check oil YAMAHA YZ125LC 2011 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2011, Model line: YZ125LC, Model: YAMAHA YZ125LC 2011Pages: 166, PDF Size: 8.49 MB

Page 45 of 166

3-4

MAINTENANCE INTERVALS

TIRE, WHEELS

Inspect air pressure, wheel

run-out, tire wear and

spoke looseness●●

Retighten sprocket bolt●●

Inspect bearings●

Replace bearings●

Lubricate●Lithium base grease

THROTTLE, CONTROL CA-

BLE

Check routing and connec-

tion●●

Lubricate●●Yamaha cable lube or SAE

10W-40 motor oil ItemAfter

break-in

Every

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)

As re-

quiredRemarks

Page 46 of 166

3-5

PRE-OPERATION INSPECTION AND MAINTENANCE

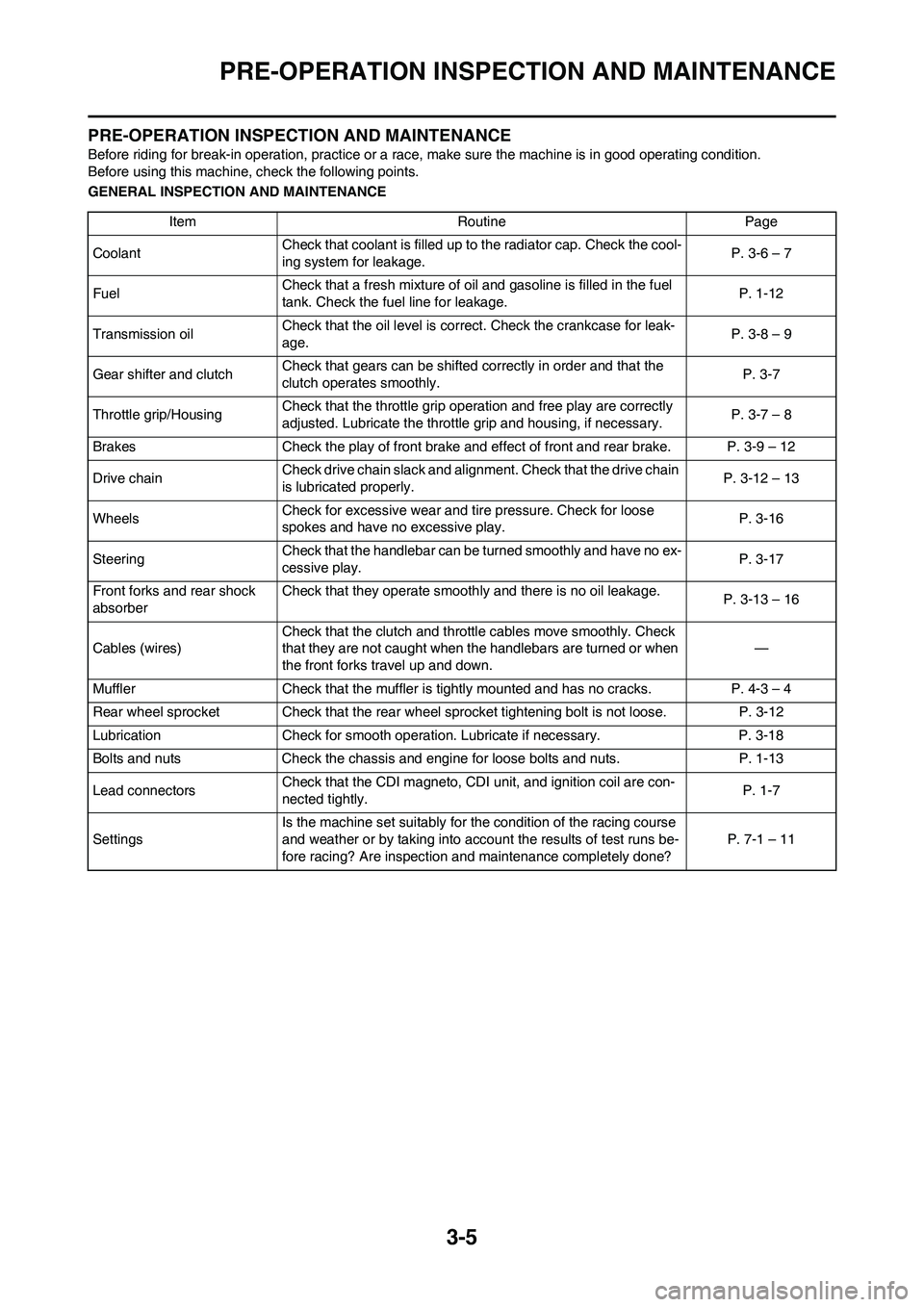

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage.P. 3-6 – 7

FuelCheck that a fresh mixture of oil and gasoline is filled in the fuel

tank. Check the fuel line for leakage.P. 1-12

Transmission oilCheck that the oil level is correct. Check the crankcase for leak-

age.P. 3-8 – 9

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P. 3-7

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P. 3-7 – 8

Brakes Check the play of front brake and effect of front and rear brake. P. 3-9 – 12

Drive chainCheck drive chain slack and alignment. Check that the drive chain

is lubricated properly.P. 3-12 – 13

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P. 3-16

SteeringCheck that the handlebar can be turned smoothly and have no ex-

cessive play.P. 3-17

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage.

P. 3-13 – 16

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks. P. 4-3 – 4

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P. 3-12

Lubrication Check for smooth operation. Lubricate if necessary. P. 3-18

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P. 1-13

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P. 1-7

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs be-

fore racing? Are inspection and maintenance completely done?P. 7-1 – 11

Page 47 of 166

3-6

ENGINE

ENGINE

CHECKING THE COOLANT LEVEL

Do not remove the radiator cap

"1", drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury. When

the engine has cooled, place a

thick towel over the radiator cap,

slowly rotate the cap counter-

clockwise to the detent. This pro-

cedure allows any residual

pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can't get soft

water.

