wheel YAMAHA YS125 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: YS125, Model: YAMAHA YS125 2017Pages: 90, PDF Size: 2.24 MB

Page 60 of 90

Periodic maintenance an d a djustment

6-25

6 4. Place the motorcycle on the cen-

terstand.

5. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

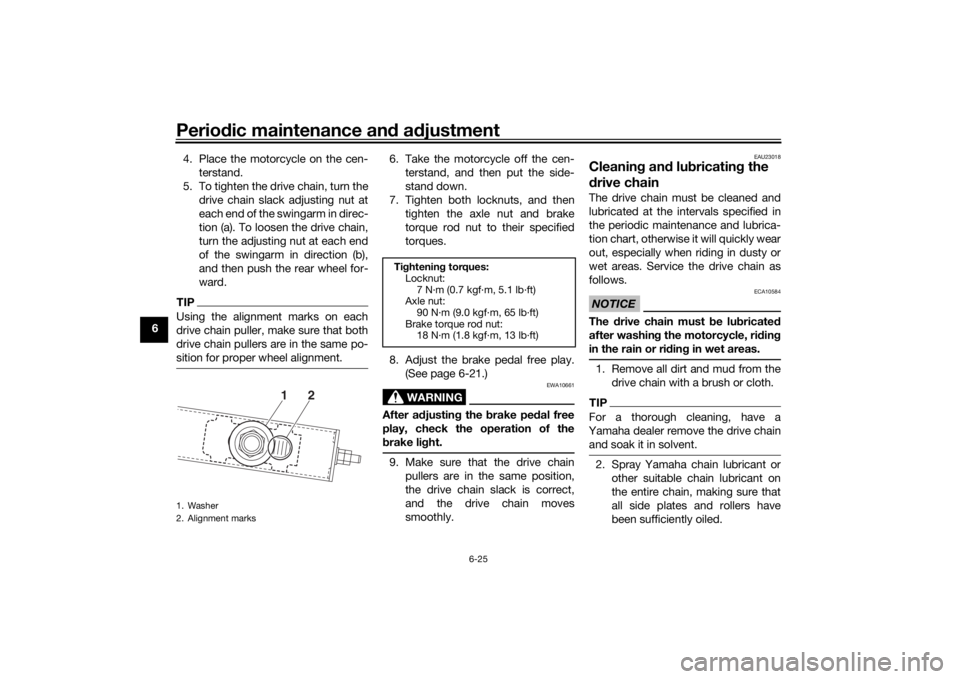

TIPUsing the alignment marks on each

drive chain puller, make sure that both

drive chain pullers are in the same po-

sition for proper wheel alignment.

6. Take the motorcycle off the cen-terstand, and then put the side-

stand down.

7. Tighten both locknuts, and then tighten the axle nut and brake

torque rod nut to their specified

torques.

8. Adjust the brake pedal free play. (See page 6-21.)

WARNING

EWA10661

After a djustin g the brake pe dal free

play, check the operation of the

b rake li ght.9. Make sure that the drive chain

pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23018

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Remove all dirt and mud from the

drive chain with a brush or cloth.TIPFor a thorough cleaning, have a

Yamaha dealer remove the drive chain and soak it in solvent.2. Spray Yamaha chain lubricant or other suitable chain lubricant on

the entire chain, making sure that

all side plates and rollers have

been sufficiently oiled.

1. Washer

2. Alignment marks

1

2

Tightenin g torques:

Locknut: 7 N·m (0.7 kgf·m, 5.1 lb·ft)

Axle nut:

90 N·m (9.0 kgf·m, 65 lb·ft)

Brake torque rod nut: 18 N·m (1.8 kgf·m, 13 lb·ft)

UBT4E0E0.book Page 25 Thursday, November 17, 2016 10:55 AM

Page 65 of 90

Periodic maintenance an d a djustment

6-30

6

EAU23292

Checkin g the wheel bearin gsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU2338A

BatteryThe battery is located behind panel B.

(See page 6-8.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to

be checked and, if necessary, tight-

ened.

