oil YAMAHA YZ250F 2005 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ250F, Model: YAMAHA YZ250F 2005Pages: 668, PDF Size: 15.74 MB

Page 458 of 668

5 - 2

CHAS

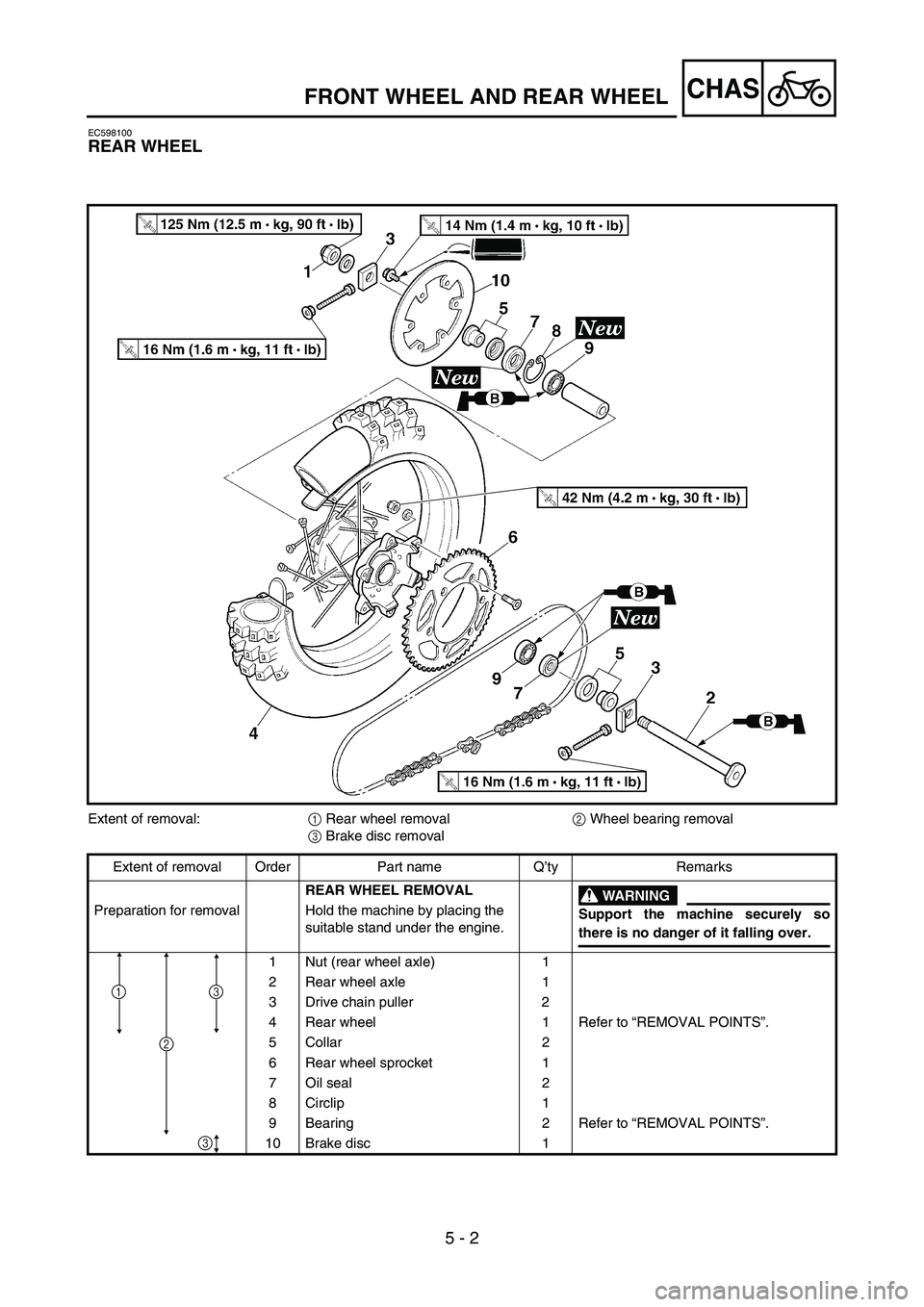

EC598100

REAR WHEEL

Extent of removal:

1 Rear wheel removal

2 Wheel bearing removal

3 Brake disc removal

Extent of removal Order Part name Q’ty Remarks

REAR WHEEL REMOVAL

WARNING

Support the machine securely so

there is no danger of it falling over. Preparation for removal Hold the machine by placing the

suitable stand under the engine.

