engine oil YAMAHA YXZ1000R SS 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: YXZ1000R SS, Model: YAMAHA YXZ1000R SS 2017Pages: 208, PDF Size: 4.79 MB

Page 145 of 208

8-19

8

12. Add 2.00 L (2.11 US qt, 1.76 Imp.qt) ofthe recommended engine oil to the oil

tank, and then install and tighten the en-

gine oil tank filler cap and the cylinder

head cap.

13. Start the engine, warm it up for several minutes, and then turn it off.

14. Remove the engine oil tank filler cap, and then add sufficient oil of the recommend-

ed type to raise it to the maximum level

mark on the dipstick.

TIPBe sure to wipe off spilled oil on any parts af-

ter the engine and exhaust system have

cooled down. NOTICEECB03020Do not use oils with a diesel specifica-

tion of “CD” or oils of a higher quality

than specified. In addition, do not use

oils labeled “ENERGY CONSERVING II”

or higher.

Make sure that no foreign material en-

ters the oil tank.

Tightening torques:

Engine oil drain bolt:10 N·m (1.0 kgf·m, 7.2 lb·ft)

Engine oil tank drain bolt: 16 N·m (1.6 kgf·m, 12 lb·ft)

Recommended engine oil: See page 10-1.

Oil quantity: Oil change only:2.50 L (2.64 US qt, 2.20 Imp.qt)

Oil change and filter replacement: 2.70 L (2.85 US qt, 2.38 Imp.qt)

U2HC7ME0.book Page 19 Tuesday, April 19, 2016 10:33 AM

Page 146 of 208

8-20

8

15. Install and tighten the engine oil tank fillercap.

16. Start the engine, and then let it idle for several minutes while checking it for oil

leakage. If oil is leaking, immediately turn

the engine off and check for the cause.

17. Turn the engine off, wait at least ten mi- nutes, and then check the oil level and

correct it if necessary.

18. Install the engine oil tank cover by install- ing the bolts.

19. Install the panel.

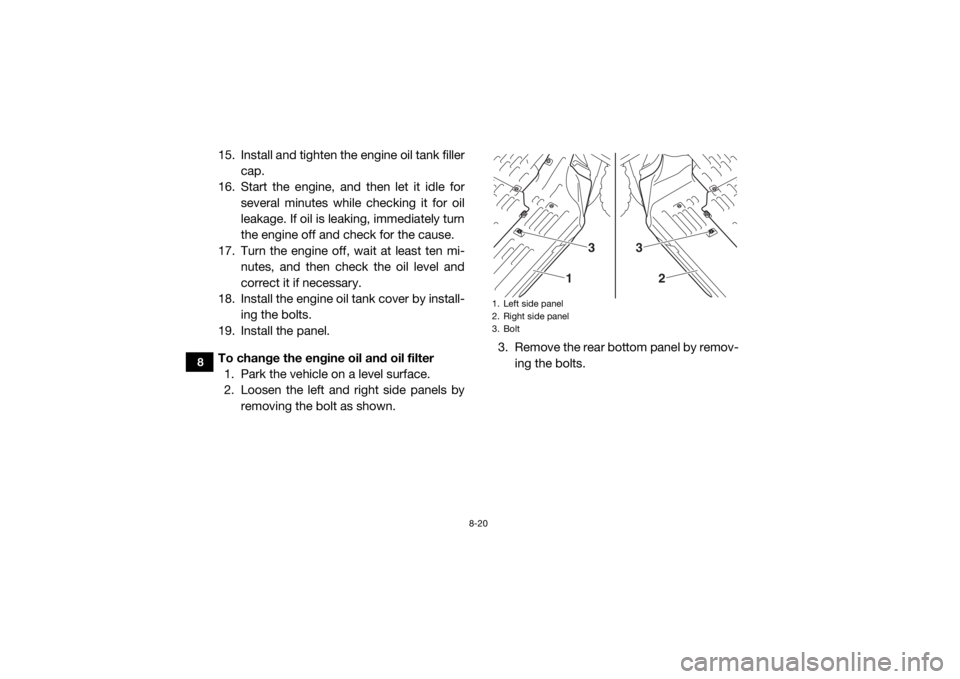

To change the engine oil and oil filter 1. Park the vehicle on a level surface.

