engine YAMAHA YZ250F 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250F, Model: YAMAHA YZ250F 2001Pages: 656, PDF Size: 24.86 MB

Page 506 of 656

5 - 27

CHASFRONT FORK

EC550000

FRONT FORK

Extent of removal:1 Front fork removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT FORK REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is nodanger of it falling over.

Front wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Front brake caliper Refer to “FRONT BRAKE AND REAR

BRAKE” section.

Number plate

Handlebar Refer to “HANDLEBAR” section.

1 Protector 1

2 Brake hose holder 2

3 Pinch bolt (upper bracket) 2 Only loosening.

4 Cap bolt 1Loosen when disassembling the front fork.

5 Pinch bolt (lower bracket) 2 Only loosening.

6 Front fork 1

1

Page 532 of 656

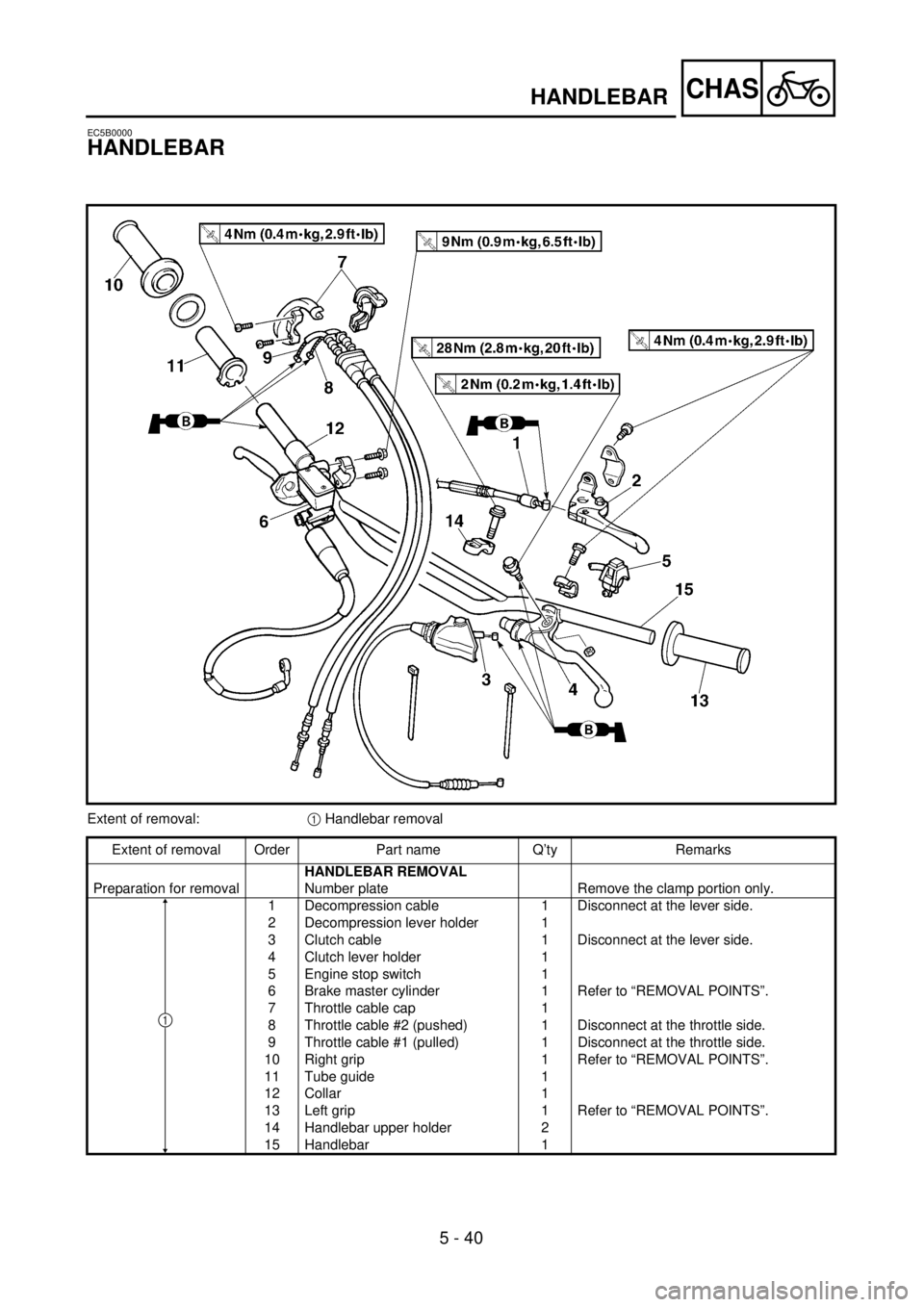

5 - 40

CHAS

EC5B0000

HANDLEBAR

Extent of removal:1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalHANDLEBAR REMOVAL

Number plate Remove the clamp portion only.

