engine YAMAHA YZ125LC 2001 Repair Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ125LC, Model: YAMAHA YZ125LC 2001Pages: 558, PDF Size: 13.11 MB

Page 330 of 558

4-61

ENGENGINE REMOVAL

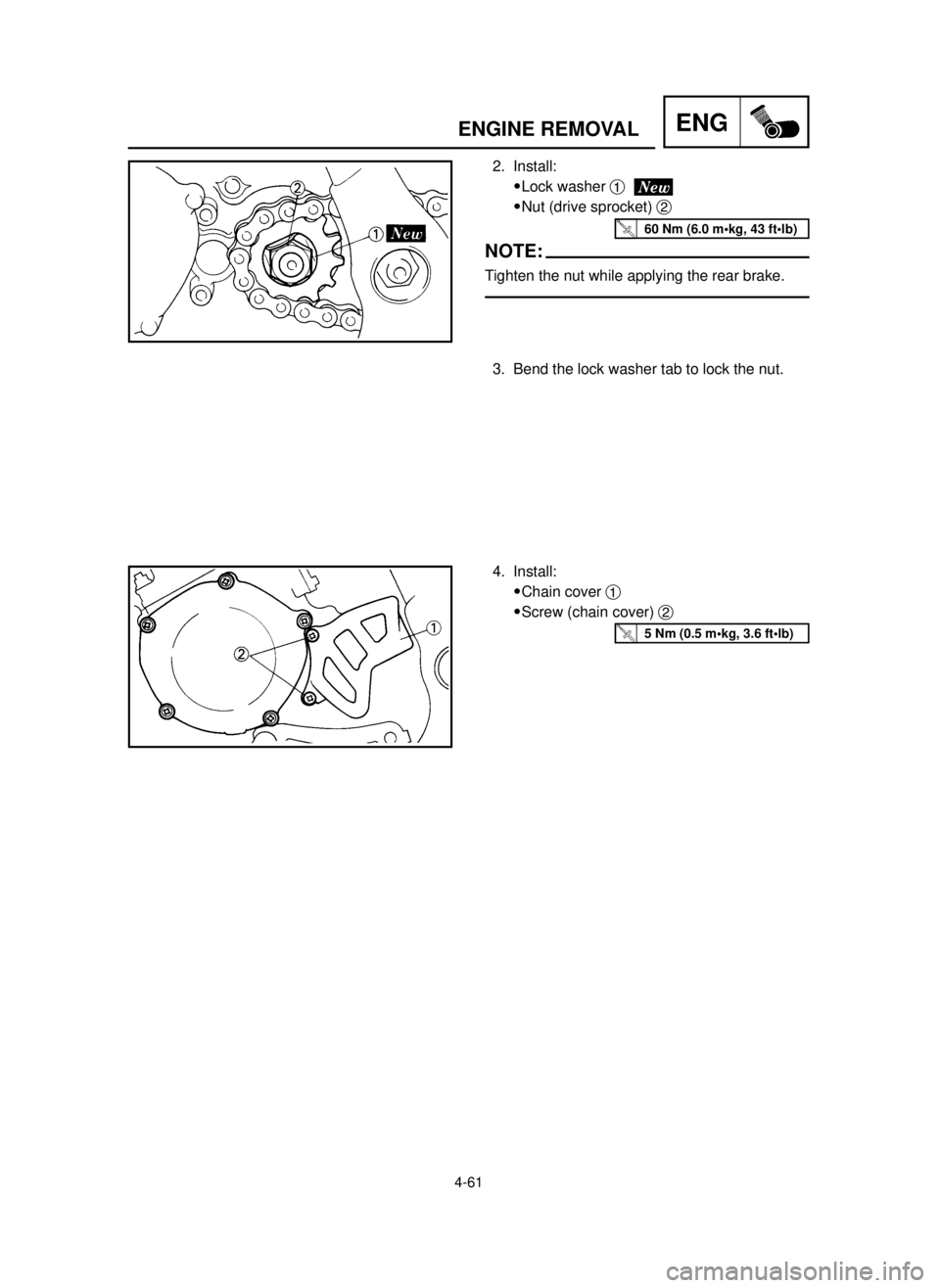

2. Install:

9Lock washer 1

9Nut (drive sprocket) 2

NOTE:

Tighten the nut while applying the rear brake.

