw.

Page 49 of 87

L

6-11

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

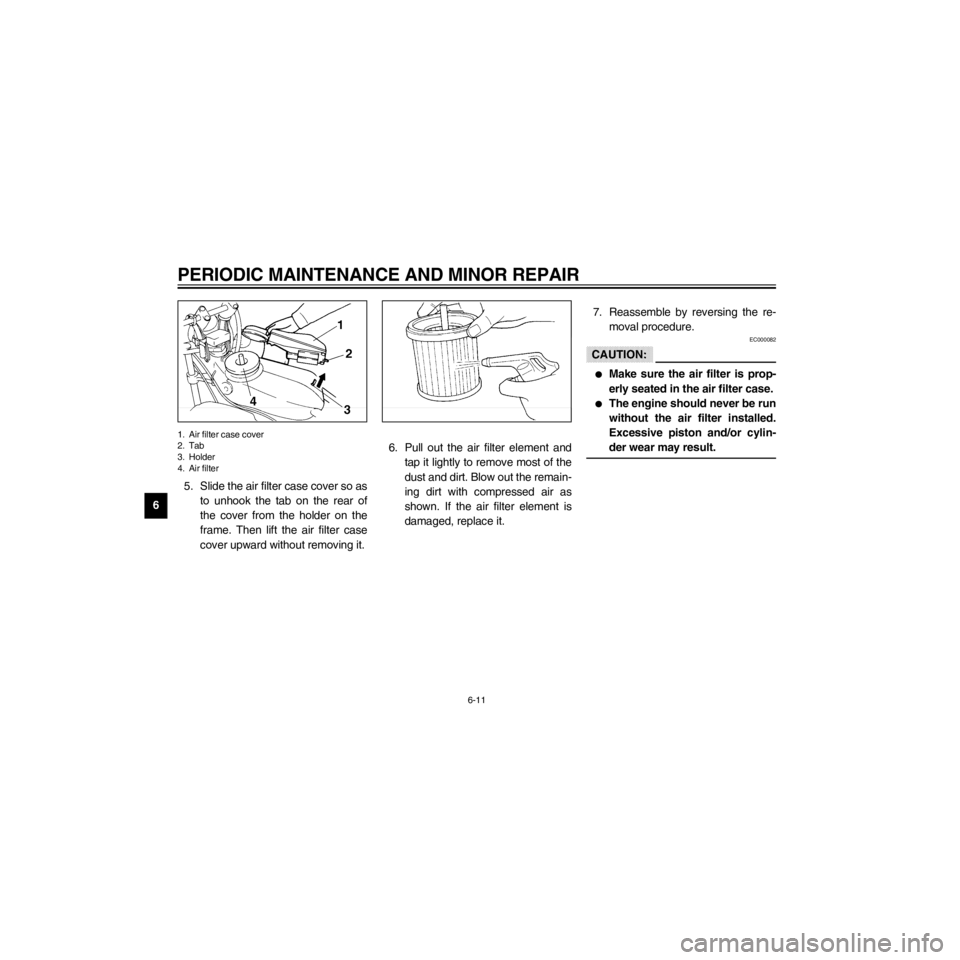

1. Air filter case cover

2. Tab

3. Holder

4. Air filter

5. Slide the air filter case cover so as

to unhook the tab on the rear of

the cover from the holder on the

frame. Then lift the air filter case

cover upward without removing it.

6. Pull out the air filter element and

tap it lightly to remove most of the

dust and dirt. Blow out the remain-

ing dirt with compressed air as

shown. If the air filter element is

damaged, replace it.7. Reassemble by reversing the re-

moval procedure.

EC000082

CAUTION:

lMake sure the air filter is prop-

erly seated in the air filter case.

lThe engine should never be run

without the air filter installed.

Excessive piston and/or cylin-

der wear may result.

