fuel pressure YAMAHA XVS125 2000 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XVS125, Model: YAMAHA XVS125 2000Pages: 86, PDF Size: 3.07 MB

Page 19 of 86

INSTRUMENT AND CONTROL FUNCTIONS

3

3-7

EAU01183

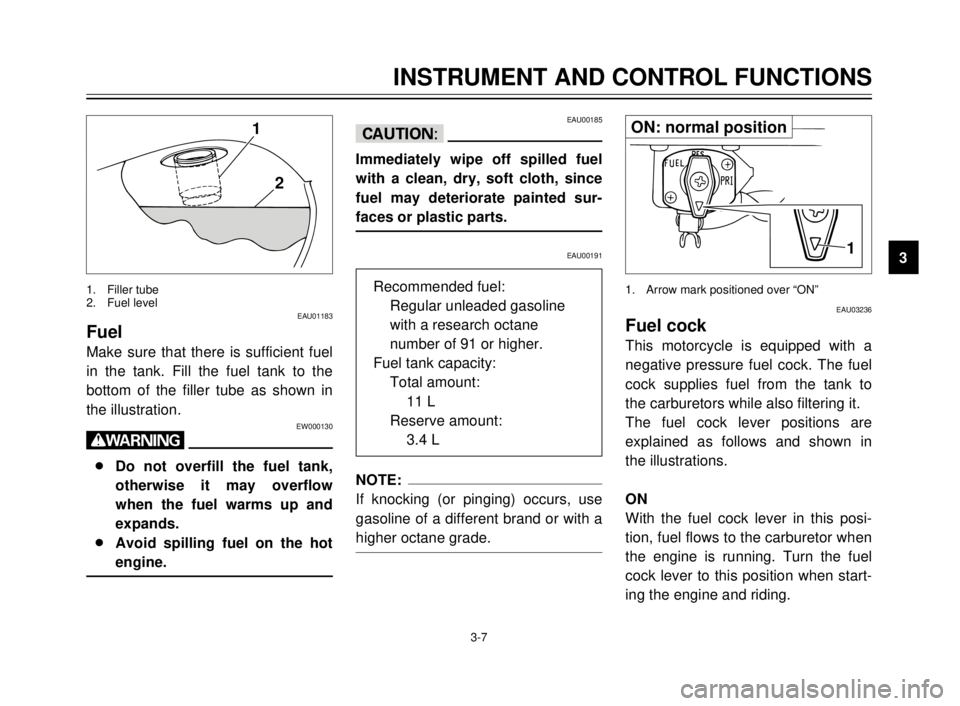

Fuel

Make sure that there is sufficient fuel

in the tank. Fill the fuel tank to the

bottom of the filler tube as shown in

the illustration.

EW000130

w

8Do not overfill the fuel tank,

otherwise it may overflow

when the fuel warms up and

expands.

8Avoid spilling fuel on the hot

engine.

1. Filler tube

2. Fuel level

EAU00185

cC

Immediately wipe off spilled fuel

with a clean, dry, soft cloth, since

fuel may deteriorate painted sur-

faces or plastic parts.

EAU00191

NOTE:

If knocking (or pinging) occurs, use

gasoline of a different brand or with a

higher octane grade.

1

2

Recommended fuel:

Regular unleaded gasoline

with a research octane

number of 91 or higher.

Fuel tank capacity:

Total amount:

11 L

Reserve amount:

3.4 L

EAU03236

Fuel cock

This motorcycle is equipped with a

negative pressure fuel cock. The fuel

cock supplies fuel from the tank to

the carburetors while also filtering it.

The fuel cock lever positions are

explained as follows and shown in

the illustrations.

ON

With the fuel cock lever in this posi-

tion, fuel flows to the carburetor when

the engine is running. Turn the fuel

cock lever to this position when start-

ing the engine and riding.

