check engine YAMAHA YXZ1000R SS 2017 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: YXZ1000R SS, Model: YAMAHA YXZ1000R SS 2017Pages: 208, PDF Size: 4.79 MB

Page 155 of 208

8-29

8

8. Start the engine and drive the vehicle fora few minutes to circulate the transmis-

sion oil.

9. Park the vehicle on a level surface, stop the engine, and then check the transmis-

sion case for oil leakage.TIPIf oil is leaking confirm that the transmission

oil filler cap is properly installed and then have

a Yamaha dealer check the transmission. 10. Check the transmission oil level and cor- rect if necessary.

11. Install the panel.EBU36050Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the general

maintenance and lubrication chart.

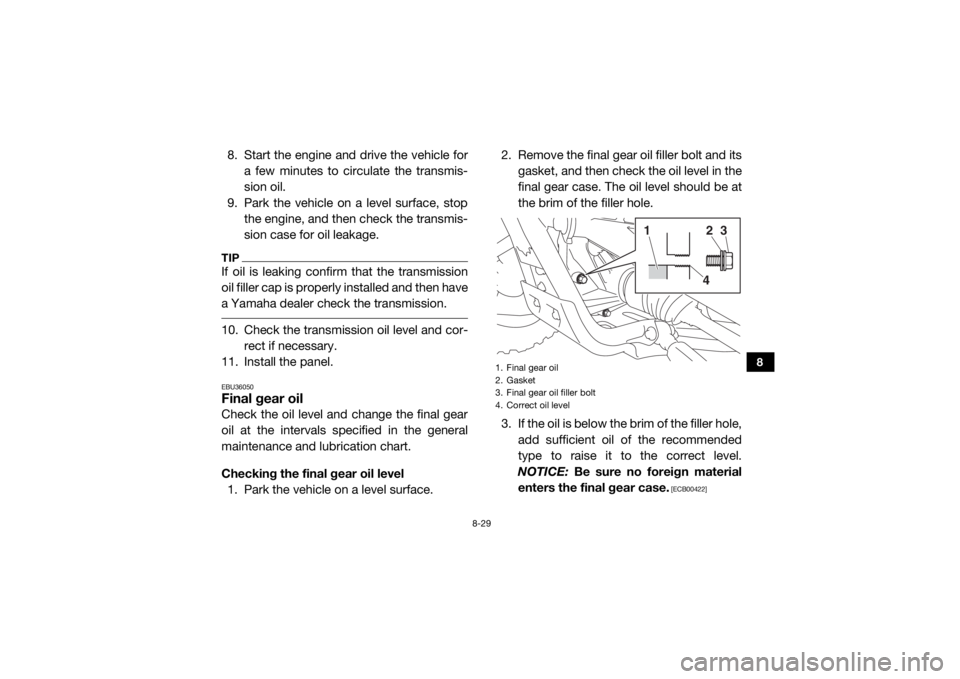

Checking the final gear oil level 1. Park the vehicle on a level surface. 2. Remove the final gear oil filler bolt and its

gasket, and then check the oil level in the

final gear case. The oil level should be at

the brim of the filler hole.

3. If the oil is below the brim of the filler hole, add sufficient oil of the recommended

type to raise it to the correct level.

NOTICE: Be sure no foreign material

enters the final gear case.

[ECB00422]