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Drive chain puller 2

4 Rear wheel 1 Refer to “REMOVAL POINTS”.

5 Collar 2

6 Rear wheel sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to “REMOVAL POINTS”.

10 Brake disc 1

2

31

3

FRONT WHEEL AND REAR WHEEL

Page 460 of 668

5 - 3

CHASFRONT WHEEL AND REAR WHEEL

EC593000

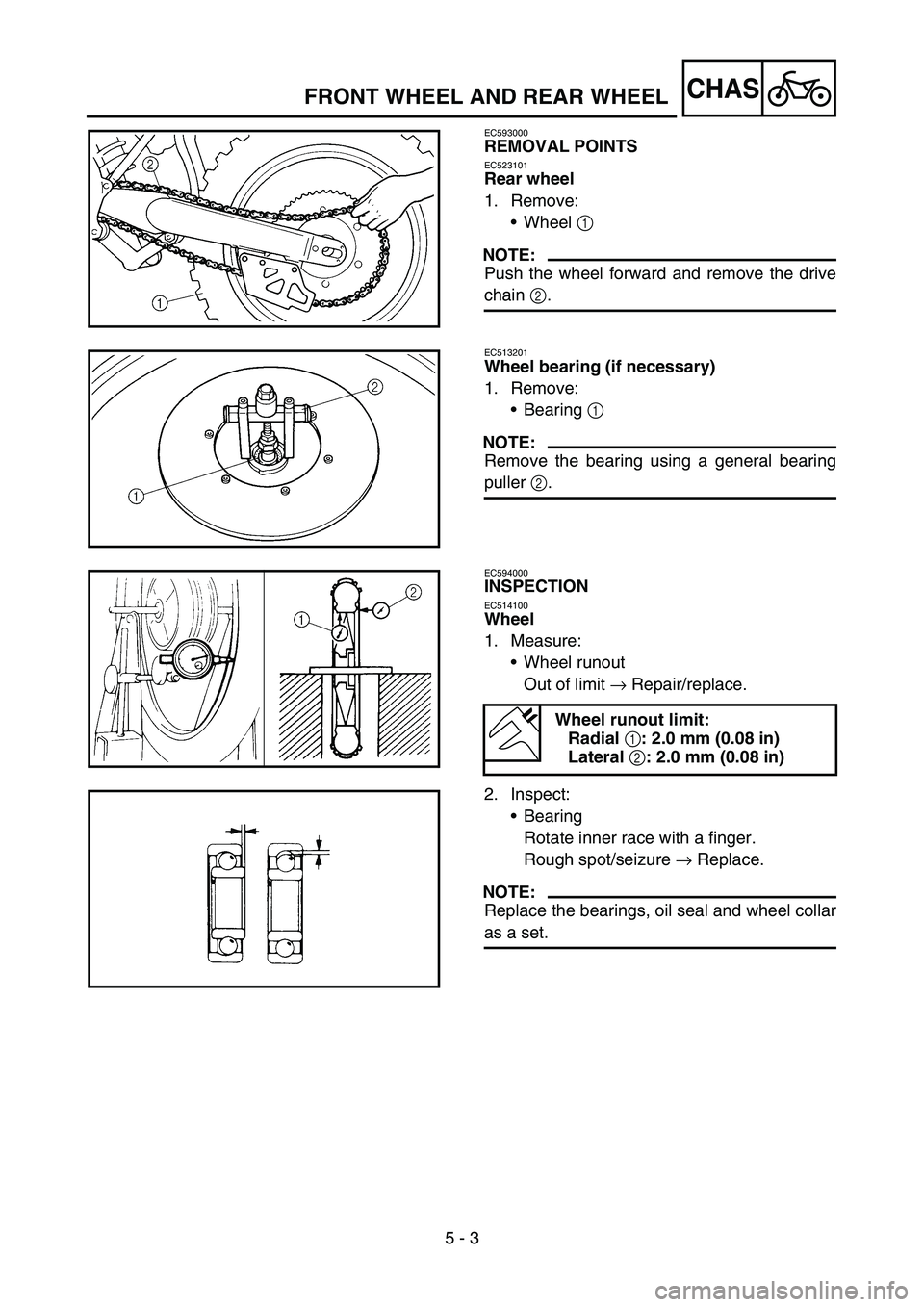

REMOVAL POINTS

EC523101

Rear wheel

1. Remove:

Wheel 1

NOTE:

Push the wheel forward and remove the drive

chain 2.