2. Loosen the left and right side panels by removing the bolt as shown. 3. Remove the rear bottom panel by remov-

ing the bolts.

1. Left side panel

2. Right side panel

3. Bolt

3

1

3

2

U2HC7ME0.book Page 20 Tuesday, April 19, 2016 10:33 AM

Page 147 of 208

8-21

8

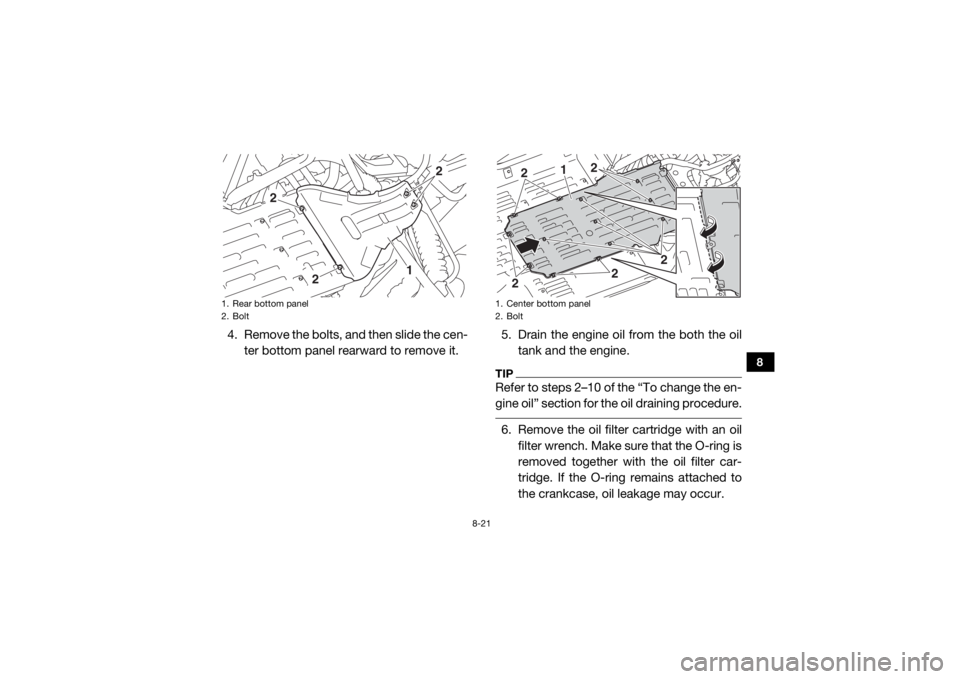

4. Remove the bolts, and then slide the cen-ter bottom panel rearward to remove it. 5. Drain the engine oil from the both the oil

tank and the engine.

TIPRefer to steps 2–10 of the “To change the en-

gine oil” section for th e oil draining procedure. 6. Remove the oil filter cartridge with an oil

filter wrench. Make sure that the O-ring is

removed together with the oil filter car-

tridge. If the O-ring remains attached to

the crankcase, oil leakage may occur.