1. Final gear oil

2. Gasket

3. Final gear oil filler bolt

4. Correct oil level

24

3

1

U2HC7ME0.book Page 29 Tuesday, April 19, 2016 10:33 AM

Page 160 of 208

8-34

8

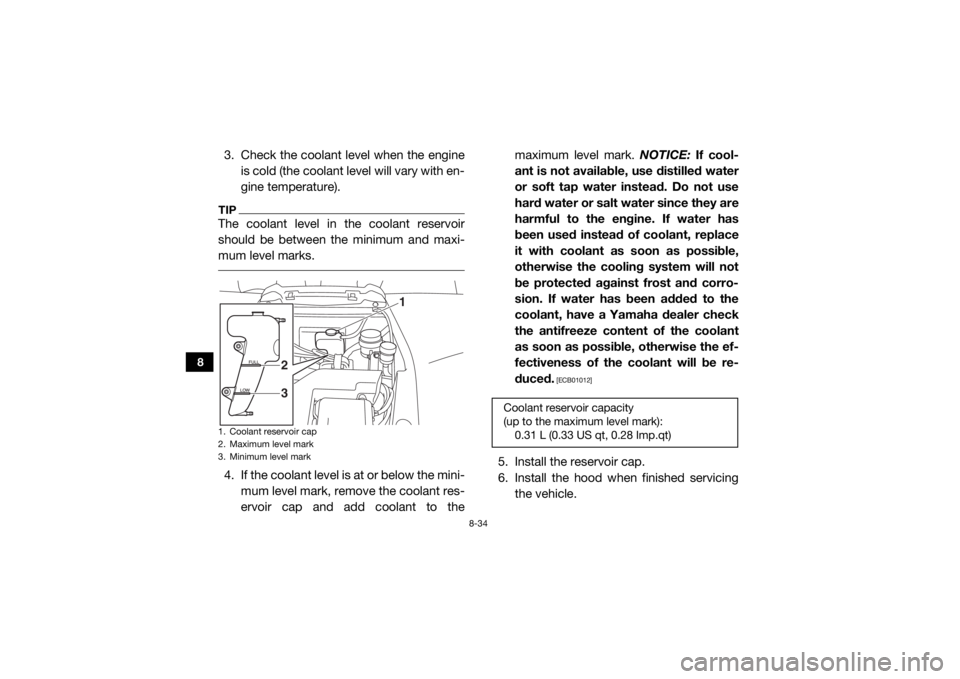

3. Check the coolant level when the engineis cold (the coolant level will vary with en-

gine temperature).TIPThe coolant level in the coolant reservoir

should be between the minimum and maxi-

mum level marks. 4. If the coolant level is at or below the mini-

mum level mark, remove the coolant res-

ervoir cap and add coolant to the maximum level mark.

NOTICE: If cool-

ant is not available, use distilled water

or soft tap water instead. Do not use

hard water or salt water since they are

harmful to the engine. If water has

been used instead of coolant, replace

it with coolant as soon as possible,

otherwise the cooling system will not

be protected against frost and corro-

sion. If water has been added to the

coolant, have a Yamaha dealer check

the antifreeze content of the coolant

as soon as possible, otherwise the ef-

fectiveness of the coolant will be re-

duced.

[ECB01012]

5. Install the reservoir cap.

6. Install the hood when finished servicing

the vehicle.

1. Coolant reservoir cap

2. Maximum level mark

3. Minimum level mark

1

32

Coolant reservoir capacity

(up to the maximum level mark):0.31 L (0.33 US qt, 0.28 Imp.qt)

U2HC7ME0.book Page 34 Tuesday, April 19, 2016 10:33 AM

Page 161 of 208

8-35

8

TIPThe radiator fan automatically switches on

or off according to the temperature of the

coolant in the radiator.

