length YAMAHA YZ125LC 2013 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: YZ125LC, Model: YAMAHA YZ125LC 2013Pages: 168, PDF Size: 8.19 MB

Page 6 of 168

FOREWORD

INTRODUCTION

Congratulations on your purchase of

a Yamaha YZ series. This model is

the culmination of Yamaha's vast ex-

perience in the production of paceset-

ting racing machines. It represents

the highest grade of craftsmanship

and reliability that have made Yama-

ha a leader.

This manual explains operation, in-

spection, basic maintenance and tun-

ing of your machine. If you have any

questions about this manual or your

machine, please contact your Yama-

ha dealer.

Yamaha continually seeks advance-

ments in product design and quality.

Therefore, while this manual contains

the most current product information

available at the time of printing, there

may be minor discrepancies between

your machine and this manual. If you

have any questions concerning this

manual, please consult your Yamaha

dealer.

PLEASE READ THIS MANUAL

CAREFULLY AND COMPLETELY

BEFORE OPERATING THIS MA-

CHINE. DO NOT ATTEMPT TO OP-

ERATE THIS MACHINE UNTIL YOU

HAVE ATTAINED A SATISFACTO-

RY KNOWLEDGE OF ITS CON-

TROLS AND OPERATING

FEATURES AND UNTIL YOU HAVE

BEEN TRAINED IN SAFE AND

PROPER RIDING TECHNIQUES.

REGULAR INSPECTIONS AND

CAREFUL MAINTENANCE,

ALONG WITH GOOD RIDING

SKILLS, WILL ENSURE THAT YOU

SAFETY ENJOY THE CAPABILI-

TIES AND THE RELIABILITY OF

THIS MACHINE.

IMPORTANT MANUAL

INFORMATION

Particularly important information is

distinguished in this manual by the

following notations.

This is the safety alert symbol. It is

used to alert you to potential per-

sonal injury hazards. Obey all safe-

ty messages that follow this

symbol to avoid possible injury or

death.

A WARNING indicates a hazardous

situation which, if not avoided,

could result in death or serious in-

jury.

A NOTICE indicates special pre-

cautions that must be taken to

avoid damage to the vehicle or oth-

er property.

A TIP provides key information to

make procedures easier or clearer.

SAFETY INFORMATION

THIS MACHINE IS DESIGNED

STRICTLY FOR COMPETITION

USE, ONLY ON A CLOSED

COURSE. It is illegal for this machine

to be operated on any public street,

road, or highway. Off-road use on

public lands may also be illegal.

Please check local regulations before

riding.

• THIS MACHINE IS TO BE OPER-

ATED BY AN EXPERIENCED RID-

ER ONLY.

Do not attempt to operate this ma-

chine at maximum power until you

are totally familiar with its character-

istics.

• THIS MACHINE IS DESIGNED TO

BE RIDDEN BY THE OPERATOR

ONLY.

Do not carry passengers on this

machine.

• ALWAYS WEAR PROTECTIVE

APPAREL.

When operating this machine, al-

ways wear an approved helmet with

goggles or a face shield. Also wear

heavy boots, gloves, and protective

clothing. Always wear proper fitting

clothing that will not be caught in

any of the moving parts or controls

of the machine.• ALWAYS MAINTAIN YOUR MA-

CHINE IN PROPER WORKING

ORDER.

For safety and reliability, the ma-

chine must be properly maintained.

Always perform the pre-operation

checks indicated in this manual.

Correcting a mechanical problem

before you ride may prevent an ac-

cident.

• GASOLINE IS HIGHLY FLAMMA-

BLE.

Always turn off the engine while re-

fueling. Take care to not spill any

gasoline on the engine or exhaust

system. Never refuel in the vicinity

of an open flame, or while smoking.

• GASOLINE CAN CAUSE INJURY.

If you should swallow some gaso-

line, inhale excess gasoline vapors,

or allow any gasoline to get into

your eyes, contact a doctor immedi-

ately. If any gasoline spills onto

your skin or clothing, immediately

wash skin areas with soap and wa-

ter, and change your clothes.

• ONLY OPERATE THE MACHINE

IN AN AREA WITH ADEQUATE

VENTILATION.

Never start the engine or let it run

for any length of time in an enclosed

area. Exhaust fumes are poison-

ous. These fumes contain carbon

monoxide, which by itself is odor-

less and colorless. Carbon monox-

ide is a dangerous gas which can

cause unconsciousness or can be

lethal.

• PARK THE MACHINE CAREFUL-

LY; TURN OFF THE ENGINE.

Always turn off the engine if you are

going to leave the machine. Do not

park the machine on a slope or soft

ground as it may fall over.

• THE ENGINE, EXHAUST PIPE,

MUFFLER, AND OIL TANK WILL

BE VERY HOT AFTER THE EN-

GINE HAS BEEN RUN.

Be careful not to touch them or to

allow any clothing item to contact

them during inspection or repair.

• PROPERLY SECURE THE MA-

CHINE BEFORE TRANSPORTING

IT.

When transporting the machine in

another vehicle, always be sure it is

properly secured and in an upright

position and that the fuel cock is in

the "OFF" position. Otherwise, fuel

may leak out of the carburetor or

fuel tank.