3. Bend the lock washer tab to lock the nut.

4. Install:

9Chain cover 1

9Screw (chain cover) 2

5 Nm (0.5 m•kg, 3.6 ft•lb)

60 Nm (6.0 m•kg, 43 ft•lb)

5MV-9-30-4D 6/19/00 1:39 PM Page 10

Page 332 of 558

4-62

ENGCRANKCASE AND CRANKSHAFT

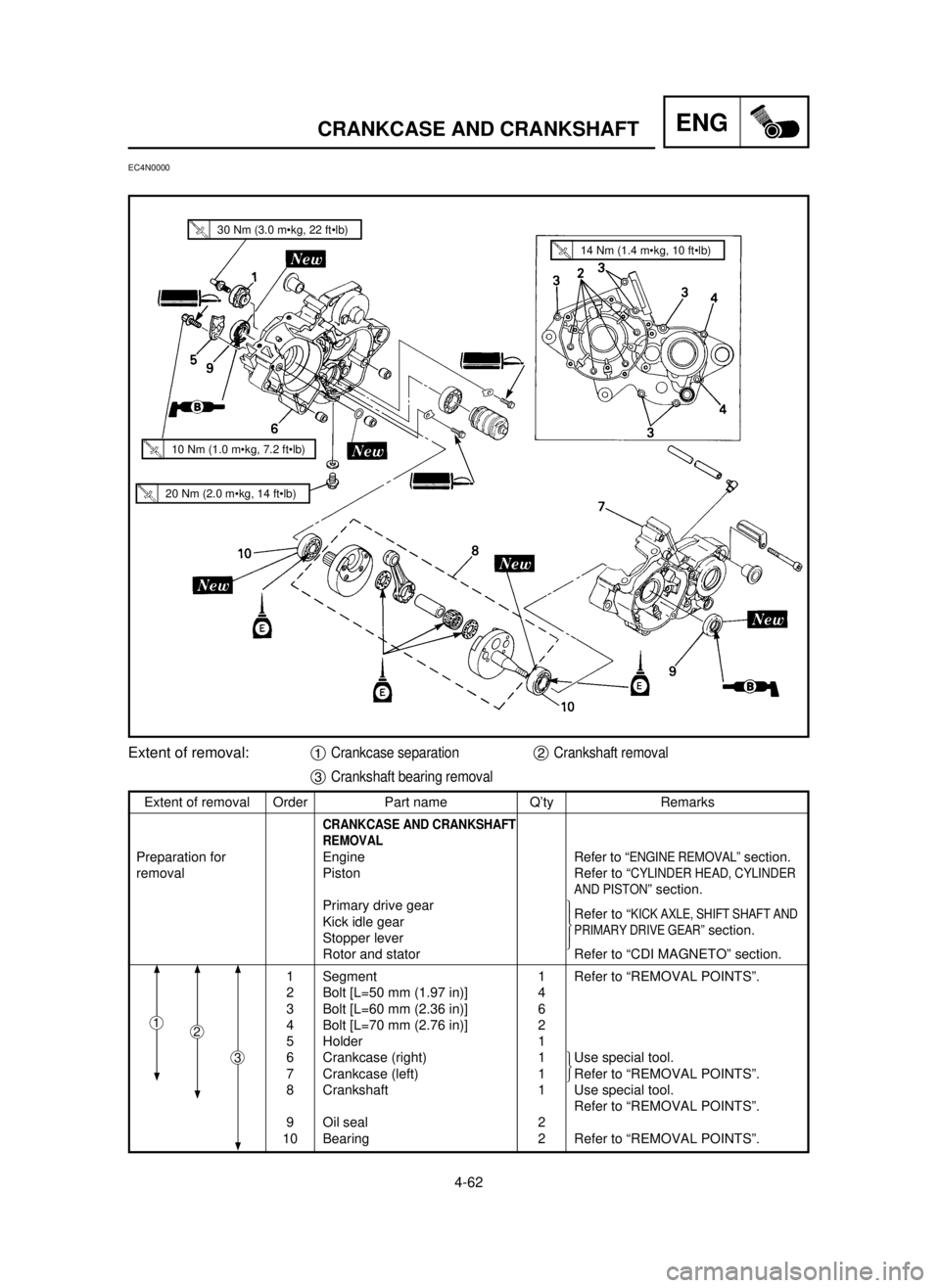

Extent of removal Order Part name Q’ty Remarks

CRANKCASE AND CRANKSHAFT

REMOVAL

Preparation for Engine Refer to “ENGINE REMOVAL”section.

removal Piston Refer to “

CYLINDER HEAD, CYLINDER

AND PISTON

” section.

Primary drive gear

Kick idle gearRefer to “

KICK AXLE, SHIFT SHAFT AND

Stopper leverPRIMARY DRIVE GEAR”section.

Rotor and stator Refer to “CDI MAGNETO” section.

1 Segment 1 Refer to “REMOVAL POINTS”.

2 Bolt [L=50 mm (1.97 in)] 4

3 Bolt [L=60 mm (2.36 in)] 6

4 Bolt [L=70 mm (2.76 in)] 2

5 Holder 1

6 Crankcase (right) 1 Use special tool.

7 Crankcase (left) 1 Refer to “REMOVAL POINTS”.

8 Crankshaft 1 Use special tool.

Refer to “REMOVAL POINTS”.