If the engine overheats, see page 8-67 for

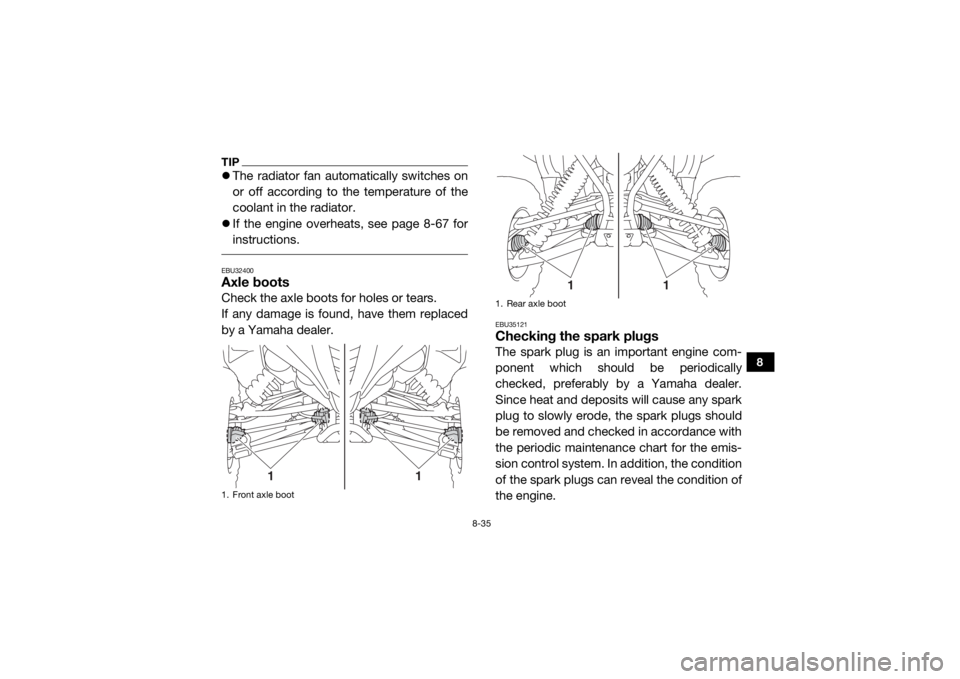

instructions. EBU32400Axle bootsCheck the axle boots for holes or tears.

If any damage is found, have them replaced

by a Yamaha dealer.

EBU35121Checking the spark plugsThe spark plug is an important engine com-

ponent which should be periodically

checked, preferably by a Yamaha dealer.

Since heat and deposits will cause any spark

plug to slowly erode, the spark plugs should

be removed and checked in accordance with

the periodic maintenance chart for the emis-

sion control system. In addition, the condition

of the spark plugs can reveal the condition of

the engine.

1. Front axle boot

1

1

1. Rear axle boot

1

1

U2HC7ME0.book Page 35 Tuesday, April 19, 2016 10:33 AM

Page 162 of 208

8-36

8

The porcelain insulator around the center

electrode of each spark plug should be a me-

dium-to-light tan color (the ideal color when

the vehicle is ridden normally), and all spark

plugs installed in the engine should have a

similar color. If any spark plug shows a dis-

tinctly different color, the engine could be op-

erating improperly. Do not attempt to

diagnose such problems yourself. Instead,

have a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode ero-

sion and excessive carbon or other deposits,

it should be replaced.

