air filter YAMAHA YZ125LC 2012 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: YZ125LC, Model: YAMAHA YZ125LC 2012Pages: 168, PDF Size: 8.27 MB

Page 71 of 168

4-9

CARBURETOR AND REED VALVE

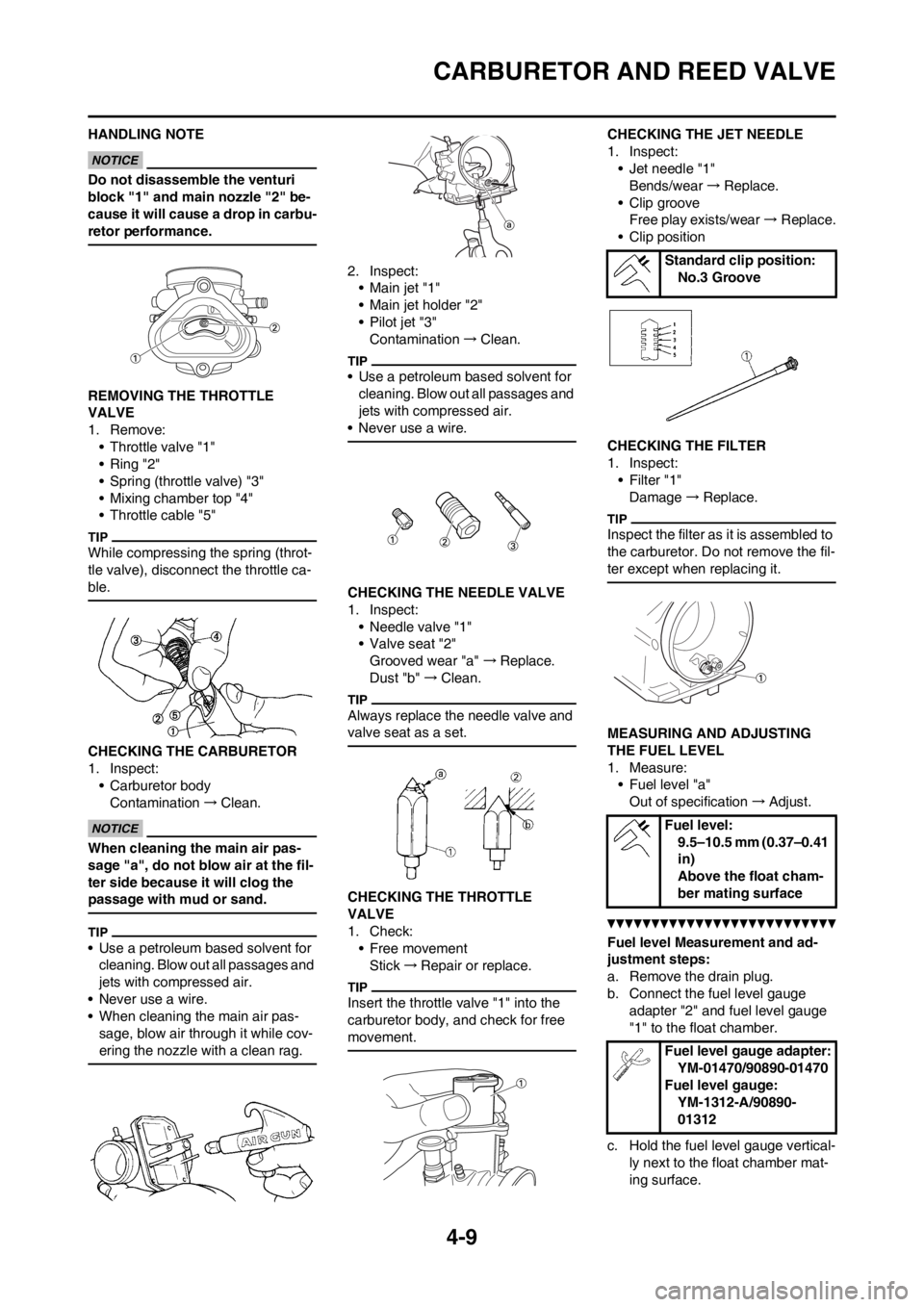

HANDLING NOTE

Do not disassemble the venturi

block "1" and main nozzle "2" be-

cause it will cause a drop in carbu-

retor performance.