Page 25 of 168

2-1

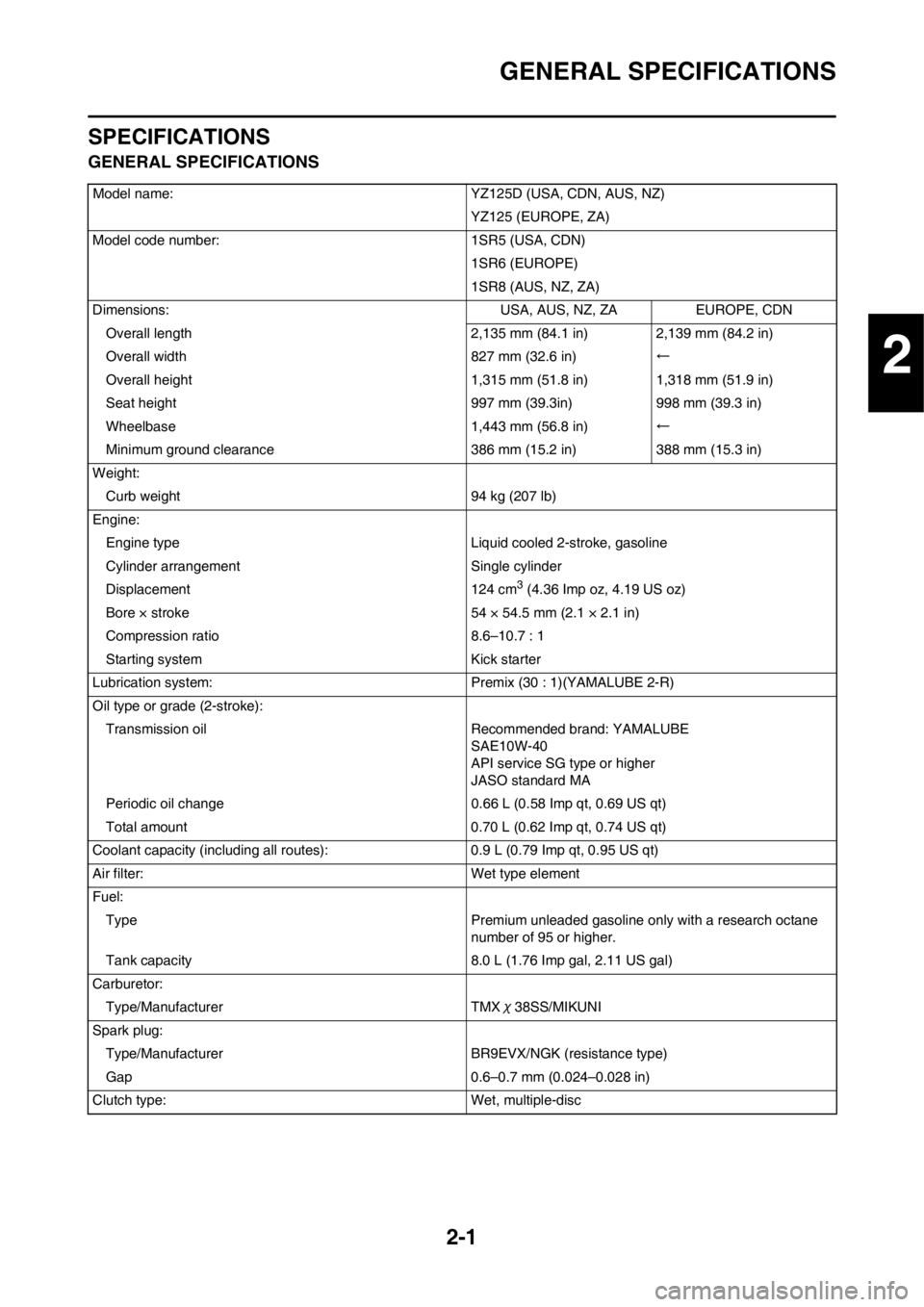

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model name:YZ125D (USA, CDN, AUS, NZ)

YZ125 (EUROPE, ZA)

Model code number: 1SR5 (USA, CDN)

1SR6 (EUROPE)

1SR8 (AUS, NZ, ZA)

Dimensions: USA, AUS, NZ, ZAEUROPE, CDN

Overall length 2,135 mm (84.1 in) 2,139 mm (84.2 in)

Overall width 827 mm (32.6 in)←

Overall height 1,315 mm (51.8 in) 1,318 mm (51.9 in)

Seat height 997 mm (39.3in)998 mm (39.3 in)

Wheelbase 1,443 mm (56.8 in)←

Minimum ground clearance 386 mm (15.2 in)388 mm (15.3 in)

Weight: Curb weight 94 kg (207 lb)

Engine: Engine type Liquid cooled 2-stroke, gasoline

Cylinder arrangement Single cylinder

Displacement 124 cm

3 (4.36 Imp oz, 4.19 US oz)

Bore × stroke 54 × 54.5 mm (2.1 × 2.1 in)

Compression ratio 8.6–10.7 : 1

Starting system Kick starter

Lubrication system: Premix (30 : 1)(YAMALUBE 2-R)

Oil type or grade (2-stroke): Transmission oil Recommended brand: YAMALUBE SAE10W-40

API service SG type or higher

JASO standard MA

Periodic oil change 0.66 L (0.58 Imp qt, 0.69 US qt)

Total amount 0.70 L (0.62 Imp qt, 0.74 US qt)

Coolant capacity (including all routes): 0.9 L (0.79 Imp qt, 0.95 US qt)

Air filter: Wet type element

Fuel: Type Premium unleaded gasoline on ly with a research octane

number of 95 or higher.

Tank capacity 8.0 L (1.76 Imp gal, 2.11 US gal)

Carburetor: Type/Manufacturer TMX χ38SS/MIKUNI

Spark plug: Type/Manufacturer BR9EVX/NGK (resistance type)

Gap 0.6–0.7 mm (0.024–0.028 in)