9 Oil seal 2

10 Bearing 2 Refer to “REMOVAL POINTS”.

ü

ï

ý

ï

þ

EC4N0000

12

3

Extent of removal:1Crankcase separation2Crankshaft removal

3Crankshaft bearing removal

ü

ý

þ

30 Nm (3.0 m•kg, 22 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

20 Nm (2.0 m•kg, 14 ft•lb)

14 Nm (1.4 m•kg, 10 ft•lb)

5MV-9-30-4D 6/19/00 1:39 PM Page 12

Page 334 of 558

4-63

ENGCRANKCASE AND CRANKSHAFT

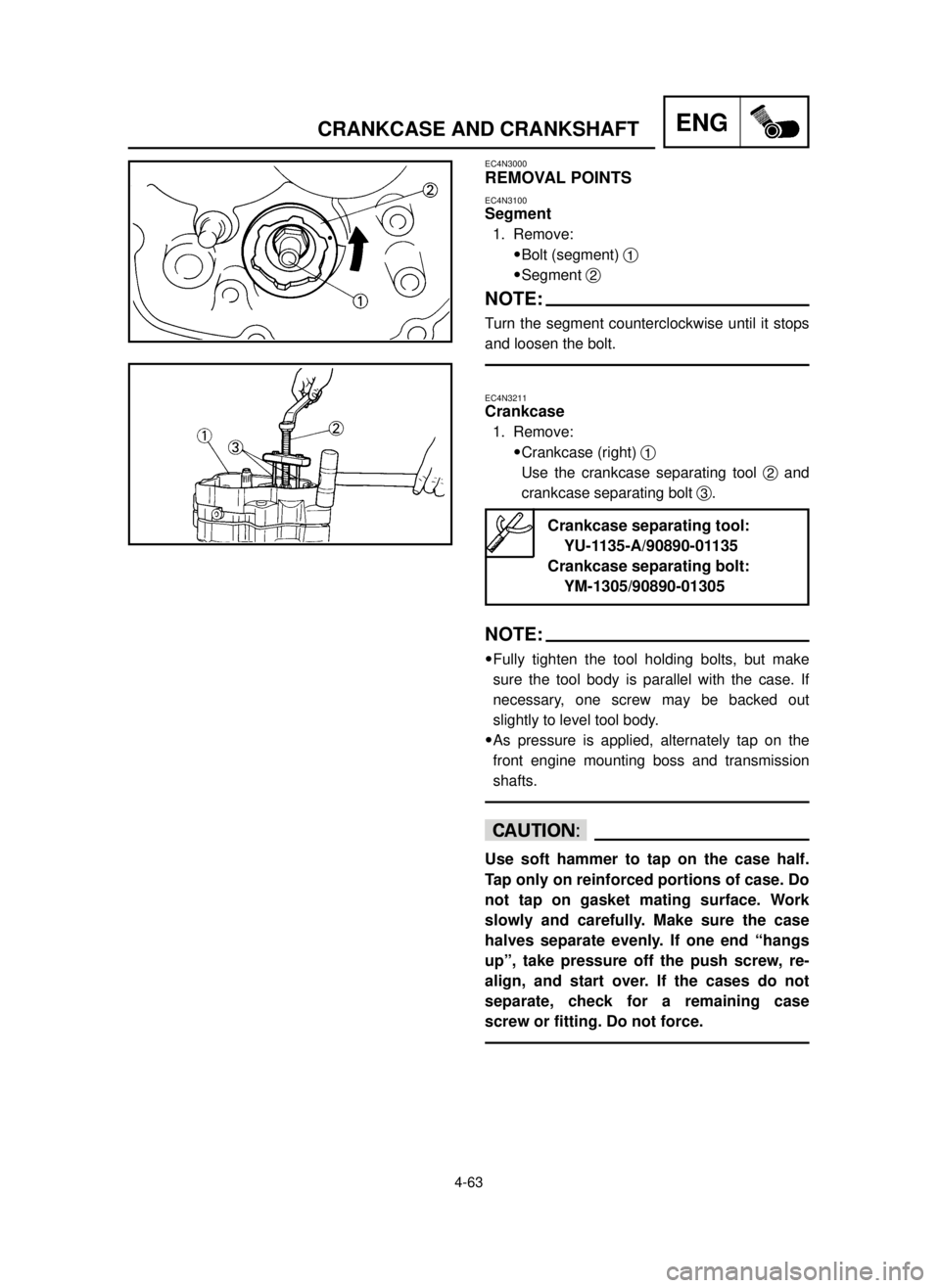

EC4N3000

REMOVAL POINTS

EC4N3100

Segment

1. Remove:

9Bolt (segment) 1

9Segment 2

NOTE:

Turn the segment counterclockwise until it stops

and loosen the bolt.

EC4N3211

Crankcase

1. Remove:

9Crankcase (right) 1

Use the crankcase separating tool 2and

crankcase separating bolt 3.

NOTE:

9Fully tighten the tool holding bolts, but make

sure the tool body is parallel with the case. If

necessary, one screw may be backed out

slightly to level tool body.

9As pressure is applied, alternately tap on the

front engine mounting boss and transmission

shafts.

cC

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case. Do

not tap on gasket mating surface. Work

slowly and carefully. Make sure the case

halves separate evenly. If one end “hangs

up”, take pressure off the push screw, re-

align, and start over. If the cases do not

separate, check for a remaining case

screw or fitting. Do not force.

Crankcase separating tool:

YU-1135-A/90890-01135

Crankcase separating bolt:

YM-1305/90890-01305

5MV-9-30-4D 6/19/00 1:39 PM Page 14

Page 336 of 558

4-64

ENGCRANKCASE AND CRANKSHAFT

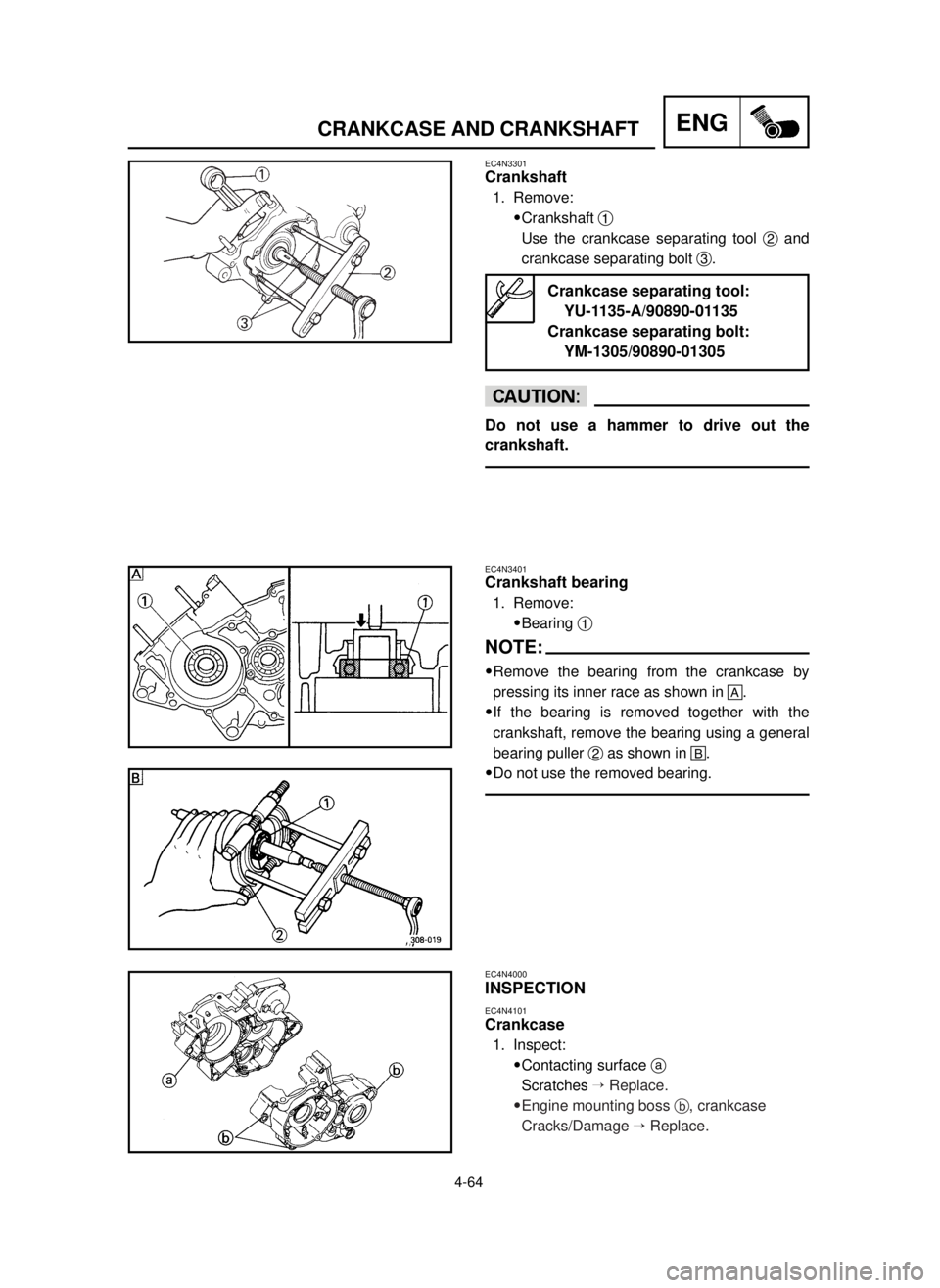

EC4N3301

Crankshaft

1. Remove:

9Crankshaft 1

Use the crankcase separating tool 2and

crankcase separating bolt 3.

cC

Do not use a hammer to drive out the

crankshaft.