REMOVING THE THROTTLE

VALVE

1. Remove:

• Throttle valve "1"

• Ring "2"

• Spring (throttle valve) "3"

• Mixing chamber top "4"

• Throttle cable "5"

While compressing the spring (throt-

tle valve), disconnect the throttle ca-

ble.

CHECKING THE CARBURETOR

1. Inspect:

• Carburetor body

Contamination→Clean.

When cleaning the main air pas-

sage "a", do not blow air at the fil-

ter side because it will clog the

passage with mud or sand.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

• When cleaning the main air pas-

sage, blow air through it while cov-

ering the nozzle with a clean rag.

2. Inspect:

•Main jet "1"

• Main jet holder "2"

• Pilot jet "3"

Contamination→Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

CHECKING THE NEEDLE VALVE

1. Inspect:

• Needle valve "1"

• Valve seat "2"

Grooved wear "a" →Replace.

Dust "b" →Clean.

Always replace the needle valve and

valve seat as a set.

CHECKING THE THROTTLE

VALVE

1. Check:

• Free movement

Stick→Repair or replace.

Insert the throttle valve "1" into the

carburetor body, and check for free

movement.

CHECKING THE JET NEEDLE

1. Inspect:

• Jet needle "1"

Bends/wear→Replace.

• Clip groove

Free play exists/wear→Replace.

• Clip position

CHECKING THE FILTER

1. Inspect:

•Filter "1"

Damage→Replace.

Inspect the filter as it is assembled to

the carburetor. Do not remove the fil-

ter except when replacing it.

MEASURING AND ADJUSTING

THE FUEL LEVEL

1. Measure:

• Fuel level "a"

Out of specification→Adjust.

Fuel level Measurement and ad-

justment steps:

a. Remove the drain plug.

b. Connect the fuel level gauge

adapter "2" and fuel level gauge

"1" to the float chamber.

c. Hold the fuel level gauge vertical-

ly next to the float chamber mat-

ing surface.

Standard clip position:

No.3 Groove

Fuel level:

9.5–10.5 mm (0.37–0.41

in)

Above the float cham-

ber mating surface

Fuel level gauge adapter:

YM-01470/90890-01470

Fuel level gauge:

YM-1312-A/90890-

01312

Page 73 of 168

4-11

CARBURETOR AND REED VALVE

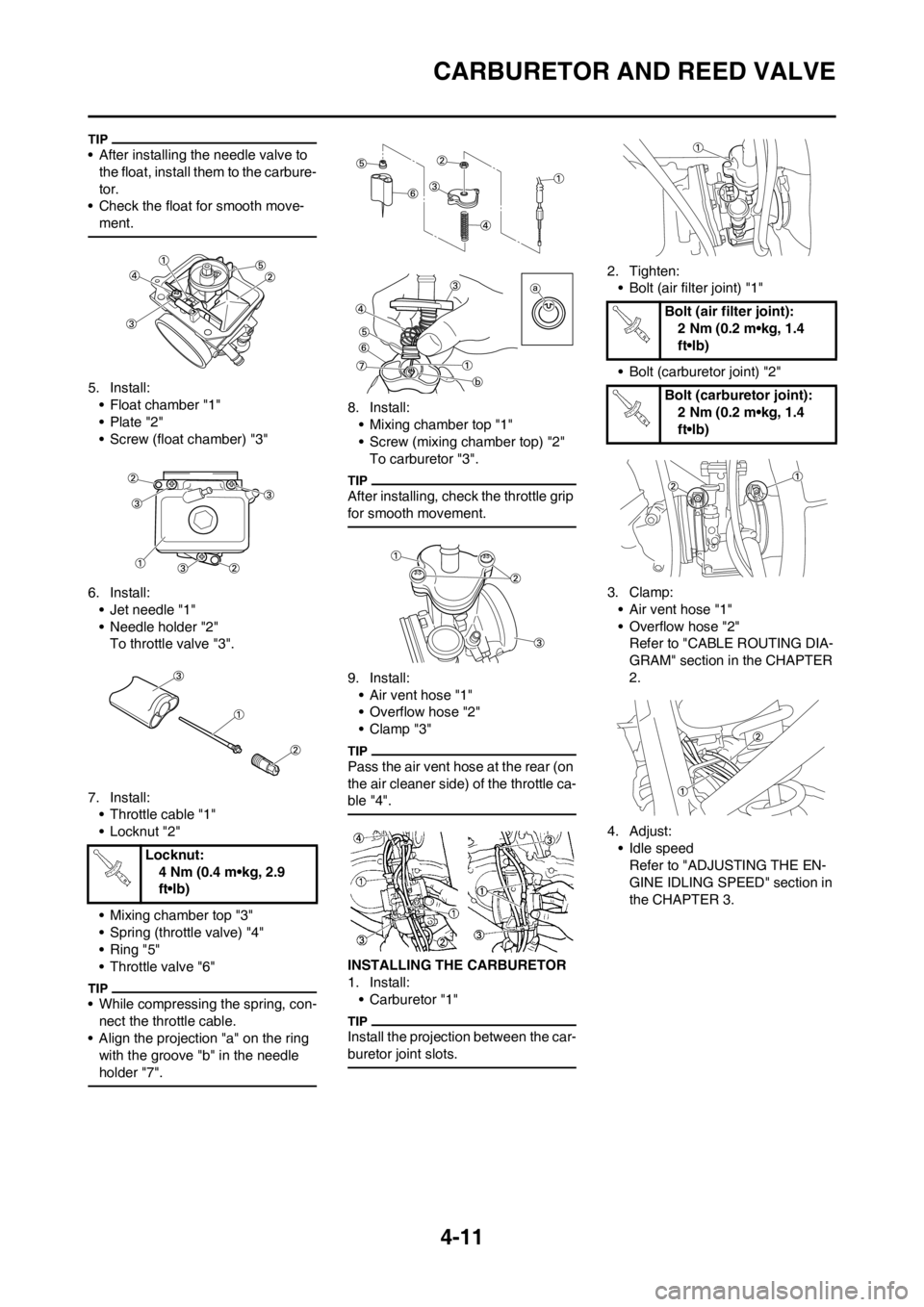

• After installing the needle valve to

the float, install them to the carbure-

tor.

• Check the float for smooth move-

ment.

5. Install:

• Float chamber "1"

• Plate "2"

• Screw (float chamber) "3"

6. Install:

• Jet needle "1"

• Needle holder "2"

To throttle valve "3".

7. Install:

• Throttle cable "1"

• Locknut "2"

• Mixing chamber top "3"

• Spring (throttle valve) "4"

• Ring "5"

• Throttle valve "6"

• While compressing the spring, con-

nect the throttle cable.

• Align the projection "a" on the ring

with the groove "b" in the needle

holder "7".

8. Install:

• Mixing chamber top "1"

• Screw (mixing chamber top) "2"

To carburetor "3".

After installing, check the throttle grip

for smooth movement.

9. Install:

• Air vent hose "1"

• Overflow hose "2"

•Clamp "3"

Pass the air vent hose at the rear (on

the air cleaner side) of the throttle ca-

ble "4".

INSTALLING THE CARBURETOR

1. Install:

• Carburetor "1"

Install the projection between the car-

buretor joint slots.