1 Decompression cable 1 Disconnect at the lever side.

2 Decompression lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1

5 Engine stop switch 1

6 Brake master cylinder 1 Refer to “REMOVAL POINTS”.

7 Throttle cable cap 1

8 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

9 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

10 Right grip 1 Refer to “REMOVAL POINTS”.

11 Tube guide 1

12 Collar 1

13 Left grip 1 Refer to “REMOVAL POINTS”.

14 Handlebar upper holder 2

15 Handlebar 1

1

HANDLEBAR

Page 540 of 656

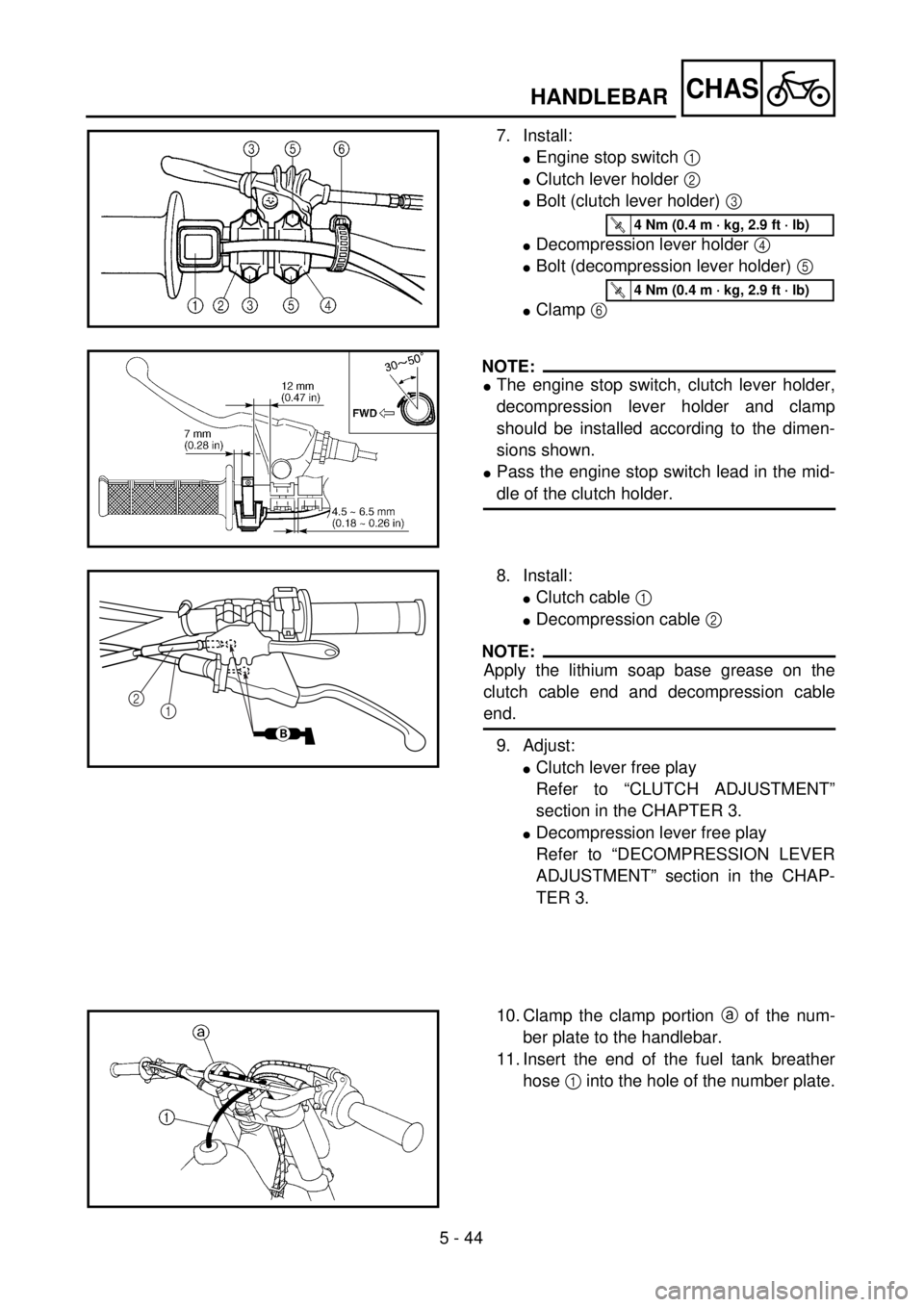

5 - 44

CHASHANDLEBAR

7. Install:

lEngine stop switch 1

lClutch lever holder 2

lBolt (clutch lever holder) 3

lDecompression lever holder 4

lBolt (decompression lever holder) 5

lClamp 6

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

NOTE:

lThe engine stop switch, clutch lever holder,

decompression lever holder and clamp

should be installed according to the dimen-

sions shown.