WARNING

EWA10761

Electrolyte is poisonous an d

d an gerous since it contains sul-

furic aci d, which causes severe b

urns. Avoi d any contact with

skin, eyes or clothin g an d al-

ways shiel d your eyes when

workin g near b atteries. In case

of contact, ad minister the fol-

lowin g FIRST AID.

EXTERNAL: Flush with plenty of water.

INTERNAL: Drink lar ge quan-

tities of water or milk an d im-

me diately call a physician.

EYES: Flush with water for 15 minutes an d seek prompt

me dical attention.

Batteries pro duce explosive hy-

d ro gen gas. Therefore, keep

sparks, flames, ci garettes, etc.,

away from the battery an d pro-

vi de sufficient ventilation when

char gin g it in an enclose d

space.

KEEP THIS AND ALL BATTER-

IES OUT OF THE REACH OF

CHILDREN.1. Battery

2. Positive battery lead (red)

3. Negative battery lead (black)

2

1

3

UBT4E0E0.book Page 30 Thursday, November 17, 2016 10:55 AM

Page 71 of 90

Periodic maintenance an d a djustment

6-36

6

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

ti g hten the screw, otherwise the

lens may break.

[ECA11192] EAU78970

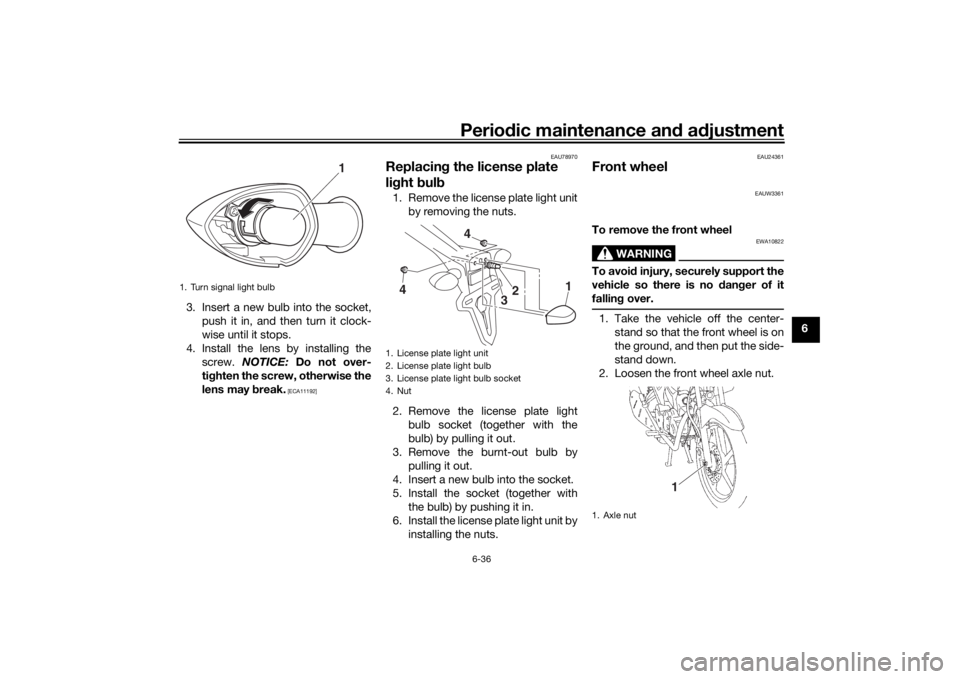

Replacin

g the license plate

lig ht bul b1. Remove the license plate light unit

by removing the nuts.

2. Remove the license plate light bulb socket (together with the

bulb) by pulling it out.

3. Remove the burnt-out bulb by pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the license plate light unit by installing the nuts.