1. Place the machine on a level

place, and hold it in an upright po-

sition.

2. Remove:

• Radiator cap

3. Check:

• Coolant level "a"

Coolant level low→Add coolant.

1. Radiator

CHANGING THE COOLANT

Do not remove the radiator cap

when the engine is hot.

Take care so that coolant does not

splash on painted surfaces. If it

splashes, wash it away with water.

1. Place a container under the en-

gine.

2. Remove:

• Coolant drain bolt "1"

3. Remove:

• Radiator cap

Drain the coolant completely.

4. Clean:

• Cooling system

Thoroughly flush the cooling sys-

tem with clean tap water.

5. Install:

• Copper washer

• Coolant drain bolt

6. Fill:

• Radiator

•Engine

To specified level.

• Do not mix more than one type of

ethylene glycol antifreeze con-

taining corrosion inhibitors for

aluminum engine.

• Do not use water containing im-

purities or oil.

Handling notes of coolant:

The coolant is harmful so it should be

handled with special care.

• When coolant splashes to your

eye.

Thoroughly wash your eye with

water and see your doctor.

• When coolant splashes to your

clothes.

Quickly wash it away with water

and then with soap.

• When coolant is swallowed.

Quickly make him vomit and take

him to a doctor.

7. Install:

• Radiator cap

Start the engine and warm it up

for a several minutes.

8. Check:

• Coolant level

Coolant level low→Add coolant.

CHECKING THE RADIATOR CAP

1. Inspect:

• Seal (radiator cap) "1"

• Valve and valve seat "2"

Crack/damage→Replace.

Exist fur deposits "3" →Clean or

replace.

CHECKING THE RADIATOR CAP

OPENING PRESSURE

1. Attach:

• Radiator cap tester "1" and adapt-

er "2"

Apply water on the radiator cap seal.

Coolant drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Recommended coolant:

High quality ethylene

glycol anti-freeze con-

taining anti-corrosion

for aluminum engine

Coolant "1" and water

(soft water) "2" mixing ra-

tio:

50%/50%

Coolant capacity:

0.9 L (0.79 Imp qt, 0.95

US qt)

Radiator cap tester:

YU-24460-01/90890-

01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Page 49 of 166

3-8

ENGINE

LUBRICATING THE THROTTLE

1. Remove:

• Cap cover "1"

• Throttle cable cap "2"

2. Apply:

• Lithium soap base grease

On the throttle cable end "a", tube

guide cable winding portion "b"

and roller sliding surface "c".

3. Install:

• Throttle cable cap

• Cap cover

CLEANING THE AIR FILTER

ELEMENT

Proper air filter maintenance is the

biggest key to preventing premature

engine wear and damage.

Never run the engine without the

air filter element in place; this

would allow dirt and dust to enter

the engine and cause rapid wear

and possible engine damage.

1. Remove:

• Seat

• Fitting bolt "1"

• Washer "2"

• Air filter element "3"

• Air filter guide "4"2. Clean:

• Air filter element

Clean them with solvent.

After cleaning, remove the remaining

solvent by squeezing the element.

• Do not twist the element when

squeezing the element.

• Leaving too much of solvent in

the element may result in poor

starting.

3. Inspect:

• Air filter element

Damage→Replace.

4. Apply:

• Foam-air-filter oil or equivalent oil

to the element

Squeeze out the excess oil. Element

should be wet but not dripping.

5. Install:

• Air filter guide "1"

Align the projection "a" on filter guide

with the hole "b" in air filter element.

6. Apply:

• Lithium soap base grease

On the matching surface "a" on air

filter element.7. Install:

• Air filter element "1"

• Washer

• Fitting bolt

Align the projection "a" on filter guide

with the hole "b" in air filter case.

CHECKING THE TRANSMISSION

OIL LEVEL

1. Start the engine, warm it up for

several minutes and wait for five

minutes.

2. Place the machine on a level

place and hold it up on upright po-

sition by placing the suitable

stand under the engine.

3. Check:

• Transmission oil level

Transmission oil level checking

steps:

a. Remove the oil check bolt "1".

b. Inspect the oil level.

Be sure the machine is positioned

straight up when inspecting the oil

level.

Never attempt to remove the oil

check bolt just after high speed

operation. The heated oil could

spout out, causing danger. Wait

until the oil cools down.

Oil flows out→Oil level is correct.

Oil does not flow out→Oil level is

low. Add transmission oil until oil

flows out. Throttle cable cap:

1 Nm (0.1 m•kg, 0.7

ft•lb)

Fitting bolt:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Recommended brand:

YAMALUBE

Recommended engine

oil type

SAE10W-40

Recommended engine

oil grade

API service SG type or

higher

JASO standard MA

Page 50 of 166

3-9

CHASSIS

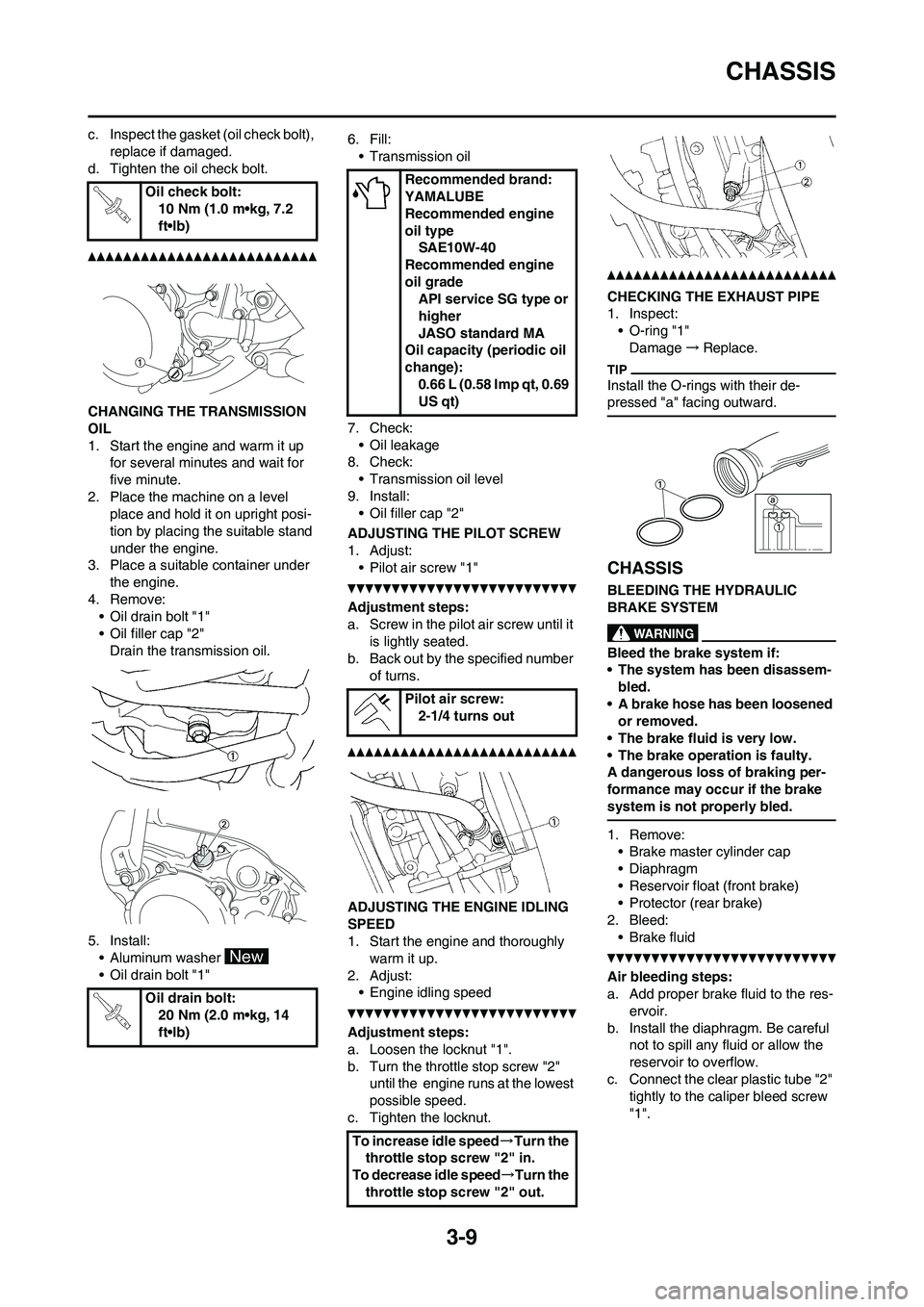

c. Inspect the gasket (oil check bolt),

replace if damaged.

d. Tighten the oil check bolt.

CHANGING THE TRANSMISSION

OIL

1. Start the engine and warm it up

for several minutes and wait for

five minute.

2. Place the machine on a level

place and hold it on upright posi-

tion by placing the suitable stand

under the engine.

3. Place a suitable container under

the engine.

4. Remove:

• Oil drain bolt "1"

• Oil filler cap "2"

Drain the transmission oil.

5. Install:

• Aluminum washer

• Oil drain bolt "1"6. Fill:

• Transmission oil

7. Check:

• Oil leakage

8. Check:

• Transmission oil level

9. Install:

• Oil filler cap "2"

ADJUSTING THE PILOT SCREW

1. Adjust:

• Pilot air screw "1"

Adjustment steps:

a. Screw in the pilot air screw until it

is lightly seated.

b. Back out by the specified number

of turns.

ADJUSTING THE ENGINE IDLING

SPEED

1. Start the engine and thoroughly

warm it up.

2. Adjust:

• Engine idling speed

Adjustment steps:

a. Loosen the locknut "1".

b. Turn the throttle stop screw "2"

until the engine runs at the lowest

possible speed.

c. Tighten the locknut.

CHECKING THE EXHAUST PIPE

1. Inspect:

• O-ring "1"

Damage→Replace.

Install the O-rings with their de-

pressed "a" facing outward.

CHASSIS

BLEEDING THE HYDRAULIC

BRAKE SYSTEM

Bleed the brake system if:

• The system has been disassem-

bled.

• A brake hose has been loosened

or removed.

• The brake fluid is very low.

• The brake operation is faulty.

A dangerous loss of braking per-

formance may occur if the brake

system is not properly bled.

1. Remove:

• Brake master cylinder cap

• Diaphragm

• Reservoir float (front brake)

• Protector (rear brake)

2. Bleed:

• Brake fluid

Air bleeding steps:

a. Add proper brake fluid to the res-

ervoir.

b. Install the diaphragm. Be careful

not to spill any fluid or allow the

reservoir to overflow.

c. Connect the clear plastic tube "2"

tightly to the caliper bleed screw

"1". Oil check bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil drain bolt:

20 Nm (2.0 m•kg, 14

ft•lb)

Recommended brand:

YAMALUBE

Recommended engine

oil type

SAE10W-40

Recommended engine

oil grade

API service SG type or

higher

JASO standard MA

Oil capacity (periodic oil

change):

0.66 L (0.58 Imp qt, 0.69

US qt)

Pilot air screw:

2-1/4 turns out

To increase idle speed→Turn the

throttle stop screw "2" in.

To decrease idle speed→Turn the

throttle stop screw "2" out.