lPass the engine stop switch lead in the mid-

dle of the clutch holder.

8. Install:

lClutch cable 1

lDecompression cable 2

NOTE:

Apply the lithium soap base grease on the

clutch cable end and decompression cable

end.

9. Adjust:

lClutch lever free play

Refer to “CLUTCH ADJUSTMENT”

section in the CHAPTER 3.

lDecompression lever free play

Refer to “DECOMPRESSION LEVER

ADJUSTMENT” section in the CHAP-

TER 3.

B

2

1

10. Clamp the clamp portion a of the num-

ber plate to the handlebar.

11. Insert the end of the fuel tank breather

hose 1 into the hole of the number plate.

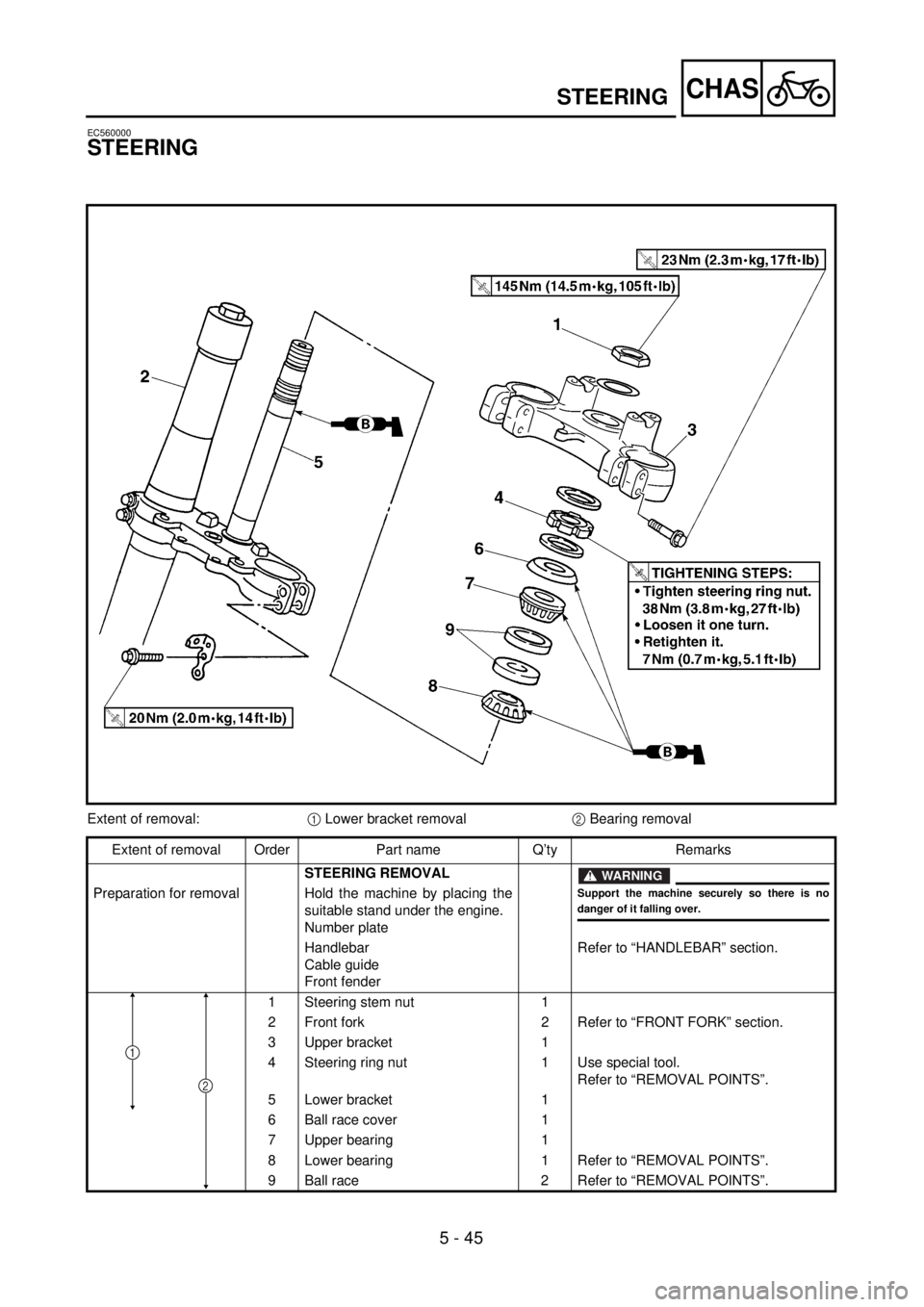

Page 542 of 656

5 - 45

CHAS

EC560000

STEERING

Extent of removal:1 Lower bracket removal2 Bearing removal

Extent of removal Order Part name Q’ty Remarks

STEERING REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over.Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Number plate

Handlebar

Cable guide

Front fenderRefer to “HANDLEBAR” section.

1 Steering stem nut 1

2 Front fork 2 Refer to “FRONT FORK” section.

3 Upper bracket 1

4 Steering ring nut 1 Use special tool.

Refer to “REMOVAL POINTS”.

5 Lower bracket 1

6 Ball race cover 1

7 Upper bearing 1

8 Lower bearing 1 Refer to “REMOVAL POINTS”.