EC4N3401

Crankshaft bearing

1. Remove:

9Bearing 1

NOTE:

9Remove the bearing from the crankcase by

pressing its inner race as shown in Œ.

9If the bearing is removed together with the

crankshaft, remove the bearing using a general

bearing puller 2as shown in º.

9Do not use the removed bearing.

EC4N4000

INSPECTION

EC4N4101

Crankcase

1. Inspect:

9Contacting surface a

Scratches ÕReplace.

9Engine mounting boss b, crankcase

Cracks/Damage ÕReplace.

Crankcase separating tool:

YU-1135-A/90890-01135

Crankcase separating bolt:

YM-1305/90890-01305

5MV-9-30-4D 6/19/00 1:39 PM Page 16

Page 344 of 558

4-68

ENGCRANKCASE AND CRANKSHAFT

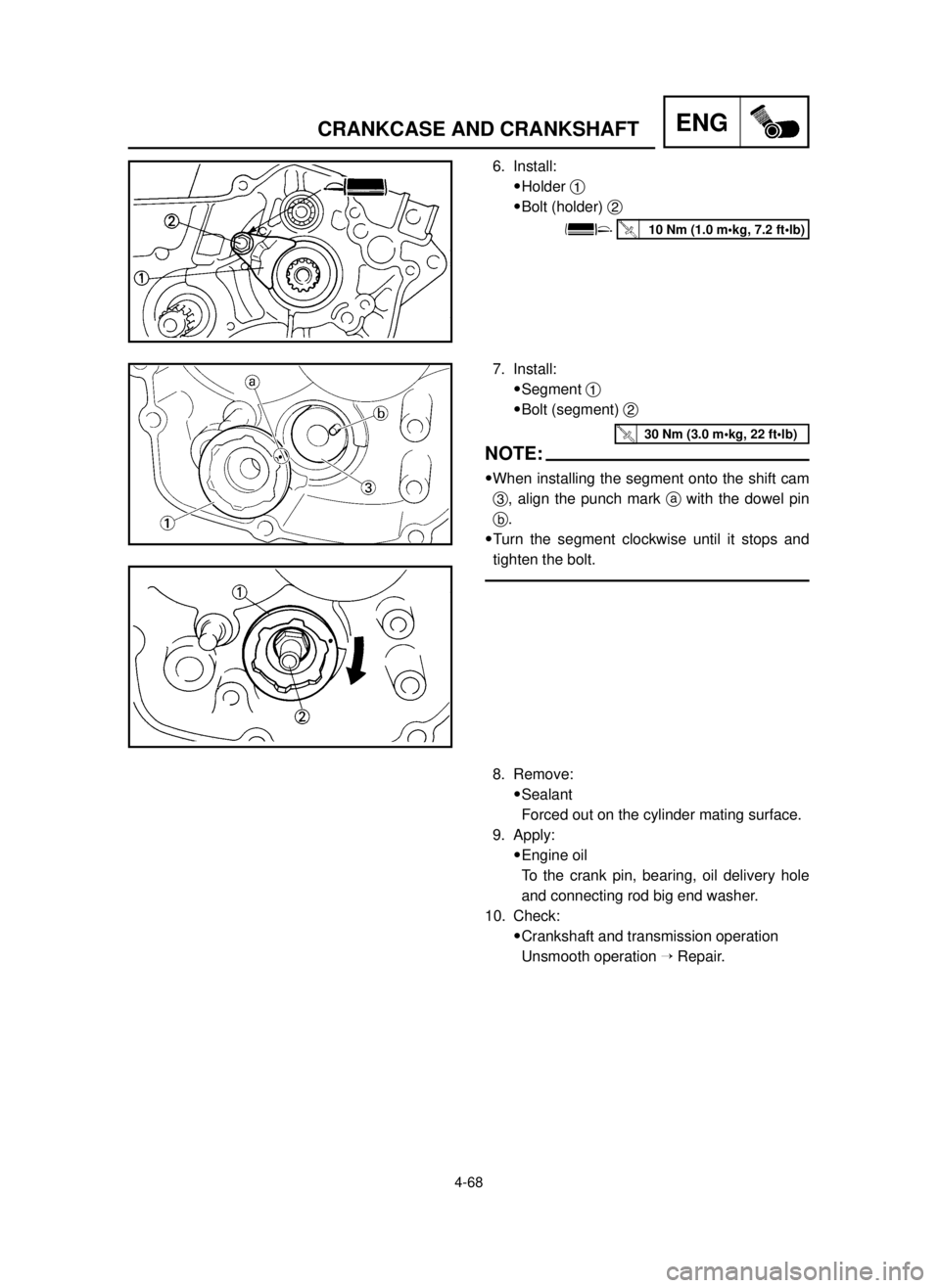

6. Install:

9Holder 1

9Bolt (holder) 2

7. Install:

9Segment 1

9Bolt (segment) 2

NOTE:

9When installing the segment onto the shift cam

3, align the punch mark awith the dowel pin

b.

9Turn the segment clockwise until it stops and

tighten the bolt.

8. Remove:

9Sealant

Forced out on the cylinder mating surface.

9. Apply:

9Engine oil

To the crank pin, bearing, oil delivery hole

and connecting rod big end washer.

10. Check:

9Crankshaft and transmission operation

Unsmooth operation ÕRepair.