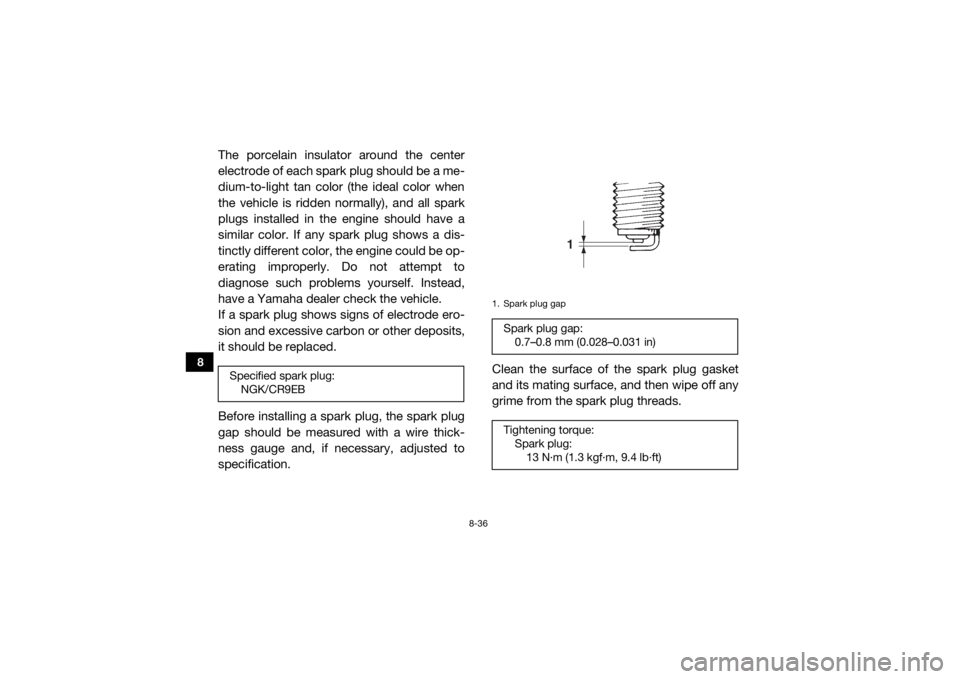

Before installing a spark plug, the spark plug

gap should be measured with a wire thick-

ness gauge and, if necessary, adjusted to

specification.Clean the surface of the spark plug gasket

and its mating surface, and then wipe off any

grime from the spark plug threads.Specified spark plug:

NGK/CR9EB

1. Spark plug gapSpark plug gap:0.7–0.8 mm (0.028–0.031 in)

Tightening torque: Spark plug:13 N·m (1.3 kgf·m, 9.4 lb·ft)

1

U2HC7ME0.book Page 36 Tuesday, April 19, 2016 10:33 AM

Page 164 of 208

8-38

8

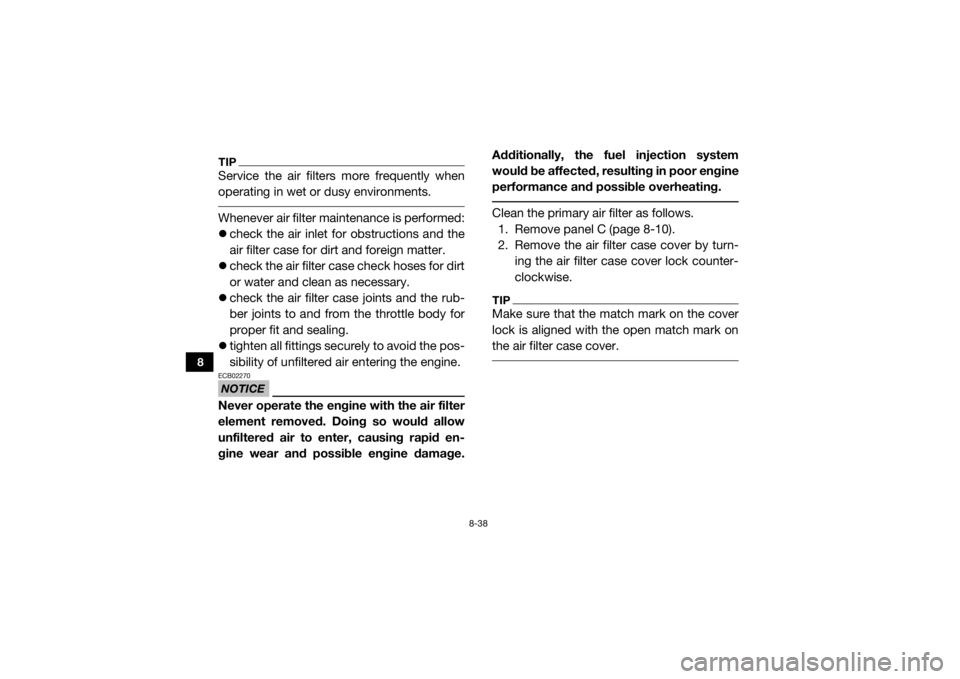

TIPService the air filters more frequently when

operating in wet or dusy environments. Whenever air filter maintenance is performed:

check the air inlet for obstructions and the

air filter case for dirt and foreign matter.

check the air filter case check hoses for dirt

or water and clean as necessary.

check the air filter cas e joints and the rub-

ber joints to and from the throttle body for

proper fit and sealing.

tighten all fittings securely to avoid the pos-

sibility of unfiltered air entering the engine.NOTICEECB02270Never operate the engine with the air filter

element removed. Doing so would allow

unfiltered air to enter, causing rapid en-

gine wear and possible engine damage. Additionally, the fuel injection system

would be affected, resulting in poor engine

performance and possible overheating.

