engine YAMAHA YZ250F 2001 Repair Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250F, Model: YAMAHA YZ250F 2001Pages: 656, PDF Size: 24.86 MB

Page 334 of 656

4 - 40

ENGVALVES AND VALVE SPRINGS

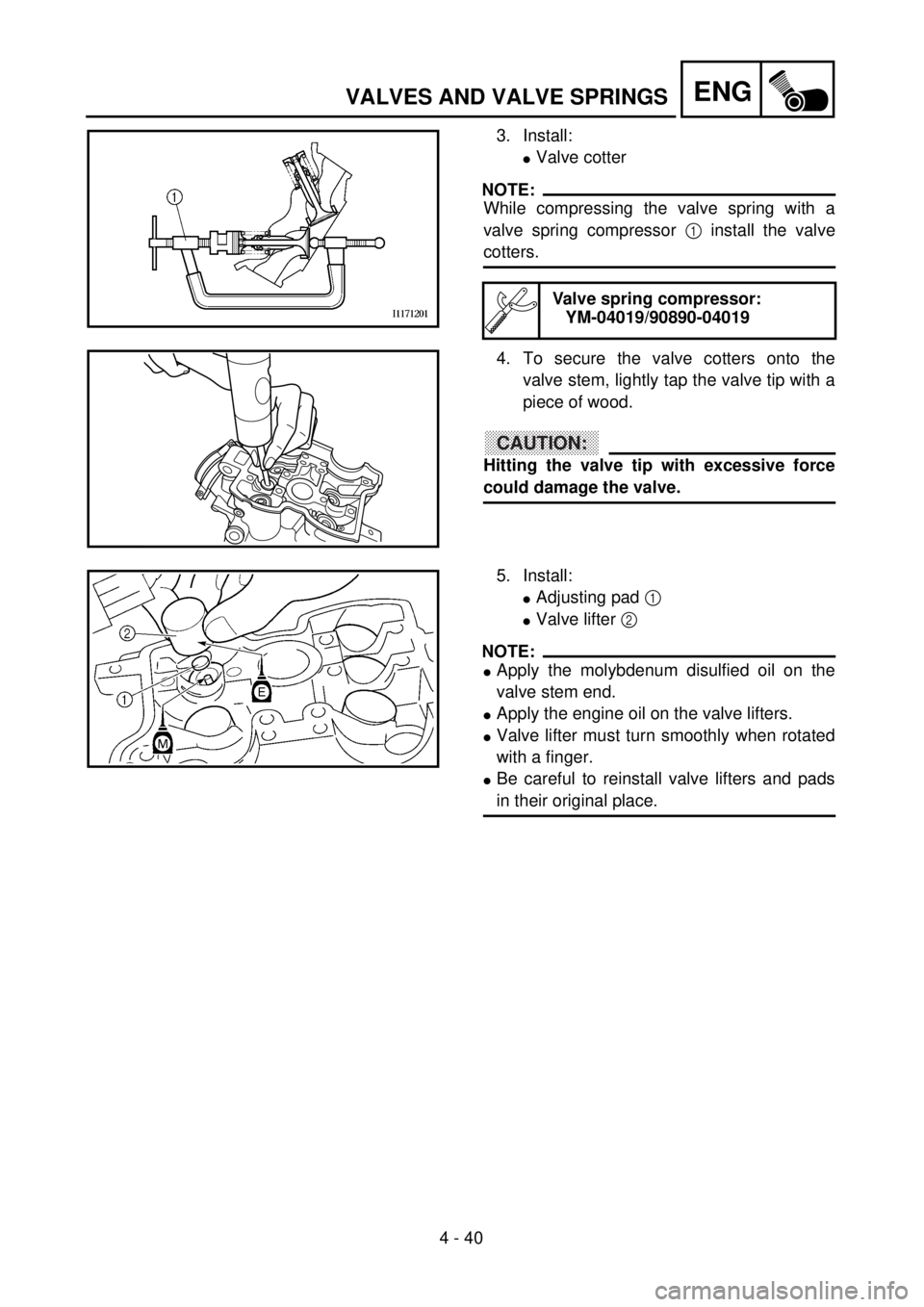

3. Install:

lValve cotter

NOTE:

While compressing the valve spring with a

valve spring compressor 1 install the valve

cotters.

4. To secure the valve cotters onto the

valve stem, lightly tap the valve tip with a

piece of wood.

CAUTION:

Hitting the valve tip with excessive force

could damage the valve.

Valve spring compressor:

YM-04019/90890-04019

5. Install:

lAdjusting pad 1

lValve lifter 2

NOTE:

lApply the molybdenum disulfied oil on the

valve stem end.

lApply the engine oil on the valve lifters.

lValve lifter must turn smoothly when rotated

with a finger.

lBe careful to reinstall valve lifters and pads

in their original place.