Page 54 of 166

3-13

CHASSIS

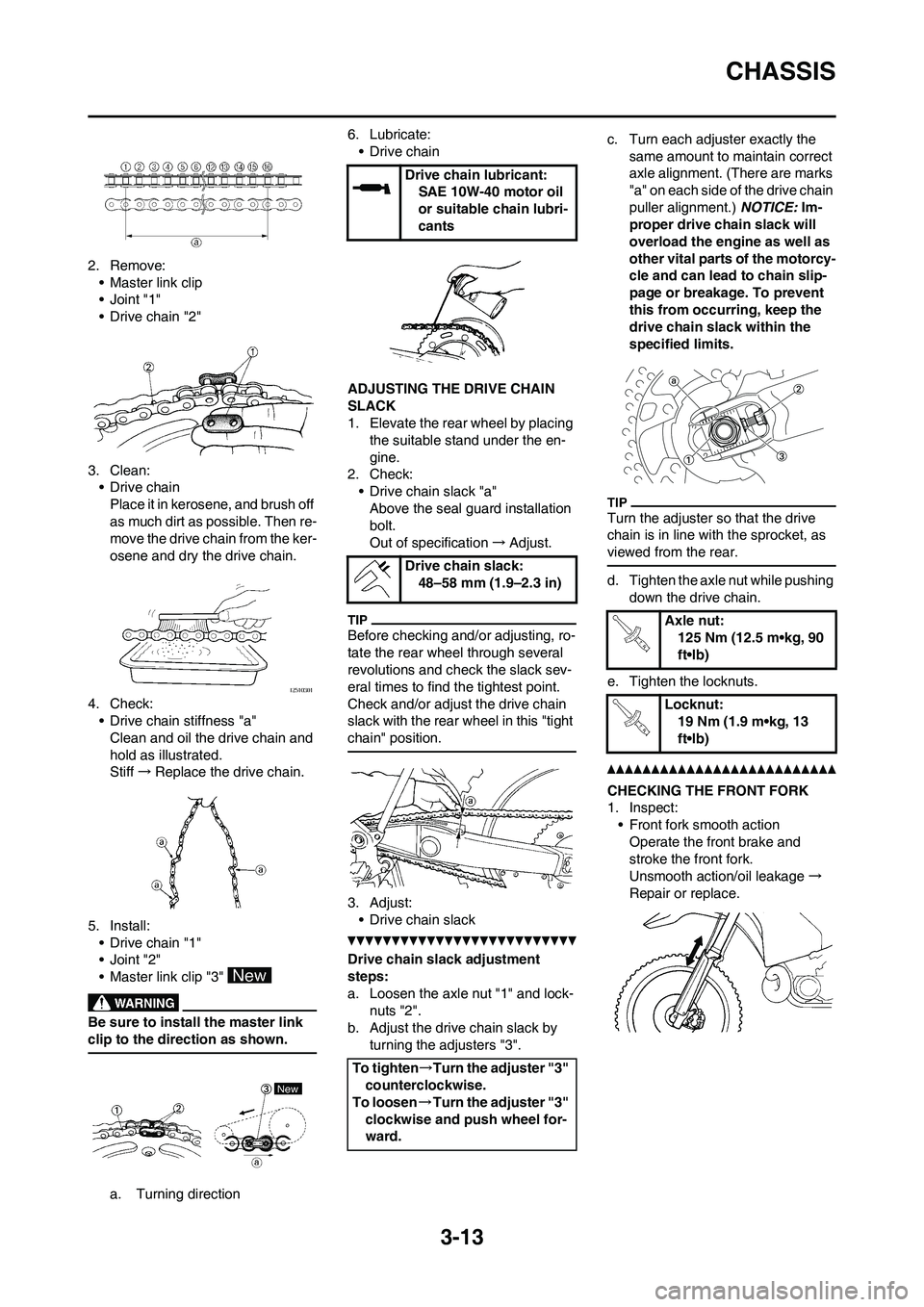

2. Remove:

• Master link clip

•Joint "1"

• Drive chain "2"

3. Clean:

• Drive chain

Place it in kerosene, and brush off

as much dirt as possible. Then re-

move the drive chain from the ker-

osene and dry the drive chain.

4. Check:

• Drive chain stiffness "a"

Clean and oil the drive chain and

hold as illustrated.

Stiff→Replace the drive chain.

5. Install:

• Drive chain "1"

•Joint "2"

• Master link clip "3"

Be sure to install the master link

clip to the direction as shown.

a. Turning direction6. Lubricate:

• Drive chain

ADJUSTING THE DRIVE CHAIN

SLACK

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Check:

• Drive chain slack "a"

Above the seal guard installation

bolt.

Out of specification→Adjust.

Before checking and/or adjusting, ro-

tate the rear wheel through several

revolutions and check the slack sev-

eral times to find the tightest point.

Check and/or adjust the drive chain

slack with the rear wheel in this "tight

chain" position.

3. Adjust:

• Drive chain slack

Drive chain slack adjustment

steps:

a. Loosen the axle nut "1" and lock-

nuts "2".

b. Adjust the drive chain slack by

turning the adjusters "3".c. Turn each adjuster exactly the

same amount to maintain correct

axle alignment. (There are marks

"a" on each side of the drive chain

puller alignment.) NOTICE: Im-

proper drive chain slack will

overload the engine as well as

other vital parts of the motorcy-

cle and can lead to chain slip-

page or breakage. To prevent

this from occurring, keep the

drive chain slack within the

specified limits.

Turn the adjuster so that the drive

chain is in line with the sprocket, as

viewed from the rear.

d. Tighten the axle nut while pushing

down the drive chain.

e. Tighten the locknuts.

CHECKING THE FRONT FORK

1. Inspect:

• Front fork smooth action

Operate the front brake and

stroke the front fork.

Unsmooth action/oil leakage→

Repair or replace.

Drive chain lubricant:

SAE 10W-40 motor oil

or suitable chain lubri-

cants

Drive chain slack:

48–58 mm (1.9–2.3 in)

To tighten→Turn the adjuster "3"

counterclockwise.

To loosen→Turn the adjuster "3"

clockwise and push wheel for-

ward.