Clutch type: Wet, multiple-disc

2

Page 28 of 168

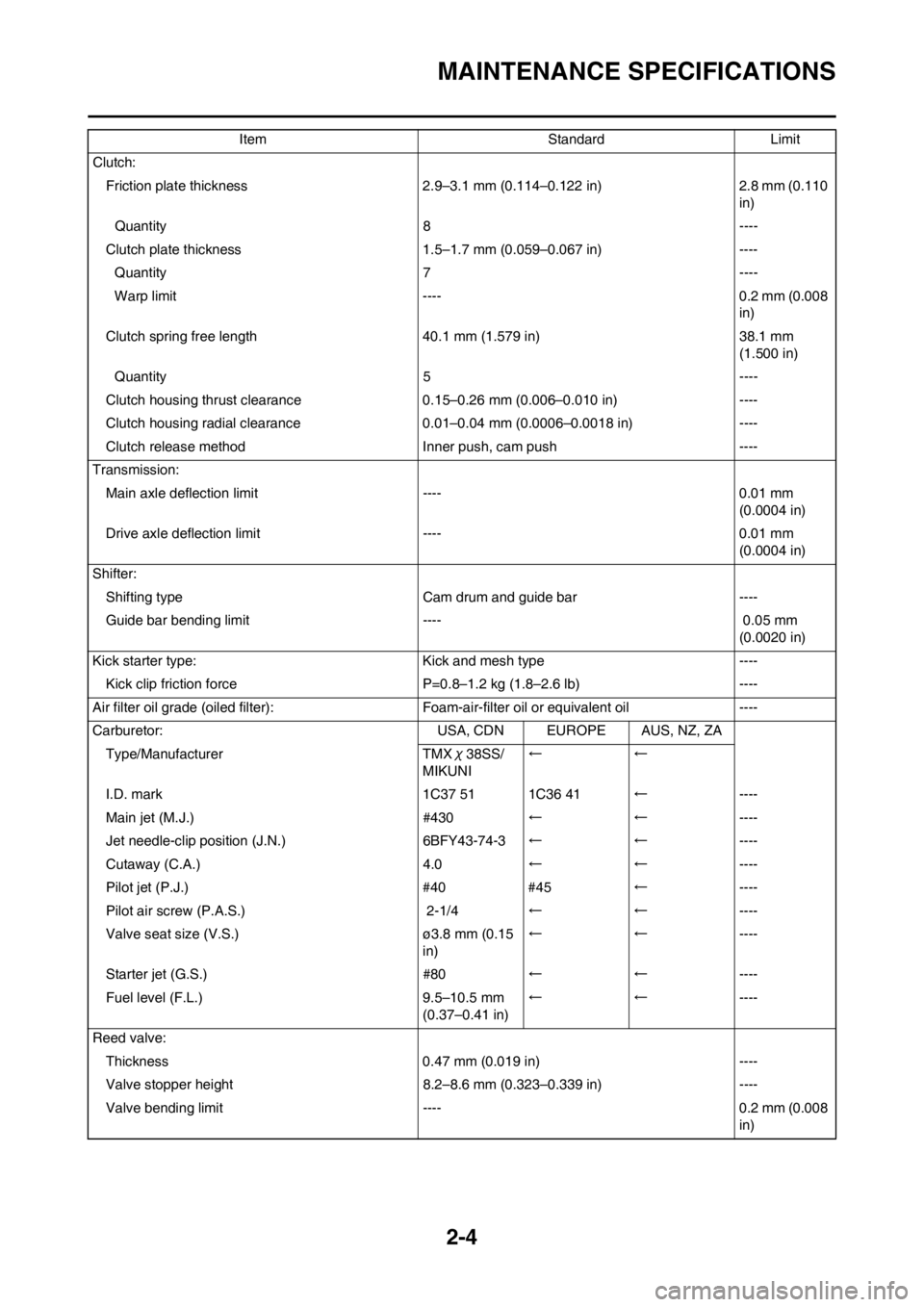

2-4

MAINTENANCE SPECIFICATIONS

Clutch:

Friction plate thickness 2.9–3.1 mm (0.114–0.122 in) 2.8 mm (0.110

in)

Quantity 8 ----

Clutch plate thickness 1.5–1.7 mm (0.059–0.067 in) ----

Quantity 7 ----

Warp limit ---- 0.2 mm (0.008

in)

Clutch spring free length 40.1 mm (1.579 in) 38.1 mm

(1.500 in)

Quantity 5 ----

Clutch housing thrust clearance 0.15–0.26 mm (0.006–0.010 in) ----

Clutch housing radial clearance 0.01–0.04 mm (0.0006–0.0018 in) ----

Clutch release methodInner push, cam push ----

Transmission:

Main axle deflection limit ---- 0.01 mm

(0.0004 in)

Drive axle deflection limit ---- 0.01 mm

(0.0004 in)

Shifter:

Shifting type Cam drum and guide bar ----

Guide bar bending limit ---- 0.05 mm

(0.0020 in)

Kick starter type: Kick and mesh type ----

Kick clip friction force P=0.8–1.2 kg (1.8–2.6 lb) ----

Air filter oil grade (oiled filter): Foam-air-filter oil or equivalent oil ----

Carburetor: USA, CDN EUROPE AUS, NZ, ZA

Type/Manufacturer TMXχ38SS/

MIKUNI ←←

I.D. mark 1C37 51 1C36 41←----

Main jet (M.J.) #430←←----

Jet needle-clip position (J.N.) 6BFY43-74-3←←----

Cutaway (C.A.) 4.0←←----

Pilot jet (P.J.) #40 #45←----

Pilot air screw (P.A.S.) 2-1/4←←----

Valve seat size (V.S.) ø3.8 mm (0.15

in)←←----

Starter jet (G.S.) #80←←----

Fuel level (F.L.) 9.5–10.5 mm

(0.37–0.41 in)←←----

Reed valve:

Thickness 0.47 mm (0.019 in) ----

Valve stopper height 8.2–8.6 mm (0.323–0.339 in) ----

Valve bending limit ---- 0.2 mm (0.008

in) Item Standard Limit

Page 29 of 168

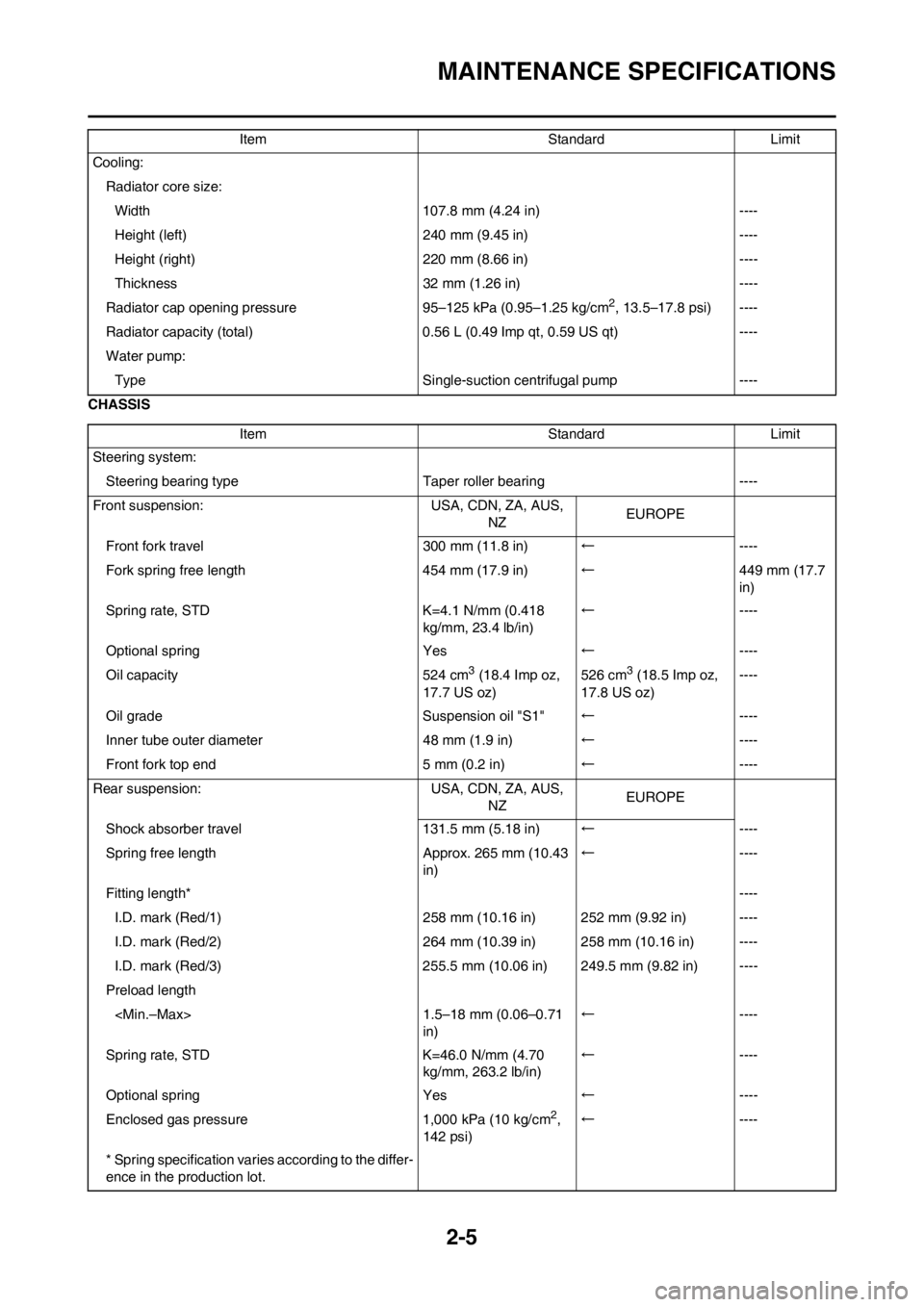

2-5

MAINTENANCE SPECIFICATIONS

CHASSISCooling:

Radiator core size:

Width 107.8 mm (4.24 in) ----

Height (left) 240 mm (9.45 in) ----

Height (right) 220 mm (8.66 in) ----

Thickness 32 mm (1.26 in) ----

Radiator cap opening pressure 95–125 kPa (0.95–1.25 kg/cm

2, 13.5–17.8 psi) ----

Radiator capacity (total) 0.56 L (0.49 Imp qt, 0.59 US qt) ----

Water pump:

Type Single-suction centrifugal pump ----

Item Standard Limit

Steering system:

Steering bearing typeTaper roller bearing ----

Front suspension: USA, CDN, ZA, AUS,

NZEUROPE

Front fork travel 300 mm (11.8 in)←----

Fork spring free length 454 mm (17.9 in)←449 mm (17.7

in)

Spring rate, STD K=4.1 N/mm (0.418

kg/mm, 23.4 lb/in)←----

Optional spring Yes←----

Oil capacity 524 cm

3 (18.4 Imp oz,

17.7 US oz) 526 cm3 (18.5 Imp oz,

17.8 US oz) ----

Oil grade Suspension oil "S1"←----

Inner tube outer diameter 48 mm (1.9 in)←----

Front fork top end 5 mm (0.2 in)←----

Rear suspension: USA, CDN, ZA, AUS,

NZEUROPE

Shock absorber travel 131.5 mm (5.18 in)←----

Spring free length Approx. 265 mm (10.43

in)←----

Fitting length*----

I.D. mark (Red/1) 258 mm (10.16 in) 252 mm (9.92 in) ----

I.D. mark (Red/2) 264 mm (10.39 in) 258 mm (10.16 in) ----

I.D. mark (Red/3) 255.5 mm (10.06 in) 249.5 mm (9.82 in) ----

Preload length

in)←----

Spring rate, STD K=46.0 N/mm (4.70

kg/mm, 263.2 lb/in)←----

Optional spring Yes←----

Enclosed gas pressure 1,000 kPa (10 kg/cm

2,

142 psi) ←----

* Spring specification varies according to the differ-

ence in the production lot.Item Standard Limit

Page 30 of 168

2-6

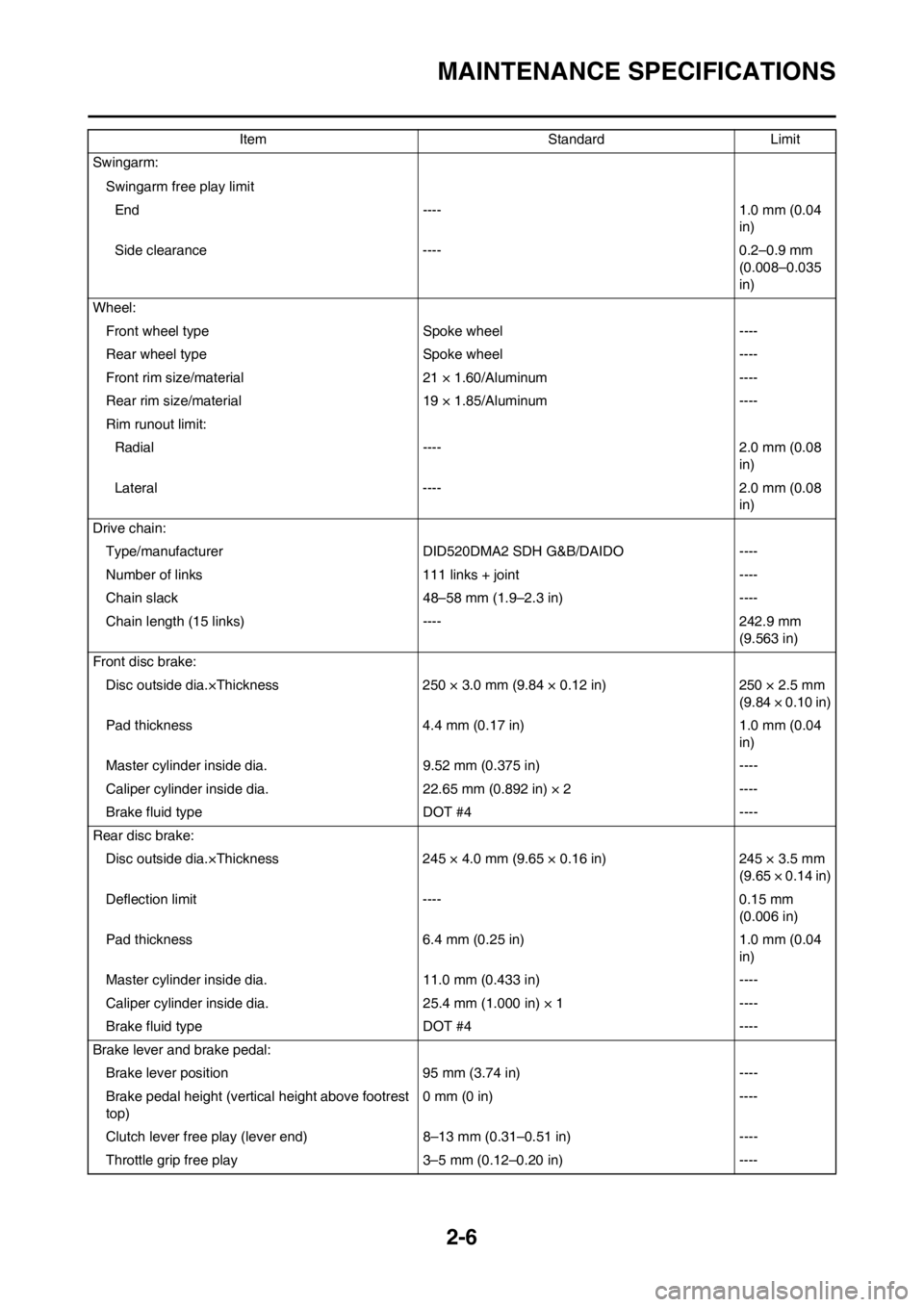

MAINTENANCE SPECIFICATIONS

Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04

in)

Side clearance ---- 0.2–0.9 mm

(0.008–0.035

in)

Wheel:

Front wheel type Spoke wheel ----

Rear wheel typeSpoke wheel ----

Front rim size/material 21 × 1.60/Aluminum ----

Rear rim size/material 19 × 1.85/Aluminum ----

Rim runout limit:

Radial ---- 2.0 mm (0.08

in)

Lateral ---- 2.0 mm (0.08

in)

Drive chain:

Type/manufacturer DID520DMA2 SDH G&B/DAIDO ----

Number of links 111 links + joint ----

Chain slack 48–58 mm (1.9–2.3 in) ----

Chain length (15 links) ---- 242.9 mm

(9.563 in)

Front disc brake:

Disc outside dia.×Thickness 250 × 3.0 mm (9.84 × 0.12 in) 250 × 2.5 mm

(9.84 × 0.10 in)

Pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 9.52 mm (0.375 in) ----

Caliper cylinder inside dia. 22.65 mm (0.892 in) × 2 ----

Brake fluid type DOT #4 ----

Rear disc brake:

Disc outside dia.×Thickness 245 × 4.0 mm (9.65 × 0.16 in) 245 × 3.5 mm

(9.65 × 0.14 in)

Deflection limit ---- 0.15 mm

(0.006 in)

Pad thickness 6.4 mm (0.25 in) 1.0 mm (0.04

in)

Master cylinder inside dia. 11.0 mm (0.433 in) ----

Caliper cylinder inside dia. 25.4 mm (1.000 in) × 1 ----

Brake fluid type DOT #4 ----

Brake lever and brake pedal:

Brake lever position 95 mm (3.74 in) ----

Brake pedal height (vertical height above footrest

top)0 mm (0 in) ----

Clutch lever free play (lever end) 8–13 mm (0.31–0.51 in) ----

Throttle grip free play3–5 mm (0.12–0.20 in) ---- Item Standard Limit

Page 36 of 168

2-12

TIGHTENING TORQUES

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for stan-

dard fasteners with standard I.S.O.

pitch threads. Torque specifications

for special components or assem-

blies are included in the applicable

sections of this book. To avoid warp-

age, tighten multi-fastener assem-

blies in a crisscross fashion, in

progressive stages, until full torque is

reached. Unless otherwise specified,

torque specifications call for clean,

dry threads. Components should be

at room temperature.A. Distance between flats

B. Outside thread diameter

DEFINITION OF UNITS

A

(Nut)B

(Bolt

)TORQUE SPECIFI-

CATION

Nm m•kg ft•lb

10

mm6 mm 6 0.6 4.3

12

mm8 mm 15 1.5 11

14

mm10

mm30 3.0 22

17

mm12

mm55 5.5 40

19

mm14

mm85 8.5 61

22

mm16

mm130 13 94

Unit Read Definition Measure

mm

millimeter 10-3 meter Length

cmcentimeter 10-2 meter Length

kgkilogram 103 gram Weight

NNewton 1 kg × m/sec2Force

NmNewton meter N × m Torque

m•kgMeter kilogram m × kg Torque

PaPascal N/m2Pressure

N/mmNewton per millimeter N/mm Spring rate

LLiter — Volume or capacity

cm3Cubic centimeter — Volume or capacity

r/minRevolution per minute — Engine speed

Page 55 of 168

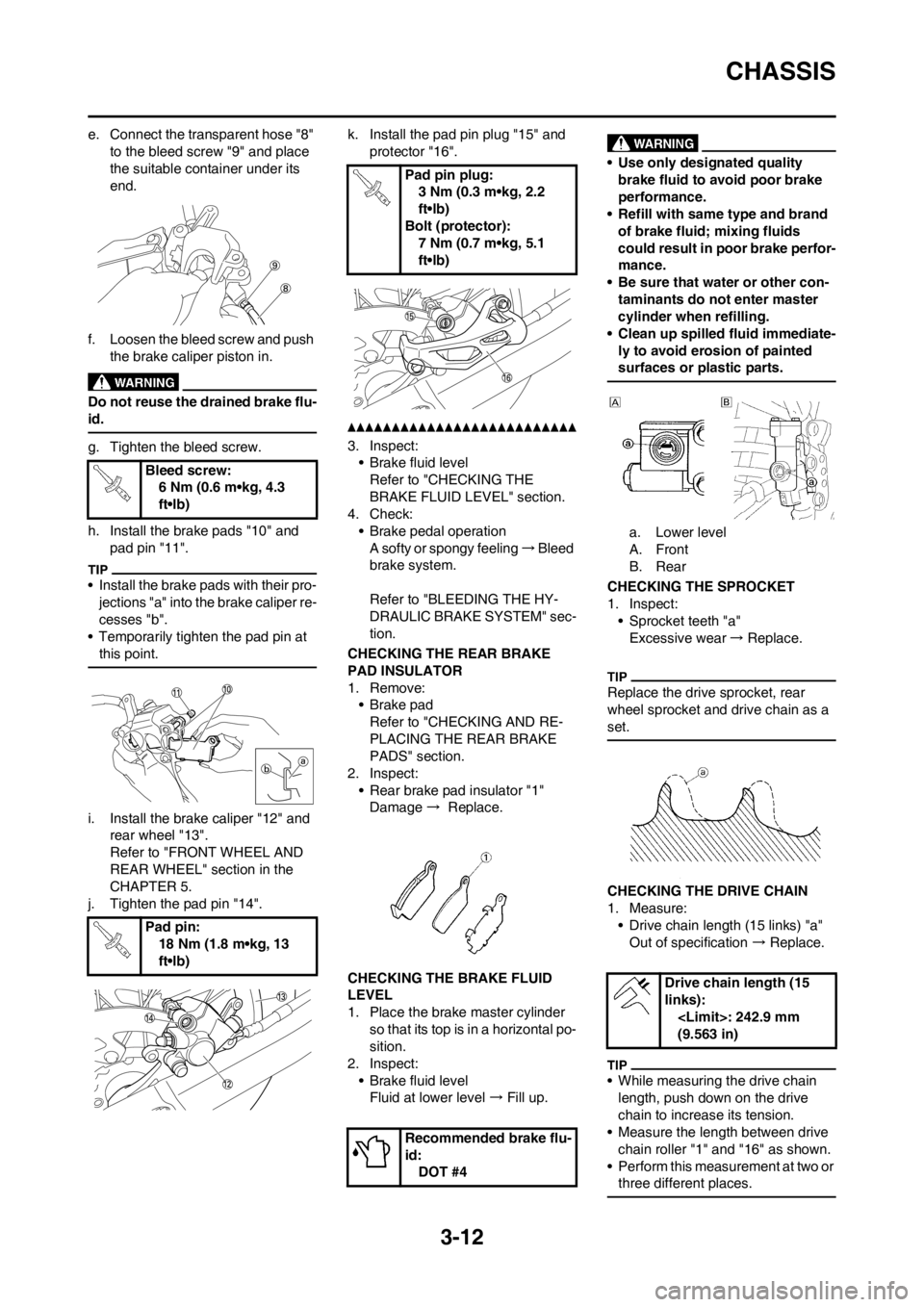

3-12

CHASSIS

e. Connect the transparent hose "8"

to the bleed screw "9" and place

the suitable container under its

end.

f. Loosen the bleed screw and push

the brake caliper piston in.

Do not reuse the drained brake flu-

id.

g. Tighten the bleed screw.

h. Install the brake pads "10" and

pad pin "11".