Page 344 of 656

4 - 45

ENGCYLINDER AND PISTON

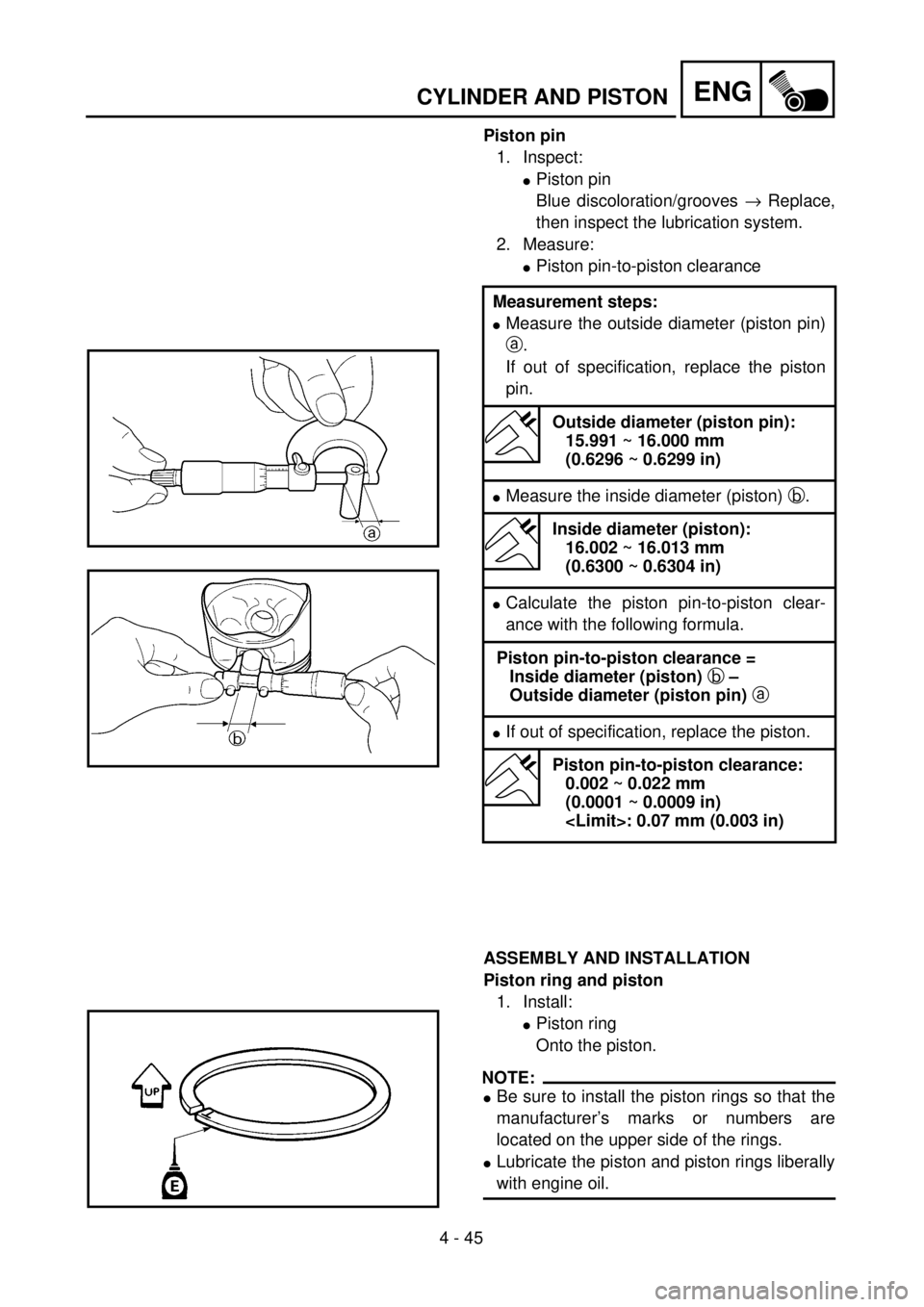

Piston pin

1. Inspect:

lPiston pin

Blue discoloration/grooves ® Replace,

then inspect the lubrication system.

2. Measure:

lPiston pin-to-piston clearance

ASSEMBLY AND INSTALLATION

Piston ring and piston

1. Install:

lPiston ring

Onto the piston.

NOTE:

lBe sure to install the piston rings so that the

manufacturer’s marks or numbers are

located on the upper side of the rings.

lLubricate the piston and piston rings liberally

with engine oil. Measurement steps:

lMeasure the outside diameter (piston pin)

a.

If out of specification, replace the piston

pin.

Outside diameter (piston pin):

15.991 ~ 16.000 mm

(0.6296 ~ 0.6299 in)

lMeasure the inside diameter (piston) b.

Inside diameter (piston):

16.002 ~ 16.013 mm

(0.6300 ~ 0.6304 in)

lCalculate the piston pin-to-piston clear-

ance with the following formula.

Piston pin-to-piston clearance =

Inside diameter (piston) b –

Outside diameter (piston pin) a

lIf out of specification, replace the piston.

Piston pin-to-piston clearance:

0.002 ~ 0.022 mm

(0.0001 ~ 0.0009 in)