Clean the primary air filter as follows.

1. Remove panel C (page 8-10).

2. Remove the air filter case cover by turn- ing the air filter case cover lock counter-

clockwise.TIPMake sure that the match mark on the cover

lock is aligned with the open match mark on

the air filter case cover.

U2HC7ME0.book Page 38 Tuesday, April 19, 2016 10:33 AM

Page 168 of 208

8-42

8

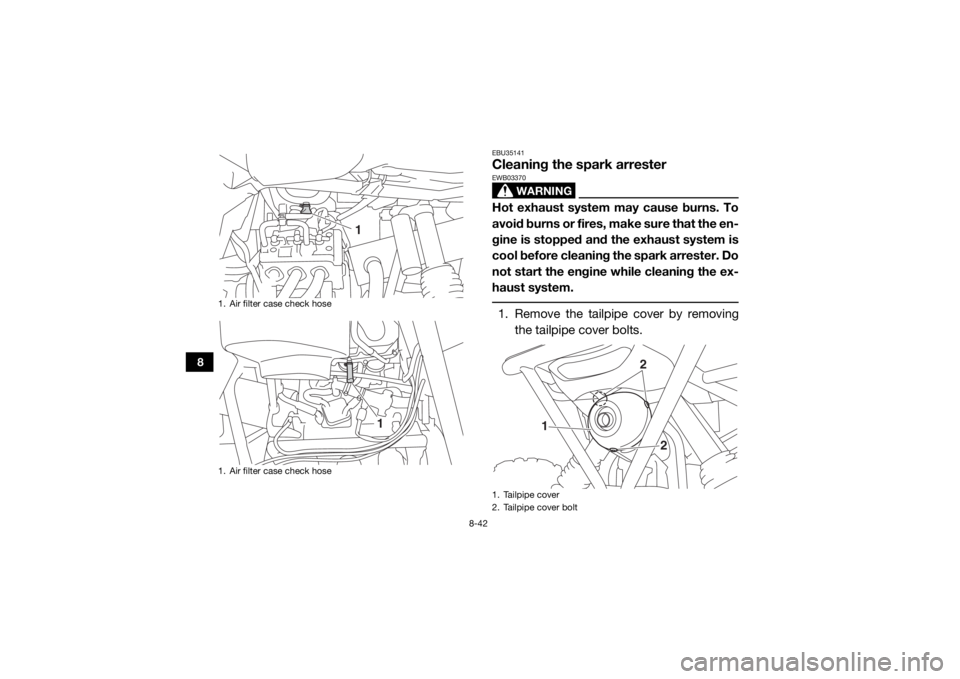

EBU35141Cleaning the spark arrester

WARNING

EWB03370Hot exhaust system may cause burns. To

avoid burns or fires, make sure that the en-

gine is stopped and the exhaust system is

cool before cleaning the spark arrester. Do

not start the engine while cleaning the ex-

haust system. 1. Remove the tailpipe cover by removingthe tailpipe cover bolts.