9Ball race

2Refer to “REMOVAL POINTS”.

2

1

STEERING

Page 552 of 656

5 - 50

CHASSWINGARM

EC570000

SWINGARM

Extent of removal:1 Swingarm removal

Extent of removal Order Part name Q’ty Remarks

STEERING REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over.

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Brake hose holder

Rear brake caliper

Bolt (brake pedal)

Drive chainRefer to “FRONT BRAKE AND REAR

BRAKE” section.

Shift the brake pedal backward.

1 Drive chain case 1

2 Lower chain tensioner 1

3 Bolt (rear shock absorber-relay

arm)1 Hold the swingarm.

4 Bolt (connecting rod) 1

5 Pivot shaft 1

6 Swingarm 1

1

Page 566 of 656

5 - 57

CHASREAR SHOCK ABSORBER

EC580000

REAR SHOCK ABSORBER

Extent of removal:1 Rear shock absorber removal2 Rear shock absorber disassembly

Extent of removal Order Part name Q’ty Remarks

Preparation for removalREAR SHOCK ABSORBER

REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is nodanger of it falling over.

Seat Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Silencer Refer to “EXHAUST PIPE AND

SILENCER” section in the CHAPTER 4.

1 Bolt (reservoir tank) 1

2 Clamp (air cleaner joint) 1 Only loosening.

3 Rear frame 1

4 Bolt (rear shock absorber-relay

arm)1 Hold the swingarm.