Axle nut:

125 Nm (12.5 m•kg, 90

ft•lb)

Locknut:

19 Nm (1.9 m•kg, 13

ft•lb)

Page 55 of 166

3-14

CHASSIS

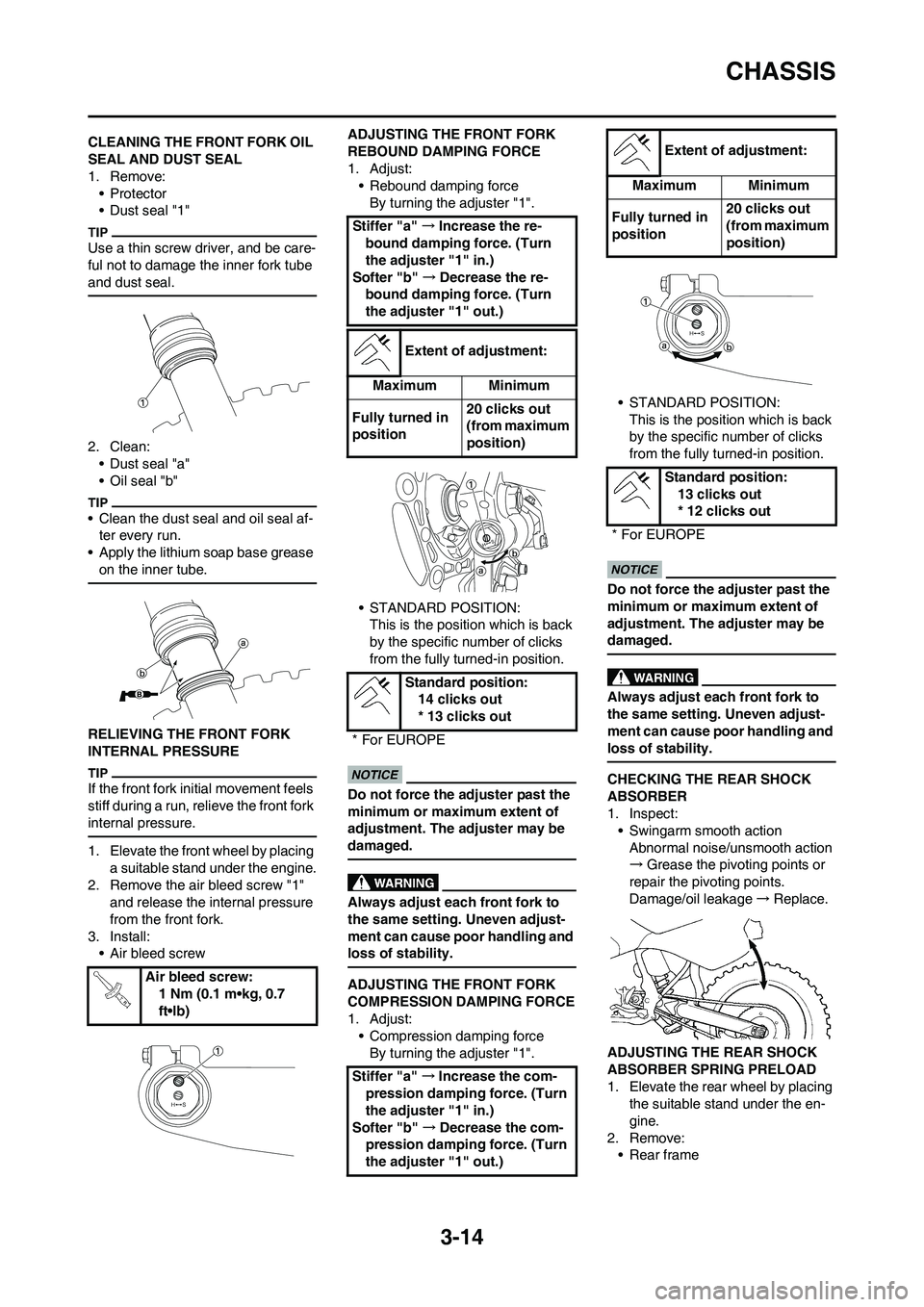

CLEANING THE FRONT FORK OIL

SEAL AND DUST SEAL

1. Remove:

•Protector

• Dust seal "1"

Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:

• Dust seal "a"

• Oil seal "b"

• Clean the dust seal and oil seal af-

ter every run.

• Apply the lithium soap base grease

on the inner tube.

RELIEVING THE FRONT FORK

INTERNAL PRESSURE

If the front fork initial movement feels

stiff during a run, relieve the front fork

internal pressure.

1. Elevate the front wheel by placing

a suitable stand under the engine.

2. Remove the air bleed screw "1"

and release the internal pressure

from the front fork.

3. Install:

• Air bleed screwADJUSTING THE FRONT FORK

REBOUND DAMPING FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1".

• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

ADJUSTING THE FRONT FORK

COMPRESSION DAMPING FORCE

1. Adjust:

• Compression damping force

By turning the adjuster "1".• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Swingarm smooth action

Abnormal noise/unsmooth action

→Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage→Replace.

ADJUSTING THE REAR SHOCK

ABSORBER SPRING PRELOAD

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Remove:

• Rear frame Air bleed screw:

1 Nm (0.1 m•kg, 0.7

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

14 clicks out

* 13 clicks out

* For EUROPE

Stiffer "a" →Increase the com-

pression damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the com-

pression damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

13 clicks out

* 12 clicks out

* For EUROPE

Page 76 of 166

4-16

CYLINDER HEAD, CYLINDER AND PISTON

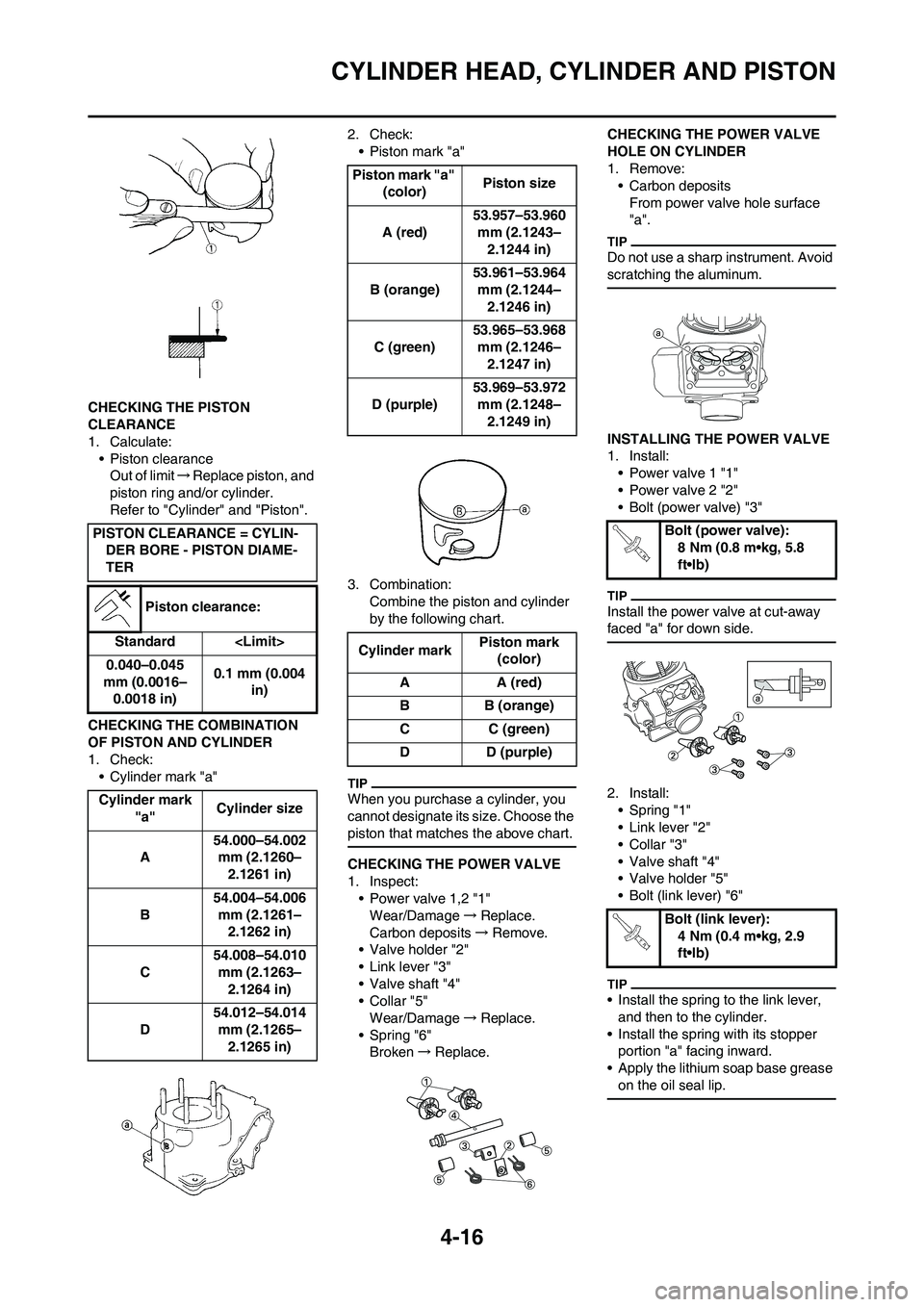

CHECKING THE PISTON

CLEARANCE

1. Calculate:

• Piston clearance

Out of limit→Replace piston, and

piston ring and/or cylinder.

Refer to "Cylinder" and "Piston".

CHECKING THE COMBINATION

OF PISTON AND CYLINDER

1. Check:

• Cylinder mark "a"2. Check:

• Piston mark "a"

3. Combination:

Combine the piston and cylinder

by the following chart.

When you purchase a cylinder, you

cannot designate its size. Choose the

piston that matches the above chart.

CHECKING THE POWER VALVE

1. Inspect:

• Power valve 1,2 "1"

Wear/Damage→Replace.

Carbon deposits→Remove.

• Valve holder "2"

• Link lever "3"

• Valve shaft "4"

• Collar "5"

Wear/Damage→Replace.

• Spring "6"

Broken→Replace.CHECKING THE POWER VALVE

HOLE ON CYLINDER

1. Remove:

• Carbon deposits

From power valve hole surface

"a".

Do not use a sharp instrument. Avoid

scratching the aluminum.

INSTALLING THE POWER VALVE

1. Install:

• Power valve 1 "1"

• Power valve 2 "2"

• Bolt (power valve) "3"

Install the power valve at cut-away

faced "a" for down side.

2. Install:

• Spring "1"

• Link lever "2"

•Collar "3"

• Valve shaft "4"

• Valve holder "5"

• Bolt (link lever) "6"

• Install the spring to the link lever,

and then to the cylinder.

• Install the spring with its stopper

portion "a" facing inward.

• Apply the lithium soap base grease

on the oil seal lip.

PISTON CLEARANCE = CYLIN-

DER BORE - PISTON DIAME-

TER

Piston clearance:

Standard

0.040–0.045

mm (0.0016–

0.0018 in)0.1 mm (0.004

in)

Cylinder mark

"a"Cylinder size

A54.000–54.002

mm (2.1260–

2.1261 in)

B54.004–54.006

mm (2.1261–

2.1262 in)

C54.008–54.010

mm (2.1263–

2.1264 in)

D54.012–54.014

mm (2.1265–

2.1265 in)

Piston mark "a"

(color)Piston size

A (red)53.957–53.960

mm (2.1243–

2.1244 in)

B (orange)53.961–53.964

mm (2.1244–

2.1246 in)

C (green)53.965–53.968

mm (2.1246–

2.1247 in)

D (purple)53.969–53.972

mm (2.1248–

2.1249 in)

Cylinder markPiston mark

(color)

AA (red)

BB (orange)

CC (green)

D D (purple)

Bolt (power valve):

8 Nm (0.8 m•kg, 5.8

ft•lb)

Bolt (link lever):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 77 of 166