Page 346 of 656

4 - 46

ENGCYLINDER AND PISTON

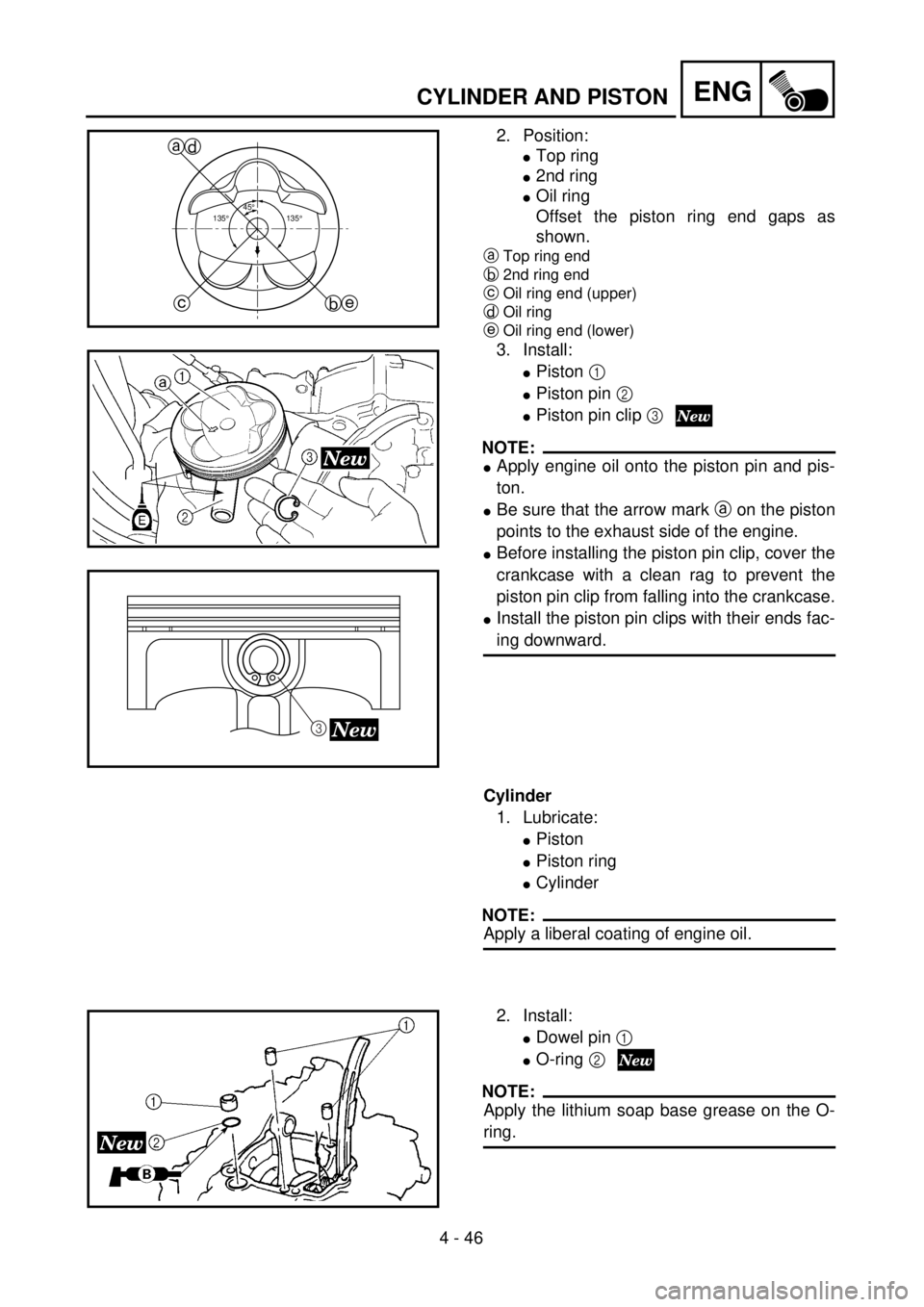

2. Position:

lTop ring

l2nd ring

lOil ring

Offset the piston ring end gaps as

shown.

aTop ring end

b2nd ring end

cOil ring end (upper)

dOil ring

eOil ring end (lower)

3. Install:

lPiston 1

lPiston pin 2

lPiston pin clip 3

NOTE:

lApply engine oil onto the piston pin and pis-

ton.

lBe sure that the arrow mark a on the piston

points to the exhaust side of the engine.

lBefore installing the piston pin clip, cover the

crankcase with a clean rag to prevent the

piston pin clip from falling into the crankcase.

lInstall the piston pin clips with their ends fac-

ing downward.

45¡

135¡135¡

a

b ced

3New

Cylinder

1. Lubricate:

lPiston

lPiston ring

lCylinder

NOTE:

Apply a liberal coating of engine oil.

2. Install:

lDowel pin 1

lO-ring 2

NOTE:

Apply the lithium soap base grease on the O-

ring.

Page 350 of 656

4 - 48

ENGCLUTCH

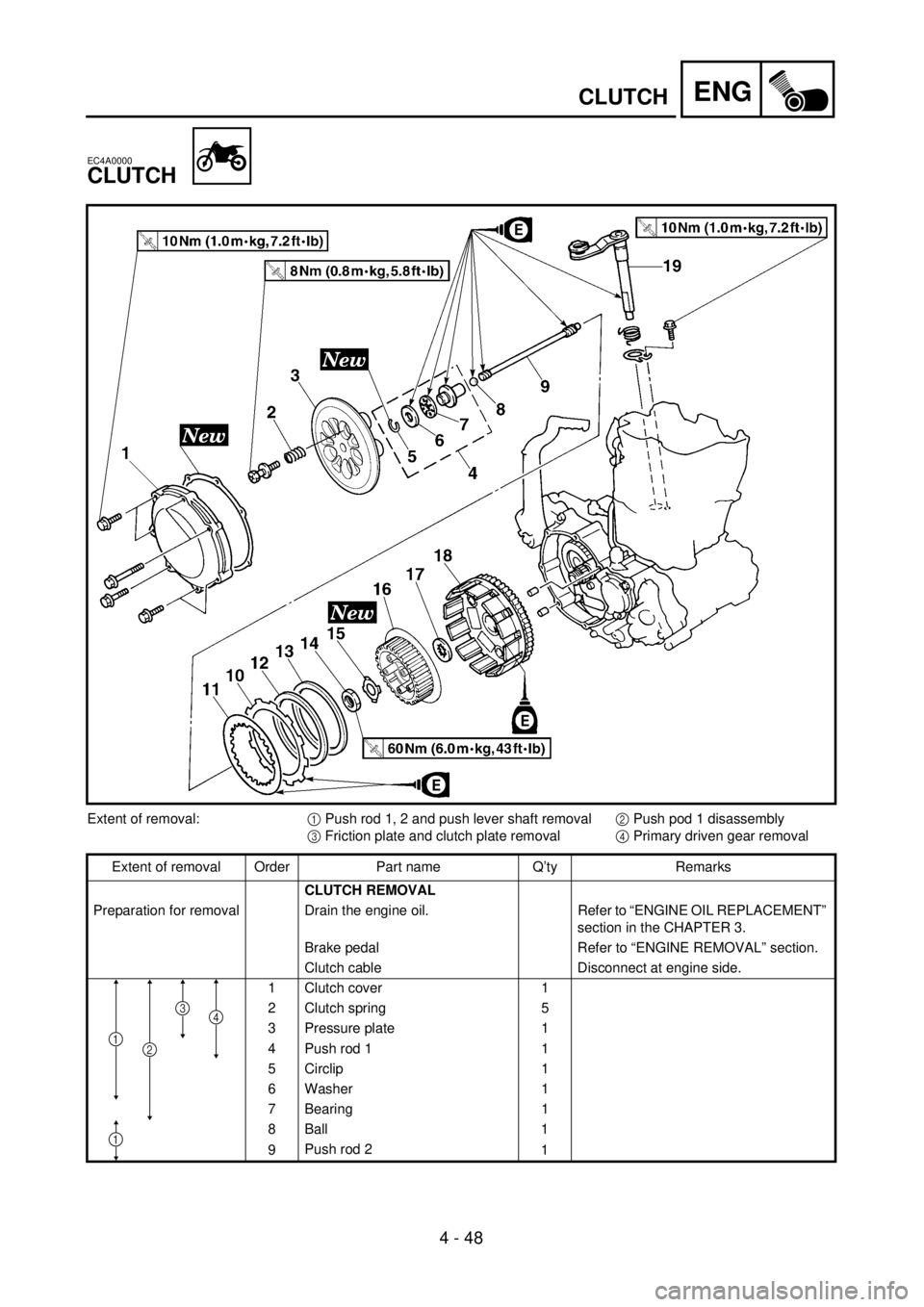

EC4A0000

CLUTCH

Extent of removal:1 Push rod 1, 2 and push lever shaft removal2 Push pod 1 disassembly