5 Bolt (rear shock absorber-frame) 1

6 Rear shock absorber 1

7 Locknut 1 Only loosening.

8 Adjuster 1 Only loosening.

9 Lower spring guide 1

1

2

Page 580 of 656

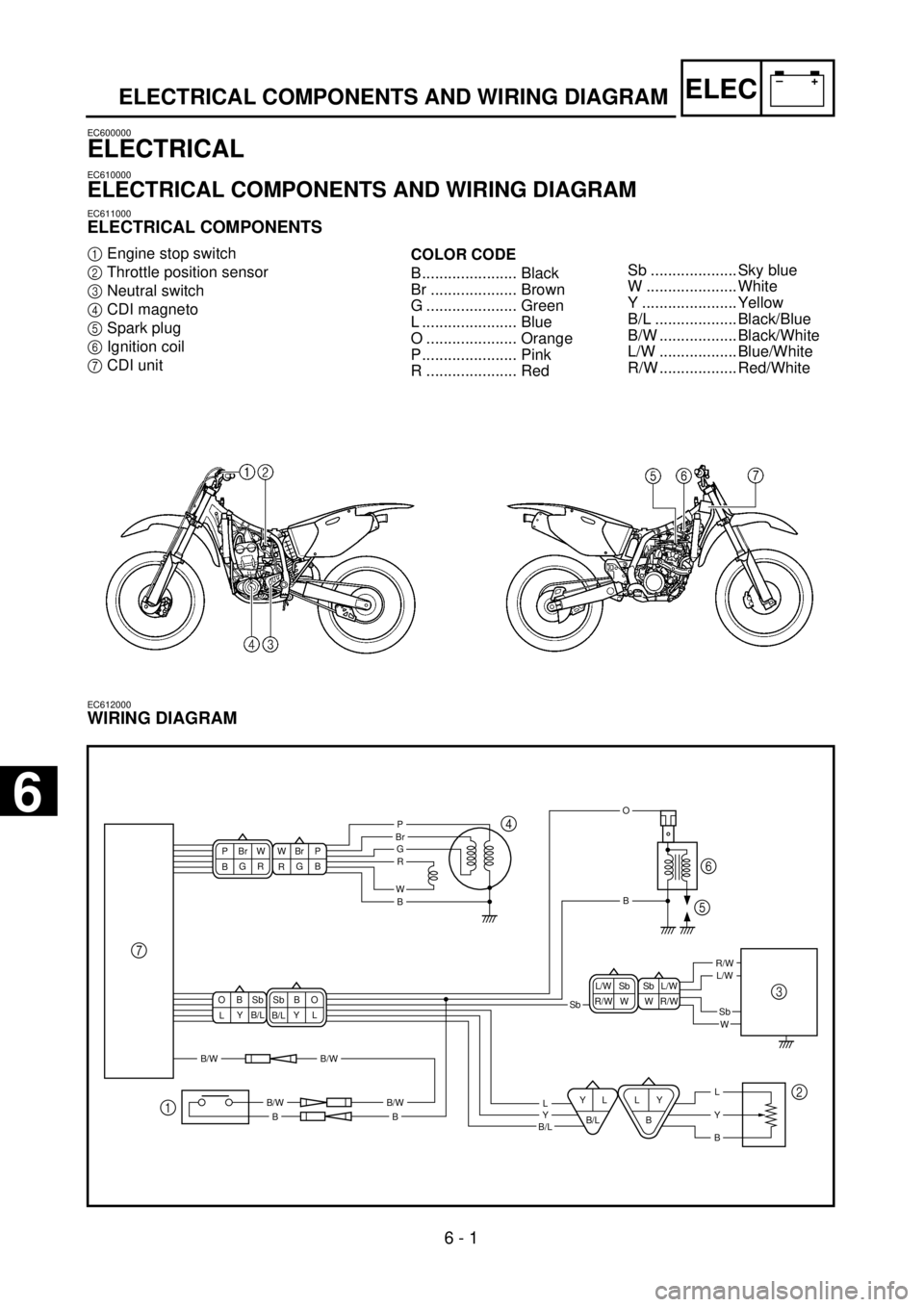

6 - 1

–+ELEC

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1

Engine stop switch

2

Throttle position sensor

3

Neutral switch

4

CDI magneto

5

Spark plug

6

Ignition coil

7

CDI unit

COLOR CODE

B...................... Black

Br .................... Brown

G ..................... Green

L ...................... Blue

O ..................... Orange

P...................... Pink

R ..................... Red

EC612000

WIRING DIAGRAM

7

16

5

2 3 4

LY

BYL

B/LL

G

P

W

R

Y

B

G

BR PBrWG

RB Br WP

R/W WL/W SbW R/W Sb L/WY

B/LL Sb B OY

LB/L B OSbSb

L/WR/W

WSb

B/L

B/WB/W

B/WB/W

Br

BB

LBBY

O

Sb .................... Sky blue

W ..................... White

Y ...................... Yellow

B/L ................... Black/Blue

B/W .................. Black/White

L/W .................. Blue/White

R/W .................. Red/White

6

Page 582 of 656

–+ELEC

6 - 2

MAP-CONTROLLED CDI UNIT

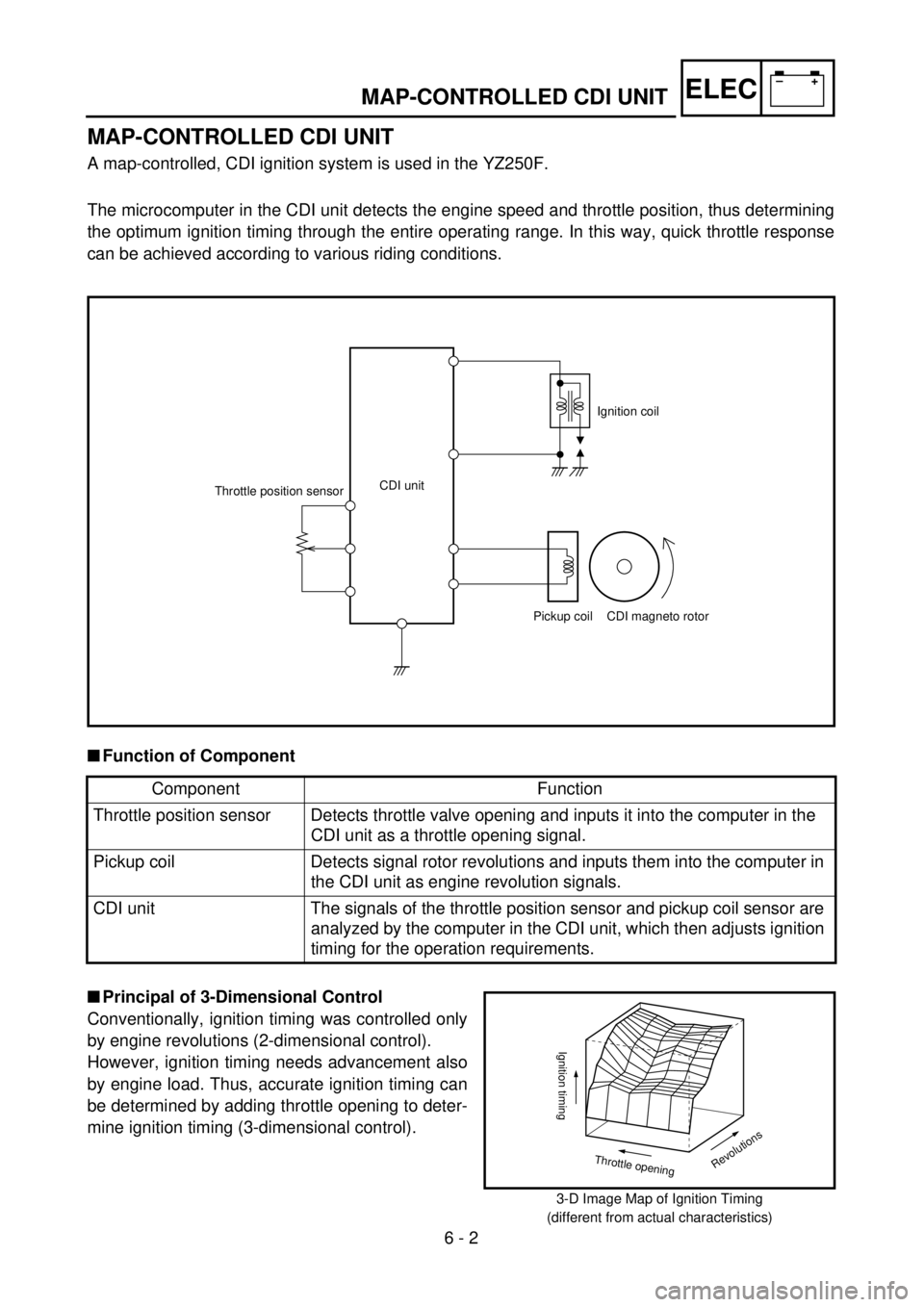

MAP-CONTROLLED CDI UNIT

A map-controlled, CDI ignition system is used in the YZ250F.

The microcomputer in the CDI unit detects the engine speed and throttle position, thus determining

the optimum ignition timing through the entire operating range. In this way, quick throttle response

can be achieved according to various riding conditions.

CDI unit

Throttle position sensor

Pickup coil CDI magneto rotorIgnition coil

n

Function of Component

Component Function

Throttle position sensor Detects throttle valve opening and inputs it into the computer in the

CDI unit as a throttle opening signal.

Pickup coil Detects signal rotor revolutions and inputs them into the computer in

the CDI unit as engine revolution signals.

CDI unit The signals of the throttle position sensor and pickup coil sensor are

analyzed by the computer in the CDI unit, which then adjusts ignition

timing for the operation requirements.

n

Principal of 3-Dimensional Control

Conventionally, ignition timing was controlled only

by engine revolutions (2-dimensional control).

However, ignition timing needs advancement also

by engine load. Thus, accurate ignition timing can

be determined by adding throttle opening to deter-

mine ignition timing (3-dimensional control).