EC513201

Wheel bearing (if necessary)

1. Remove:

Bearing 1

NOTE:

Remove the bearing using a general bearing

puller 2.

EC594000

INSPECTION

EC514100

Wheel

1. Measure:

Wheel runout

Out of limit → Repair/replace.

2. Inspect:

Bearing

Rotate inner race with a finger.

Rough spot/seizure → Replace.

NOTE:

Replace the bearings, oil seal and wheel collar

as a set.

Wheel runout limit:

Radial

1: 2.0 mm (0.08 in)

Lateral

2: 2.0 mm (0.08 in)

Page 461 of 668

5 - 3

CHAS

DEMONTAGE-EINZELHEITEN

Hinterrad

1. Demontieren:

Rad

1

HINWEIS:

Das Hinterrad nach vorn drücken

und die Antriebskette

2 abnehmen.

Radlager (nach Bedarf)

1. Demontieren:

Lager

1

HINWEIS:

Das Lager mit einem Lageraustreiber

2 ausbauen.

KONTROLLE

Rad

1. Messen:

Felgenschlag

Nicht nach Vorgabe

→ Instand

setzen/erneuern.

Max. Felgenschlag:

Höhenschlag 1:

2,0 mm (0,08 in)

Seitenschlag 2:

2,0 mm (0,08 in)

2. Kontrollieren:

Lager

Den Innenlaufring mit den Fin-

gern drehen.

Stockend/fest

→ Erneuern.

HINWEIS:

Lager, Dichtring und Distanzhülse

satzweise erneuern. POINTS DE DEPOSE

Roue arrière

1. Déposer:

Roue 1

N.B.:

Pousser la roue vers l’avant et déposer la

chaîne de transmission 2.

Roulement de roue (si nécessaire)

1. Déposer:

Roulement 1

N.B.:

Déposer le roulement à l’aide d’un arra-

che-roulement courant 2.

CONTROLE

Roue

1. Mesurer:

Voile de roue

Hors spécifications → Réparer/

remplacer.

Limite de voile de roue:

Radial 1:

2,0 mm (0,08 in)

Latéral 2:

2,0 mm (0,08 in)

2. Contrôler:

Roulement

Faire tourner la cage interne avec

le doigt.

Rugosité/grippage → Remplacer.

N.B.:

Remplacer ensemble les roulements, la

bague d’étanchéité et l’entretoise épau-

lée de roue.PUNTI DI RIMOZIONE

Ruota posteriore

1. Togliere:

Ruota 1

NOTA:

Spingere la ruota in avanti e togliere la

catena di trasmissione 2.

Cuscinetto della ruota (se necessario)

1. Togliere:

Cuscinetto 1

NOTA:

Togliere il cuscinetto con un normale

estrattore di cuscinetti 2.

CONTROLLO

Ruota

1. Misurare:

Scentratura ruota

Fuori limite → Riparare/sostituire.

Limite di disassamento della

ruota:

Radiale 1:

2,0 mm (0,08 in)

Laterale 2:

2,0 mm (0,08 in)

2. Controllare:

Cuscinetto

Ruotare la pista interna con un

dito.

Punto ruvido/blocco → Sostitu-

ire.

NOTA:

Sostituire i cuscinetti, il paraolio e il col-

larino della ruota in blocco.

ROUE AVANT ET ROUE ARRIERE

VORDER- UND HINTERRAD

RUOTA ANTERIORE E POSTERIORE

Page 463 of 668

5 - 4

CHAS

Radachse

1. Messen:

Radachs-Verbiegung

Nicht nach Vorgabe

→ Erneu-

ern.

Eine Meßuhr

1 verwenden.

HINWEIS:

Der von der Meßuhr angezeigte Wert

ist zu halbieren, um den Wert der

Verbiegung zu erhalten.

WARNUNG

Eine verbogene Radachse darf

unter keinen Umständen gerichtet

werden.

Max. Radachs-Verbie-

gung:

0,5 mm (0,020 in)

Bremsscheibe

1. Messen:

Bremsscheiben-Verzug (nur

Hinterrad)

Eine Meßuhr

1 verwenden.