3 Friction plate and clutch plate removal4 Primary driven gear removal

Extent of removal Order Part name Q’ty Remarks

CLUTCH REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Brake pedal Refer to “ENGINE REMOVAL” section.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Clutch spring 5

3 Pressure plate 1

4 Push rod 1 1

5 Circlip 1

6 Washer 1

7 Bearing 1

8 Ball 1

9Push rod 2

1

4

1

12

3

Page 358 of 656

4 - 52

ENGCLUTCH

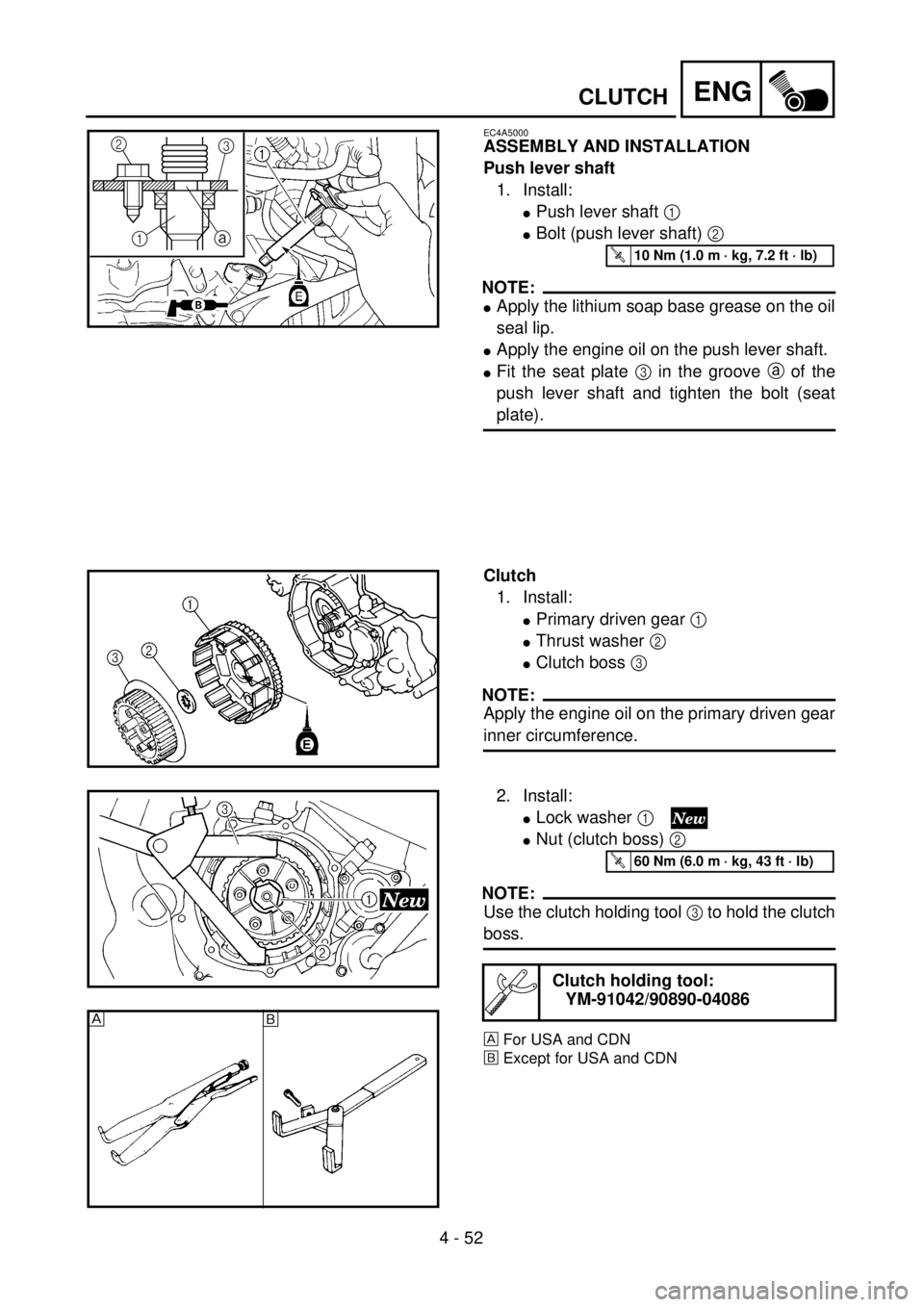

EC4A5000

ASSEMBLY AND INSTALLATION

Push lever shaft

1. Install:

lPush lever shaft 1

lBolt (push lever shaft) 2

NOTE:

lApply the lithium soap base grease on the oil

seal lip.

lApply the engine oil on the push lever shaft.

lFit the seat plate 3 in the groove a of the

push lever shaft and tighten the bolt (seat

plate).

3

1

a2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Clutch

1. Install:

lPrimary driven gear 1

lThrust washer 2

lClutch boss 3

NOTE:

Apply the engine oil on the primary driven gear

inner circumference.

2. Install:

lLock washer 1

lNut (clutch boss) 2

NOTE:

Use the clutch holding tool 3 to hold the clutch

boss.