30 Nm (3.0 m•kg, 22 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

5MV-9-30-4D 6/19/00 1:39 PM Page 24

Page 346 of 558

4-69

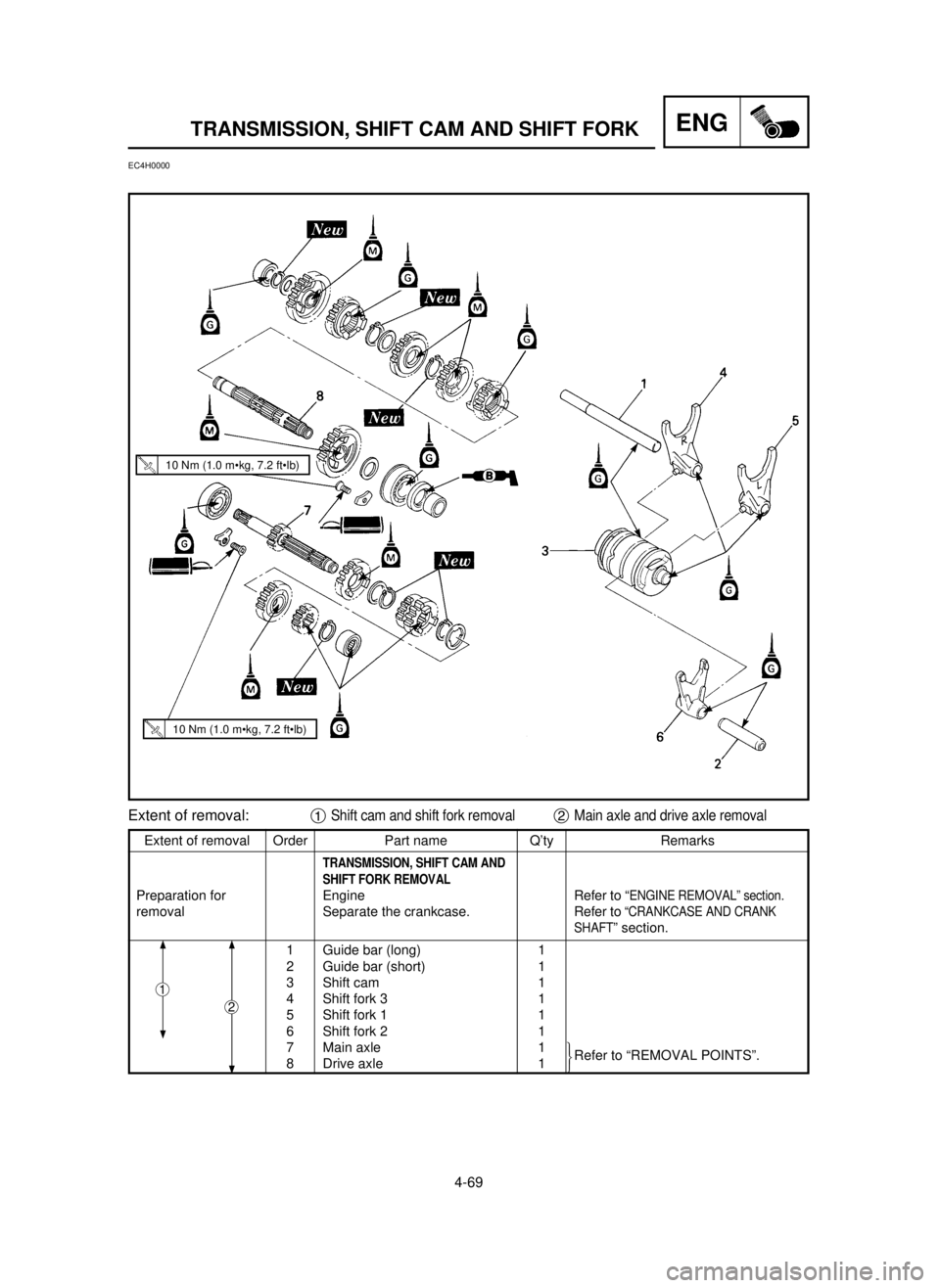

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

Extent of removal Order Part name Q’ty Remarks

TRANSMISSION, SHIFT CAM AND

SHIFT FORK REMOVAL

Preparation for EngineRefer to “ENGINE REMOVAL” section.

removal Separate the crankcase. Refer to“CRANKCASE AND CRANK

SHAFT

” section.

1 Guide bar (long) 1

2 Guide bar (short) 1

3 Shift cam 1

4 Shift fork 3 1

5 Shift fork 1 1

6 Shift fork 2 1

7 Main axle 1

8 Drive axle 1Refer to “REMOVAL POINTS”.

EC4H0000

Extent of removal:1Shift cam and shift fork removal2Main axle and drive axle removal