1. Rear bottom panel

2. Bolt

2

1

2

2

1. Center bottom panel

2. Bolt

2

2

2

2

2

1

U2HC7ME0.book Page 21 Tuesday, April 19, 2016 10:33 AM

Page 148 of 208

8-22

8

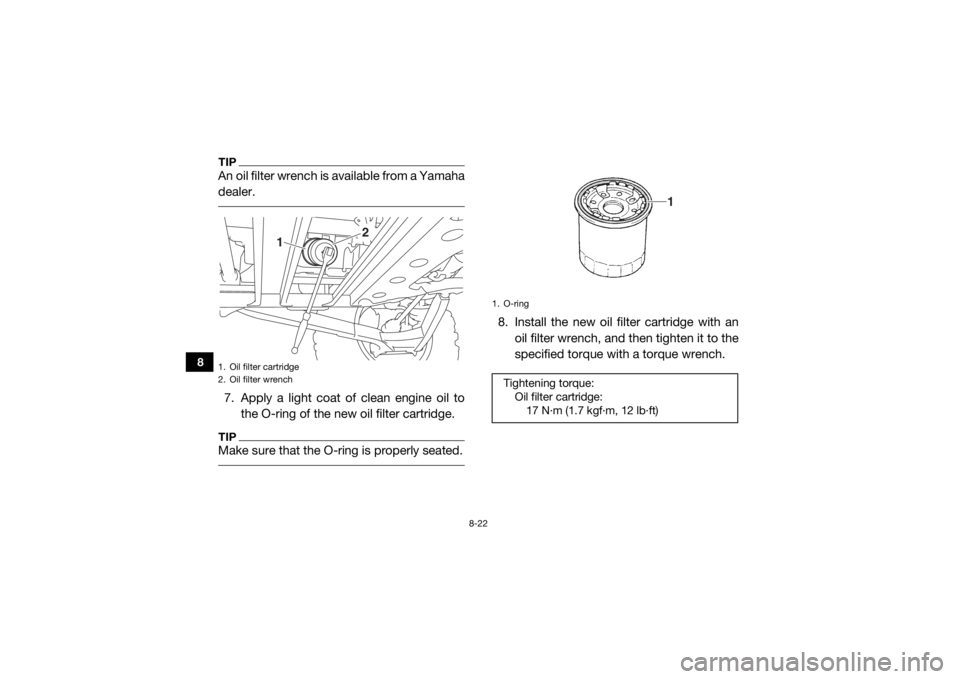

TIPAn oil filter wrench is available from a Yamaha

dealer. 7. Apply a light coat of clean engine oil to

the O-ring of the new oil filter cartridge.TIPMake sure that the O-ring is properly seated.

8. Install the new oil filter cartridge with anoil filter wrench, and then tighten it to the

specified torque with a torque wrench.

1. Oil filter cartridge

2. Oil filter wrench

2

1

1. O-ringTightening torque:Oil filter cartridge:17 N·m (1.7 kgf·m, 12 lb·ft)

1

U2HC7ME0.book Page 22 Tuesday, April 19, 2016 10:33 AM

Page 149 of 208

8-23

8

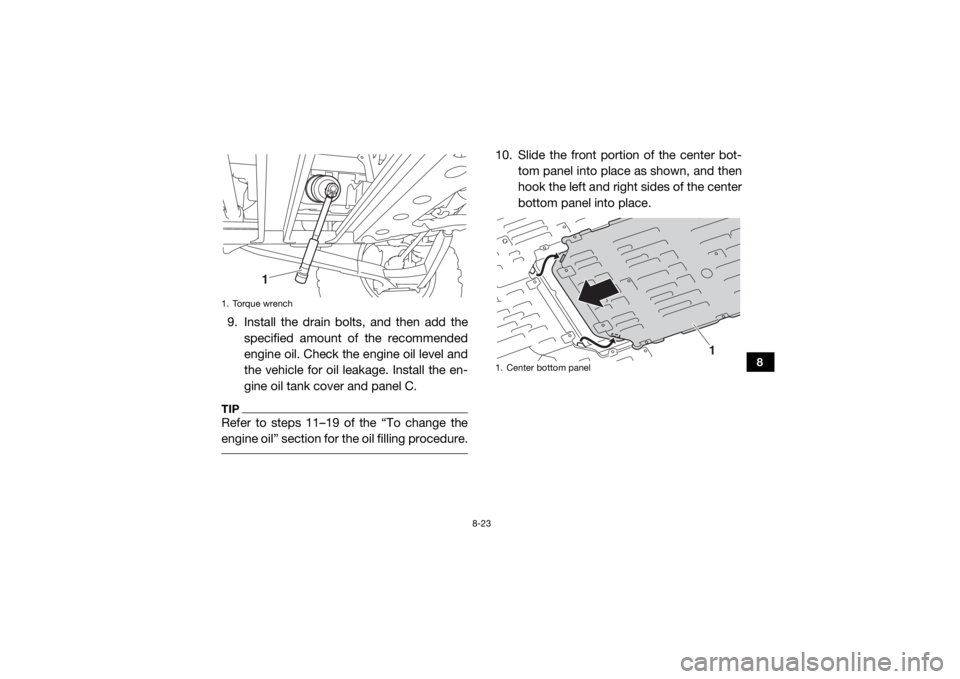

9. Install the drain bolts, and then add thespecified amount of the recommended

engine oil. Check the engine oil level and

the vehicle for oil leakage. Install the en-

gine oil tank cover and panel C.TIPRefer to steps 11–19 of the “To change the

engine oil” section for the oil filling procedure.