Page 50 of 87

R

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

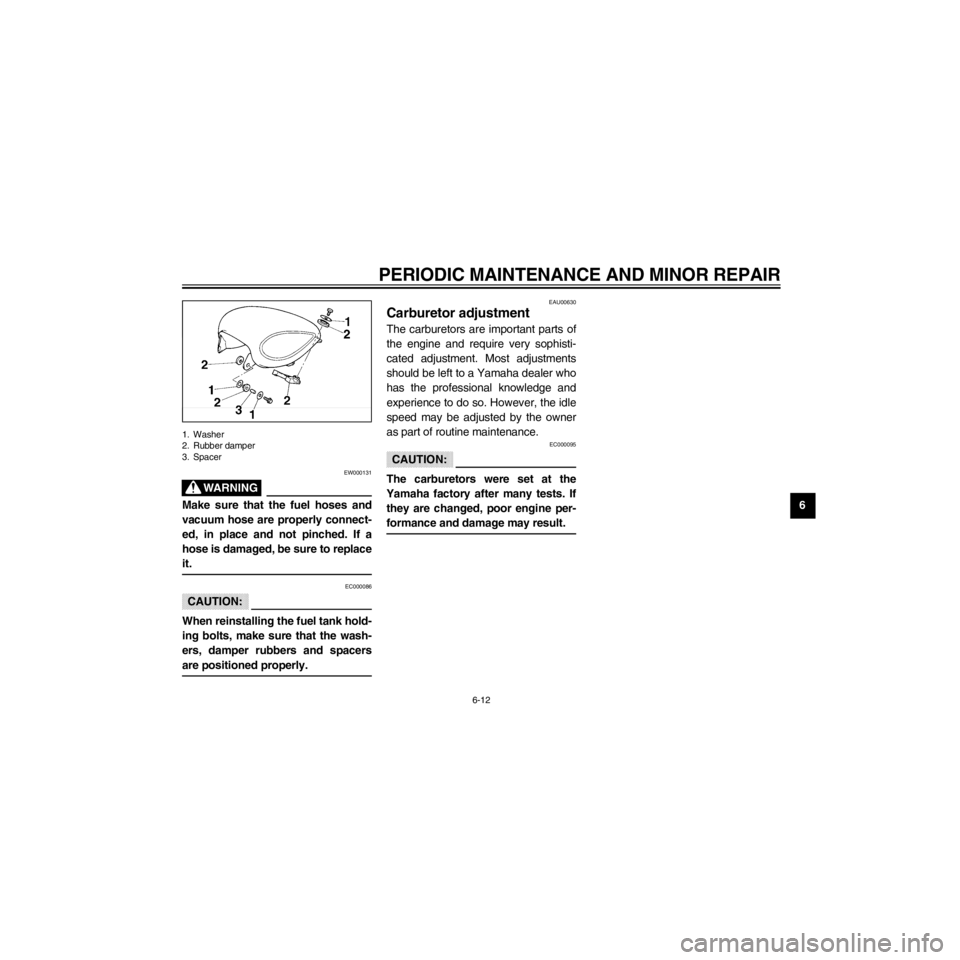

1. Washer

2. Rubber damper

3. Spacer

EW000131

Make sure that the fuel hoses and

vacuum hose are properly connect-

ed, in place and not pinched. If a

hose is damaged, be sure to replace

it.

EC000086

CAUTION:

When reinstalling the fuel tank hold-

ing bolts, make sure that the wash-

ers, damper rubbers and spacers

are positioned properly.

EAU00630

Carburetor adjustment

The carburetors are important parts of

the engine and require very sophisti-

cated adjustment. Most adjustments

should be left to a Yamaha dealer who

has the professional knowledge and

experience to do so. However, the idle

speed may be adjusted by the owner

as part of routine maintenance.

EC000095

CAUTION:

The carburetors were set at the

Yamaha factory after many tests. If

they are changed, poor engine per-

formance and damage may result.