1

2

ü

ý

þ

10 Nm (1.0 m•kg, 7.2 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

5MV-9-30-4D 6/19/00 1:39 PM Page 26

Page 356 of 558

5-1

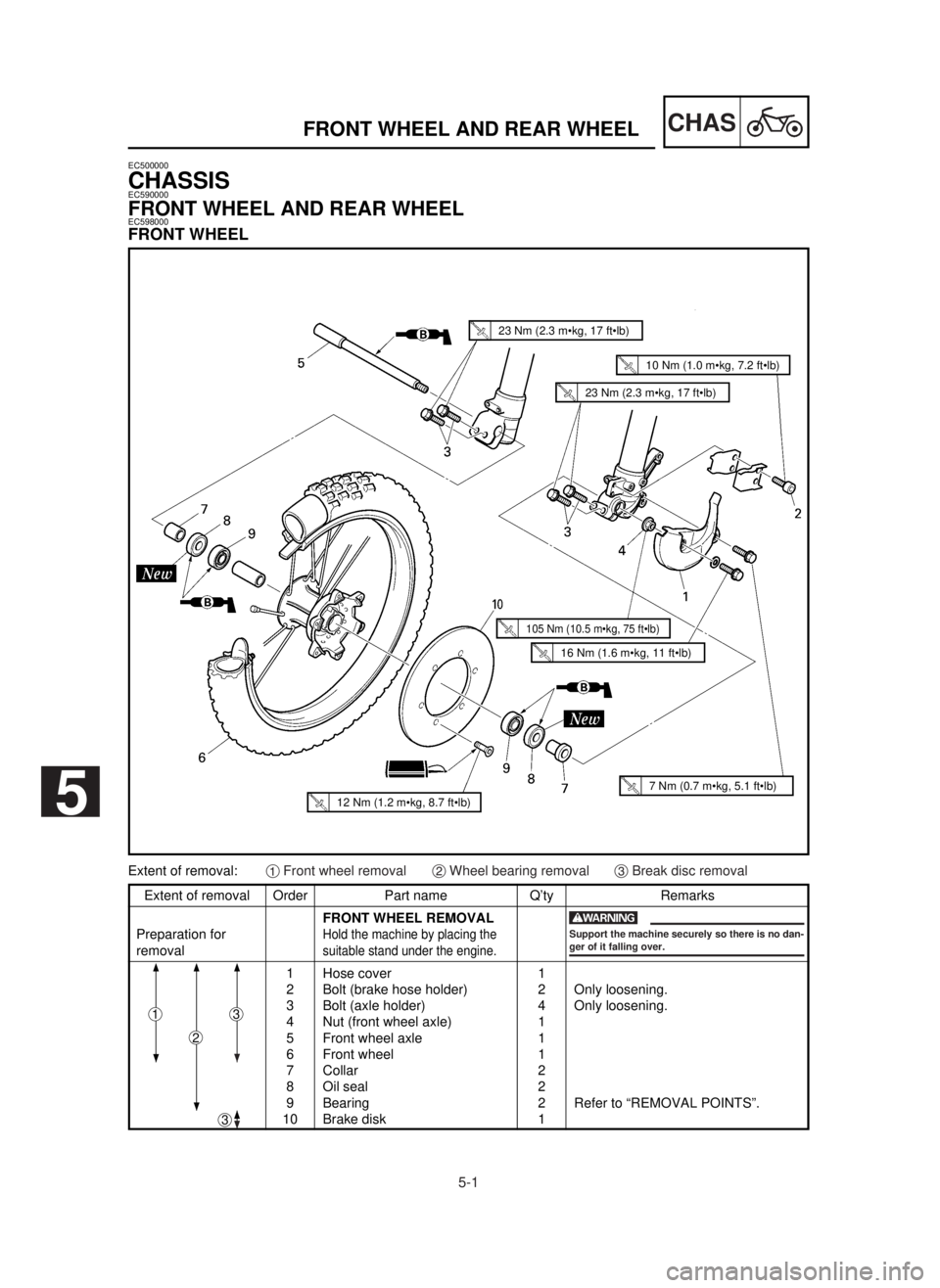

CHASFRONT WHEEL AND REAR WHEEL

Extent of removal Order Part name Q’ty Remarks

FRONT WHEEL REMOVAL

Preparation for

Hold the machine by placing the

removalsuitable stand under the engine.

1 Hose cover 1

2 Bolt (brake hose holder) 2 Only loosening.

3 Bolt (axle holder) 4 Only loosening.

4 Nut (front wheel axle) 1

5 Front wheel axle 1

6 Front wheel 1

7 Collar 2

8 Oil seal 2

9 Bearing 2 Refer to “REMOVAL POINTS”.

10 Brake disk 1

EC500000

CHASSISEC590000

FRONT WHEEL AND REAR WHEELEC598000

FRONT WHEEL

2

13

3

Extent of removal:1Front wheel removal2Wheel bearing removal3Break disc removal

w

Support the machine securely so there is no dan-

ger of it falling over.