EAU24361

Front wheel

EAUW3361

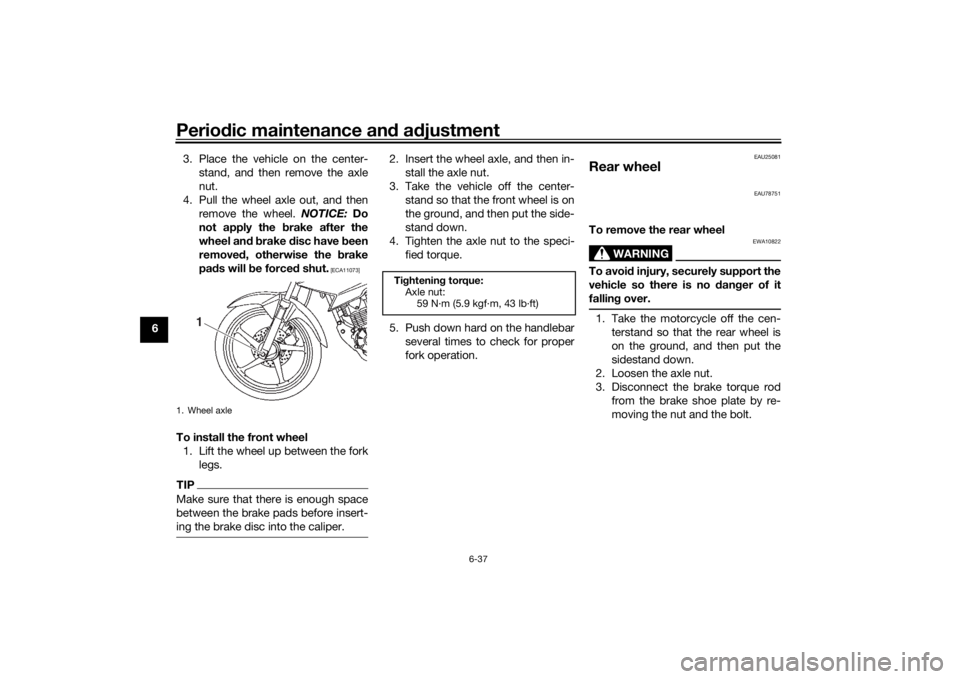

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Take the vehicle off the center-

stand so that the front wheel is on

the ground, and then put the side-

stand down.

2. Loosen the front wheel axle nut.

1. Turn signal light bulb

1

1. License plate light unit

2. License plate light bulb

3. License plate light bulb socket

4. Nut

1

32

4

4

1. Axle nut

1

UBT4E0E0.book Page 36 Thursday, November 17, 2016 10:55 AM

Page 72 of 90

Periodic maintenance an d a djustment

6-37

6 3. Place the vehicle on the center-

stand, and then remove the axle

nut.

4. Pull the wheel axle out, and then remove the wheel. NOTICE: Do

not apply the b rake after the

wheel an d b rake disc have b een

remove d, otherwise the brake

pa ds will be forced shut.

[ECA11073]

To install the front wheel

1. Lift the wheel up between the fork legs.TIPMake sure that there is enough space

between the brake pads before insert-

ing the brake disc into the caliper.

2. Insert the wheel axle, and then in-stall the axle nut.

3. Take the vehicle off the center- stand so that the front wheel is on

the ground, and then put the side-

stand down.

4. Tighten the axle nut to the speci- fied torque.

5. Push down hard on the handlebar several times to check for proper

fork operation.

EAU25081

Rear wheel

EAU78751

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Take the motorcycle off the cen-

terstand so that the rear wheel is

on the ground, and then put the

sidestand down.

2. Loosen the axle nut.

3. Disconnect the brake torque rod from the brake shoe plate by re-

moving the nut and the bolt.

1. Wheel axle

1

Tightenin g torque:

Axle nut: 59 N·m (5.9 kgf·m, 43 lb·ft)

