YAMAHA YFZ450R 2021 Service Manual

Manufacturer: YAMAHA, Model Year: 2021, Model line: YFZ450R, Model: YAMAHA YFZ450R 2021Pages: 150, PDF Size: 3.84 MB

Page 41 of 150

5-15

5

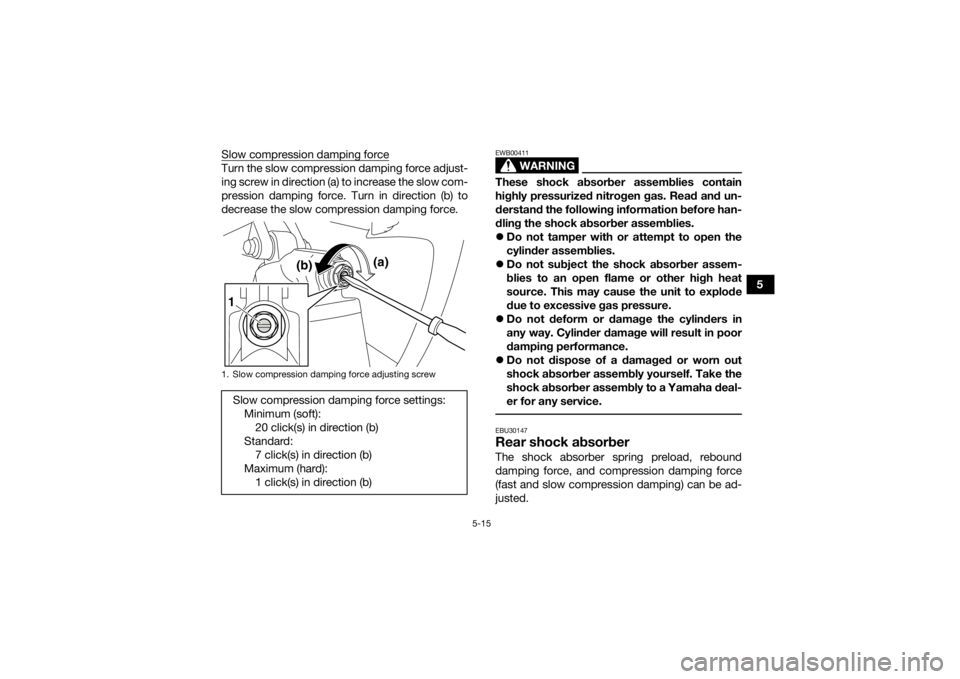

Slow compression damping force

Turn the slow compression damping force adjust-

ing screw in direction (a) to increase the slow com-

pression damping force. Turn in direction (b) to

decrease the slow compression damping force.

WARNING

EWB00411These shock absorber assemblies contain

highly pressurized nitrogen gas. Read and un-

derstand the following information before han-

dling the shock absorber assemblies.

Do not tamper with or attempt to open the

cylinder assemblies.

Do not subject the shock absorber assem-

blies to an open flame or other high heat

source. This may cause the unit to explode

due to excessive gas pressure.

Do not deform or damage the cylinders in

any way. Cylinder damage will result in poor

damping performance.

Do not dispose of a damaged or worn out

shock absorber assembly yourself. Take the

shock absorber assembly to a Yamaha deal-

er for any service. EBU30147Rear shock absorberThe shock absorber spring preload, rebound

damping force, and compression damping force

(fast and slow compression damping) can be ad-

justed.

1. Slow compression damping force adjusting screwSlow compression damping force settings:

Minimum (soft):20 click(s) in direction (b)

Standard: 7 click(s) in direction (b)

Maximum (hard): 1 click(s) in direction (b)

(a)

(b)

1

UBKD60E0.book Page 15 Wednesday, November 18, 2020 8:39 AM

Page 42 of 150

5-16

5

WARNING

EWB02681Suspension components become hot during

operation. Never touch the compression

damping force adjusting bolt and screw, the

rebound damping force adjusting screw or the

oil reservoir with your bare hand or skin until

the suspension components have cooled. Notes on adjusting the suspension

A special wrench can be obtained at a Yamaha

dealer to make the spring preload adjustment.

When adjusting the damping force settings, turn

the adjuster in direction (a) until it stops, and

then count the turns or clicks in direction (b).

