engine oil YAMAHA YXZ1000R 2020 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: YXZ1000R, Model: YAMAHA YXZ1000R 2020Pages: 198, PDF Size: 8.22 MB

Page 134 of 198

9-21

9

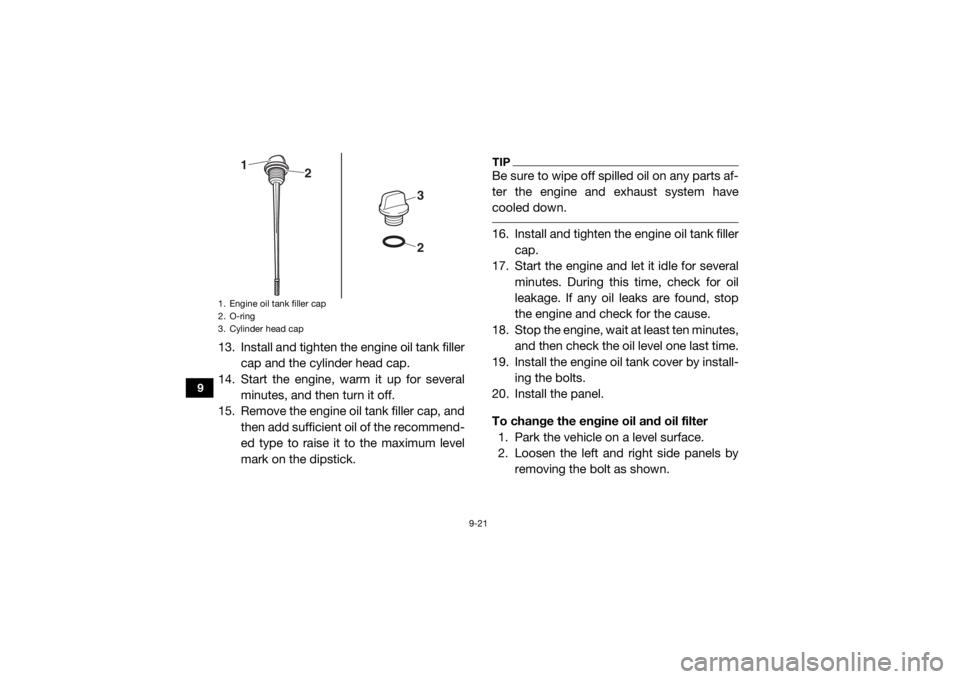

13. Install and tighten the engine oil tank fillercap and the cylinder head cap.

14. Start the engine, warm it up for several minutes, and then turn it off.

15. Remove the engine oil tank filler cap, and then add sufficient oil of the recommend-

ed type to raise it to the maximum level

mark on the dipstick.

TIPBe sure to wipe off spilled oil on any parts af-

ter the engine and exhaust system have

cooled down. 16. Install and tighten the engine oil tank fillercap.

17. Start the engine and let it idle for several minutes. During this time, check for oil

leakage. If any oil leaks are found, stop

the engine and check for the cause.

18. Stop the engine, wait at least ten minutes, and then check the oil level one last time.

19. Install the engine oil tank cover by install- ing the bolts.

20. Install the panel.

To change the engine oil and oil filter

1. Park the vehicle on a level surface.

2. Loosen the left and right side panels by removing the bolt as shown.

1. Engine oil tank filler cap

2. O-ring

3. Cylinder head cap

3

2

1

2

UB5J7BE0.book Page 21 Tuesday, June 18, 2019 10:07 AM

Page 136 of 198

9-23

9

5. Follow steps 2–9 of the “To change theengine oil” section for the oil draining pro-

cedure.

6. Remove the oil filter cartridge with an oil filter wrench. Make sure the O-ring is re-

moved together with the oil filter car-

tridge. If the O-ring remains attached to

the crankcase, oil leakage may occur.