Page 51 of 87

L

6-13

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

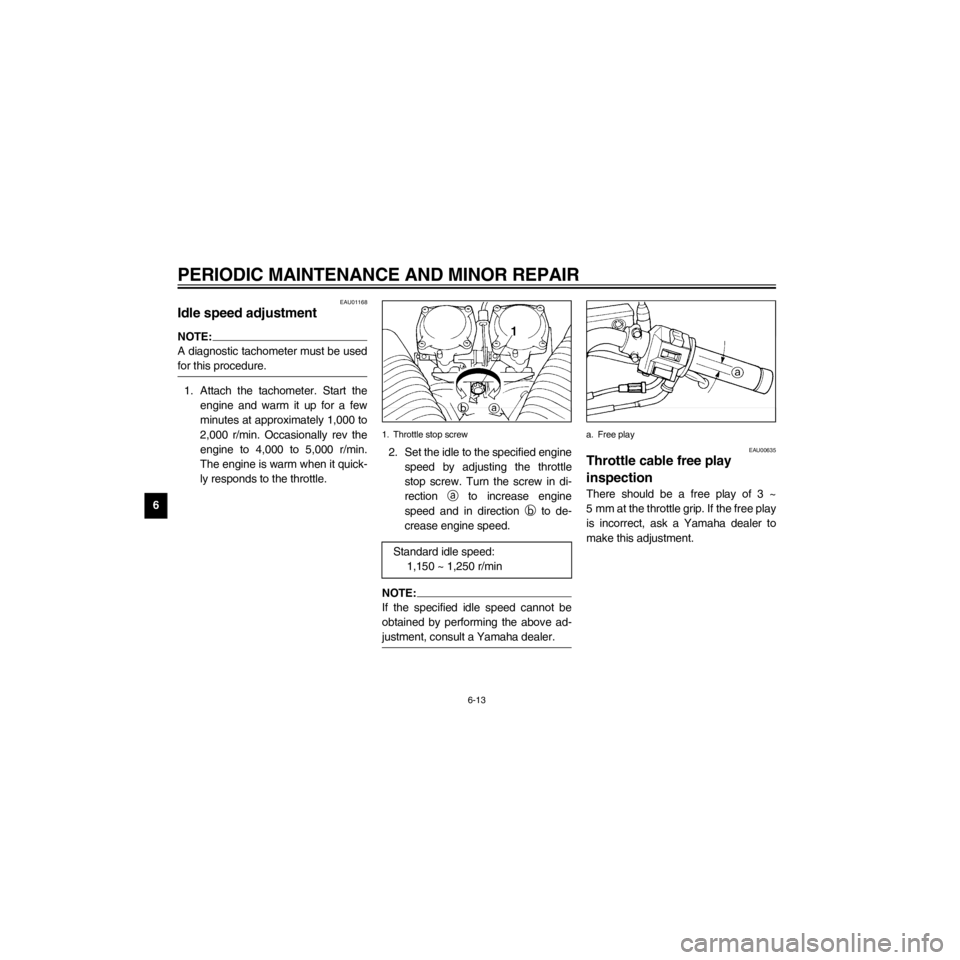

EAU01168

Idle speed adjustment

NOTE:

A diagnostic tachometer must be used

for this procedure.

1. Attach the tachometer. Start the

engine and warm it up for a few

minutes at approximately 1,000 to

2,000 r/min. Occasionally rev the

engine to 4,000 to 5,000 r/min.

The engine is warm when it quick-

ly responds to the throttle.

1. Throttle stop screw

2. Set the idle to the specified engine

speed by adjusting the throttle

stop screw. Turn the screw in di-

rectiona

to increase engine

speed and in direction b

to de-

crease engine speed.

NOTE:

If the specified idle speed cannot be

obtained by performing the above ad-

justment, consult a Yamaha dealer.Standard idle speed:

1,150 ~ 1,250 r/min

a. Free play

EAU00635

Throttle cable free play

inspection

There should be a free play of 3 ~

5 mm at the throttle grip. If the free play

is incorrect, ask a Yamaha dealer to

make this adjustment.

Page 52 of 87

R

6-14

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

EAU00637

Valve clearance adjustment

The correct valve clearance changes

with use, resulting in improper fuel/air

supply or engine noise. To prevent this,

the valve clearance must be adjusted

regularly. This adjustment however,

should be left to a professional

Yamaha service technician.