UBT4E0E0.book Page 37 Thursday, November 17, 2016 10:55 AM

Page 73 of 90

Periodic maintenance an d a djustment

6-38

6

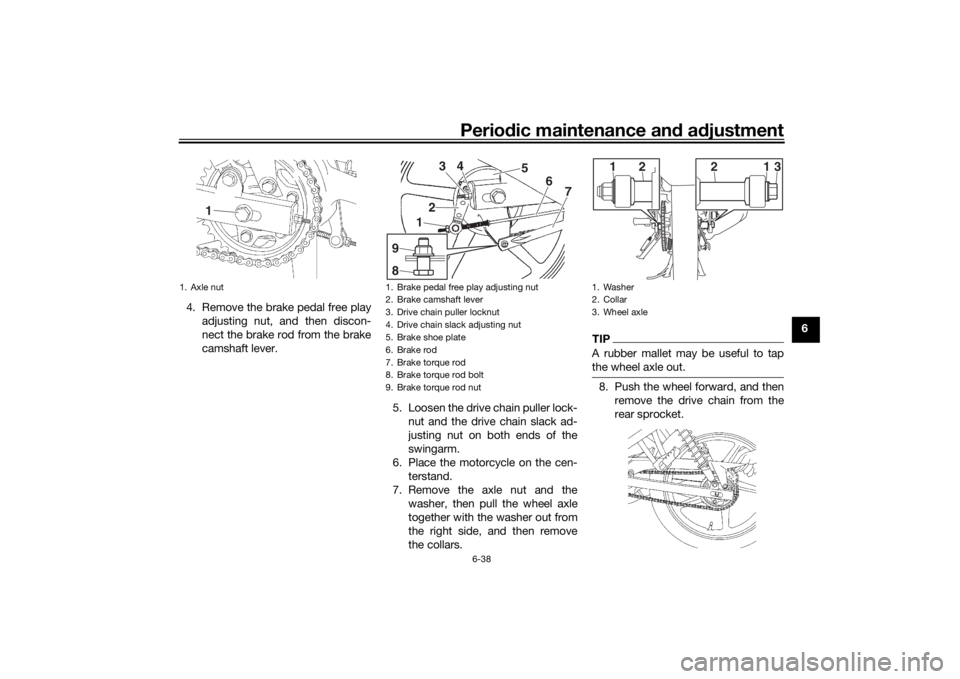

4. Remove the brake pedal free play

adjusting nut, and then discon-

nect the brake rod from the brake

camshaft lever.

5. Loosen the drive chain puller lock-nut and the drive chain slack ad-

justing nut on both ends of the

swingarm.

6. Place the motorcycle on the cen- terstand.

7. Remove the axle nut and the washer, then pull the wheel axle

together with the washer out from

the right side, and then remove

the collars.

TIPA rubber mallet may be useful to tap

the wheel axle out.8. Push the wheel forward, and thenremove the drive chain from the

rear sprocket.

1. Axle nut

1

1. Brake pedal free play adjusting nut

2. Brake camshaft lever

3. Drive chain puller locknut

4. Drive chain slack adjusting nut

5. Brake shoe plate

6. Brake rod

7. Brake torque rod

8. Brake torque rod bolt

9. Brake torque rod nut

234

5

67

1

98

1. Washer

2. Collar

3. Wheel axle

2

1

2

31

UBT4E0E0.book Page 38 Thursday, November 17, 2016 10:55 AM

Page 74 of 90

Periodic maintenance an d a djustment

6-39

6

TIPThe drive chain does not need to be

disassembled in order to remove and

install the wheel.9. Remove the wheel.

To install the rear wheel 1. Install the drive chain onto the rear sprocket.

2. Install the wheel by installing the collars on both sides and installing

the washer and the wheel axle

from the right side.

3. Install the washer and the axle nut.

4. Connect the brake rod to the brake camshaft lever, and then in-

stall the brake pedal free play ad-

justing nut onto the brake rod.

5. Connect the brake torque rod to the brake shoe plate by installing

the bolt and the nut.

6. Adjust the drive chain slack. (See page 6-24.)

7. Take the motorcycle off the cen- terstand so that the rear wheel is

on the ground, and then put the

sidestand down. 8. Adjust the brake pedal free play.

(See page 6-21.)

WARNING

EWA10661

After a djustin g the brake pe dal free

play, check the operation of the

b rake li ght.

EAU25853

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting chart

represents a quick and easy procedure

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, do

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

UBT4E0E0.book Page 39 Thursday, November 17, 2016 10:55 AM

Page 77 of 90

Motorcycle care and stora ge

7-1

7

EAU37834

Matte color cautionNOTICE

ECA15193

Some mo dels are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

a d vice on what prod ucts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical pro ducts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applie d to any matte colored fin-

ishe d parts.

EAU26005

CareWhile the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a mo-

torcycle. Frequent and proper care

does not only comply with the terms of

the warranty, but it will also keep your

motorcycle looking good, extend its

life and optimize its performance.