1. Air filter case check hose

1. Air filter case check hose

1

1

1. Tailpipe cover

2. Tailpipe cover bolt

1

2

2

U2HC7ME0.book Page 42 Tuesday, April 19, 2016 10:33 AM

Page 170 of 208

8-44

8

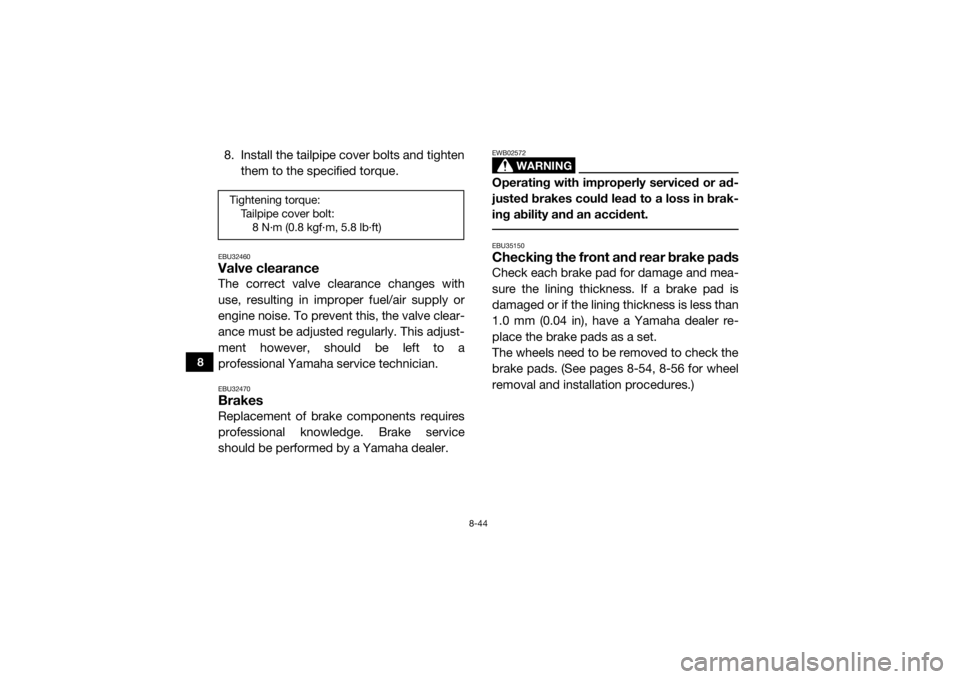

8. Install the tailpipe cover bolts and tightenthem to the specified torque.EBU32460Valve clearanceThe correct valve clearance changes with

use, resulting in improper fuel/air supply or

engine noise. To preven t this, the valve clear-

ance must be adjusted regularly. This adjust-

ment however, should be left to a

professional Yamaha service technician.EBU32470BrakesReplacement of brake components requires

professional knowledge. Brake service

should be performed by a Yamaha dealer.

WARNING

EWB02572Operating with improperly serviced or ad-

justed brakes could lead to a loss in brak-

ing ability and an accident. EBU35150Checking the front and rear brake padsCheck each brake pad for damage and mea-

sure the lining thickness. If a brake pad is

damaged or if the lining thickness is less than

1.0 mm (0.04 in), have a Yamaha dealer re-

place the brake pads as a set.

The wheels need to be removed to check the

brake pads. (See pages 8-54, 8-56 for wheel

removal and installation procedures.)

Tightening torque: Tailpipe cover bolt:8 N·m (0.8 kgf·m, 5.8 lb·ft)