3-D Image Map of Ignition Timing

(different from actual characteristics)

Revolutions

Ignition timing

Throttle opening

Page 586 of 656

–+ELEC

6 - 3

IGNITION SYSTEM

EC620000

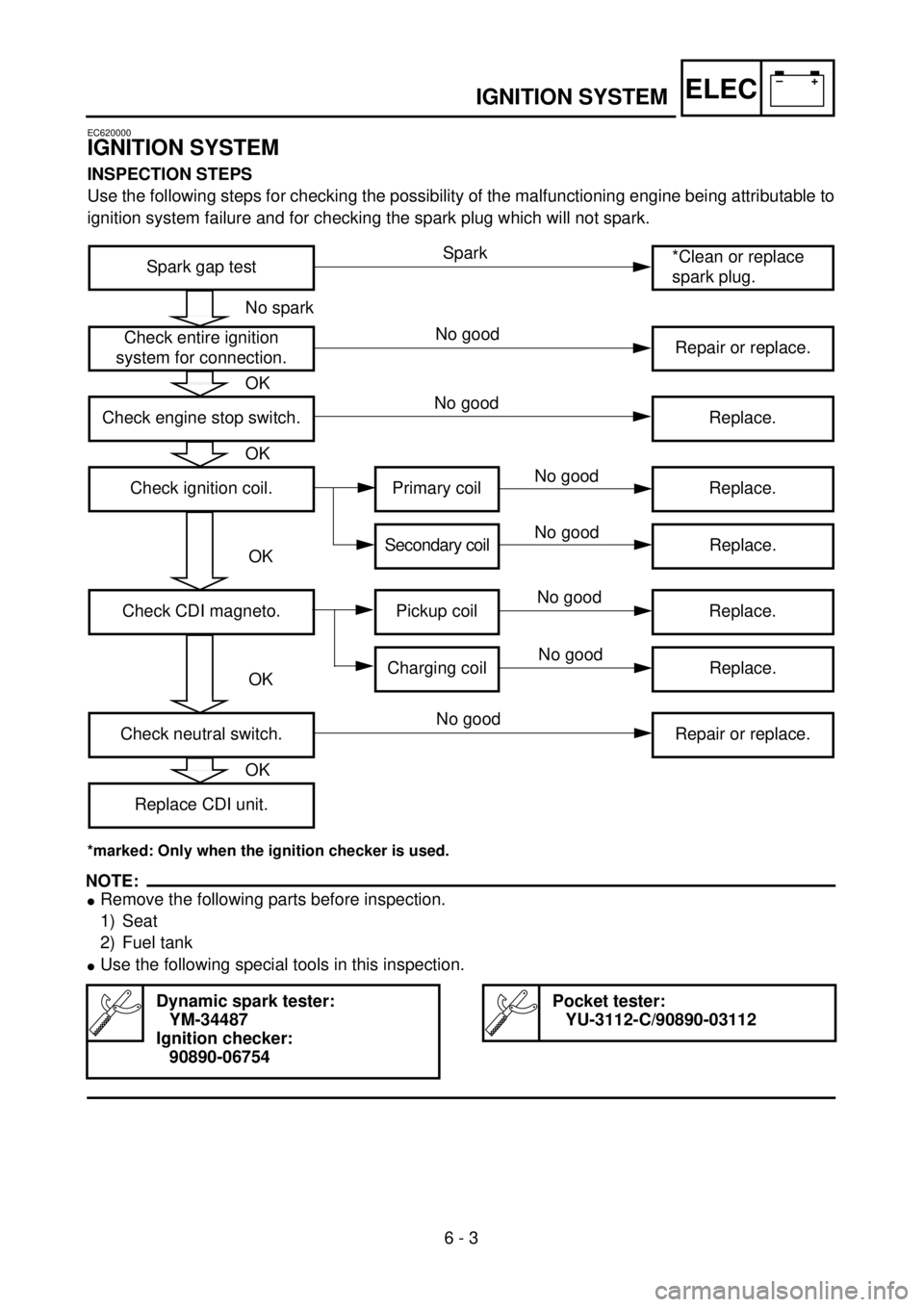

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

*marked: Only when the ignition checker is used.

NOTE:

l

Remove the following parts before inspection.

1) Seat

2) Fuel tank

l

Use the following special tools in this inspection.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754

Pocket tester:

YU-3112-C/90890-03112

Spark gap test*Clean or replace

spark plug.

Check entire ignition

system for connection.Repair or replace.

Check engine stop switch. Replace.

Check ignition coil. Primary coil Replace.

Secondary coil Replace.

Check CDI magneto. Pickup coil Replace.

Charging coil Replace.

Check neutral switch. Repair or replace.

Replace CDI unit.