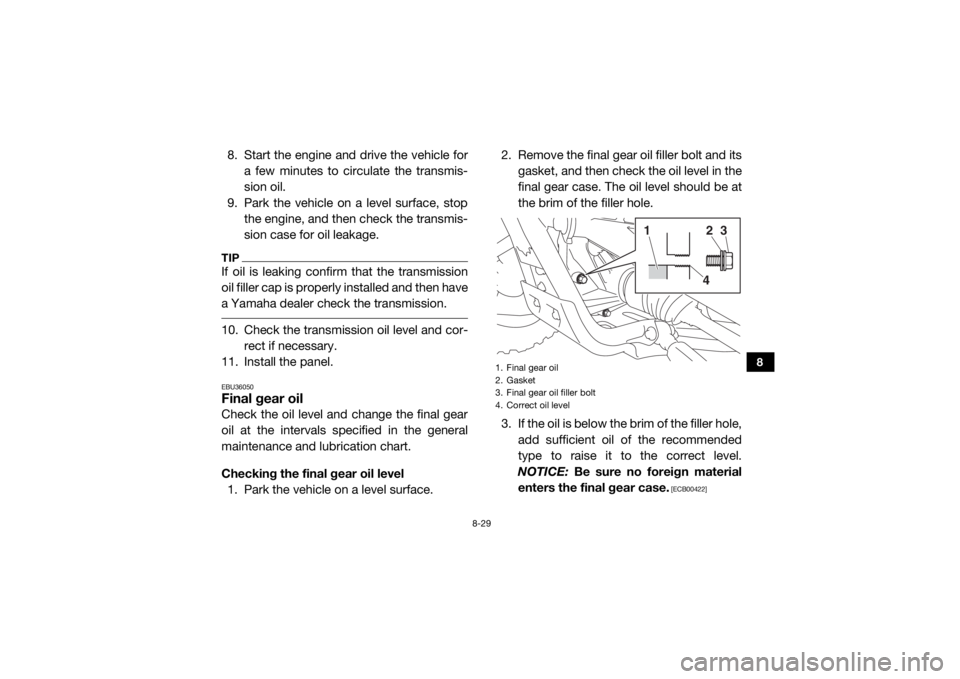

10. Slide the front portion of the center bot- tom panel into place as shown, and then

hook the left and right sides of the center

bottom panel into place.

1. Torque wrench

1

1. Center bottom panel

1

U2HC7ME0.book Page 23 Tuesday, April 19, 2016 10:33 AM

Page 155 of 208

8-29

8

8. Start the engine and drive the vehicle fora few minutes to circulate the transmis-

sion oil.

9. Park the vehicle on a level surface, stop the engine, and then check the transmis-

sion case for oil leakage.TIPIf oil is leaking confirm that the transmission

oil filler cap is properly installed and then have

a Yamaha dealer check the transmission. 10. Check the transmission oil level and cor- rect if necessary.