TIPAn oil filter wrench is available from a Yamaha

dealer. 7. Apply a light coat of clean engine oil to

the O-ring of the new oil filter cartridge.TIPMake sure that the O-ring is properly seated.

1. Center bottom panel

2. Bolt

2

2

2

2

2

1

1. Oil filter cartridge

2. Oil filter wrench

2

1

UB5J7BE0.book Page 23 Tuesday, June 18, 2019 10:07 AM

Page 137 of 198

9-24

9

8. Install the new oil filter cartridge, and thentighten to the specified torque. 9. Follow steps 10–20 of the “To change the

engine oil” section for the oil filling proce-

dure.

10. Slide the front portion of the center bot- tom panel into place as shown, and then

hook the left and right sides of the center

bottom panel into place.1. O-ringTightening torque:Oil filter cartridge:17 N·m (1.7 kgf·m, 13 lb·ft)

1

1. Torque wrench

1

UB5J7BE0.book Page 24 Tuesday, June 18, 2019 10:07 AM

Page 140 of 198

9-27

9

EBU38630Why YamalubeYAMALUBE oil is a Genuine YAMAHA Partborn of the engineers’ passion and belief that

engine oil is an important liquid engine com-

ponent. We form teams of specialists in the

fields of mechanical engineering, chemistry,

electronics and track testing, and have them

develop the engine together with the oil it will use. Yamalube oils take full advantage of the

base oil’s qualities and blend in the ideal ba-

lance of additives to make sure the final oil

clears our performance standards. Thus,

Yamalube mineral, semisynthetic and syn-

thetic oils have their own distinct characters

and value. Yamaha’s experience gained over

many years of research and development into

oil since the 1960’s helps make Yamalube the

best choice for your Yamaha engine.

EBU35108Transmission oilCheck the oil level and change the transmis-

sion oil at the intervals specified in the period-

ic maintenance chart.

1. Bolt BTightening torque: Bolt B:7 N·m (0.7 kgf·m, 5.2 lb·ft)

1

1

UB5J7BE0.book Page 27 Tuesday, June 18, 2019 10:07 AM

Page 143 of 198

9-30

9

6. Check the O-ring for damage, and re-place it if necessary.

7. Refill the transmission with the specified amount of the recommended oil.

8. Install the transmission oil filler cap.

9. Start the engine and let it idle while checking for oil leakage.

10. Stop the engine and check the oil level one last time.EBU36054Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the periodic

maintenance chart.

NOTICEECB03590When checking or changing the final gear

oil, make sure that no foreign material en-

ters the final gear case. If necessary, clean

the final gear oil filler bolt and surrounding

area. TIPIf the recommended gear oil is not available,

SAE 80W-90 API GL-4 or GL-5 hypoid gear

oil may be used instead. Checking the final gear oil level1. Park the vehicle on a level surface.

Tightening torque: Transmission oil drain bolt:20 N·m (2.0 kgf·m, 15 lb·ft)

Recommended oil:SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.47 L (0.50 US qt, 0.41 Imp.qt)

UB5J7BE0.book Page 30 Tuesday, June 18, 2019 10:07 AM

Page 184 of 198

10-2

10

7. Automotive-type wax may be applied toall painted and chrome-plated surfaces.

Avoid combination cleaner-waxes. Many

contain abrasives which may scratch the

paint or protective finish. When finished,

start the engine and let it idle for several

minutes.EBU32741StorageLong term storage (60 days or more) of your

vehicle will require some preventive proce-

dures to guard against deterioration. Make

any necessary repairs before storing the vehi-

cle.

After thoroughly cleaning the vehicle, prepare

for storage as follows:

1. Fill the fuel tank with fresh fuel and add the specified amount of Fuel Med Rx or

another high-quality fuel stabilizer prod-

uct. Follow the instructions on the prod- uct label. Operate the vehicle for at least

5 minutes to distribute treated fuel

through the fuel system.

2. Remove the spark plugs and pour one ta- blespoon of fresh engine oil into each cyl-

inder and then re-install the spark plugs.