No spark

OK

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

No good

Page 590 of 656

6 - 4

–+ELEC

IGNITION SYSTEM

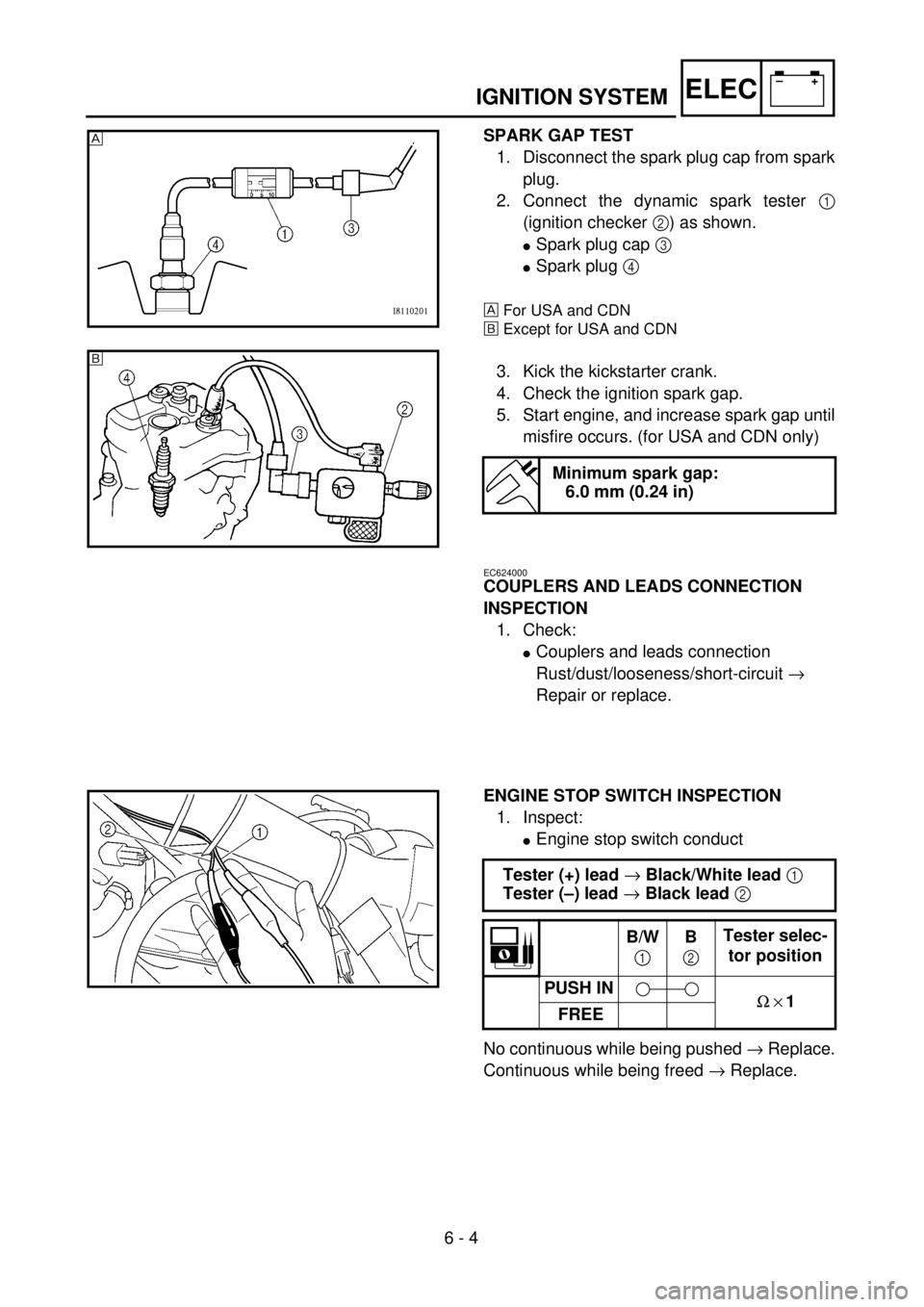

SPARK GAP TEST

1. Disconnect the spark plug cap from spark

plug.

2. Connect the dynamic spark tester

1

(ignition checker

2

) as shown.

l

Spark plug cap

3

l

Spark plug

4

For USA and CDN

õ

Except for USA and CDN

3. Kick the kickstarter crank.

4. Check the ignition spark gap.

5. Start engine, and increase spark gap until

misfire occurs. (for USA and CDN only)

Minimum spark gap:

6.0 mm (0.24 in)

õ

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

l

Couplers and leads connection

Rust/dust/looseness/short-circuit

®

Repair or replace.

ENGINE STOP SWITCH INSPECTION

1. Inspect:

l

Engine stop switch conduct

No continuous while being pushed

®

Replace.

Continuous while being freed

®

Replace.

Tester (+) lead

®

Black/White lead

1

Tester (–) lead

®

Black lead

2

B/W

1

B

2

Tester selec-

tor position

PUSH IN

W

´

1

FREE