wheel bolts YAMAHA YFM350R 2011 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2011, Model line: YFM350R, Model: YAMAHA YFM350R 2011Pages: 138, PDF Size: 4.56 MB

Page 43 of 138

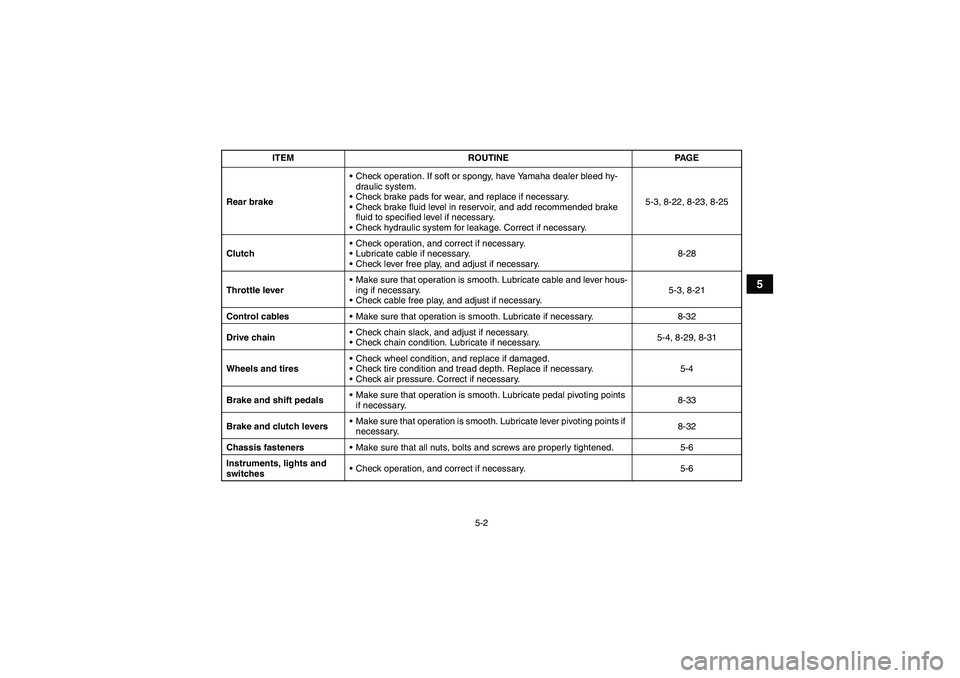

5-2

5

Rear brakeCheck operation. If soft or spongy, have Yamaha dealer bleed hy-

draulic system.

Check brake pads for wear, and replace if necessary.

Check brake fluid level in reservoir, and add recommended brake

fluid to specified level if necessary.

Check hydraulic system for leakage. Correct if necessary.5-3, 8-22, 8-23, 8-25

ClutchCheck operation, and correct if necessary.

Lubricate cable if necessary.

Check lever free play, and adjust if necessary.8-28

Throttle leverMake sure that operation is smooth. Lubricate cable and lever hous-

ing if necessary.

Check cable free play, and adjust if necessary.5-3, 8-21

Control cablesMake sure that operation is smooth. Lubricate if necessary. 8-32

Drive chainCheck chain slack, and adjust if necessary.

Check chain condition. Lubricate if necessary.5-4, 8-29, 8-31

Wheels and tiresCheck wheel condition, and replace if damaged.

Check tire condition and tread depth. Replace if necessary.

Check air pressure. Correct if necessary.5-4

Brake and shift pedalsMake sure that operation is smooth. Lubricate pedal pivoting points

if necessary.8-33

Brake and clutch leversMake sure that operation is smooth. Lubricate lever pivoting points if

necessary.8-32

Chassis fastenersMake sure that all nuts, bolts and screws are properly tightened. 5-6