Although a damping force adjuster may turn or

click beyond the stated minimum settings, such

adjustments are ineffective and may damage

the suspension.NOTICEECB00091Never turn an adjusting mechanism beyond

the minimum and maximum settings.

Spring preload

1. Elevate the vehicle and place a suitable stand under the frame.

2. Remove the cowling. (See page 9-10.)

3. Remove the clip from the hose holder, re- move the bolt, and then move the blow-by

gas chamber away from the vehicle.

4. Loosen the clamp screw at the air filter case side.1. Hose holder

2. Clip

3. Bolt

4. Blow-by gas chamber

2 3

4

1

UBKD60E0.book Page 16 Wednesday, November 18, 2020 8:39 AM

Page 43 of 150

5-17

5

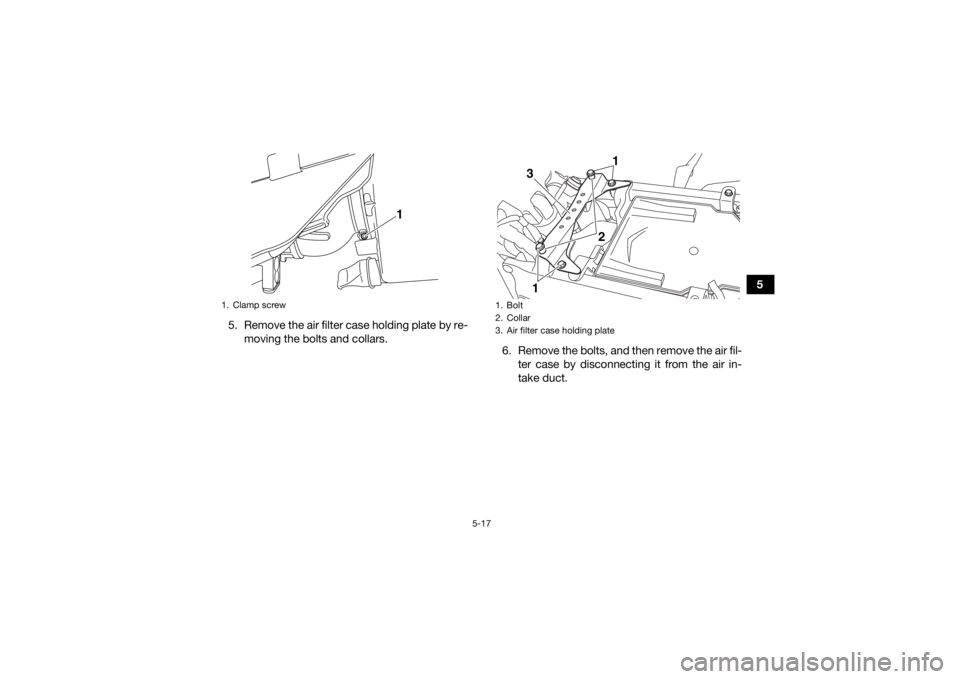

5. Remove the air filter case holding plate by re- moving the bolts and collars. 6. Remove the bolts, and then remove the air fil-

ter case by disconnecting it from the air in-

take duct.