1. Arrow mark positioned over “ON”

1

ON: normal position

5JX-9-E0 4/9/0 4:11 AM Page 17

Page 32 of 86

6-2

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU00473

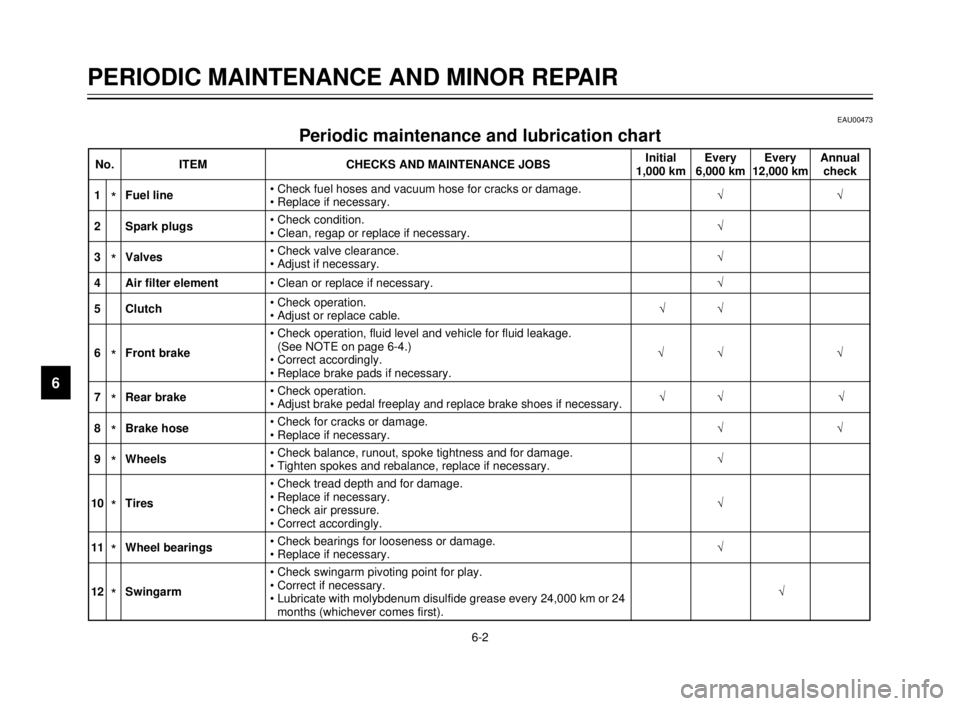

Periodic maintenance and lubrication chart

No. ITEM CHECKS AND MAINTENANCE JOBSInitial

1,000 kmEvery

6,000 kmEvery

12,000 kmAnnual

check

1

*Fuel line¥ Check fuel hoses and vacuum hose for cracks or damage.

¥ Replace if necessary.ÖÖ

2 Spark plugs¥ Check condition.

¥ Clean, regap or replace if necessary.Ö

3

*Valves¥ Check valve clearance.

¥ Adjust if necessary.Ö

4 Air filter element¥ Clean or replace if necessary.Ö

5 Clutch¥ Check operation.

¥ Adjust or replace cable.ÖÖ

6

*Front brake¥ Check operation, fluid level and vehicle for fluid leakage.

(See NOTE on page 6-4.)

¥ Correct accordingly.

¥ Replace brake pads if necessary.ÖÖ Ö

7

*Rear brake¥ Check operation.

¥ Adjust brake pedal freeplay and replace brake shoes if necessary.ÖÖ Ö

8

*Brake hose¥ Check for cracks or damage.

¥ Replace if necessary.ÖÖ

9

*Wheels¥ Check balance, runout, spoke tightness and for damage.

¥ Tighten spokes and rebalance, replace if necessary.Ö

10

*Tires¥ Check tread depth and for damage.

¥ Replace if necessary.

¥ Check air pressure.

¥ Correct accordingly.Ö

11

*Wheel bearings¥ Check bearings for looseness or damage.

¥ Replace if necessary.Ö

12

*Swingarm¥ Check swingarm pivoting point for play.

¥ Correct if necessary.

¥ Lubricate with molybdenum disulfide grease every 24,000 km or 24

months (whichever comes first).Ö

5JX-9-E0 4/9/0 4:11 AM Page 30

Page 46 of 86

6-16

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU00637

Adjusting the valve

clearance

The valve clearance changes with

use, resulting in improper air-fuel mix-

ture and/or engine noise. To prevent

this from occurring, the valve clear-

ance must be adjusted by a Yamaha

dealer at the intervals specified in the

periodic maintenance and lubrication

chart.