For USA and CDN

õExcept for USA and CDN

Clutch holding tool:

YM-91042/90890-04086

T R..60 Nm (6.0 m · kg, 43 ft · lb)

õ

Page 360 of 656

4 - 53

ENGCLUTCH

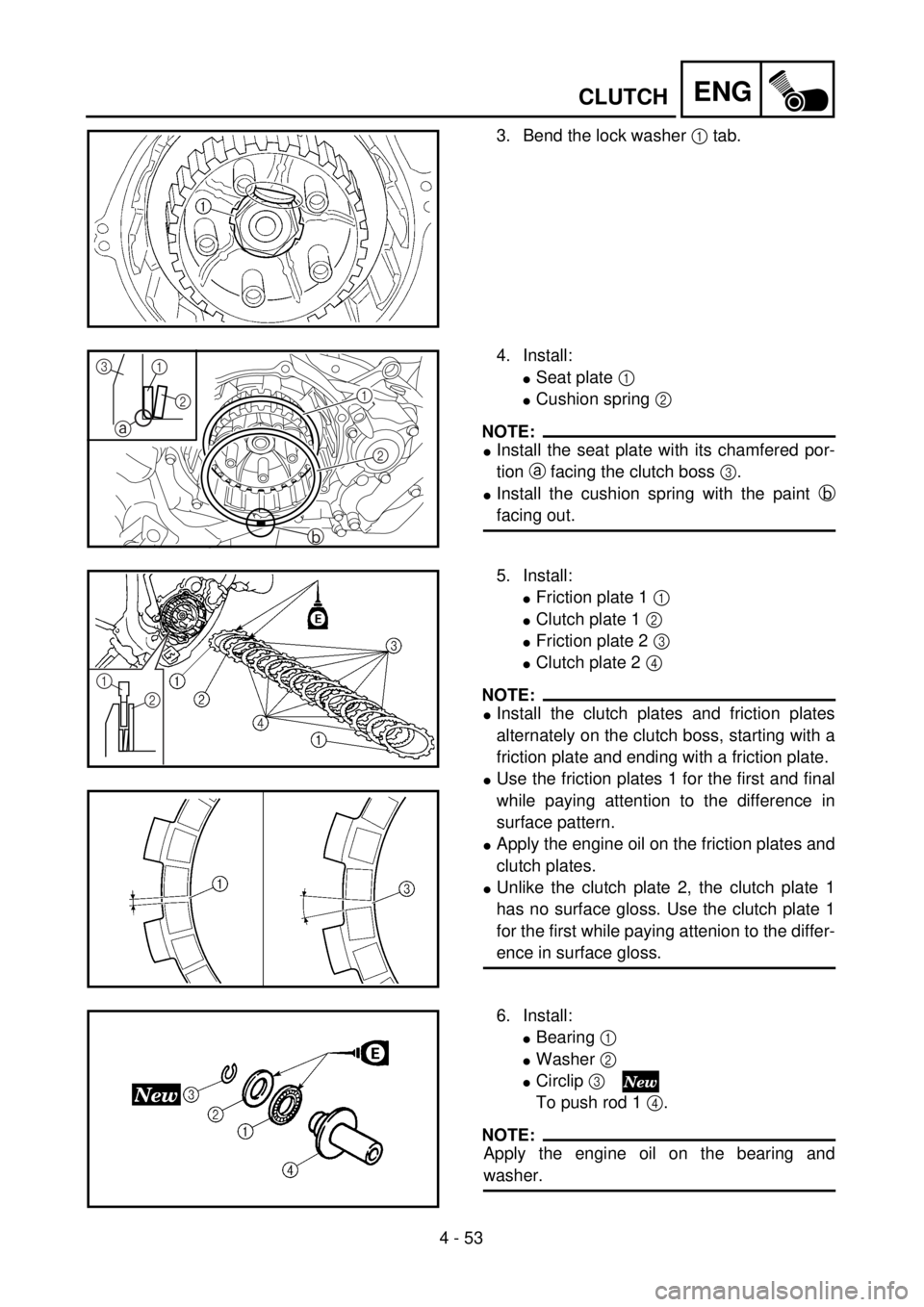

3. Bend the lock washer 1 tab.

4. Install:

lSeat plate 1

lCushion spring 2

NOTE:

lInstall the seat plate with its chamfered por-

tion a facing the clutch boss 3.

lInstall the cushion spring with the paint b

facing out.

1

2 1

2 3

a

b

5. Install:

lFriction plate 1 1

lClutch plate 1 2

lFriction plate 2 3

lClutch plate 2 4

NOTE:

lInstall the clutch plates and friction plates

alternately on the clutch boss, starting with a

friction plate and ending with a friction plate.

lUse the friction plates 1 for the first and final

while paying attention to the difference in

surface pattern.

lApply the engine oil on the friction plates and

clutch plates.

lUnlike the clutch plate 2, the clutch plate 1

has no surface gloss. Use the clutch plate 1

for the first while paying attenion to the differ-

ence in surface gloss.

1

2

6. Install:

lBearing 1

lWasher 2

lCirclip 3

To push rod 1 4.

NOTE:

Apply the engine oil on the bearing and

washer.