4-17

CYLINDER HEAD, CYLINDER AND PISTON

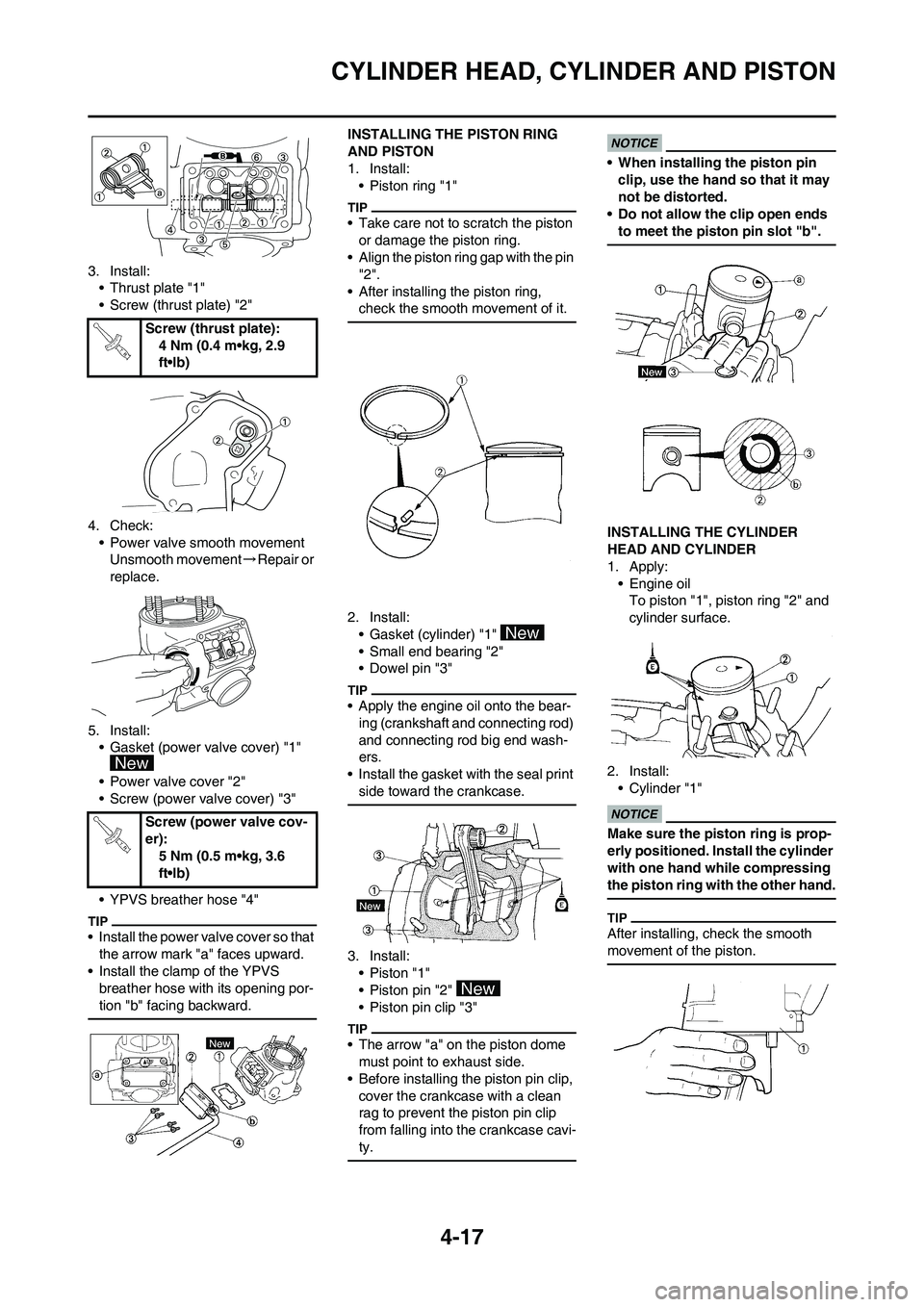

3. Install:

• Thrust plate "1"

• Screw (thrust plate) "2"

4. Check:

• Power valve smooth movement

Unsmooth movement→Repair or

replace.

5. Install:

• Gasket (power valve cover) "1"

• Power valve cover "2"

• Screw (power valve cover) "3"

• YPVS breather hose "4"

• Install the power valve cover so that

the arrow mark "a" faces upward.

• Install the clamp of the YPVS

breather hose with its opening por-

tion "b" facing backward.

INSTALLING THE PISTON RING

AND PISTON

1. Install:

• Piston ring "1"

• Take care not to scratch the piston

or damage the piston ring.

• Align the piston ring gap with the pin

"2".

• After installing the piston ring,

check the smooth movement of it.

2. Install:

• Gasket (cylinder) "1"

• Small end bearing "2"

• Dowel pin "3"

• Apply the engine oil onto the bear-

ing (crankshaft and connecting rod)

and connecting rod big end wash-

ers.

• Install the gasket with the seal print

side toward the crankcase.

3. Install:

•Piston "1"

• Piston pin "2"

• Piston pin clip "3"

• The arrow "a" on the piston dome

must point to exhaust side.

• Before installing the piston pin clip,

cover the crankcase with a clean

rag to prevent the piston pin clip

from falling into the crankcase cavi-

ty.

• When installing the piston pin

clip, use the hand so that it may

not be distorted.

• Do not allow the clip open ends

to meet the piston pin slot "b".

INSTALLING THE CYLINDER

HEAD AND CYLINDER

1. Apply:

• Engine oil

To piston "1", piston ring "2" and

cylinder surface.

2. Install:

• Cylinder "1"

Make sure the piston ring is prop-

erly positioned. Install the cylinder

with one hand while compressing

the piston ring with the other hand.

After installing, check the smooth

movement of the piston.