5

23 Nm (2.3 m•kg, 17 ft•lb)

23 Nm (2.3 m•kg, 17 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

105 Nm (10.5 m•kg, 75 ft•lb)

16 Nm (1.6 m•kg, 11 ft•lb)

7 Nm (0.7 m•kg, 5.1 ft•lb)

12 Nm (1.2 m•kg, 8.7 ft•lb)

5MV-9-30-5A 6/19/00 1:35 PM Page 2

Page 358 of 558

5-2

CHASFRONT WHEEL AND REAR WHEEL

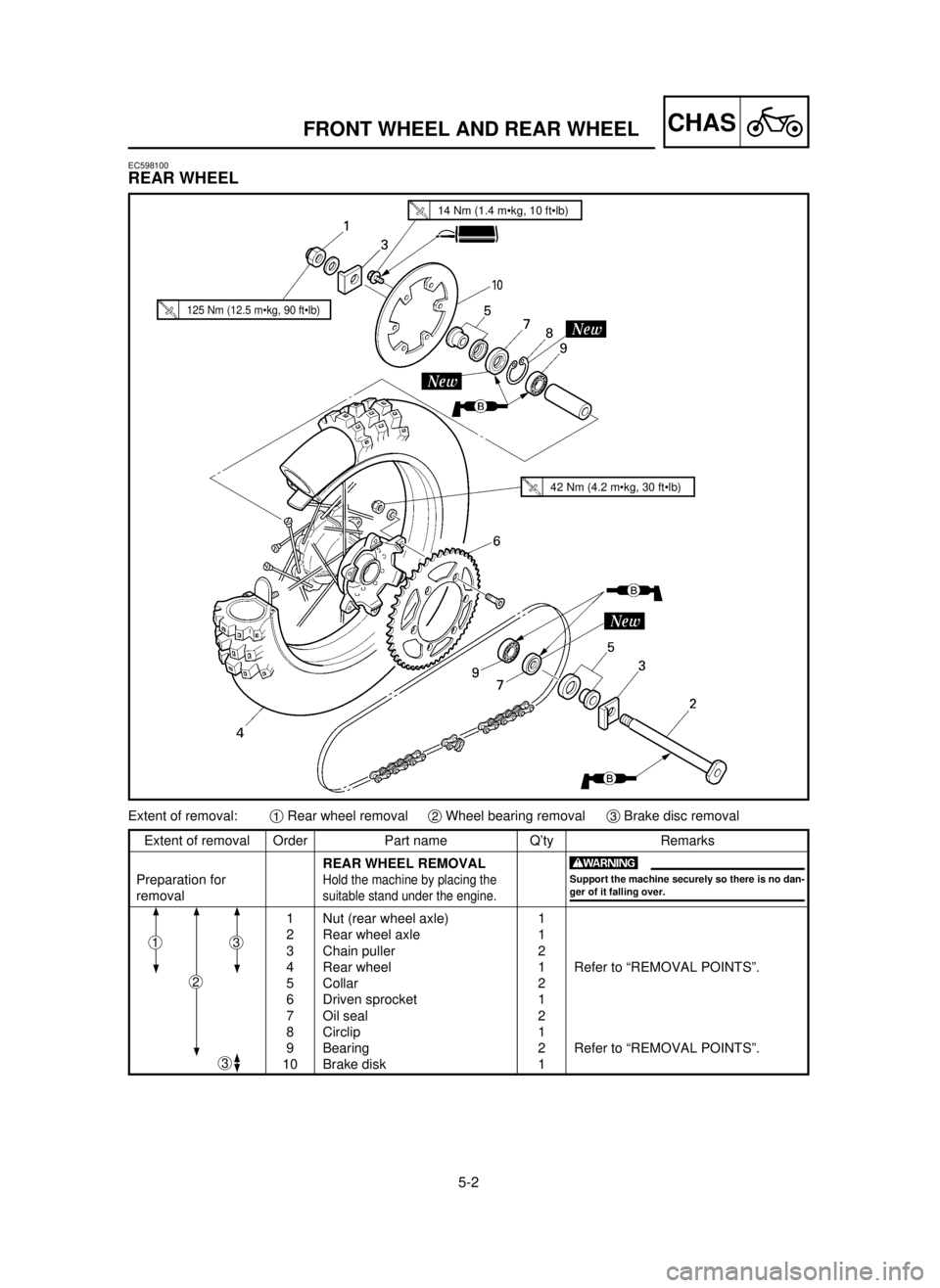

EC598100

REAR WHEEL

Extent of removal:1Rear wheel removal2Wheel bearing removal3Brake disc removal

Extent of removal Order Part name Q’ty Remarks

REAR WHEEL REMOVAL

Preparation for

Hold the machine by placing the

removalsuitable stand under the engine.

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Chain puller 2

4 Rear wheel 1 Refer to “REMOVAL POINTS”.

5 Collar 2

6 Driven sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to “REMOVAL POINTS”.

10 Brake disk 1

2

13

3

w

Support the machine securely so there is no dan-

ger of it falling over.

125 Nm (12.5 m•kg, 90 ft•lb)

14 Nm (1.4 m•kg, 10 ft•lb)

42 Nm (4.2 m•kg, 30 ft•lb)

5MV-9-30-5A 6/19/00 1:35 PM Page 4

Page 374 of 558

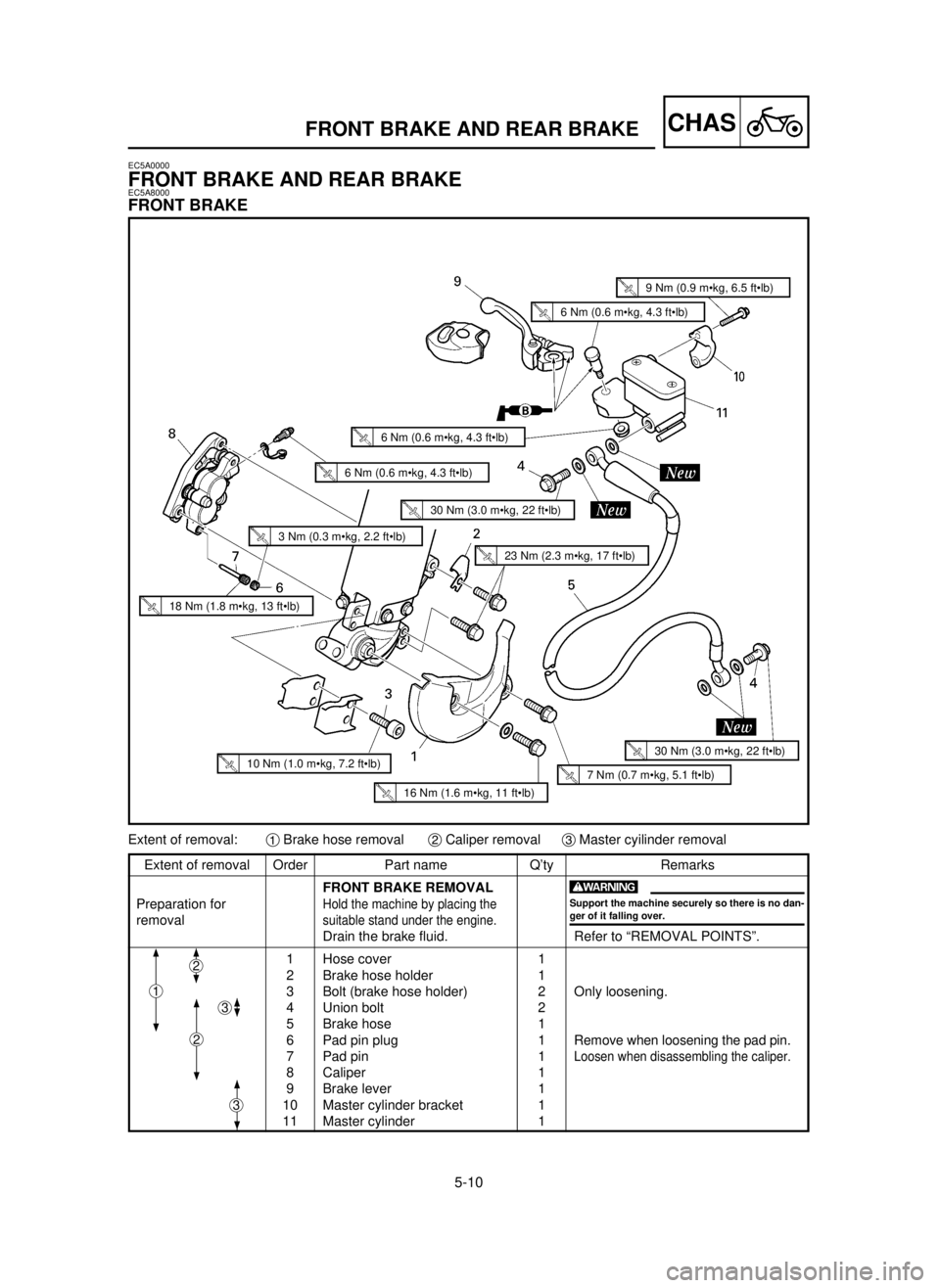

5-10

CHASFRONT BRAKE AND REAR BRAKE

Extent of removal Order Part name Q’ty Remarks

FRONT BRAKE REMOVAL

Preparation for

Hold the machine by placing the

removalsuitable stand under the engine.

Drain the brake fluid. Refer to “REMOVAL POINTS”.

1 Hose cover 1

2 Brake hose holder 1

3 Bolt (brake hose holder) 2 Only loosening.

4 Union bolt 2

5 Brake hose 1

6 Pad pin plug 1

Remove when loosening the pad pin.

7 Pad pin 1Loosen when disassembling the caliper.

8 Caliper 1

9 Brake lever 1

10 Master cylinder bracket 1

11 Master cylinder 1

EC5A0000

FRONT BRAKE AND REAR BRAKEEC5A8000

FRONT BRAKE

Extent of removal:1Brake hose removal2Caliper removal3Master cyilinder removal

w

Support the machine securely so there is no dan-

ger of it falling over.