Before cleanin g

1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov- ers as well as all electrical cou-

plers and connectors, including

the spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod- ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.

Cleanin g

NOTICE

ECA10773

Avoi d usin g stron g aci dic wheel

cleaners, especially on spoked

wheels. If such pro ducts are

use d on har d-to-remove dirt, do

not leave the cleaner on the af-

fected area any lon ger than in-

structed . Also, thorou ghly rinse

the area off with water, immed i-

ately dry it, an d then apply a cor-

rosion protection spray.

Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, win dshiel ds, hea dlig ht

lenses, meter lenses, etc.) an d

the mufflers. Use only a soft,

clean cloth or spon ge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

ou ghly cleaned with water, di-

lute d mil d d eter gent with water

may be used . Be sure to rinse

UBT4E0E0.book Page 1 Thursday, November 17, 2016 10:55 AM

Page 78 of 90

Motorcycle care and stora ge

7-2

7 off any d

etergent resi due usin g

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d using cloths or

spon ges which have been in

contact with stron g or a brasive

cleanin g prod ucts, solvent or

thinner, fuel ( gasoline), rust re-

movers or inhi bitors, brake flui d,

antifreeze or electrolyte.

Do not use hi gh-pressure wash-

ers or steam-jet cleaners since

they cause water seepa ge an d

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, instruments,

switches an d lig hts), breather

hoses an d vents.

For motorcycles equippe d with

a win dshield : Do not use stron g

cleaners or har d spon ges as

they will cause dullin g

or

scrat

ching . Some cleanin g

compoun ds for plastic may

leave scratches on the win d- shield

. Test the pro duct on a

small hidden part of the win d-

shield to make sure that it does

not leave any marks. If the win d-

shield is scratche d, use a quality

plastic polishin g compoun d af-

ter washin g.

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive

in combination with water, carry out

the following steps after each ride in

the rain, near the sea or on salt-

sprayed roads.

TIPSalt sprayed on roads in the winter

may remain well into spring.1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleanin g

1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

UBT4E0E0.book Page 2 Thursday, November 17, 2016 10:55 AM

Page 80 of 90

Motorcycle care and stora ge

7-4

7 2. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

3. Perform the following steps to protect the cylinder, piston rings,

etc. from corrosion.a. Remove the spark plug cap and spark plug.

b. Pour a teaspoonful of engine oil into the spark plug bore.

c. Install the spark plug cap onto the spark plug, and then place

the spark plug on the cylinder

head so that the electrodes are

grounded. (This will limit spark-

ing during the next step.)

d. Turn the engine over several times with the starter. (This will

coat the cylinder wall with oil.)

WARNING! To prevent d am-

a g e or injury from sparkin g,

make sure to groun d the

spark plu g electro des while

turnin g the en gine over.

[EWA10952]

e. Remove the spark plug cap

from the spark plug, and then

install the spark plug and the

spark plug cap.

4. Lubricate all control cables and the pivoting points of all levers and

pedals as well as of the side-

stand/centerstand.

5. Check and, if necessary, correct the tire air pressure, and then lift

the motorcycle so that both of its

wheels are off the ground. Alterna-

tively, turn the wheels a little every

month in order to prevent the tires

from becoming degraded in one

spot.

6. Cover the muffler outlet with a plastic bag to prevent moisture

from entering it.

7. Remove the battery and fully char- ge it. Store it in a cool, dry place

and charge it once a month. Do

not store the battery in an exces-

sively cold or warm place [less

than 0 °C (30 °F) or more than 30

°C (90 °F)]. For more information

on storing the battery, see page

6-30.

TIPMake any necessary repairs before

storing the motorcycle.