Page 362 of 656

4 - 54

ENGCLUTCH

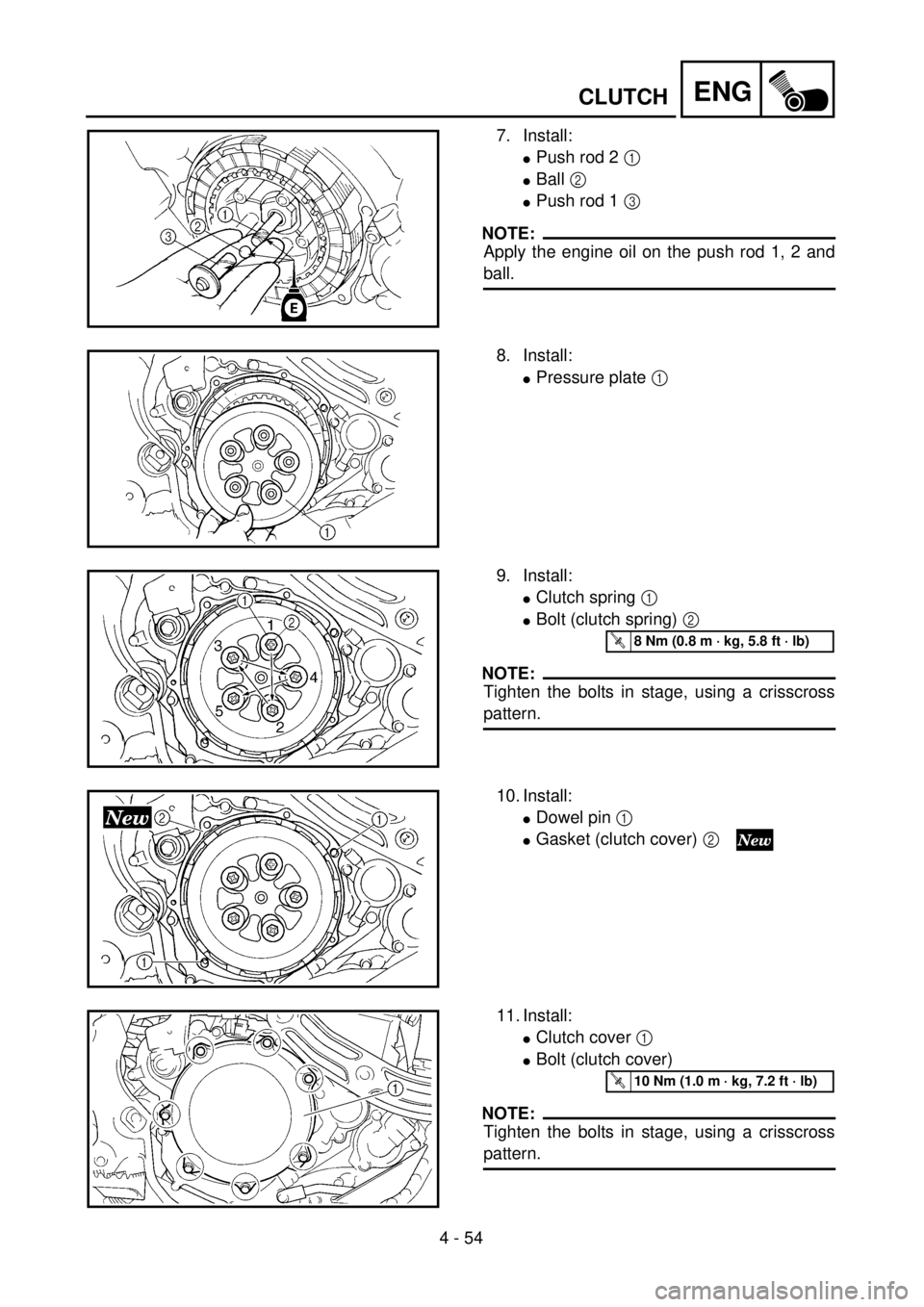

7. Install:

lPush rod 2 1

lBall 2

lPush rod 1 3

NOTE:

Apply the engine oil on the push rod 1, 2 and

ball.

8. Install:

lPressure plate 1

9. Install:

lClutch spring 1

lBolt (clutch spring) 2

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

10. Install:

lDowel pin 1

lGasket (clutch cover) 2

11. Install:

lClutch cover 1

lBolt (clutch cover)