2

1

3

3

2

9 Nm (0.9 m•kg, 6.5 ft•lb)

6 Nm (0.6 m•kg, 4.3 ft•lb)

6 Nm (0.6 m•kg, 4.3 ft•lb)

6 Nm (0.6 m•kg, 4.3 ft•lb)

3 Nm (0.3 m•kg, 2.2 ft•lb)

18 Nm (1.8 m•kg, 13 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)30 Nm (3.0 m•kg, 22 ft•lb)

7 Nm (0.7 m•kg, 5.1 ft•lb)

16 Nm (1.6 m•kg, 11 ft•lb)

23 Nm (2.3 m•kg, 17 ft•lb)

30 Nm (3.0 m•kg, 22 ft•lb)

5MV-9-30-5A 6/19/00 1:36 PM Page 20

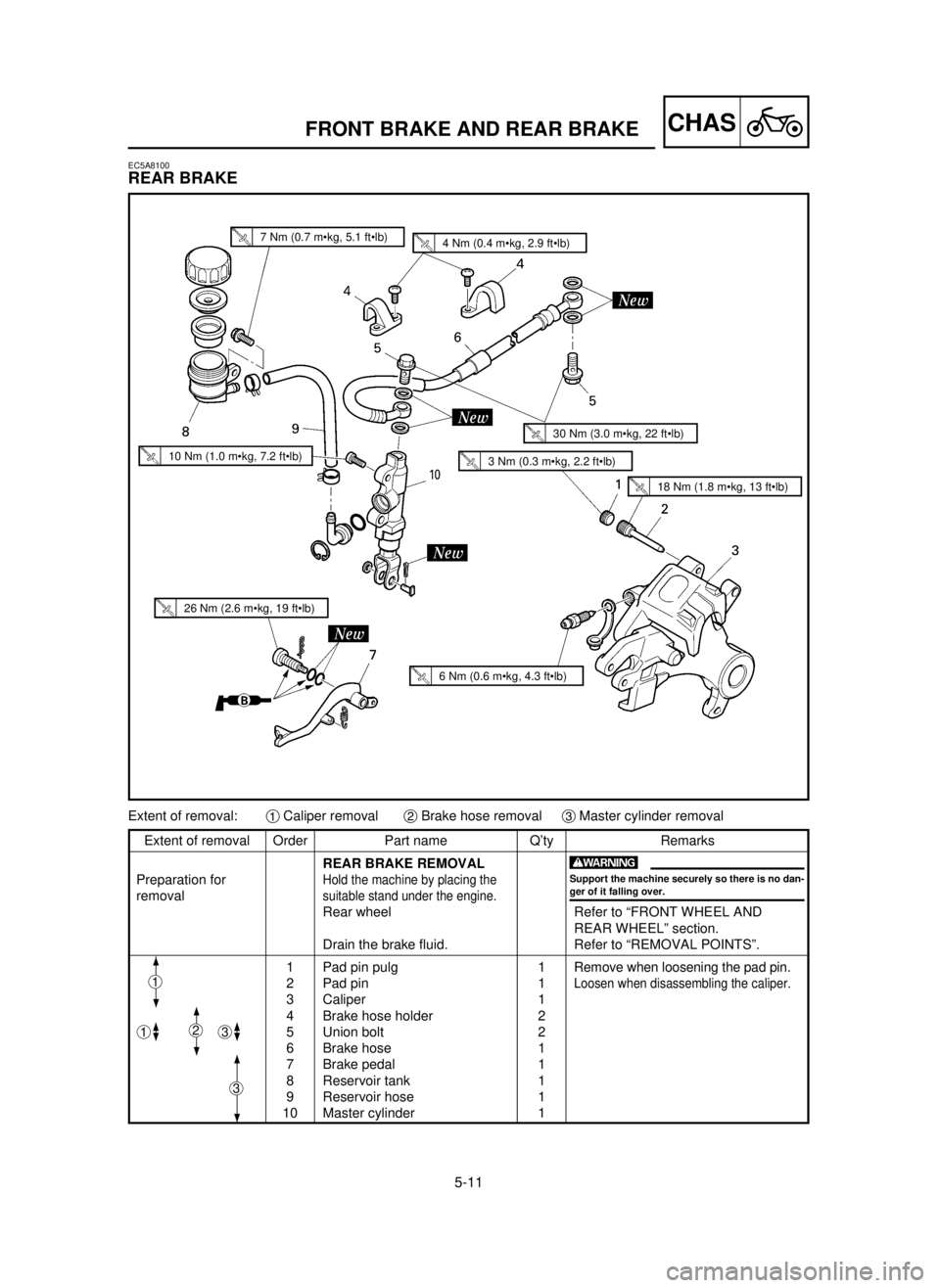

Page 376 of 558

5-11

CHASFRONT BRAKE AND REAR BRAKE

EC5A8100

REAR BRAKE

Extent of removal Order Part name Q’ty Remarks

REAR BRAKE REMOVAL

Preparation for

Hold the machine by placing the

removalsuitable stand under the engine.

Rear wheel Refer to “FRONT WHEEL AND

REAR WHEEL” section.

Drain the brake fluid. Refer to “REMOVAL POINTS”.

1 Pad pin pulg 1

Remove when loosening the pad pin.

2 Pad pin 1Loosen when disassembling the caliper.

3 Caliper 1

4 Brake hose holder 2

5 Union bolt 2

6 Brake hose 1

7 Brake pedal 1

8 Reservoir tank 1

9 Reservoir hose 1

10 Master cylinder 1

Extent of removal:1Caliper removal2Brake hose removal3Master cylinder removal

w

Support the machine securely so there is no dan-

ger of it falling over.

2

1

3

31

4 Nm (0.4 m•kg, 2.9 ft•lb)7 Nm (0.7 m•kg, 5.1 ft•lb)

30 Nm (3.0 m•kg, 22 ft•lb)

3 Nm (0.3 m•kg, 2.2 ft•lb)

18 Nm (1.8 m•kg, 13 ft•lb)

6 Nm (0.6 m•kg, 4.3 ft•lb)

26 Nm (2.6 m•kg, 19 ft•lb)

10 Nm (1.0 m•kg, 7.2 ft•lb)

5MV-9-30-5A 6/19/00 1:36 PM Page 22