U2HC7ME0.book Page 44 Tuesday, April 19, 2016 10:33 AM

Page 192 of 208

8-66

8

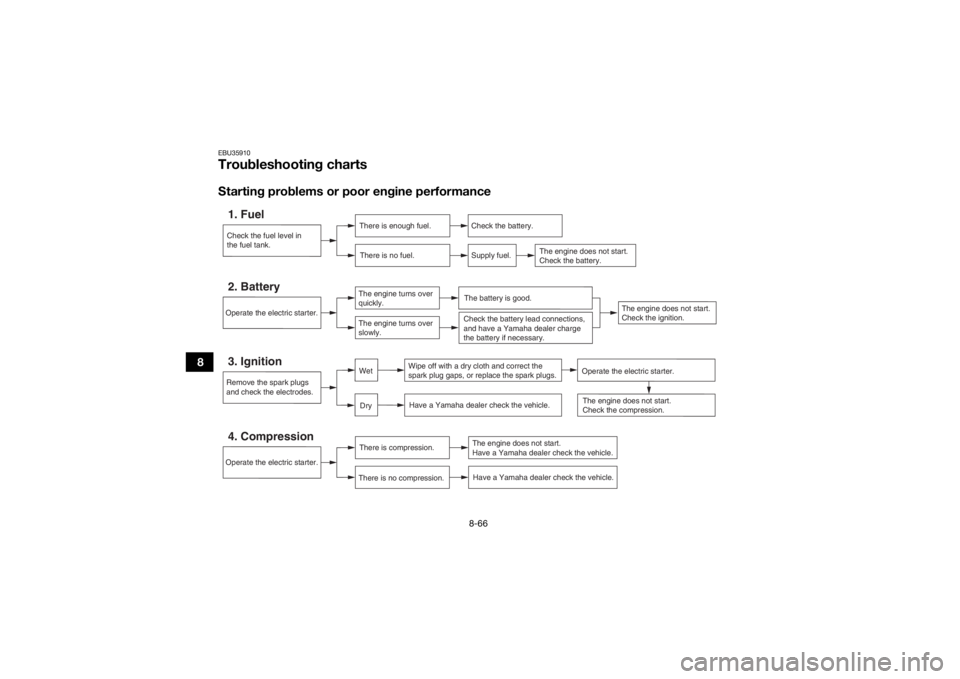

EBU35910Troubleshooting chartsStarting problems or poor engine performanceCheck the fuel level in

the fuel tank.1. Fuel

There is enough fuel.There is no fuel.

Check the battery.

Supply fuel.

The engine does not start.

Check the battery.

Operate the electric starter.4. Compression

There is compression.

There is no compression.

The engine does not start.

Have a Yamaha dealer check the vehicle.Have a Yamaha dealer check the vehicle.

Remove the spark plugs

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gaps, or replace the spark plugs. Have a Yamaha dealer check the vehicle.

The engine does not start.

Check the compression.

Operate the electric starter.2. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.

DryWet

Operate the electric starter.

Check the battery lead connections,

and have a Yamaha dealer charge

the battery if necessary.

The engine does not start.

Check the ignition.

U2HC7ME0.book Page 66 Tuesday, April 19, 2016 10:33 AM

Page 193 of 208

8-67

8

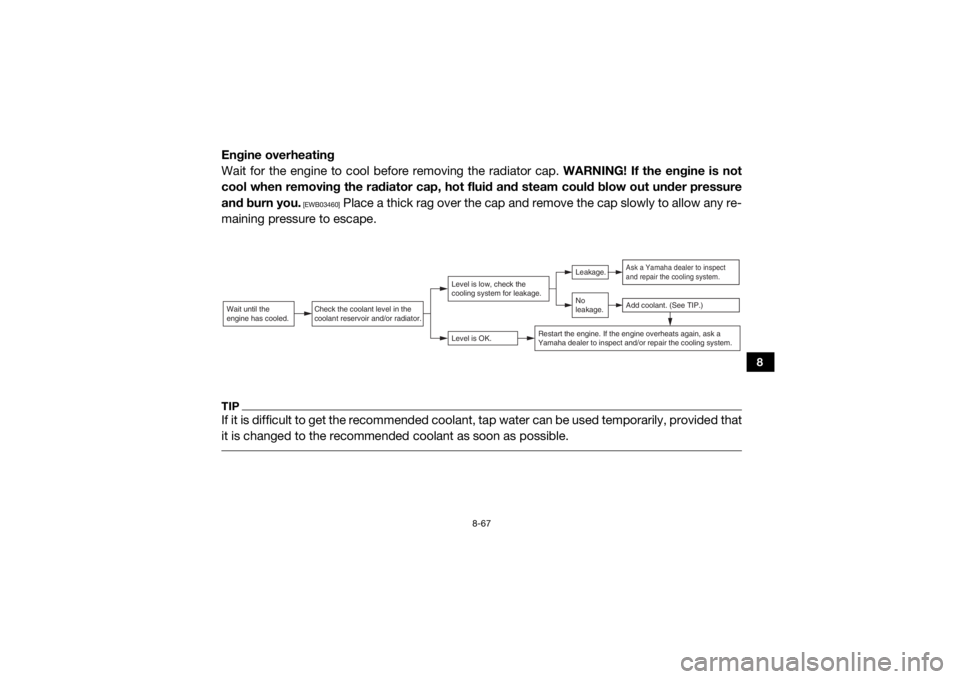

Engine overheating

Wait for the engine to cool before removing the radiator cap. WARNING! If the engine is not

cool when removing the radiator cap, hot fluid and steam could blow out under pressure

and burn you.