EAU00647

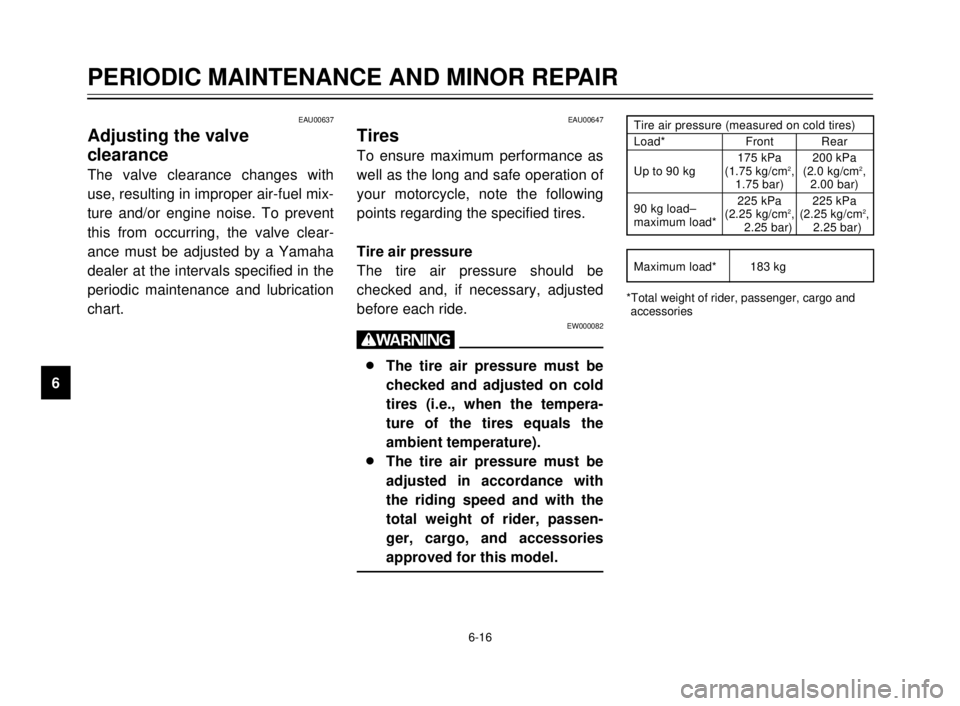

Tires

To ensure maximum performance as

well as the long and safe operation of

your motorcycle, note the following

points regarding the specified tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

EW000082

w

8The tire air pressure must be

checked and adjusted on cold

tires (i.e., when the tempera-

ture of the tires equals the

ambient temperature).

8The tire air pressure must be

adjusted in accordance with

the riding speed and with the

total weight of rider, passen-

ger, cargo, and accessories

approved for this model.

*Total weight of rider, passenger, cargo and

accessories

Tire air pressure (measured on cold tires)

Load* Front Rear

175 kPa 200 kPa

Up to 90 kg (1.75 kg/cm

2, (2.0 kg/cm2,1.75 bar) 2.00 bar)

90 kg load–225 kPa 225 kPa

maximum load*(2.25 kg/cm

2, (2.25 kg/cm2,

2.25 bar) 2.25 bar)

Maximum load* 183 kg

5JX-9-E0 4/9/0 4:11 AM Page 44

Page 74 of 86

7-2

MOTORCYCLE CARE AND STORAGE

1

2

3

4

5

6

7

8

98Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abra-

sive cleaning products, sol-

vent or thinner, fuel (gasoline),

rust removers or inhibitors,

brake fluid, antifreeze or elec-

trolyte.

8Do not use high-pressure

washers or steam-jet cleaners

since they cause water seep-

age and deterioration in the

following areas: seals (of

wheel and swingarm bearings,

fork and brakes), electric com-

ponents (couplers, connec-

tors, instruments, switches

and lights), breather hoses

and vents.8For motorcycles equipped

with a windshield: Do not use

strong cleaners or hard

sponges as they will cause

dulling or scratching. Some

cleaning compounds for plas-

tic may leave scratches on the

windshield. Test the product

on a small hidden part of the

windshield to make sure that it

does not leave any marks. If

the windshield is scratched,

use a quality plastic polishing

compound after washing.After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottle-

brush for hard-to-reach areas.

Stubborn dirt and insects will come

off more easily if the area is covered

with a wet cloth for a few minutes

before cleaning.After riding in the rain, near the sea

or on salt-sprayed roads

Since sea salt or salt sprayed on

roads during winter are extremely

corrosive in combination with water,

carry out the following steps after

each ride in the rain, near the sea or

on salt-sprayed roads.

NOTE:

Salt sprayed on roads in the winter

may remain well into spring.

1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

ECA00012

cC

Do not use warm water since it

increases the corrosive action of

the salt.

2. After drying the motorcycle,

apply a corrosion protection

spray on all metal, including

chrome- and nickel-plated, sur-

faces to prevent corrosion.

5JX-9-E0 4/9/0 4:11 AM Page 72