1. Clamp screw

1

1. Bolt

2. Collar

3. Air filter case holding plate

1

1

2

3

UBKD60E0.book Page 17 Wednesday, November 18, 2020 8:39 AM

Page 44 of 150

5-18

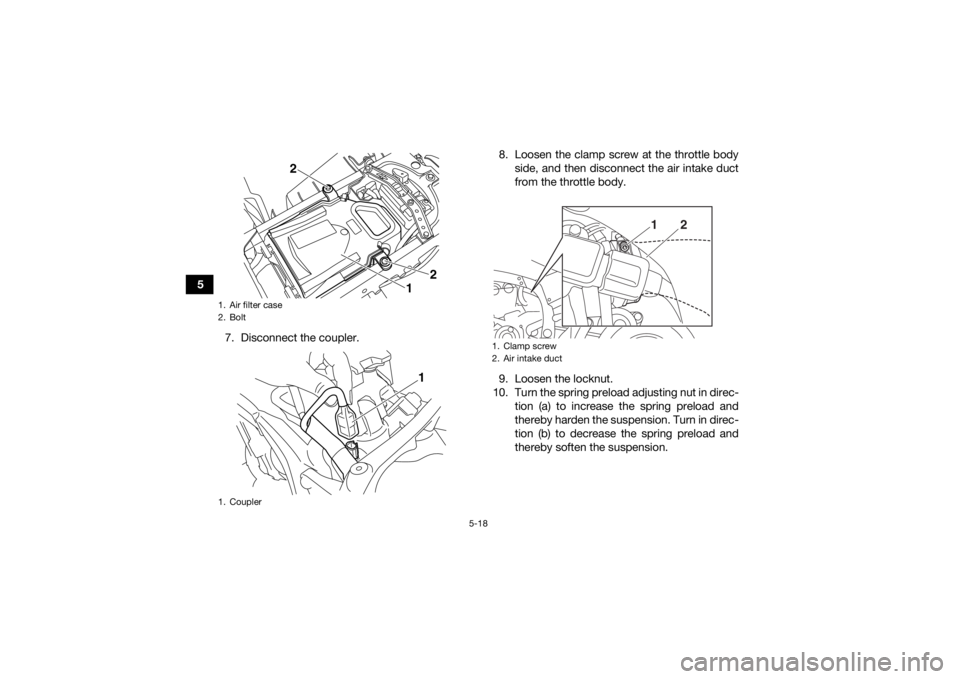

57. Disconnect the coupler. 8. Loosen the clamp screw at the throttle body

side, and then disconnect the air intake duct

from the throttle body.

9. Loosen the locknut.

10. Turn the spring preload adjusting nut in direc- tion (a) to increase the spring preload and

thereby harden the suspension. Turn in direc-

tion (b) to decrease the spring preload and

thereby soften the suspension.

1. Air filter case

2. Bolt

1. Coupler

12

2

1

1. Clamp screw

2. Air intake duct

1

2

UBKD60E0.book Page 18 Wednesday, November 18, 2020 8:39 AM

Page 45 of 150

5-19

5

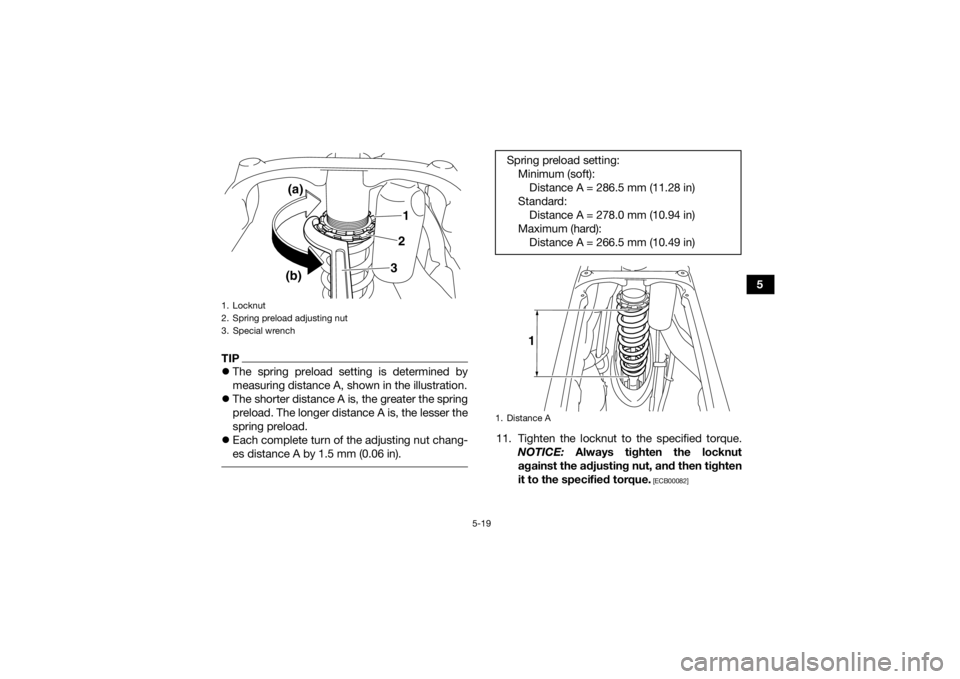

TIPThe spring preload setting is determined by

measuring distance A, shown in the illustration.