[EWB03460]

Place a thick rag over the cap and remove the cap slowly to allow any re-

maining pressure to escape.

TIPIf it is difficult to get the recommended coolant, tap water can be used temporarily, provided that

it is changed to the recommended coolant as soon as possible. Wait until the

engine has cooled.

Check the coolant level in the

coolant reservoir and/or radiator.

Level is OK.Level is low, check the

cooling system for leakage.

No

leakage.Leakage.

Ask a Yamaha dealer to inspect

and repair the cooling system.Add coolant. (See TIP.)

Restart the engine. If the engine overheats again, ask a

Yamaha dealer to inspect and/or repair the cooling system.

U2HC7ME0.book Page 67 Tuesday, April 19, 2016 10:33 AM

Page 205 of 208

12-1

12

INDEX

AAccelerator pedal ......................................................... 4-18

Accelerator pedal, checking ........................................ 8-49

Accelerator pedal, Pre-operation check ........................ 5-7

Air filter ......................................................................... 8-37

Air filter case hoses, cleaning ...................................... 8-41

Auxiliary DC jack .......................................................... 4-46

Axle boots .................................................................... 8-35BBasic guide for safe use ................................................ 7-1

Battery, Periodic maintenance .................................... 8-57

Bead lock, checking and tightening (YXZ10YMSH) .... 8-55

Brake and clutch fluid levels, checking ....................... 8-45

Brake fluid, replacing ................................................... 8-47

Brake light switch, adjusting ........................................ 8-50

Brake pedal .................................................................. 4-19

Brake pedal, checking ................................................. 8-48

Brakes, Periodic maintenance ..................................... 8-44

Brakes, Pre-operation check ......................................... 5-3CCable, inspecting and lubrication ................................ 8-51

Cargo bed .................................................................... 4-29

Cleaning ......................................................................... 9-1

Clutch pedal ................................................................. 4-19

Clutch pedal, checking ................................................ 8-47

Clutch, Pre-operation check .......................................... 5-3

Control cables, Pre-operation check ............................. 5-8

Coolant, Periodic maintenance ................................... 8-33

Coolant, Pre-operation check ........................................ 5-6Coolant temperature warning light ................................ 4-4

Cup holders ................................................................. 4-28

DDifferential gear lock indicator light ............................... 4-3

Differential gear oil, Periodic maintenance .................. 8-31

Differential gear, Pre-operation check ........................... 5-7

Doors ........................................................................... 4-22

Drive mode, selecting .................................................... 6-7

Driver seat position ...................................................... 4-24

Drive shaft universal joint, lubrication .......................... 8-53

Drivetrain icon ................................................................ 4-3EEngine break-in .............................................................. 6-1

Engine oil and oil filter, Periodic maintenance ............. 8-15

Engine oil, Pre-operation check .................................... 5-5

Engine trouble warning light .......................................... 4-5

EPS warning light .......................................................... 4-5FFinal gear oil, Periodic maintenance ............................ 8-29

Final gear, Pre-operation check .................................... 5-6

Fittings and fasteners, Pre-operation check ................. 5-8

Flag pole bracket ......................................................... 4-30

Front and rear brake pads, checking .......................... 8-44

Fuel, Pre-operation check ............................................. 5-4

Fuel tank cap ............................................................... 4-21

Fuse, replacing ............................................................ 8-61GGlove compartment ..................................................... 4-25HHeadlight beam, adjusting ........................................... 8-64

Headlights .................................................................... 8-63

U2HC7ME0.book Page 1 Tuesday, April 19, 2016 10:33 AM