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 364 of 656

4 - 55

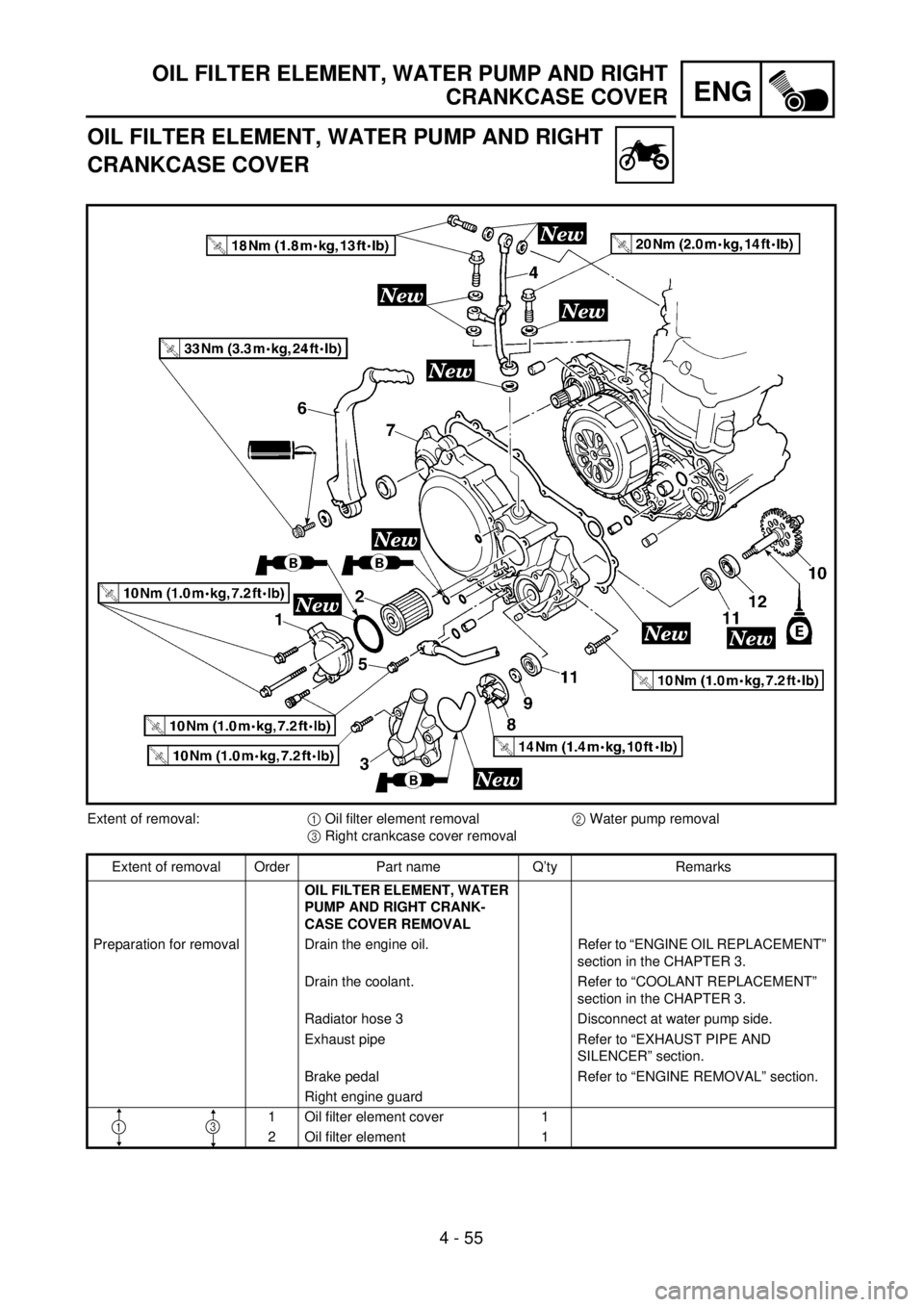

ENG

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

Extent of removal:1 Oil filter element removal2 Water pump removal

3 Right crankcase cover removal

Extent of removal Order Part name Q’ty Remarks

OIL FILTER ELEMENT, WATER

PUMP AND RIGHT CRANK-

CASE COVER REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Drain the coolant. Refer to “COOLANT REPLACEMENT”

section in the CHAPTER 3.

Radiator hose 3 Disconnect at water pump side.

Exhaust pipe Refer to “EXHAUST PIPE AND

SILENCER” section.

Brake pedal Refer to “ENGINE REMOVAL” section.

Right engine guard

1 Oil filter element cover 1

2 Oil filter element 1

13

Page 374 of 656

4 - 60

ENG

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

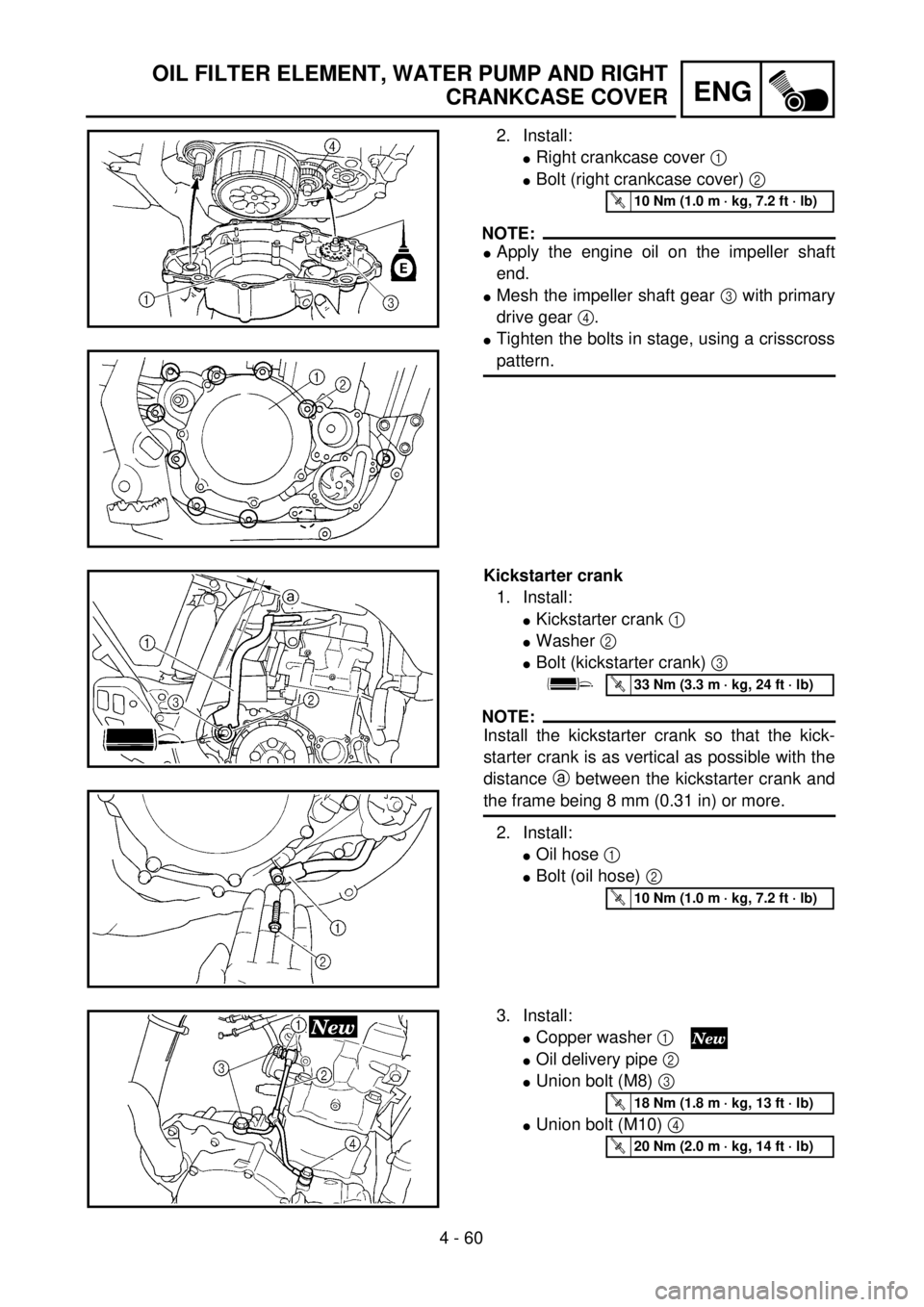

2. Install:

lRight crankcase cover 1

lBolt (right crankcase cover) 2

NOTE:

lApply the engine oil on the impeller shaft

end.

lMesh the impeller shaft gear 3 with primary

drive gear 4.

lTighten the bolts in stage, using a crisscross

pattern.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Kickstarter crank

1. Install:

lKickstarter crank 1

lWasher 2

lBolt (kickstarter crank) 3

NOTE:

Install the kickstarter crank so that the kick-

starter crank is as vertical as possible with the

distance a between the kickstarter crank and

the frame being 8 mm (0.31 in) or more.