The shorter distance A is, the greater the spring

preload. The longer distance A is, the lesser the

spring preload.

Each complete turn of the adjusting nut chang-

es distance A by 1.5 mm (0.06 in).

11. Tighten the locknut to the specified torque.

NOTICE: Always tighten the locknut

against the adjusting nut, and then tighten

it to the specified torque.

[ECB00082]

1. Locknut

2. Spring preload adjusting nut

3. Special wrench

2 13

(a)

(b)

Spring preload setting: Minimum (soft):Distance A = 286.5 mm (11.28 in)

Standard: Distance A = 278.0 mm (10.94 in)

Maximum (hard): Distance A = 266.5 mm (10.49 in)1. Distance A

1

UBKD60E0.book Page 19 Wednesday, November 18, 2020 8:39 AM

Page 46 of 150

5-20

512. Connect the air intake duct to the throttle

body, and then tighten the clamp screw at the

throttle body side. NOTICE: Make sure that

the air intake duct is properly connected to

the throttle body, and that the clamp

screw is tightened securely.

[ECB00962]

13. Connect the coupler.

14. Connect the air filter case to the air intake duct, place the air filter case in the original po-

sition, and then tighten the clamp screw at

the air filter case side. NOTICE: Make sure

that the air intake duct is properly con-

nected to the air filter case, and that the

clamp screw is tightened securely.

[ECB00972]

15. Install the air filter case bolts, and then tighten them to the specified torque. 16. Install the air filter case holding plate by in-

stalling the bolts and collars, and then tighten

the bolts to the specified torque.

17. Install the blow-by gas chamber by installing the bolt, tighten the bolt to the specified

torque, and then install the clip to the hose

holder.

18. Install the cowling.

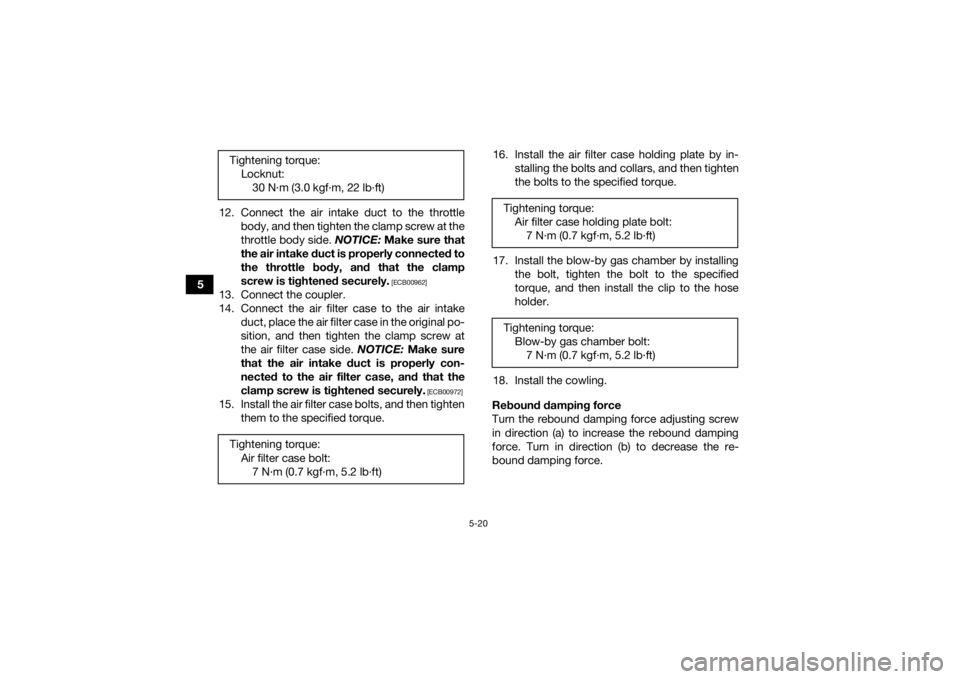

Rebound damping force

Turn the rebound damping force adjusting screw

in direction (a) to increase the rebound damping

force. Turn in direction (b) to decrease the re-

bound damping force.