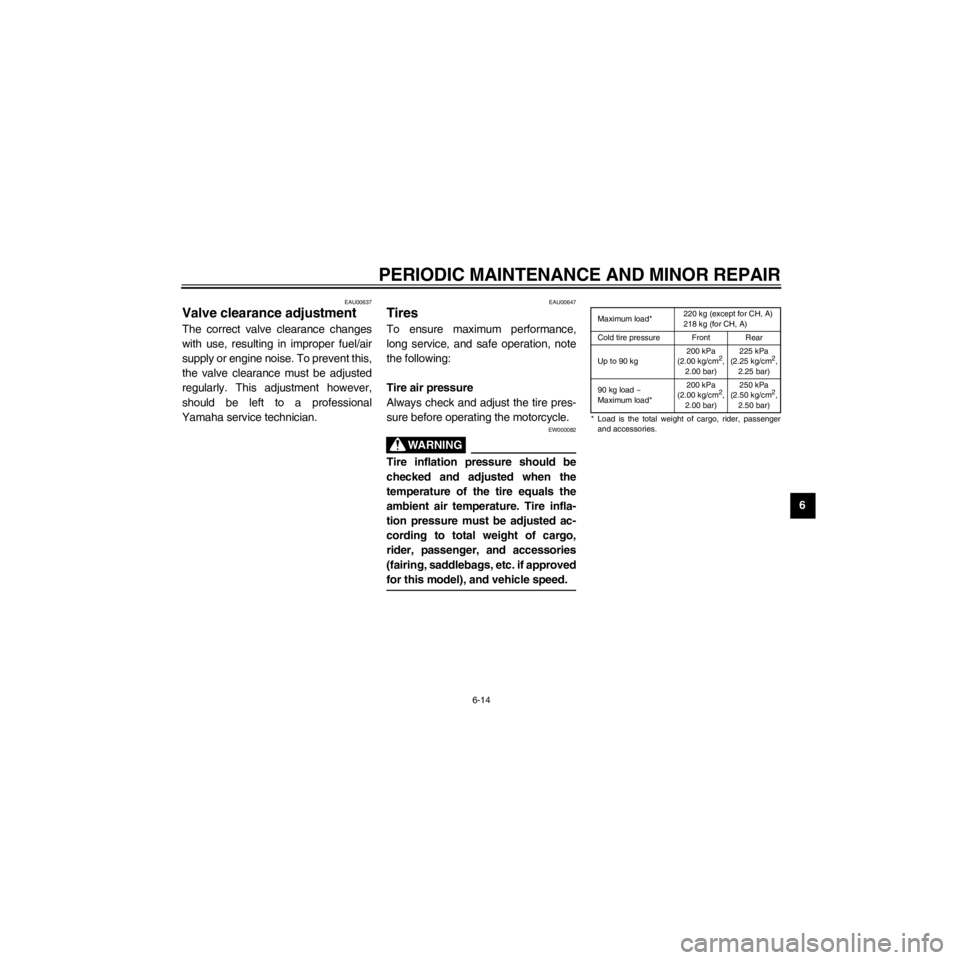

EAU00647

Tires

To ensure maximum performance,

long service, and safe operation, note

the following:

Tire air pressure

Always check and adjust the tire pres-

sure before operating the motorcycle.

EW000082

Tire inflation pressure should be

checked and adjusted when the

temperature of the tire equals the

ambient air temperature. Tire infla-

tion pressure must be adjusted ac-

cording to total weight of cargo,

rider, passenger, and accessories

(fairing, saddlebags, etc. if approved

for this model), and vehicle speed.

Maximum load*220 kg (except for CH, A)

218 kg (for CH, A)

Cold tire pressure Front Rear

Up to 90 kg200 kPa

(2.00 kg/cm

2,

2.00 bar)225 kPa

(2.25 kg/cm2,

2.25 bar)

90 kg load ~

Maximum load*200 kPa

(2.00 kg/cm

2,

2.00 bar)250 kPa

(2.50 kg/cm2,

2.50 bar)

* Load is the total weight of cargo, rider, passenger

and accessories.

Page 53 of 87

L

6-15

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

EW000083

Proper loading of your motorcycle

is important for several characteris-

tics of your motorcycle, such as

handling, braking, performance and

safety. Do not carry loosely packed

items that can shift. Securely pack

your heaviest items close to the

center of the motorcycle, and dis-

tribute the weight evenly from side

to side. Properly adjust the suspen-

sion for your load, and check the

condition and pressure of your tires.

NEVER OVERLOAD YOUR MOTOR-

CYCLE. Make sure the total weight

of the cargo, rider, passenger, and

accessories (fairing, saddlebags,

etc. if approved for this model) does

not exceed the maximum load of the

motorcycle. Operation of an over-

loaded motorcycle could cause tire

damage, an accident, or even injury.