2. Install:

lOil hose 1

lBolt (oil hose) 2

T R..33 Nm (3.3 m · kg, 24 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

3. Install:

lCopper washer 1

lOil delivery pipe 2

lUnion bolt (M8) 3

lUnion bolt (M10) 4

T R..18 Nm (1.8 m · kg, 13 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 382 of 656

4 - 64

ENGBALANCER

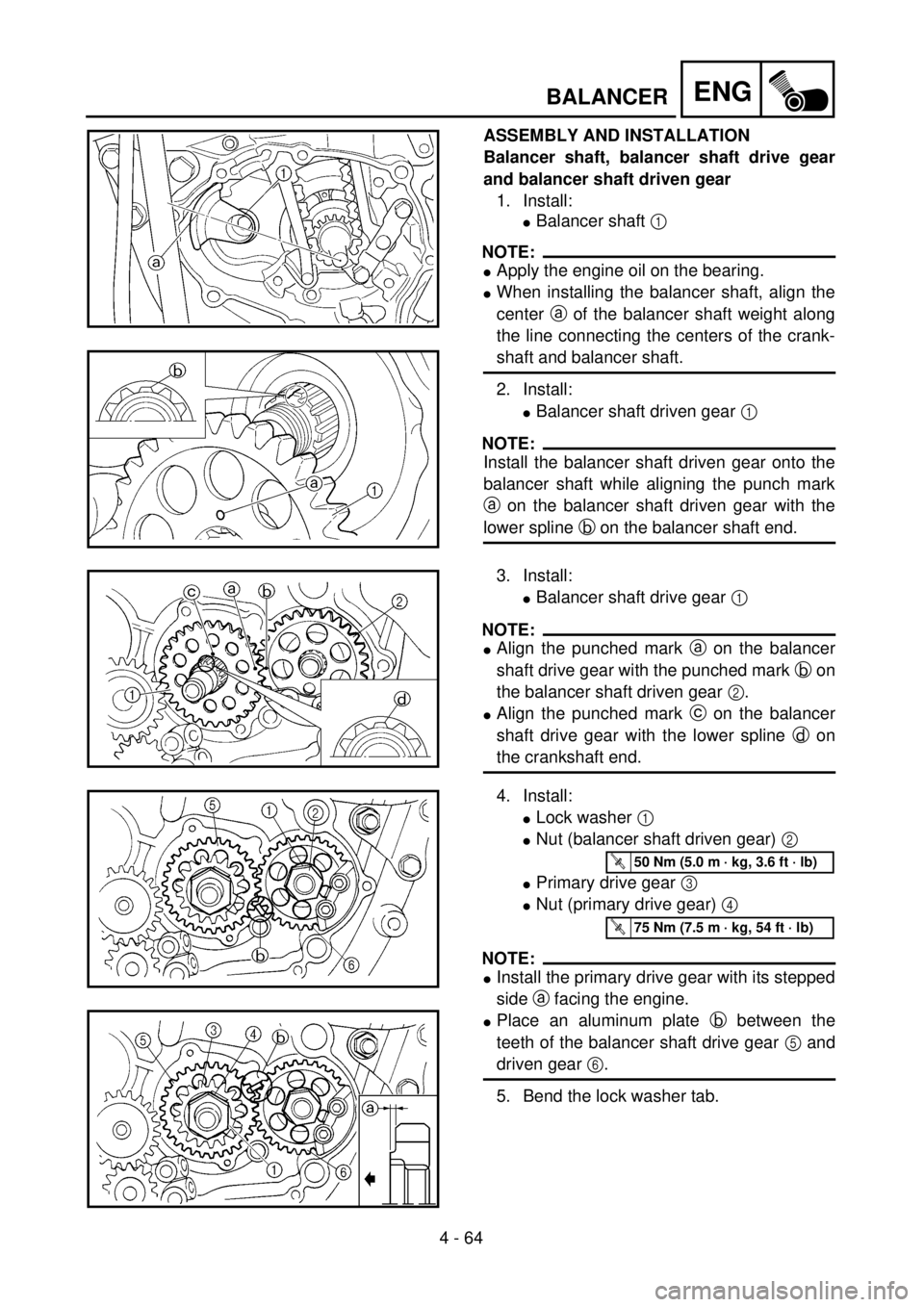

ASSEMBLY AND INSTALLATION

Balancer shaft, balancer shaft drive gear

and balancer shaft driven gear

1. Install:

lBalancer shaft 1

NOTE:

lApply the engine oil on the bearing.

lWhen installing the balancer shaft, align the

center a of the balancer shaft weight along

the line connecting the centers of the crank-

shaft and balancer shaft.

2. Install:

lBalancer shaft driven gear 1

NOTE:

Install the balancer shaft driven gear onto the

balancer shaft while aligning the punch mark

a on the balancer shaft driven gear with the

lower spline b on the balancer shaft end.

3. Install:

lBalancer shaft drive gear 1

NOTE:

lAlign the punched mark a on the balancer

shaft drive gear with the punched mark b on

the balancer shaft driven gear 2.

lAlign the punched mark c on the balancer

shaft drive gear with the lower spline d on

the crankshaft end.

4. Install:

lLock washer 1

lNut (balancer shaft driven gear) 2

lPrimary drive gear 3

lNut (primary drive gear) 4

NOTE:

lInstall the primary drive gear with its stepped

side a facing the engine.

lPlace an aluminum plate b between the

teeth of the balancer shaft drive gear 5 and

driven gear 6.

5. Bend the lock washer tab.

T R..50 Nm (5.0 m · kg, 3.6 ft · lb)

T R..75 Nm (7.5 m · kg, 54 ft · lb)