Tightening torque:

Locknut:30 N·m (3.0 kgf·m, 22 lb·ft)

Tightening torque: Air filter case bolt:7 N·m (0.7 kgf·m, 5.2 lb·ft)

Tightening torque:Air filter case holding plate bolt:7 N·m (0.7 kgf·m, 5.2 lb·ft)

Tightening torque: Blow-by gas chamber bolt:7 N·m (0.7 kgf·m, 5.2 lb·ft)

UBKD60E0.book Page 20 Wednesday, November 18, 2020 8:39 AM

Page 47 of 150

5-21

5

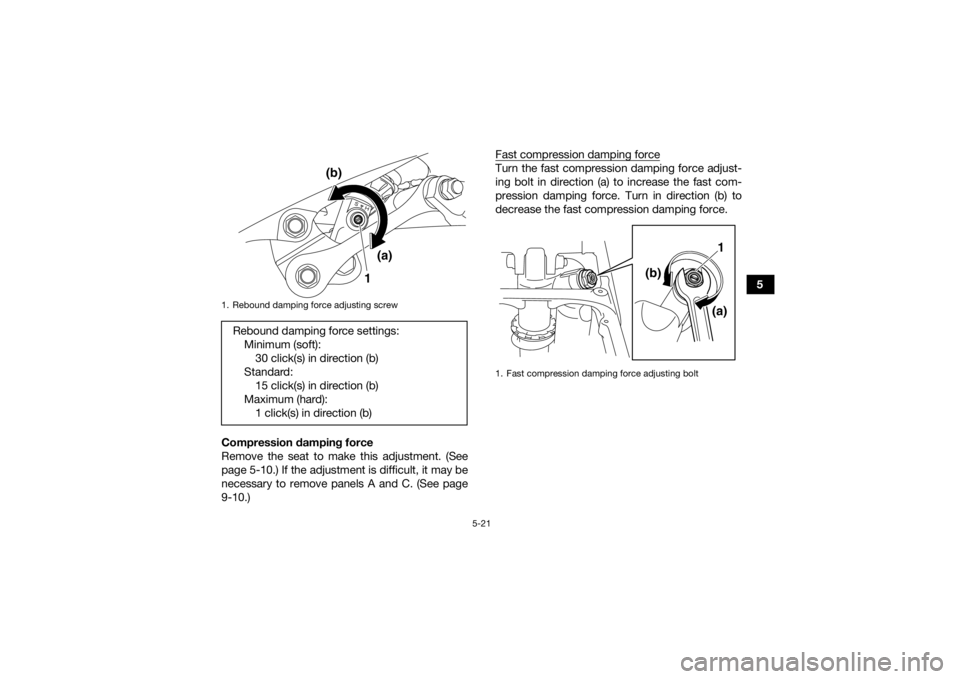

Compression damping force

Remove the seat to make this adjustment. (See

page 5-10.) If the adjustment is difficult, it may be

necessary to remove panels A and C. (See page

9-10.) Fast compression damping force

Turn the fast compression damping force adjust-

ing bolt in direction (a) to increase the fast com-

pression damping force. Turn in direction (b) to

decrease the fast compression damping force.

1. Rebound damping force adjusting screwRebound damping force settings:

Minimum (soft):30 click(s) in direction (b)

Standard: 15 click(s) in direction (b)

Maximum (hard): 1 click(s) in direction (b)

1

(a)

(b)

1. Fast compression damping force adjusting bolt

(a)

(b)