2. Tighten:

• Bolt (air filter joint) "1"

• Bolt (carburetor joint) "2"

3. Clamp:

• Air vent hose "1"

• Overflow hose "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

4. Adjust:

• Idle speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section in

the CHAPTER 3. Locknut:

4 Nm (0.4 m•kg, 2.9

ft•lb)

Bolt (air filter joint):

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (carburetor joint):

2 Nm (0.2 m•kg, 1.4

ft•lb)

Page 146 of 168

5-38

REAR SHOCK ABSORBER

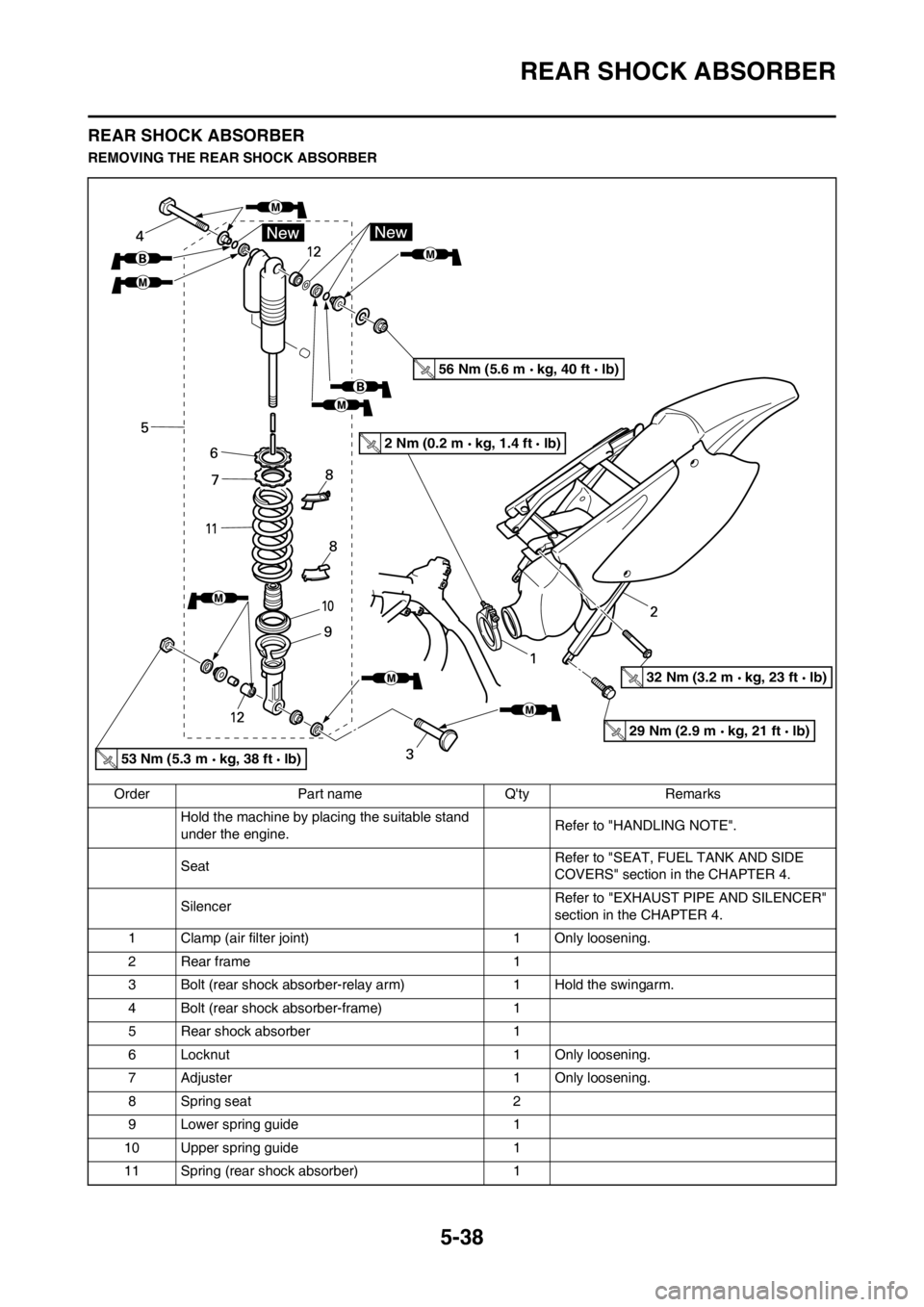

REAR SHOCK ABSORBER

REMOVING THE REAR SHOCK ABSORBER

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Seat Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section in the CHAPTER 4.