Nicht nach Vorgabe

→ Fel-

genschlag kontrollieren.

Falls Felgenschlag in Ordnung

ist, die Bremsscheibe erneu-

ern.

2. Messen:

Bremsscheiben-Stärke

a

Nicht nach Vorgabe

→ Erneu-

ern.

Max. Bremsscheiben-

Verzug:

Hinten:

0,15 mm (0,006 in)

Bremsscheiben-Stärke:

Vorn:

3,0 mm (0,12 in)

2,5 mm (0,10 in)

Hinten:

4,0 mm (0,16 in)

3,5 mm (0,14 in)

Axe de roue

1. Mesurer:

Déformations de l’axe de roue

Hors spécifications → Rempla-

cer.

Utiliser le comparateur à cadran

1.

N.B.:

La valeur de flexion est égale à la moitié

de la valeur affichée sur le comparateur à

cadran.

AVERTISSEMENT

Ne pas tenter de redresser un axe

déformé.

Limite de flexion d’axe de

roue:

0,5 mm (0,020 in)

Disque de frein

1. Mesurer:

Déflexion du disque de frein (dis-

que de frein arrière seulement)

Utiliser le comparateur à cadran

1.

Hors spécifications → Contrôler

le voile de roue.

Si le voile de roue est normal,

remplacer le disque de frein.

2. Mesurer:

Epaisseur du disque de frein a

Hors spécifications → Rempla-

cer.

Limite de déflexion du dis-

que de frein:

Arrière:

0,15 mm (0,006 in)

Epaisseur du disque de

frein:

Avant:

3,0 mm (0,12 in)

2,5 mm (0,10 in)

Arrière:

4,0 mm (0,16 in)

3,5 mm (0,14 in)

Asse della ruota

1. Misurare:

Deformazioni dell’asse della

ruota

Non conforme alle specifiche →

Sostituire.

Utilizzare un comparatore 1.

NOTA:

Il valore di piegatura corrisponde a metà

della lettura del comparatore.

AVVERTENZA

Non tentare di raddrizzare un asse

deformato.

Limite di piegatura

dell’asse della ruota:

0,5 mm (0,020 in)

Disco freno

1. Misurare:

Deflessione del disco del freno

(solo disco posteriore)

Utilizzare un comparatore 1.

Non conforme alle specifiche →

Controllare la scentratura ruota.

Se la scentratura è in buone con-

dizioni, sostituire il disco del

freno.

2. Misurare:

Spessore del disco freno a

Non conforme ai limiti → Sosti-

tuire.

Limite di deflessione del

disco del freno:

Posteriore:

0,15 mm (0,006 in)

Spessore del disco freno:

Anteriore:

3,0 mm (0,12 in)

2,5 mm (0,10 in)

Posteriore:

4,0 mm (0,16 in)

3,5 mm (0,14 in)