• Install the brake pads with their pro-

jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at

this point.

i. Install the brake caliper "12" and

rear wheel "13".

Refer to "FRONT WHEEL AND

REAR WHEEL" section in the

CHAPTER 5.

j. Tighten the pad pin "14".k. Install the pad pin plug "15" and

protector "16".

3. Inspect:

• Brake fluid level

Refer to "CHECKING THE

BRAKE FLUID LEVEL" section.

4. Check:

• Brake pedal operation

A softy or spongy feeling → Bleed

brake system.

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion.

CHECKING THE REAR BRAKE

PAD INSULATOR

1. Remove:

•Brake pad

Refer to "CHECKING AND RE-

PLACING THE REAR BRAKE

PADS" section.

2. Inspect:

• Rear brake pad insulator "1"

Damage → Replace.

CHECKING THE BRAKE FLUID

LEVEL

1. Place the brake master cylinder

so that its top is in a horizontal po-

sition.

2. Inspect:

• Brake fluid level

Fluid at lower level → Fill up.

• Use only designated quality

brake fluid to avoid poor brake

performance.

• Refill with same type and brand

of brake fluid; mixing fluids

could result in poor brake perfor-

mance.

• Be sure that water or other con-

taminants do not enter master

cylinder when refilling.

• Clean up spilled fluid immediate-

ly to avoid erosion of painted

surfaces or plastic parts.

a. Lower level

A. Front

B. Rear

CHECKING THE SPROCKET

1. Inspect:

• Sprocket teeth "a"

Excessive wear→ Replace.

Replace the drive sprocket, rear

wheel sprocket and drive chain as a

set.

CHECKING THE DRIVE CHAIN

1. Measure:

• Drive chain length (15 links) "a"

Out of specification → Replace.

• While measuring the drive chain

length, push down on the drive

chain to increase its tension.

• Measure the length between drive

chain roller "1" and "16" as shown.

• Perform this measurement at two or

three different places.

Bleed screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Pad pin:

18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug:

3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (protector):

7 Nm (0.7 m•kg, 5.1

ft•lb)

Recommended brake flu-

id:

DOT #4

Drive chain length (15

links):

(9.563 in)

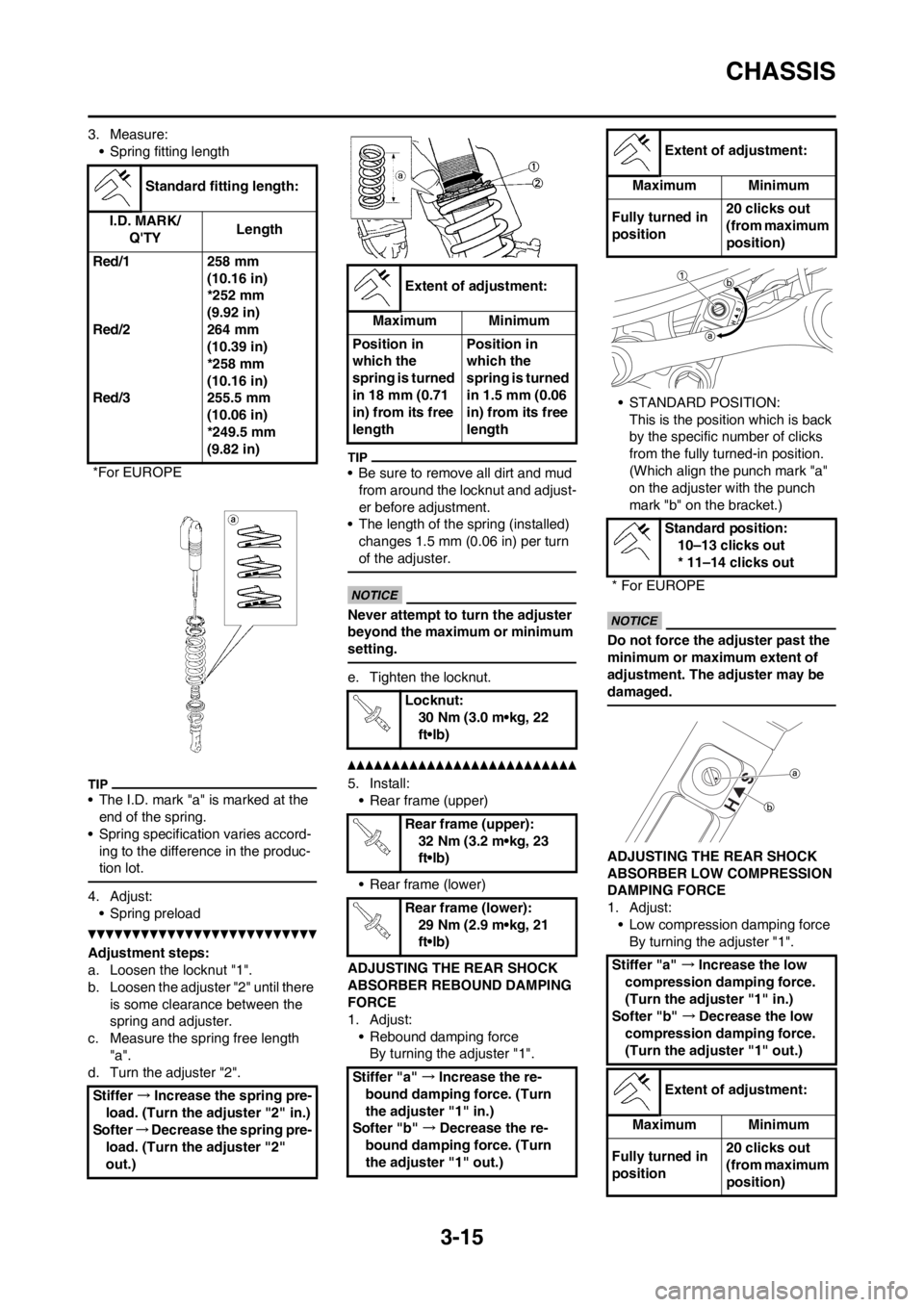

Page 58 of 168

3-15

CHASSIS

3. Measure:

• Spring fitting length

• The I.D. mark "a" is marked at the

end of the spring.

• Spring specification varies accord-

ing to the difference in the produc-

tion lot.

4. Adjust:

• Spring preload

Adjustment steps:

a. Loosen the locknut "1".

b. Loosen the adjuster "2" until there

is some clearance between the

spring and adjuster.

c. Measure the spring free length

"a".

d. Turn the adjuster "2".

• Be sure to remove all dirt and mud

from around the locknut and adjust-

er before adjustment.

• The length of the spring (installed)

changes 1.5 mm (0.06 in) per turn

of the adjuster.

Never attempt to turn the adjuster

beyond the maximum or minimum

setting.

e. Tighten the locknut.