Silencer Refer to "EXHAUST PIPE AND SILENCER"

section in the CHAPTER 4.

1 Clamp (air filter joint) 1 Only loosening.

2Rear frame 1

3 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

4 Bolt (rear shock absorber-frame) 1

5 Rear shock absorber 1

6 Locknut 1 Only loosening.

7 Adjuster 1 Only loosening.

8 Spring seat 2

9 Lower spring guide 1

10 Upper spring guide 1

11 Spring (rear shock absorber) 1

53 Nm (5.3 m kg, 38 ft lb)

56 Nm (5.6 m kg, 40 ft lb)

2 Nm (0.2 m kg, 1.4 ft lb)

32 Nm (3.2 m kg, 23 ft lb)

29 Nm (2.9 m kg, 21 ft lb)

Page 150 of 168

![YAMAHA YZ125LC 2012 User Guide 5-42

REAR SHOCK ABSORBER

6. Install:

• Rear frame "1"

• Bolt [rear frame (upper)] "2"

• Bolt [rear frame (lower)] "3"

7. Tighten:

• Bolt (air filter joint) "1"Bolt [rear frame (upper)]:

32 Nm YAMAHA YZ125LC 2012 User Guide 5-42

REAR SHOCK ABSORBER

6. Install:

• Rear frame "1"

• Bolt [rear frame (upper)] "2"

• Bolt [rear frame (lower)] "3"

7. Tighten:

• Bolt (air filter joint) "1"Bolt [rear frame (upper)]:

32 Nm](/img/51/53905/w960_53905-149.png)

5-42

REAR SHOCK ABSORBER

6. Install:

• Rear frame "1"

• Bolt [rear frame (upper)] "2"

• Bolt [rear frame (lower)] "3"

7. Tighten:

• Bolt (air filter joint) "1"Bolt [rear frame (upper)]:

32 Nm (3.2 m•kg, 23

ft•lb)

Bolt [rear frame (lower)]:

29 Nm (2.9 m•kg, 21

ft•lb)

Bolt (air filter joint):

2 Nm (0.2 m•kg, 1.4

ft•lb)