Screw (thrust plate):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Screw (power valve cov-

er):

5 Nm (0.5 m•kg, 3.6

ft•lb)

Page 81 of 166

4-21

CLUTCH

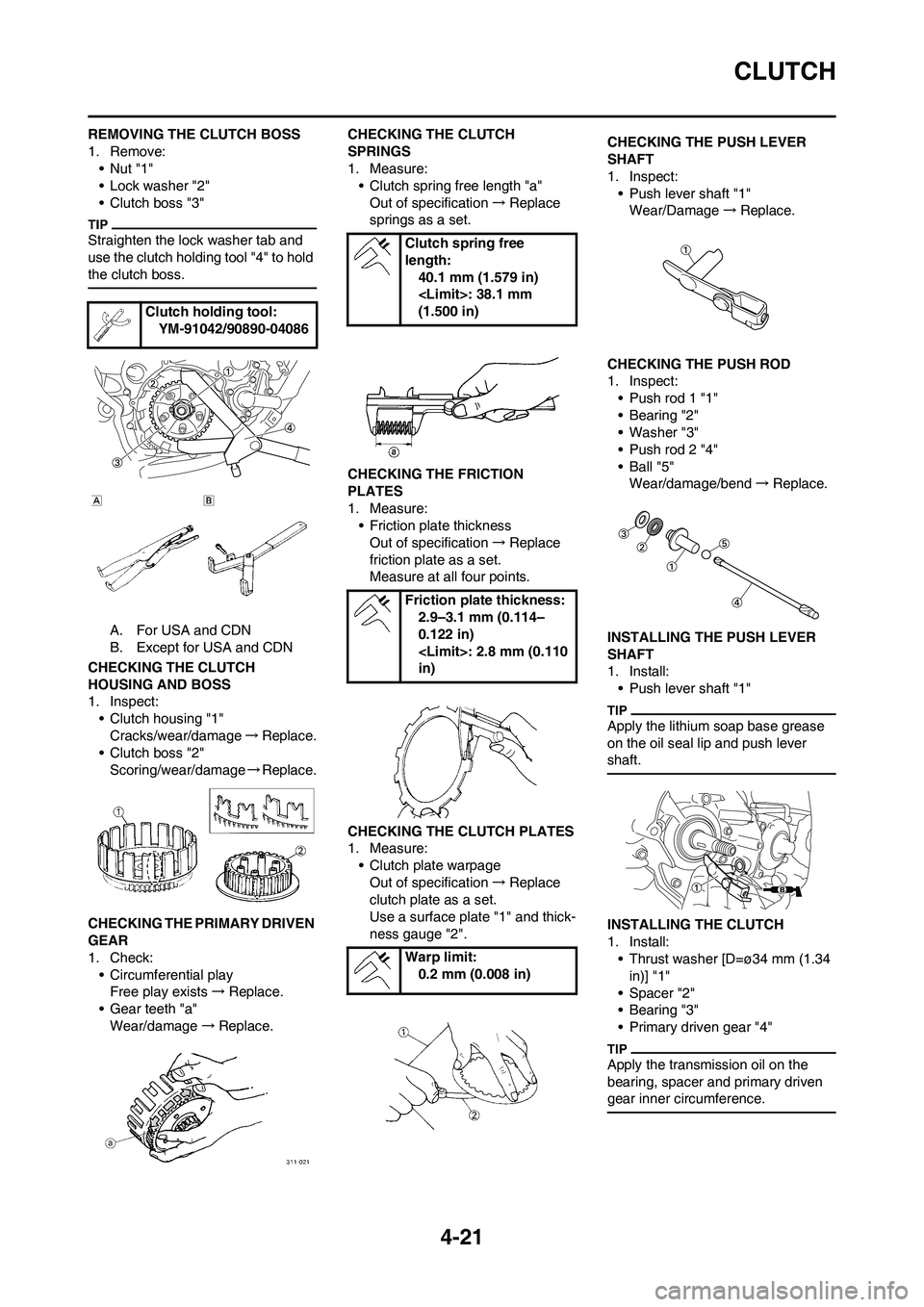

REMOVING THE CLUTCH BOSS

1. Remove:

•Nut "1"

• Lock washer "2"

• Clutch boss "3"

Straighten the lock washer tab and

use the clutch holding tool "4" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

CHECKING THE CLUTCH

HOUSING AND BOSS

1. Inspect:

• Clutch housing "1"

Cracks/wear/damage→Replace.

• Clutch boss "2"

Scoring/wear/damage→Replace.

CHECKING THE PRIMARY DRIVEN

GEAR

1. Check:

• Circumferential play

Free play exists→Replace.

• Gear teeth "a"

Wear/damage→Replace.CHECKING THE CLUTCH

SPRINGS

1. Measure:

• Clutch spring free length "a"

Out of specification→Replace

springs as a set.

CHECKING THE FRICTION

PLATES

1. Measure:

• Friction plate thickness

Out of specification→Replace

friction plate as a set.

Measure at all four points.

CHECKING THE CLUTCH PLATES

1. Measure:

• Clutch plate warpage

Out of specification→Replace

clutch plate as a set.

Use a surface plate "1" and thick-

ness gauge "2".CHECKING THE PUSH LEVER

SHAFT

1. Inspect:

• Push lever shaft "1"

Wear/Damage→Replace.

CHECKING THE PUSH ROD

1. Inspect:

• Push rod 1 "1"

• Bearing "2"

• Washer "3"

• Push rod 2 "4"

•Ball "5"

Wear/damage/bend→Replace.

INSTALLING THE PUSH LEVER

SHAFT

1. Install:

• Push lever shaft "1"

Apply the lithium soap base grease

on the oil seal lip and push lever

shaft.

INSTALLING THE CLUTCH

1. Install:

• Thrust washer [D=ø34 mm (1.34

in)] "1"

• Spacer "2"

• Bearing "3"

• Primary driven gear "4"

Apply the transmission oil on the

bearing, spacer and primary driven

gear inner circumference.

Clutch holding tool:

YM-91042/90890-04086

Clutch spring free

length:

40.1 mm (1.579 in)

(1.500 in)

Friction plate thickness:

2.9–3.1 mm (0.114–

0.122 in)

in)

Warp limit:

0.2 mm (0.008 in)