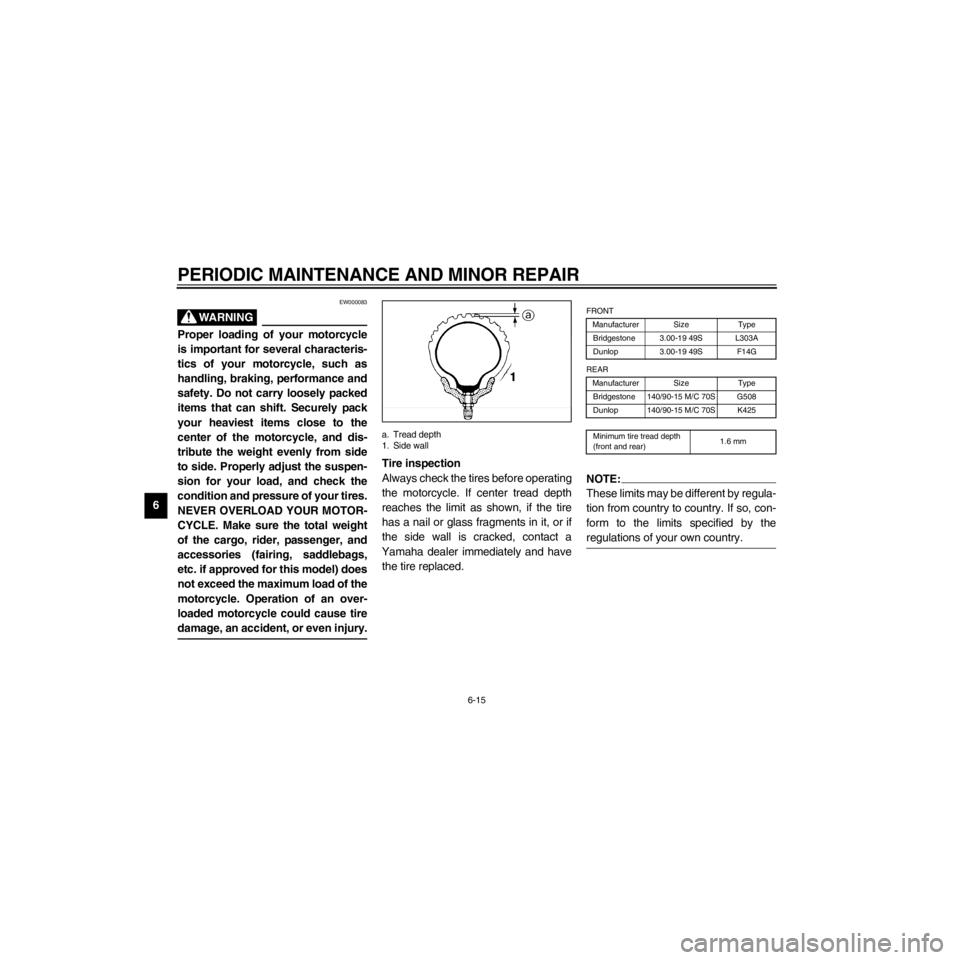

a. Tread depth

1. Side wall

Tire inspection

Always check the tires before operating

the motorcycle. If center tread depth

reaches the limit as shown, if the tire

has a nail or glass fragments in it, or if

the side wall is cracked, contact a

Yamaha dealer immediately and have

the tire replaced.

NOTE:

These limits may be different by regula-

tion from country to country. If so, con-

form to the limits specified by the

regulations of your own country.

FRONT

Manufacturer Size Type

Bridgestone 3.00-19 49S L303A

Dunlop 3.00-19 49S F14G

REAR

Manufacturer Size Type

Bridgestone 140/90-15 M/C 70S G508

Dunlop 140/90-15 M/C 70S K425

Minimum tire tread depth

(front and rear)1.6 mm

Page 54 of 87

R

6-16

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

EAU00681

lOperating the motorcycle with

excessively worn tires decrease

riding stability and can lead to

loss of control. Have excessive-

ly worn tires replaced by a

Yamaha dealer immediately.

Brakes, tires, and related wheel

parts replacement should be

left to a Yamaha Service Techni-

cian.

lPatching a punctured tube is

not recommended. If it is abso-

lutely necessary to do so, use

great care and replace the tube

as soon as possible with a good

quality replacement.

EAU00685

Wheels

To ensure maximum performance,

long service, and safe operation, note

the following:

lAlways inspect the wheels before

a ride. Check for cracks, bends or

warpage of the wheel. Be sure the

spokes are tight and undamaged.

If any abnormal condition exists in

a wheel, consult a Yamaha dealer.

Do not attempt even small repairs

to the wheel. If a wheel is de-

formed or cracked, it must be re-

placed.

lTires and wheels should be bal-

anced whenever either one is

changed or replaced. Failure to

have a wheel balanced can result

in poor performance, adverse han-

dling characteristics, and short-

ened tire life.

lRide at moderate speeds after

changing a tire since the tire sur-

face must first be broken in for it to

develop its optimal characteristics.