UBT4E0E0.book Page 4 Thursday, November 17, 2016 10:55 AM

Page 81 of 90

Specifications

8-1

8

Dimensions:Overall length:2005 mm (78.9 in)

Overall width:

735 mm (28.9 in)

Overall height: 1050 mm (41.3 in)

Seat height: 795 mm (31.3 in)

Wheelbase:

1320 mm (52.0 in)

Ground clearance: 150 mm (5.91 in)

Minimum turning radius: 2.2 m (7.22 ft)Wei ght:Curb weight:

129 kg (284 lb)Engine:Combustion cycle:

4-stroke

Cooling system: Air cooled

Valve train: SOHC

Number of cylinders:

Single cylinder

Displacement: 125 cm³

Bore × stroke:

52.4 × 57.9 mm (2.06 × 2.28 in)

Compression ratio:

10.0 : 1 Starting system:

Electric starter

Lubrication system: Wet sump

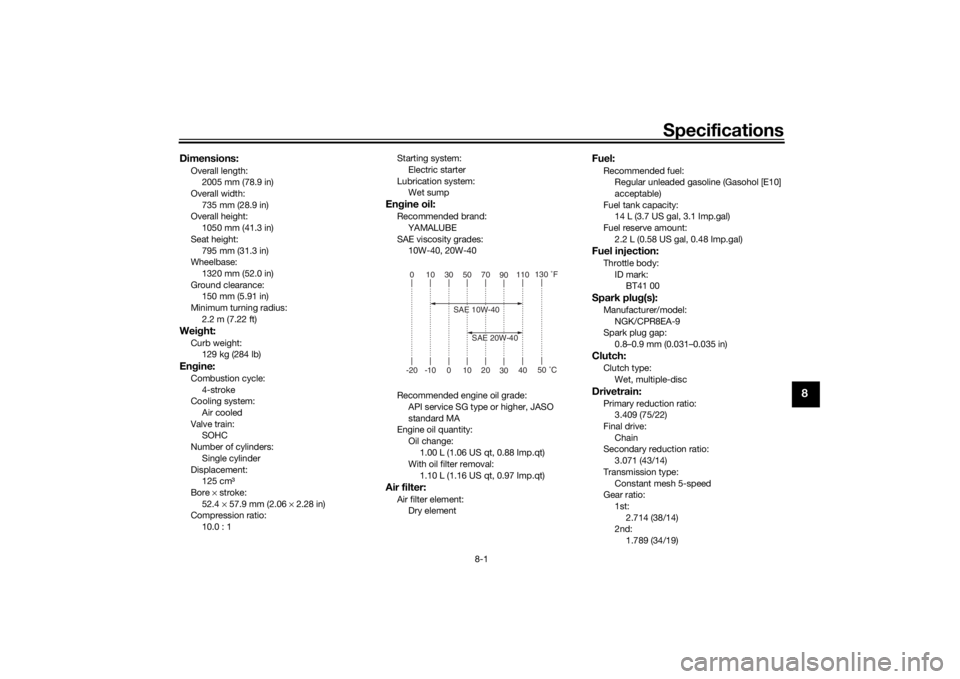

Engine oil:Recommended brand:

YAMALUBE

SAE viscosity grades: 10W-40, 20W-40

Recommended engine oil grade: API service SG type or higher, JASO

standard MA

Engine oil quantity:

Oil change:1.00 L (1.06 US qt, 0.88 Imp.qt)

With oil filter removal:

1.10 L (1.16 US qt, 0.97 Imp.qt)Air filter:Air filter element:Dry element

Fuel:Recommended fuel:Regular unleaded gasoline (Gasohol [E10]

acceptable)

Fuel tank capacity: 14 L (3.7 US gal, 3.1 Imp.gal)

Fuel reserve amount:

2.2 L (0.58 US gal, 0.48 Imp.gal)Fuel injection:Throttle body:ID mark:BT41 00Spark plu g(s):Manufacturer/model:

NGK/CPR8EA-9

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)Clutch:Clutch type:

Wet, multiple-discDrivetrain:Primary reduction ratio:3.409 (75/22)

Final drive:

Chain

Secondary reduction ratio: 3.071 (43/14)

Transmission type: Constant mesh 5-speed

Gear ratio:

1st:2.714 (38/14)

2nd:

1.789 (34/19)

010305070 90110

130 ˚F

-20 -10 0 10 20 3040

50 ˚C

SAE 10W-40

SAE 20W-40

UBT4E0E0.book Page 1 Thursday, November 17, 2016 10:55 AM