1

UBKD60E0.book Page 21 Wednesday, November 18, 2020 8:39 AM

Page 48 of 150

5-22

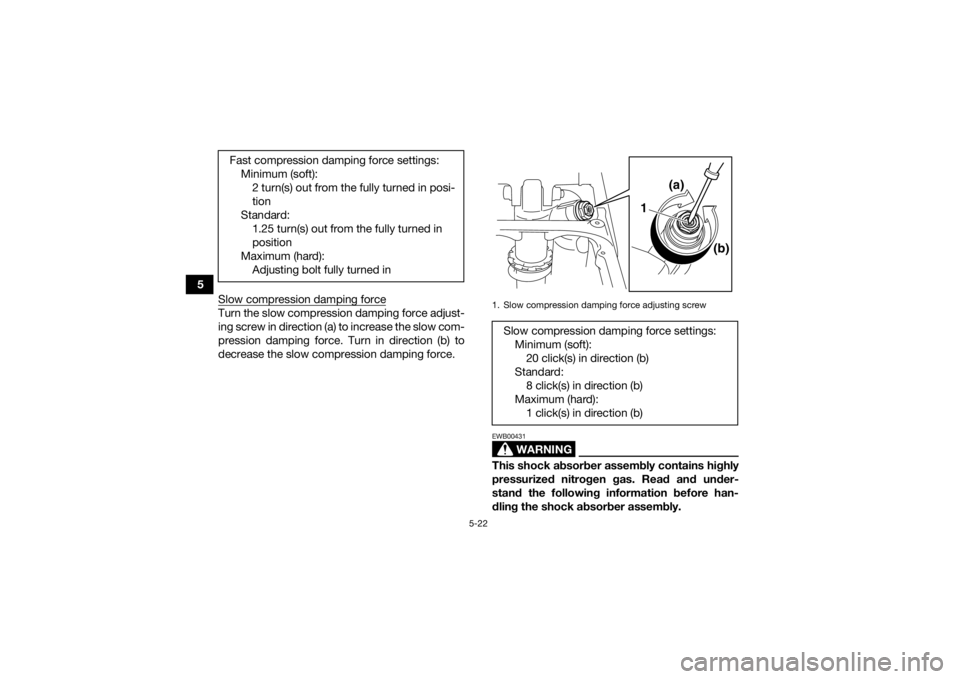

5Slow compression damping force

Turn the slow compression damping force adjust-

ing screw in direction (a) to increase the slow com-

pression damping force. Turn in direction (b) to

decrease the slow compression damping force.

WARNING

EWB00431This shock absorber assembly contains highly

pressurized nitrogen gas. Read and under-

stand the following information before han-

dling the shock absorber assembly.

Fast compression damping force settings:

Minimum (soft):2 turn(s) out from the fully turned in posi-

tion

Standard: 1.25 turn(s) out from the fully turned in

position

Maximum (hard): Adjusting bolt fully turned in1. Slow compression damping force adjusting screwSlow compression damping force settings:Minimum (soft):20 click(s) in direction (b)

Standard: 8 click(s) in direction (b)

Maximum (hard): 1 click(s) in direction (b)

(a)

(b)

1

UBKD60E0.book Page 22 Wednesday, November 18, 2020 8:39 AM

Page 49 of 150

5-23

5

Do not tamper with or attempt to open the

cylinder assembly.

Do not subject the shock absorber assembly

to an open flame or other high heat source.

This may cause the unit to explode due to ex-

cessive gas pressure.

Do not deform or damage the cylinder in any

way. Cylinder damage will result in poor

damping performance.

Do not dispose of a damaged or worn out

shock absorber assembly yourself. Take the

shock absorber assembly to a Yamaha deal-

er for any service.

EBU29404Handlebar positionThe handlebar can be adjusted to one of four po-

sitions to suit your preference. Have a Yamaha

dealer adjust the position of the handlebar.1. Handlebar

1

UBKD60E0.book Page 23 Wednesday, November 18, 2020 8:39 AM

Page 50 of 150

6-1

6

EBU19203

PRE-OPERATION CHECKS

EBU19227Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always

follow the inspection and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWB00482Failure to inspect or maintain the vehicle properly increases the possibility of an accident or equip-

ment damage. Do not operate the vehicle if you find any problem. If a problem cannot be corrected

by the procedures provided in this manual, have the vehicle inspected by a Yamaha dealer. Before using this vehicle, check the following points:

ITEMROUTINE PAGE

Fuel • Check fuel level in fuel tank,

and add recommended fuel if neces-

sary.

• Check fuel line for leakage. Correct if necessary. 5-9, 6-4

Engine oil • Check oil level in engine oil

tank, and add recommended oil to

specified level if necessary.

• Check ATV for oil leakage. Correct if necessary. 6-4, 9-14

Coolant • Check coolant level in reservoir, and add recommended coolant to

specified level if necessary.

• Check cooling system for leakage. Correct if necessary. 6-4, 9-20

UBKD60E0.book Page 1 Wednesday, November 18, 2020 8:39 AM