ROUE AVANT ET ROUE ARRIERE

VORDER- UND HINTERRAD

RUOTA ANTERIORE E POSTERIORE

Page 464 of 668

5 - 5

CHASFRONT WHEEL AND REAR WHEEL

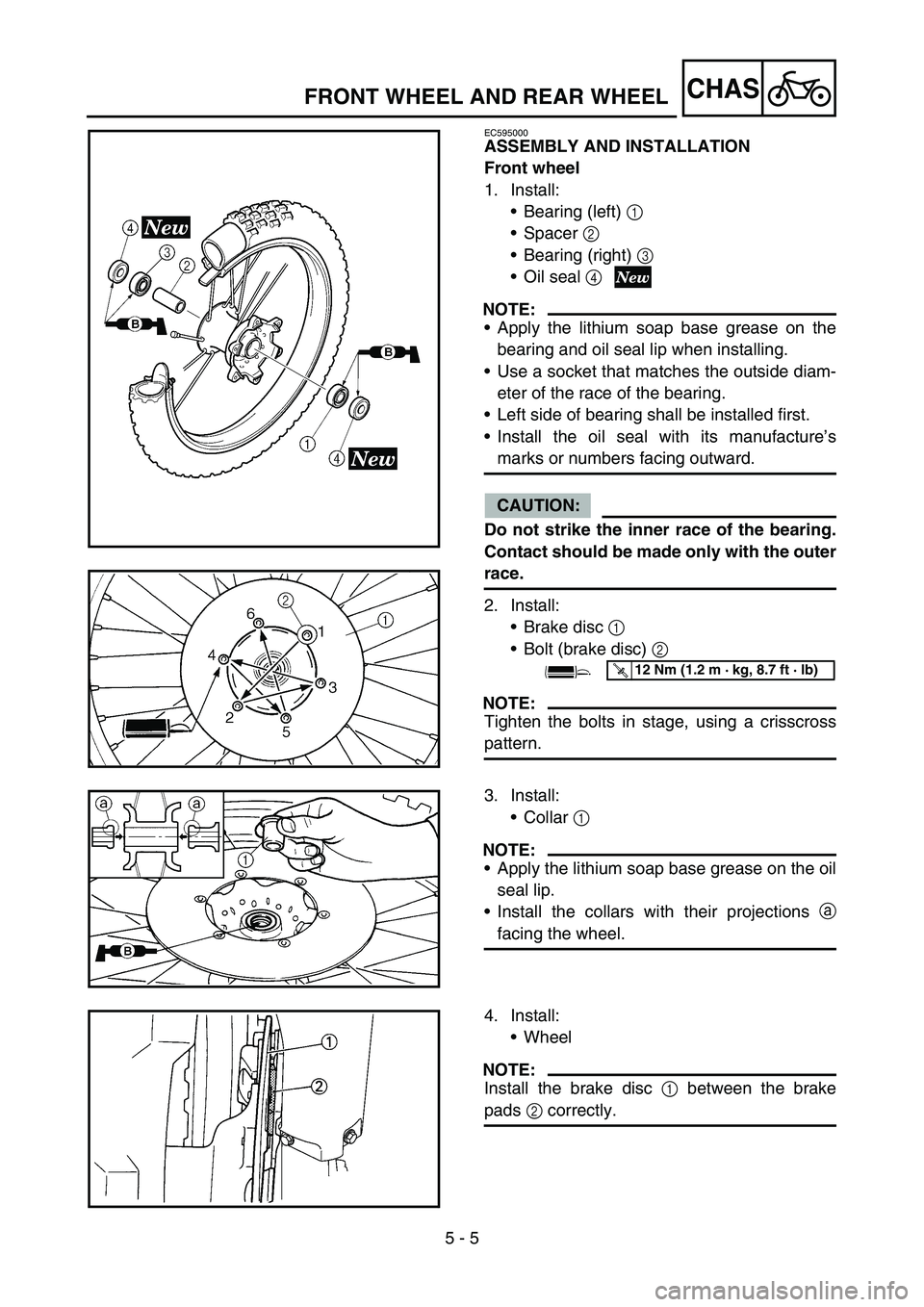

EC595000

ASSEMBLY AND INSTALLATION

Front wheel

1. Install:

Bearing (left) 1

Spacer 2

Bearing (right) 3

Oil seal 4

NOTE:

Apply the lithium soap base grease on the

bearing and oil seal lip when installing.

Use a socket that matches the outside diam-

eter of the race of the bearing.

Left side of bearing shall be installed first.

Install the oil seal with its manufacture’s

marks or numbers facing outward.

CAUTION:

Do not strike the inner race of the bearing.

Contact should be made only with the outer

race.

2. Install:

Brake disc 1

Bolt (brake disc) 2

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

3. Install:

Collar 1

NOTE:

Apply the lithium soap base grease on the oil

seal lip.

Install the collars with their projections a

facing the wheel.

4. Install:

Wheel

NOTE:

Install the brake disc 1 between the brake

pads 2 correctly.