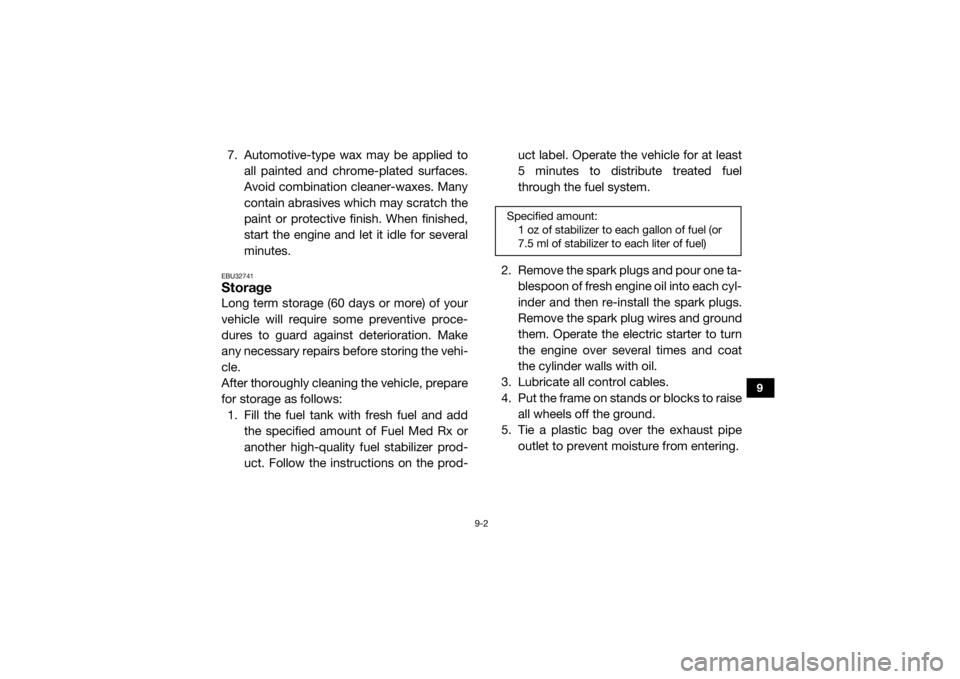

11. Install the panel.EBU36050Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the general

maintenance and lubrication chart.

Checking the final gear oil level 1. Park the vehicle on a level surface. 2. Remove the final gear oil filler bolt and its

gasket, and then check the oil level in the

final gear case. The oil level should be at

the brim of the filler hole.

3. If the oil is below the brim of the filler hole, add sufficient oil of the recommended

type to raise it to the correct level.

NOTICE: Be sure no foreign material

enters the final gear case.

[ECB00422]

1. Final gear oil

2. Gasket

3. Final gear oil filler bolt

4. Correct oil level

24

3

1

U2HC7ME0.book Page 29 Tuesday, April 19, 2016 10:33 AM

Page 195 of 208

9-2

9

7. Automotive-type wax may be applied toall painted and chrome-plated surfaces.

Avoid combination cleaner-waxes. Many

contain abrasives which may scratch the

paint or protective finish. When finished,

start the engine and let it idle for several

minutes.EBU32741StorageLong term storage (60 days or more) of your

vehicle will require some preventive proce-

dures to guard against deterioration. Make

any necessary repairs before storing the vehi-

cle.

After thoroughly cleaning the vehicle, prepare

for storage as follows:

1. Fill the fuel tank with fresh fuel and add the specified amount of Fuel Med Rx or

another high-quality fuel stabilizer prod-

uct. Follow the instructions on the prod- uct label. Operate the vehicle for at least

5 minutes to distribute treated fuel

through the fuel system.

2. Remove the spark plugs and pour one ta- blespoon of fresh engine oil into each cyl-

inder and then re-install the spark plugs.

Remove the spark plug wires and ground

them. Operate the electric starter to turn

the engine over several times and coat

the cylinder walls with oil.

3. Lubricate all control cables.

4. Put the frame on stands or blocks to raise all wheels off the ground.

5. Tie a plastic bag over the exhaust pipe outlet to prevent moisture from entering.

Specified amount:1 oz of stabilizer to each gallon of fuel (or

7.5 ml of stabilizer to each liter of fuel)

U2HC7ME0.book Page 2 Tuesday, April 19, 2016 10:33 AM

Page 197 of 208

10-1

10

EBU32750

SPECIFICATIONS

Dimensions:Overall length:3121 mm (122.9 in)

Overall width: 1626 mm (64.0 in)

Overall height:

1834 mm (72.2 in)

Wheelbase: 2300 mm (90.6 in)

Ground clearance: 330 mm (13.0 in)

Minimum turning radius:

6000 mm (236 in)Weight:Curb weight:685.0 kg (1510 lb) (YXZ10YMXH)

708.0 kg (1561 lb) (YXZ10YMSH)Noise and vibration level:Noise level (77/311/EEC):

85.8 dB(A) at 4125 r/min (YXZ10YMSH,

YXZ10YMXH_EUR/FRA/GBR)

Uncertainty of measurement:

3.0 dB(A) (YXZ10YMSH, YXZ10YMXH_EUR/FRA/GBR)