Instruments, lights and

switchesCheck operation, and correct if necessary. 5-6 ITEM ROUTINE PAGE

U1BS61E0.book Page 2 Tuesday, April 13, 2010 10:25 AM

Page 110 of 138

8-30

8

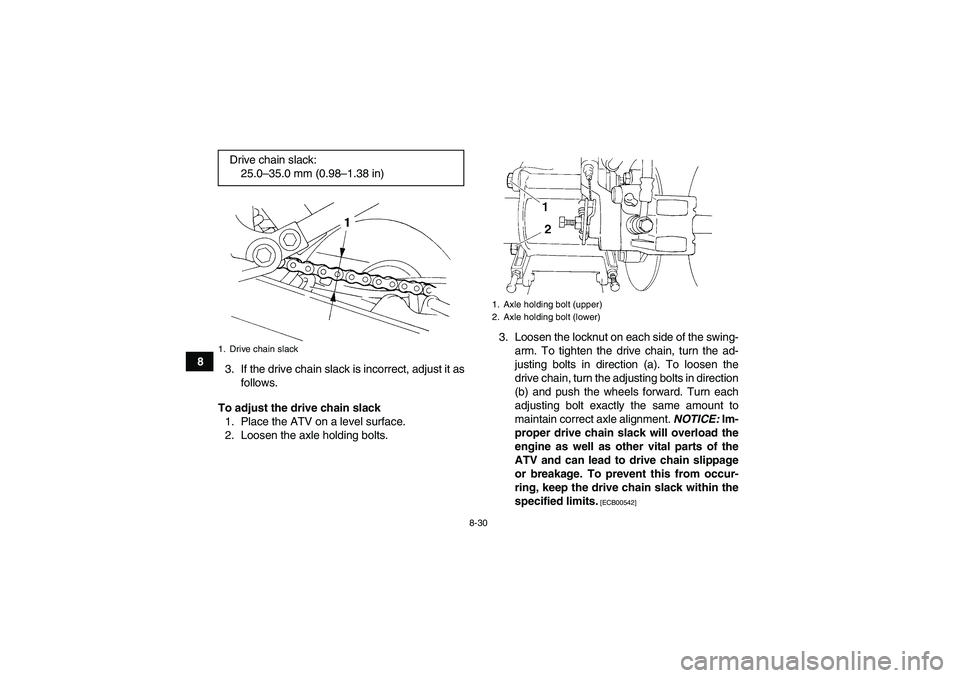

3. If the drive chain slack is incorrect, adjust it as

follows.

To adjust the drive chain slack

1. Place the ATV on a level surface.

2. Loosen the axle holding bolts.3. Loosen the locknut on each side of the swing-

arm. To tighten the drive chain, turn the ad-

justing bolts in direction (a). To loosen the

drive chain, turn the adjusting bolts in direction

(b) and push the wheels forward. Turn each

adjusting bolt exactly the same amount to

maintain correct axle alignment. NOTICE: Im-

proper drive chain slack will overload the

engine as well as other vital parts of the

ATV and can lead to drive chain slippage

or breakage. To prevent this from occur-

ring, keep the drive chain slack within the

specified limits.

[ECB00542]

Drive chain slack:

25.0–35.0 mm (0.98–1.38 in)1. Drive chain slack

1. Axle holding bolt (upper)

2. Axle holding bolt (lower)

U1BS61E0.book Page 30 Tuesday, April 13, 2010 10:25 AM

Page 111 of 138

8-31

8

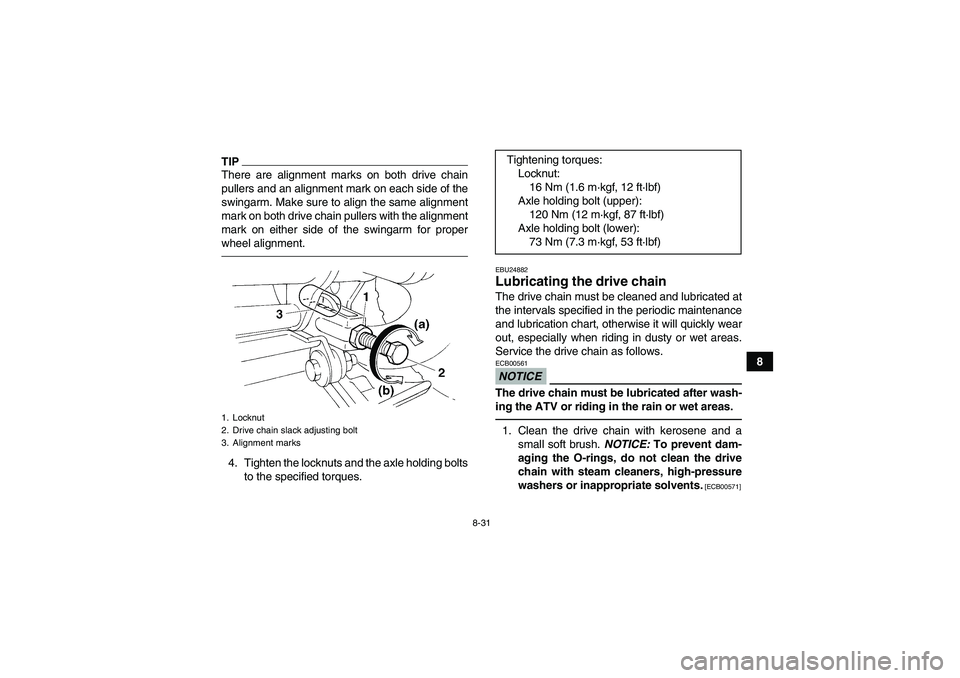

TIPThere are alignment marks on both drive chain

pullers and an alignment mark on each side of the

swingarm. Make sure to align the same alignment

mark on both drive chain pullers with the alignment

mark on either side of the swingarm for proper

wheel alignment.4. Tighten the locknuts and the axle holding bolts

to the specified torques.

EBU24882Lubricating the drive chain The drive chain must be cleaned and lubricated at

the intervals specified in the periodic maintenance

and lubrication chart, otherwise it will quickly wear

out, especially when riding in dusty or wet areas.

Service the drive chain as follows.NOTICEECB00561The drive chain must be lubricated after wash-

ing the ATV or riding in the rain or wet areas.1. Clean the drive chain with kerosene and a

small soft brush. NOTICE: To prevent dam-

aging the O-rings, do not clean the drive

chain with steam cleaners, high-pressure

washers or inappropriate solvents.

[ECB00571]

1. Locknut

2. Drive chain slack adjusting bolt

3. Alignment marks

Tightening torques:

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

Axle holding bolt (upper):

120 Nm (12 m·kgf, 87 ft·lbf)

Axle holding bolt (lower):

73 Nm (7.3 m·kgf, 53 ft·lbf)

U1BS61E0.book Page 31 Tuesday, April 13, 2010 10:25 AM