5. Install:

• Rear frame (upper)

• Rear frame (lower)

ADJUSTING THE REAR SHOCK

ABSORBER REBOUND DAMPING

FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1".• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

(Which align the punch mark "a"

on the adjuster with the punch

mark "b" on the bracket.)

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

ADJUSTING THE REAR SHOCK

ABSORBER LOW COMPRESSION

DAMPING FORCE

1. Adjust:

• Low compression damping force

By turning the adjuster "1". Standard fitting length:

I.D. MARK/

Q'TYLength

Red/1

Red/2

Red/3258 mm

(10.16 in)

*252 mm

(9.92 in)

264 mm

(10.39 in)

*258 mm

(10.16 in)

255.5 mm

(10.06 in)

*249.5 mm

(9.82 in)

*For EUROPE

Stiffer →Increase the spring pre-

load. (Turn the adjuster "2" in.)

Softer→Decrease the spring pre-

load. (Turn the adjuster "2"

out.)

Extent of adjustment:

Maximum Minimum

Position in

which the

spring is turned

in 18 mm (0.71

in) from its free

lengthPosition in

which the

spring is turned

in 1.5 mm (0.06

in) from its free

length

Locknut:

30 Nm (3.0 m•kg, 22

ft•lb)

Rear frame (upper):

32 Nm (3.2 m•kg, 23

ft•lb)

Rear frame (lower):

29 Nm (2.9 m•kg, 21

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

10–13 clicks out

* 11–14 clicks out

* For EUROPE

Stiffer "a" →Increase the low

compression damping force.

(Turn the adjuster "1" in.)

Softer "b" →Decrease the low

compression damping force.

(Turn the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

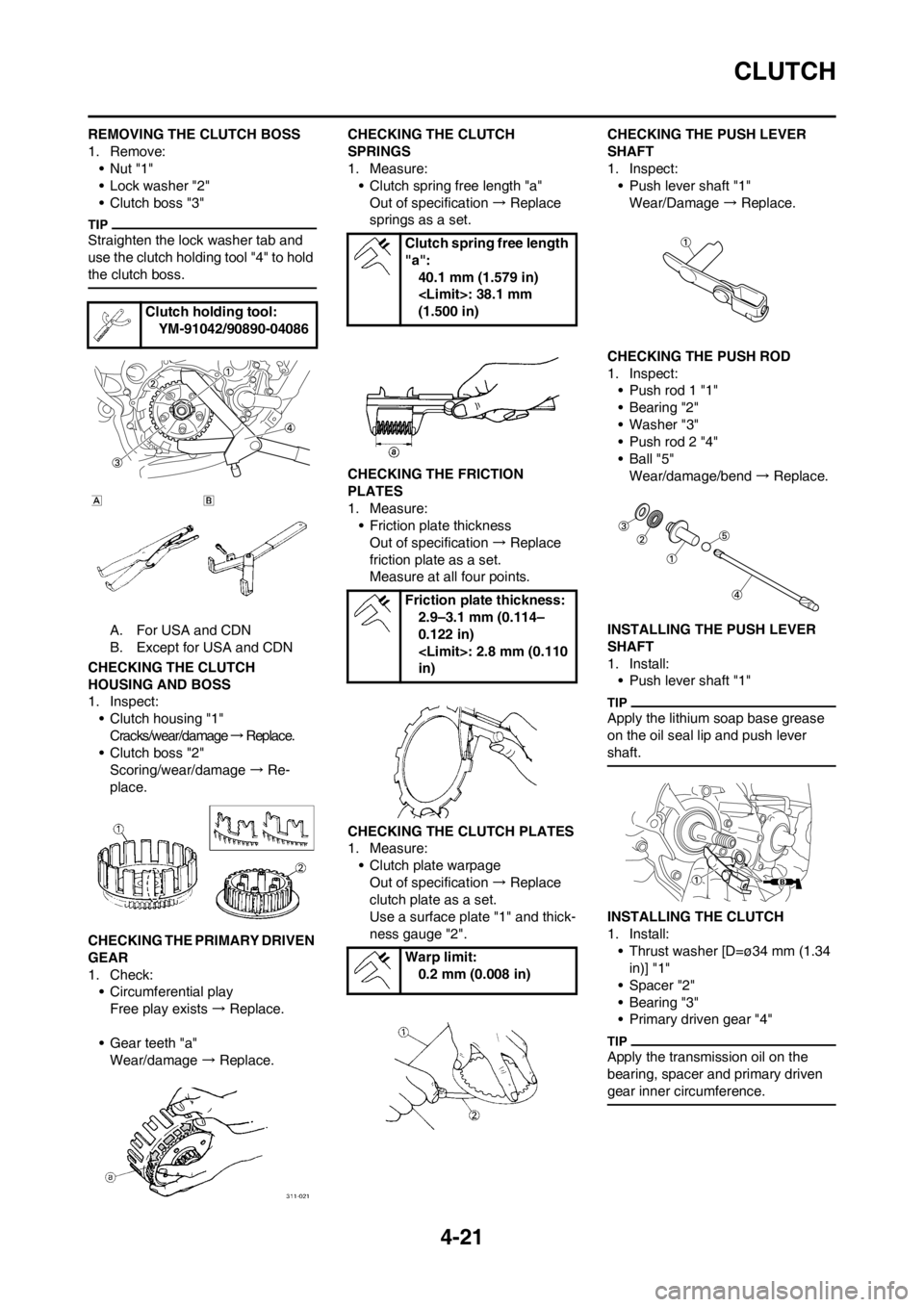

Page 83 of 168

4-21

CLUTCH

REMOVING THE CLUTCH BOSS

1. Remove:

•Nut "1"

• Lock washer "2"

• Clutch boss "3"

Straighten the lock washer tab and

use the clutch holding tool "4" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

CHECKING THE CLUTCH

HOUSING AND BOSS

1. Inspect:

• Clutch housing "1"

Cracks/wear/damage → R e p l a c e .

• Clutch boss "2"

Scoring/wear/damage → Re-

place.

CHECKING THE PRIMARY DRIVEN

GEAR

1. Check:

• Circumferential play

Free play exists → Replace.

• Gear teeth "a"

Wear/damage → Replace. CHECKING THE CLUTCH

SPRINGS

1. Measure:

• Clutch spring free length "a"

Out of specification → Replace

springs as a set.

CHECKING THE FRICTION

PLATES

1. Measure:

• Friction plate thickness

Out of specification → Replace

friction plate as a set.

Measure at all four points.

CHECKING THE CLUTCH PLATES

1. Measure:

• Clutch plate warpage

Out of specification → Replace

clutch plate as a set.

Use a surface plate "1" and thick-

ness gauge "2".CHECKING THE PUSH LEVER

SHAFT

1. Inspect:

• Push lever shaft "1"

Wear/Damage → Replace.

CHECKING THE PUSH ROD

1. Inspect:

• Push rod 1 "1"

• Bearing "2"

• Washer "3"

• Push rod 2 "4"

•Ball "5"

Wear/damage/bend → Replace.