A-weighted sound power level: 100.0 dB(A) at 4125 r/min (YXZ10YMSH,

YXZ10YMXH_EUR/FRA/GBR)

Uncertainty of measurement: 3.0 dB(A) (YXZ10YMSH, YXZ10YMXH_EUR/FRA/GBR) Vibration on seat (EN1032, ISO5008):

Will not exceed 0.5 m/s² (YXZ10YMSH,

YXZ10YMXH_EUR/FRA/GBR)

Uncertainty of measurement:

0.0 m/s² (YXZ10YMSH, YXZ10YMXH_EUR/FRA/GBR)

Vibration on handle (EN1032, ISO5008): Will not exceed 2.5 m/s² (YXZ10YMSH,

YXZ10YMXH_EUR/FRA/GBR)

Uncertainty of measurement: 0.2 m/s² (YXZ10YMSH, YXZ10YMXH_EUR/FRA/GBR)

Engine:Engine type:

Liquid cooled 4-stroke, DOHC

Cylinder arrangement: Inline 3-cylinder

Displacement: 998 cm³

Bore × stroke:

80.0 × 66.2 mm (3.15 × 2.61 in)

Compression ratio: 11.3 : 1

Starting system: Electric starter

Lubrication system:

Dry sumpEngine oil:Recommended brand:YAMALUBE

U2HC7ME0.book Page 1 Tuesday, April 19, 2016 10:33 AM

Page 198 of 208

10-2

10

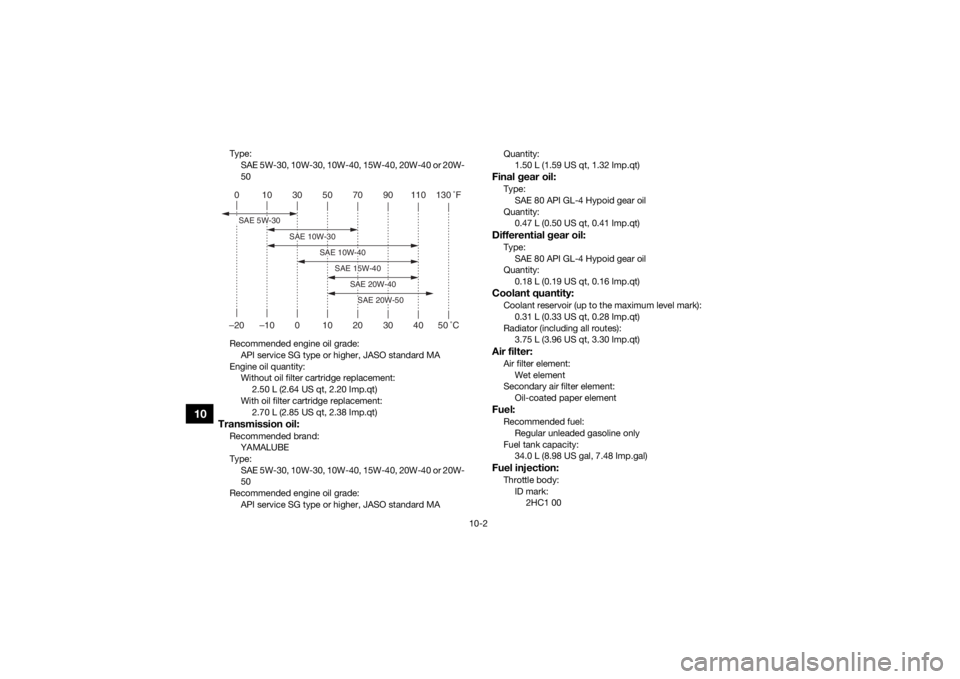

Type:SAE 5W-30, 10W-30, 10W-40, 15W-40, 20W-40 or 20W-

50

Recommended engine oil grade: API service SG type or higher, JASO standard MA

Engine oil quantity: Without oil filter cartridge replacement: 2.50 L (2.64 US qt, 2.20 Imp.qt)

With oil filter cartridge replacement: 2.70 L (2.85 US qt, 2.38 Imp.qt)Transmission oil:Recommended brand:YAMALUBE