Page 55 of 87

L

6-17

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

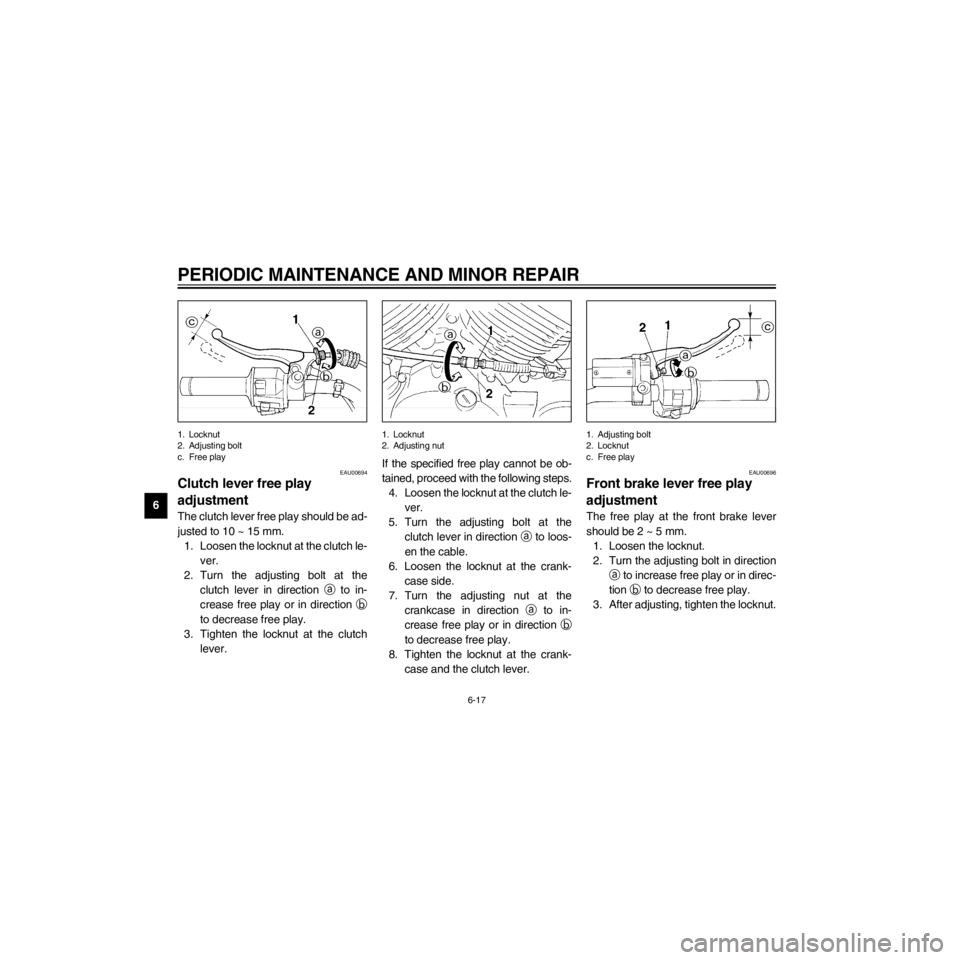

1. Locknut

2. Adjusting bolt

c. Free play

EAU00694

Clutch lever free play

adjustment

The clutch lever free play should be ad-

justed to 10 ~ 15 mm.

1. Loosen the locknut at the clutch le-

ver.

2. Turn the adjusting bolt at the

clutch lever in direction a

to in-

crease free play or in direction b

to decrease free play.

3. Tighten the locknut at the clutch

lever.

1. Locknut

2. Adjusting nut

If the specified free play cannot be ob-

tained, proceed with the following steps.

4. Loosen the locknut at the clutch le-

ver.

5. Turn the adjusting bolt at the

clutch lever in direction a

to loos-

en the cable.

6. Loosen the locknut at the crank-

case side.

7. Turn the adjusting nut at the

crankcase in direction a

to in-

crease free play or in direction b

to decrease free play.

8. Tighten the locknut at the crank-

case and the clutch lever.

1. Adjusting bolt

2. Locknut

c. Free play

EAU00696

Front brake lever free play

adjustment

The free play at the front brake lever

should be 2 ~ 5 mm.

1. Loosen the locknut.

2. Turn the adjusting bolt in direction

a

to increase free play or in direc-

tionb

to decrease free play.

3. After adjusting, tighten the locknut.