Page 159 of 168

7-4

ENGINE

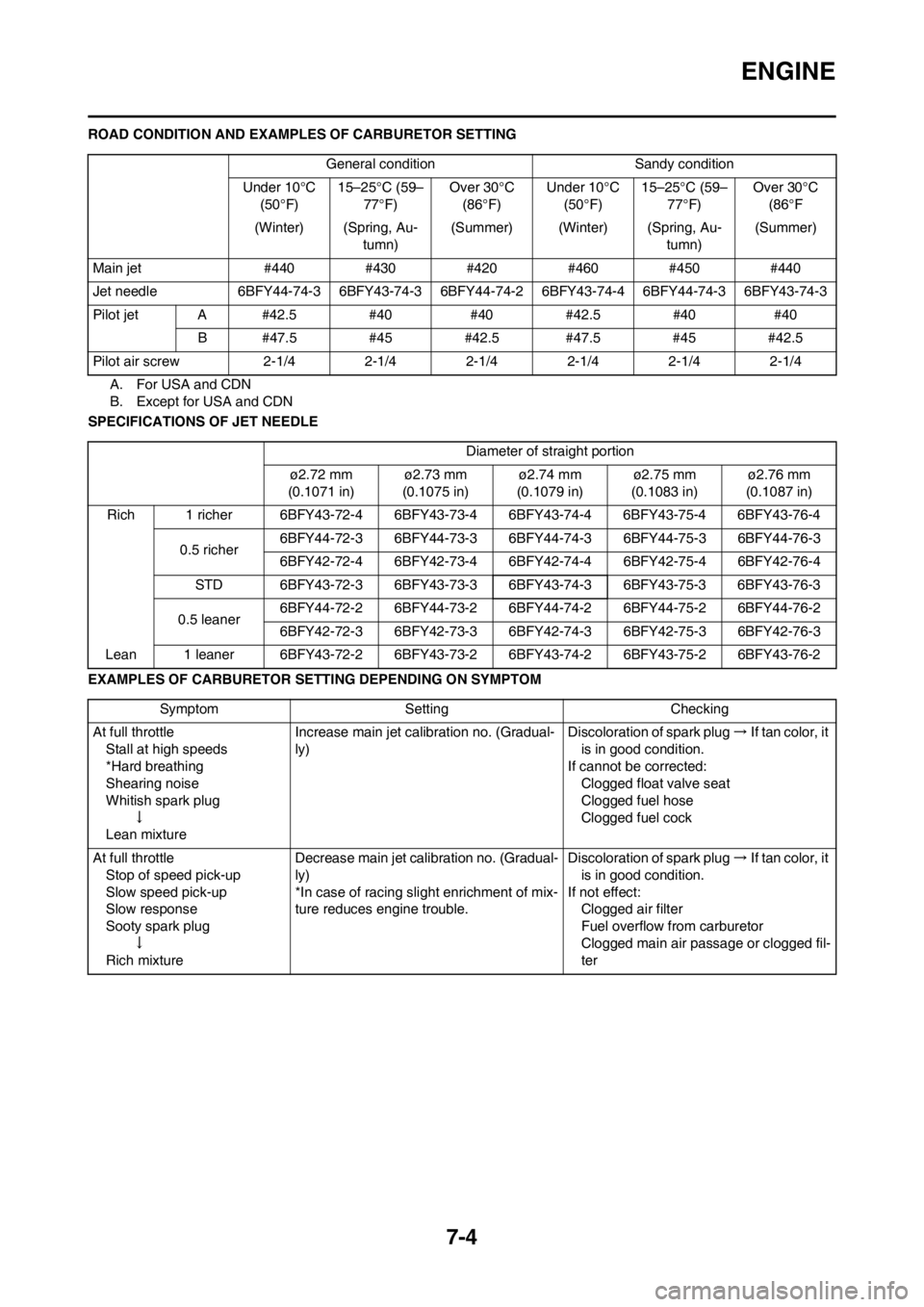

ROAD CONDITION AND EXAMPLES OF CARBURETOR SETTING

A. For USA and CDN

B. Except for USA and CDN

SPECIFICATIONS OF JET NEEDLE

EXAMPLES OF CARBURETOR SETTING DEPENDING ON SYMPTOMGeneral condition Sandy condition

Under 10°C

(50°F)15–25°C (59–

77°F)Over 30°C

(86°F)Under 10°C

(50°F)15–25°C (59–

77°F)Over 30°C

(86°F

(Winter) (Spring, Au-

tumn)(Summer) (Winter) (Spring, Au-

tumn)(Summer)

Main jet #440 #430 #420 #460 #450 #440

Jet needle 6BFY44-74-3 6BFY43-74-3 6BFY44-74-2 6BFY43-74-4 6BFY44-74-3 6BFY43-74-3

Pilot jet A #42.5 #40 #40 #42.5 #40 #40

B #47.5 #45 #42.5 #47.5 #45 #42.5

Pilot air screw 2-1/4 2-1/4 2-1/4 2-1/4 2-1/4 2-1/4

Diameter of straight portion

ø2.72 mm

(0.1071 in)ø2.73 mm

(0.1075 in)ø2.74 mm

(0.1079 in)ø2.75 mm

(0.1083 in)ø2.76 mm

(0.1087 in)