Type: SAE 5W-30, 10W-30, 10W-40, 15W-40, 20W-40 or 20W-

50

Recommended engine oil grade: API service SG type or higher, JASO standard MA Quantity:

1.50 L (1.59 US qt, 1.32 Imp.qt)

Final gear oil:Type:

SAE 80 API GL-4 Hypoid gear oil

Quantity: 0.47 L (0.50 US qt, 0.41 Imp.qt)Differential gear oil:Type:

SAE 80 API GL-4 Hypoid gear oil

Quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)Coolant quantity:Coolant reservoir (up to the maximum level mark):

0.31 L (0.33 US qt, 0.28 Imp.qt)

Radiator (including all routes): 3.75 L (3.96 US qt, 3.30 Imp.qt)Air filter:Air filter element:

Wet element

Secondary air filter element: Oil-coated paper elementFuel:Recommended fuel:

Regular unleaded gasoline only

Fuel tank capacity: 34.0 L (8.98 US gal, 7.48 Imp.gal)Fuel injection:Throttle body:

ID mark: 2HC1 00

0 10 30 50 70 90 110 130 �F

–20 –10 0 10 20 30 40 50 �CSAE 5W-30

SAE 10W-30

SAE 10W-40

SAE 15W-40

SAE 20W-40SAE 20W-50

U2HC7ME0.book Page 2 Tuesday, April 19, 2016 10:33 AM

Page 205 of 208

12-1

12

INDEX

AAccelerator pedal ......................................................... 4-18

Accelerator pedal, checking ........................................ 8-49

Accelerator pedal, Pre-operation check ........................ 5-7

Air filter ......................................................................... 8-37

Air filter case hoses, cleaning ...................................... 8-41

Auxiliary DC jack .......................................................... 4-46

Axle boots .................................................................... 8-35BBasic guide for safe use ................................................ 7-1

Battery, Periodic maintenance .................................... 8-57

Bead lock, checking and tightening (YXZ10YMSH) .... 8-55

Brake and clutch fluid levels, checking ....................... 8-45

Brake fluid, replacing ................................................... 8-47

Brake light switch, adjusting ........................................ 8-50

Brake pedal .................................................................. 4-19

Brake pedal, checking ................................................. 8-48

Brakes, Periodic maintenance ..................................... 8-44

Brakes, Pre-operation check ......................................... 5-3CCable, inspecting and lubrication ................................ 8-51

Cargo bed .................................................................... 4-29

Cleaning ......................................................................... 9-1

Clutch pedal ................................................................. 4-19

Clutch pedal, checking ................................................ 8-47

Clutch, Pre-operation check .......................................... 5-3

Control cables, Pre-operation check ............................. 5-8

Coolant, Periodic maintenance ................................... 8-33

Coolant, Pre-operation check ........................................ 5-6Coolant temperature warning light ................................ 4-4

Cup holders ................................................................. 4-28

DDifferential gear lock indicator light ............................... 4-3

Differential gear oil, Periodic maintenance .................. 8-31

Differential gear, Pre-operation check ........................... 5-7

Doors ........................................................................... 4-22

Drive mode, selecting .................................................... 6-7

Driver seat position ...................................................... 4-24

Drive shaft universal joint, lubrication .......................... 8-53

Drivetrain icon ................................................................ 4-3EEngine break-in .............................................................. 6-1

Engine oil and oil filter, Periodic maintenance ............. 8-15

Engine oil, Pre-operation check .................................... 5-5

Engine trouble warning light .......................................... 4-5

EPS warning light .......................................................... 4-5FFinal gear oil, Periodic maintenance ............................ 8-29

Final gear, Pre-operation check .................................... 5-6

Fittings and fasteners, Pre-operation check ................. 5-8

Flag pole bracket ......................................................... 4-30

Front and rear brake pads, checking .......................... 8-44

Fuel, Pre-operation check ............................................. 5-4

Fuel tank cap ............................................................... 4-21

Fuse, replacing ............................................................ 8-61GGlove compartment ..................................................... 4-25HHeadlight beam, adjusting ........................................... 8-64

Headlights .................................................................... 8-63

U2HC7ME0.book Page 1 Tuesday, April 19, 2016 10:33 AM