INSTALLING THE PUSH LEVER

SHAFT

1. Install:

• Push lever shaft "1"

Apply the lithium soap base grease

on the oil seal lip and push lever

shaft.

INSTALLING THE CLUTCH

1. Install:

• Thrust washer [D=ø34 mm (1.34

in)] "1"

• Spacer "2"

• Bearing "3"

• Primary driven gear "4"

Apply the transmission oil on the

bearing, spacer and primary driven

gear inner circumference.

Clutch holding tool:

YM-91042/90890-04086

Clutch spring free length

"a":

40.1 mm (1.579 in)

(1.500 in)

Friction plate thickness:

2.9–3.1 mm (0.114–

0.122 in)

in)

Warp limit:

0.2 mm (0.008 in)

Page 127 of 168

5-19

FRONT FORK

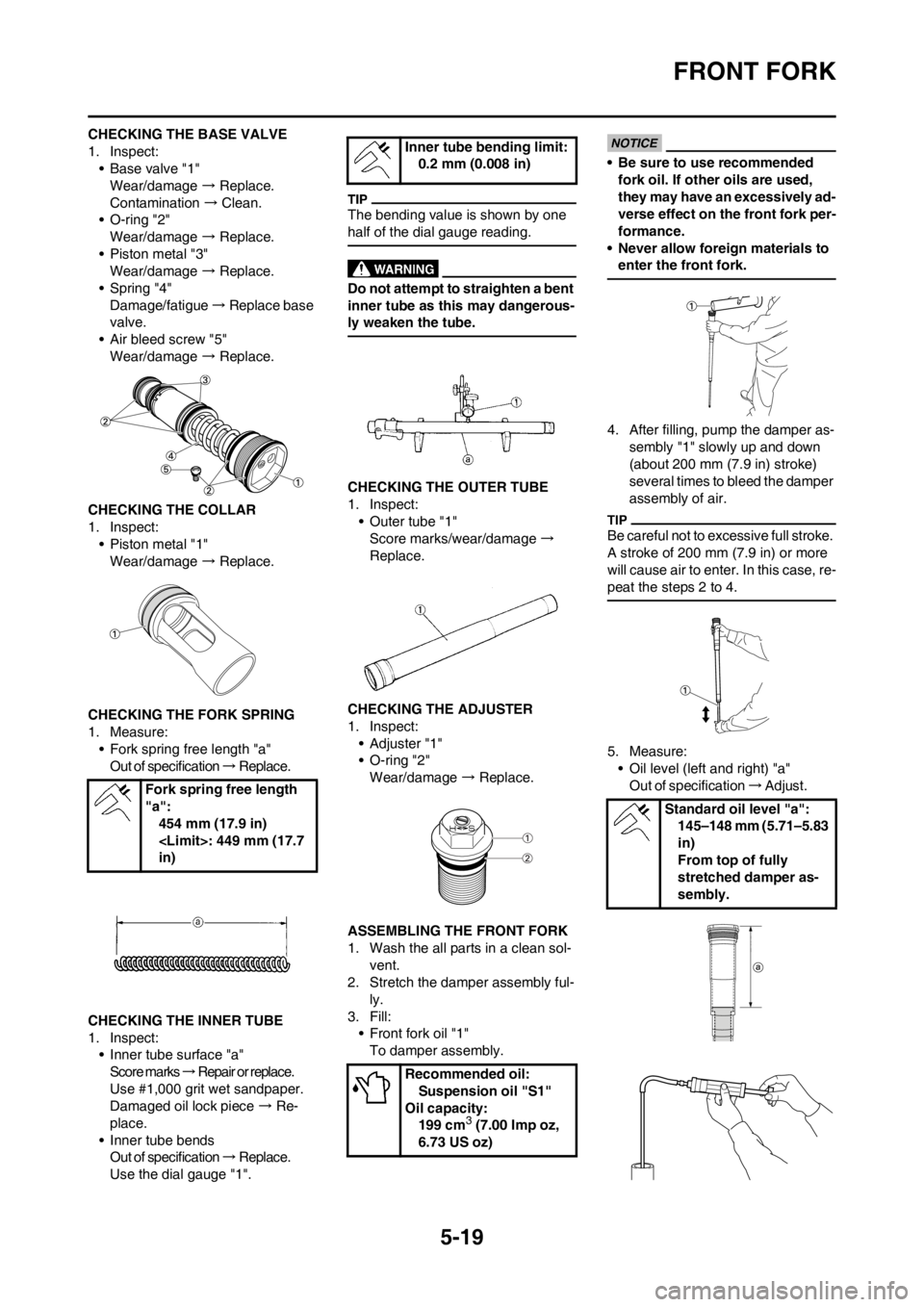

CHECKING THE BASE VALVE

1. Inspect:

• Base valve "1"

Wear/damage → Replace.

Contamination → Clean.

• O-ring "2"

Wear/damage → Replace.

• Piston metal "3"

Wear/damage → Replace.

• Spring "4"

Damage/fatigue → Replace base

valve.

• Air bleed screw "5"

Wear/damage → Replace.

CHECKING THE COLLAR

1. Inspect:

• Piston metal "1"

Wear/damage → Replace.

CHECKING THE FORK SPRING

1. Measure:

• Fork spring free length "a"

Out of specification → R e p l a c e .

CHECKING THE INNER TUBE

1. Inspect:

• Inner tube surface "a"

Score marks → Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece → Re-

place.

• Inner tube bends

Out of specification → R e p l a c e .

Use the dial gauge "1".

The bending value is shown by one

half of the dial gauge reading.

Do not attempt to straighten a bent

inner tube as this may dangerous-

ly weaken the tube.

CHECKING THE OUTER TUBE

1. Inspect:

• Outer tube "1"

Score marks/wear/damage →

Replace.

CHECKING THE ADJUSTER

1. Inspect:

•Adjuster "1"

• O-ring "2"

Wear/damage → Replace.

ASSEMBLING THE FRONT FORK

1. Wash the all parts in a clean sol-

vent.

2. Stretch the damper assembly ful-

ly.

3. Fill:

• Front fork oil "1"

To damper assembly.

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to

enter the front fork.

4. After filling, pump the damper as-

sembly "1" slowly up and down

(about 200 mm (7.9 in) stroke)

several times to bleed the damper

assembly of air.

Be careful not to excessive full stroke.

A stroke of 200 mm (7.9 in) or more

will cause air to enter. In this case, re-

peat the steps 2 to 4.

5. Measure:

• Oil level (left and right) "a"

Out of specification → A d j u s t .

Fork spring free length

"a":

454 mm (17.9 in)

in)

Inner tube bending limit:

0.2 mm (0.008 in)

Recommended oil:

Suspension oil "S1"

Oil capacity:

199 cm

3 (7.00 Imp oz,

6.73 US oz)

Standard oil level "a":

145–148 mm (5.71–5.83

in)

From top of fully

stretched damper as-

sembly.