Remove the spark plug wires and ground

them. Operate the electric starter to turn

the engine over several times and coat

the cylinder walls with oil.

3. Lubricate all control cables.

4. Put the frame on stands or blocks to raise all wheels off the ground.

5. Tie a plastic bag over the exhaust pipe outlet to prevent moisture from entering.

Specified amount:1 oz of stabilizer to each gallon of fuel (or

7.5 ml of stabilizer to each liter of fuel)

UB5J7BE0.book Page 2 Tuesday, June 18, 2019 10:07 AM

Page 187 of 198

11-2

11

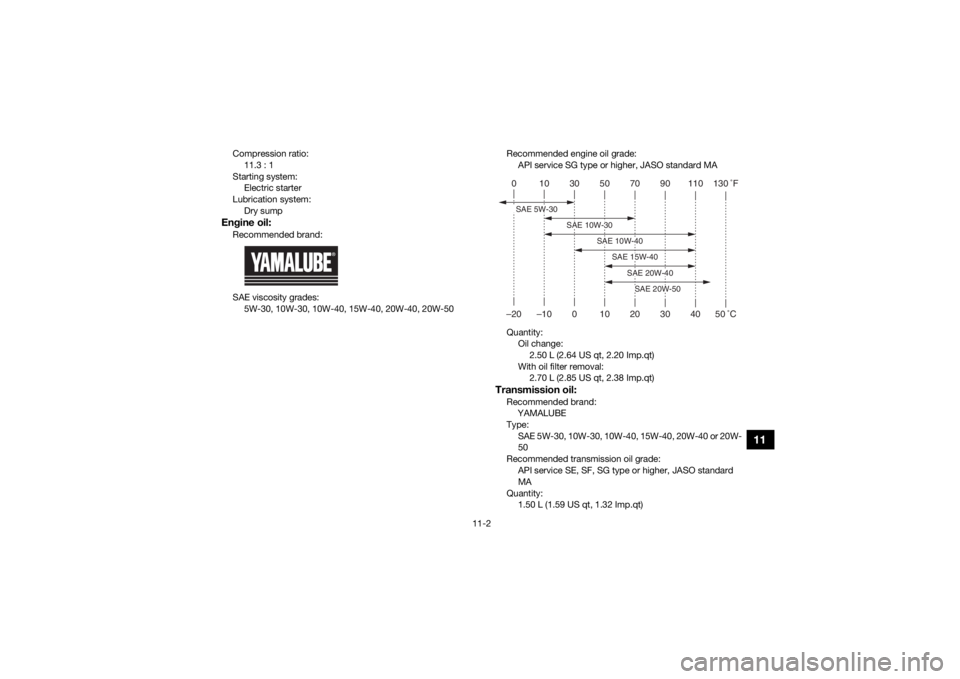

Compression ratio:11.3 : 1

Starting system: Electric starter

Lubrication system:

Dry sumpEngine oil:Recommended brand:

SAE viscosity grades:5W-30, 10W-30, 10W-40, 15W-40, 20W-40, 20W-50 Recommended engine oil grade:

API service SG type or higher, JASO standard MA

Quantity: Oil change:2.50 L (2.64 US qt, 2.20 Imp.qt)

With oil filter removal: 2.70 L (2.85 US qt, 2.38 Imp.qt)

Transmission oil:Recommended brand:YAMALUBE

Type: SAE 5W-30, 10W-30, 10W-40, 15W-40, 20W-40 or 20W-

50

Recommended transmission oil grade: API service SE, SF, SG type or higher, JASO standard

MA

Quantity: 1.50 L (1.59 US qt, 1.32 Imp.qt)0 10 30 50 70 90 110 130 �F

–20 –10 0 10 20 30 40 50 �CSAE 5W-30

SAE 10W-30

SAE 10W-40

SAE 15W-40

SAE 20W-40SAE 20W-50

UB5J7BE0.book Page 2 Tuesday, June 18, 2019 10:07 AM

Page 190 of 198

11-5

11

Rear suspension:Type:Double wishbone

Spring:

Coil spring

Shock absorber: Gas-hydraulic damper

Wheel travel: 432 mm (17.0 in)Electrical system:System voltage:12 V

Ignition system: TCI

Charging system:

AC magnetoBattery:Model:U1-H11L

Voltage, capacity:

12 V, 28.0 AhLights:Headlight:LED

Brake/tail light:

LED

Meter lighting: LED

Neutral indicator light: LED High beam indicator light:

LED

Reverse indicator light: LED

Coolant temperature warning light:

LED

Parking brake indicator light: LED

Engine trouble warning light: LED

Differential gear lock indicator light:

LED

EPS warning light: LED

Helmet reminder light: 0.8 W

Seat belt reminder light:

0.8 W

Shift timing indicator light: LED

Fuses:Main fuse:

50.0 A

Fuel injection system fuse: 15.0 A

EPS fuse: 40.0 A

Headlight fuse:

15.0 A

Signaling system fuse: 10.0 A

UB5J7BE0.book Page 5 Tuesday, June 18, 2019 10:07 AM

Page 194 of 198

13-1

13

INDEX

AAccelerator pedal ......................................................... 5-18

Accelerator pedal, checking ........................................ 9-51

Accelerator pedal, Pre-operation check ........................ 6-7

Air filter ......................................................................... 9-39

Air filter case hoses, cleaning ...................................... 9-43

Auxiliary DC jack .......................................................... 5-38

Axle boots .................................................................... 9-37BBasic guide for safe use ................................................. 8-1

Battery, Periodic maintenance ..................................... 9-58

Brake and clutch fluid levels, checking ........................ 9-47

Brake fluid, replacing ...................................................9-49

Brake light switch, adjusting ........................................ 9-52

Brake pedal .................................................................. 5-19

Brake pedal, checking ................................................. 9-50

Brakes, Periodic maintenance ..................................... 9-46

Brakes, Pre-operation check ......................................... 6-3

Brake/tail light .............................................................. 9-66CCable, inspecting and lubrication ................................ 9-53

Cargo bed .................................................................... 5-27

Cleaning ....................................................................... 10-1

Clutch pedal ................................................................. 5-18

Clutch pedal, checking ................................................ 9-49

Clutch, Pre-operation check .......................................... 6-3

Control cables, Pre-operation check ............................. 6-8

Coolant, Periodic maintenance .................................... 9-35

Coolant, Pre-operation check ........................................ 6-6Coolant temperature warning light ................................ 5-4

Cup holders ................................................................. 5-26

DData recording, vehicle ................................................ 12-1

Differential gear lock indicator light ............................... 5-3

Differential gear oil, Periodic maintenance .................. 9-32

Differential gear, Pre-operation check ........................... 6-6

Doors ........................................................................... 5-21

Drive mode, selecting .................................................... 7-7

Driver seat position ...................................................... 5-23

Drive shaft universal joint, lubrication .......................... 9-55

Drivetrain icon ................................................................ 5-3EEngine break-in .............................................................. 7-1

Engine oil and oil filter, Periodic maintenance ............. 9-16

Engine oil, Pre-operation check ..................................... 6-6

Engine trouble warning light .......................................... 5-5

EPS warning light ........................................................... 5-5FFinal gear oil, Periodic maintenance ............................ 9-30

Final gear, Pre-operation check ..................................... 6-6

Fittings and fasteners, Pre-operation check .................. 6-8

Flag pole bracket ......................................................... 5-28

Four–wheel drive knob (On–Command 4WD) .............. 5-17

Front and rear brake pads, checking ........................... 9-46

Fuel, Pre-operation check .............................................. 6-4

Fuel tank cap ............................................................... 5-21

Fuse, replacing ............................................................. 9-63GGlove compartment ..................................................... 5-25

UB5J7BE0.book Page 1 Tuesday, June 18, 2019 10:07 AM