Rich 1 richer 6BFY43-72-4 6BFY43-73-4 6BFY43-74-4 6BFY43-75-4 6BFY43-76-4

0.5 richer6BFY44-72-3 6BFY44-73-3 6BFY44-74-3 6BFY44-75-3 6BFY44-76-3

6BFY42-72-4 6BFY42-73-4 6BFY42-74-4 6BFY42-75-4 6BFY42-76-4

STD 6BFY43-72-3 6BFY43-73-3 6BFY43-74-3 6BFY43-75-3 6BFY43-76-3

0.5 leaner6BFY44-72-2 6BFY44-73-2 6BFY44-74-2 6BFY44-75-2 6BFY44-76-2

6BFY42-72-3 6BFY42-73-3 6BFY42-74-3 6BFY42-75-3 6BFY42-76-3

Lean 1 leaner 6BFY43-72-2 6BFY43-73-2 6BFY43-74-2 6BFY43-75-2 6BFY43-76-2

Symptom Setting Checking

At full throttle

Stall at high speeds

*Hard breathing

Shearing noise

Whitish spark plug

↓

Lean mixtureIncrease main jet calibration no. (Gradual-

ly)Discoloration of spark plug→If tan color, it

is in good condition.

If cannot be corrected:

Clogged float valve seat

Clogged fuel hose

Clogged fuel cock

At full throttle

Stop of speed pick-up

Slow speed pick-up

Slow response

Sooty spark plug

↓

Rich mixtureDecrease main jet calibration no. (Gradual-

ly)

*In case of racing slight enrichment of mix-

ture reduces engine trouble.Discoloration of spark plug→If tan color, it

is in good condition.

If not effect:

Clogged air filter

Fuel overflow from carburetor

Clogged main air passage or clogged fil-

ter

Page 160 of 168

7-5

ENGINE

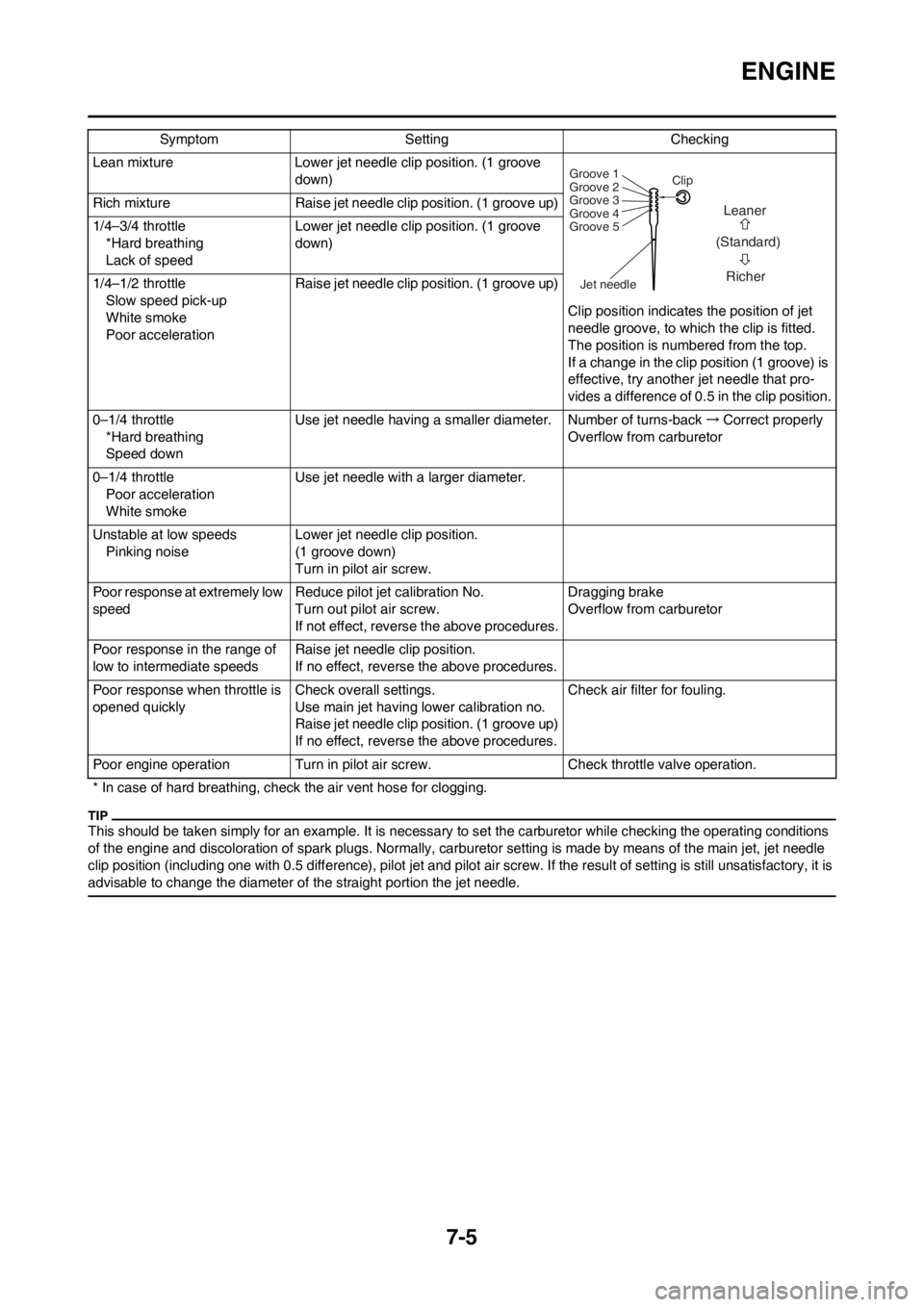

This should be taken simply for an example. It is necessary to set the carburetor while checking the operating conditions

of the engine and discoloration of spark plugs. Normally, carburetor setting is made by means of the main jet, jet needle

clip position (including one with 0.5 difference), pilot jet and pilot air screw. If the result of setting is still unsatisfactory, it is

advisable to change the diameter of the straight portion the jet needle.

Lean mixture Lower jet needle clip position. (1 groove

down)

Clip position indicates the position of jet

needle groove, to which the clip is fitted.

The position is numbered from the top.

If a change in the clip position (1 groove) is

effective, try another jet needle that pro-

vides a difference of 0.5 in the clip position. Rich mixture Raise jet needle clip position. (1 groove up)

1/4–3/4 throttle

*Hard breathing

Lack of speedLower jet needle clip position. (1 groove

down)

1/4–1/2 throttle

Slow speed pick-up

White smoke

Poor accelerationRaise jet needle clip position. (1 groove up)

0–1/4 throttle

*Hard breathing

Speed downUse jet needle having a smaller diameter. Number of turns-back→Correct properly

Overflow from carburetor

0–1/4 throttle

Poor acceleration

White smokeUse jet needle with a larger diameter.

Unstable at low speeds

Pinking noiseLower jet needle clip position.

(1 groove down)

Turn in pilot air screw.

Poor response at extremely low

speedReduce pilot jet calibration No.

Turn out pilot air screw.

If not effect, reverse the above procedures.Dragging brake

Overflow from carburetor

Poor response in the range of

low to intermediate speedsRaise jet needle clip position.

If no effect, reverse the above procedures.

Poor response when throttle is

opened quicklyCheck overall settings.

Use main jet having lower calibration no.

Raise jet needle clip position. (1 groove up)

If no effect, reverse the above procedures.Check air filter for fouling.

Poor engine operation Turn in pilot air screw. Check throttle valve operation.

* In case of hard breathing, check the air vent hose for clogging.Symptom Setting CheckingGroove 1

Groove 2

Groove 3

Groove 4

Groove 5Clip

Jet needle

Leaner

(Standard)

Richer