Page 468 of 668

5 - 7

CHASFRONT WHEEL AND REAR WHEEL

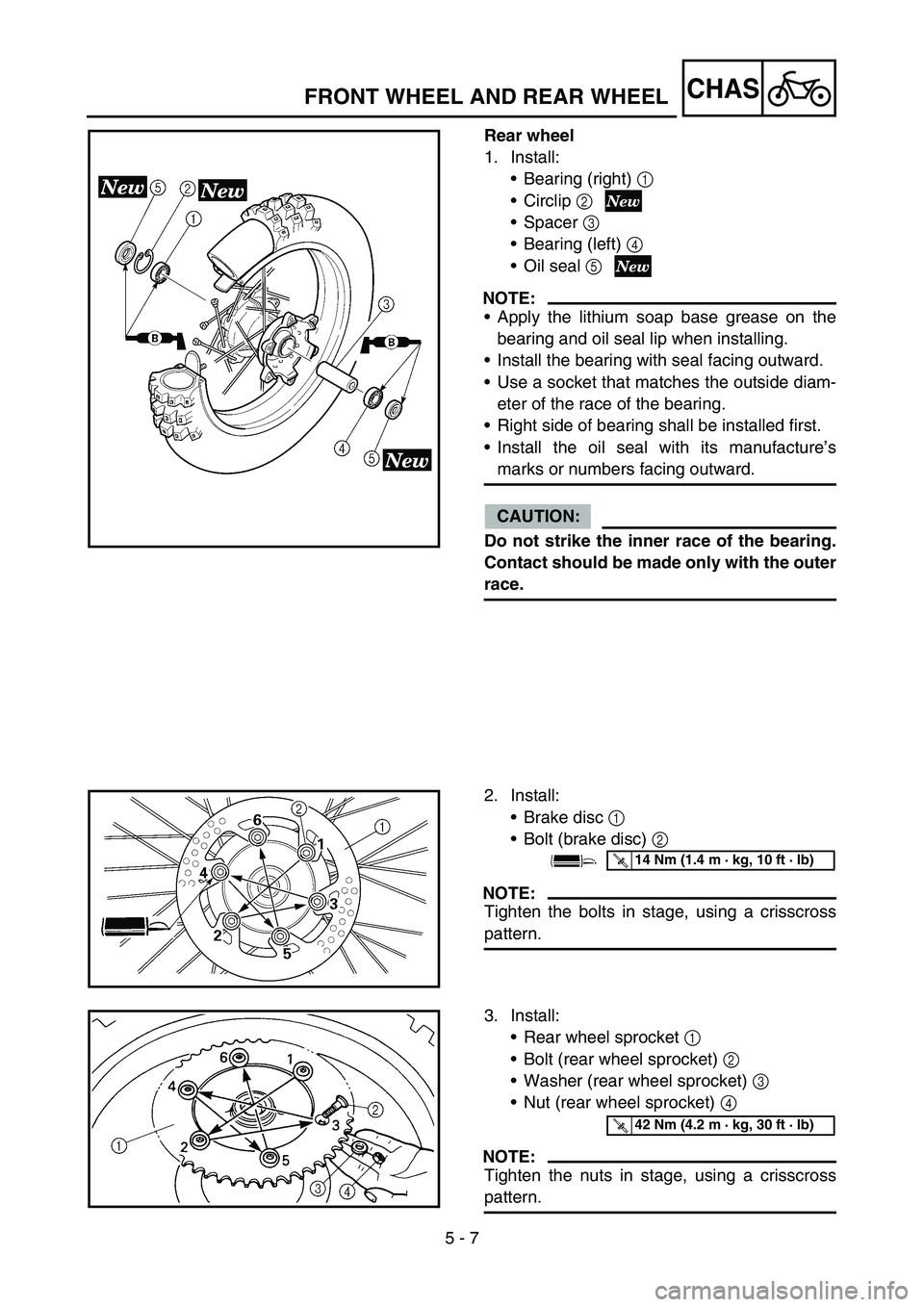

Rear wheel

1. Install:

Bearing (right) 1

Circlip 2

Spacer 3

Bearing (left) 4

Oil seal 5

NOTE:

Apply the lithium soap base grease on the

bearing and oil seal lip when installing.

Install the bearing with seal facing outward.

Use a socket that matches the outside diam-

eter of the race of the bearing.

Right side of bearing shall be installed first.

Install the oil seal with its manufacture’s

marks or numbers facing outward.

CAUTION:

Do not strike the inner race of the bearing.

Contact should be made only with the outer

race.

2. Install:

Brake disc 1

Bolt (brake disc) 2

NOTE:

Tighten the bolts in stage, using a crisscross

pattern.

T R..14 Nm (1.4 m · kg, 10 ft · lb)

3. Install:

Rear wheel sprocket 1

Bolt (rear wheel sprocket) 2

Washer (rear wheel sprocket) 3

Nut (rear wheel sprocket) 4

NOTE:

Tighten the nuts in stage, using a crisscross

pattern.

T R..42 Nm (4.2 m · kg, 30 ft · lb)

Page 470 of 668

5 - 8

CHAS

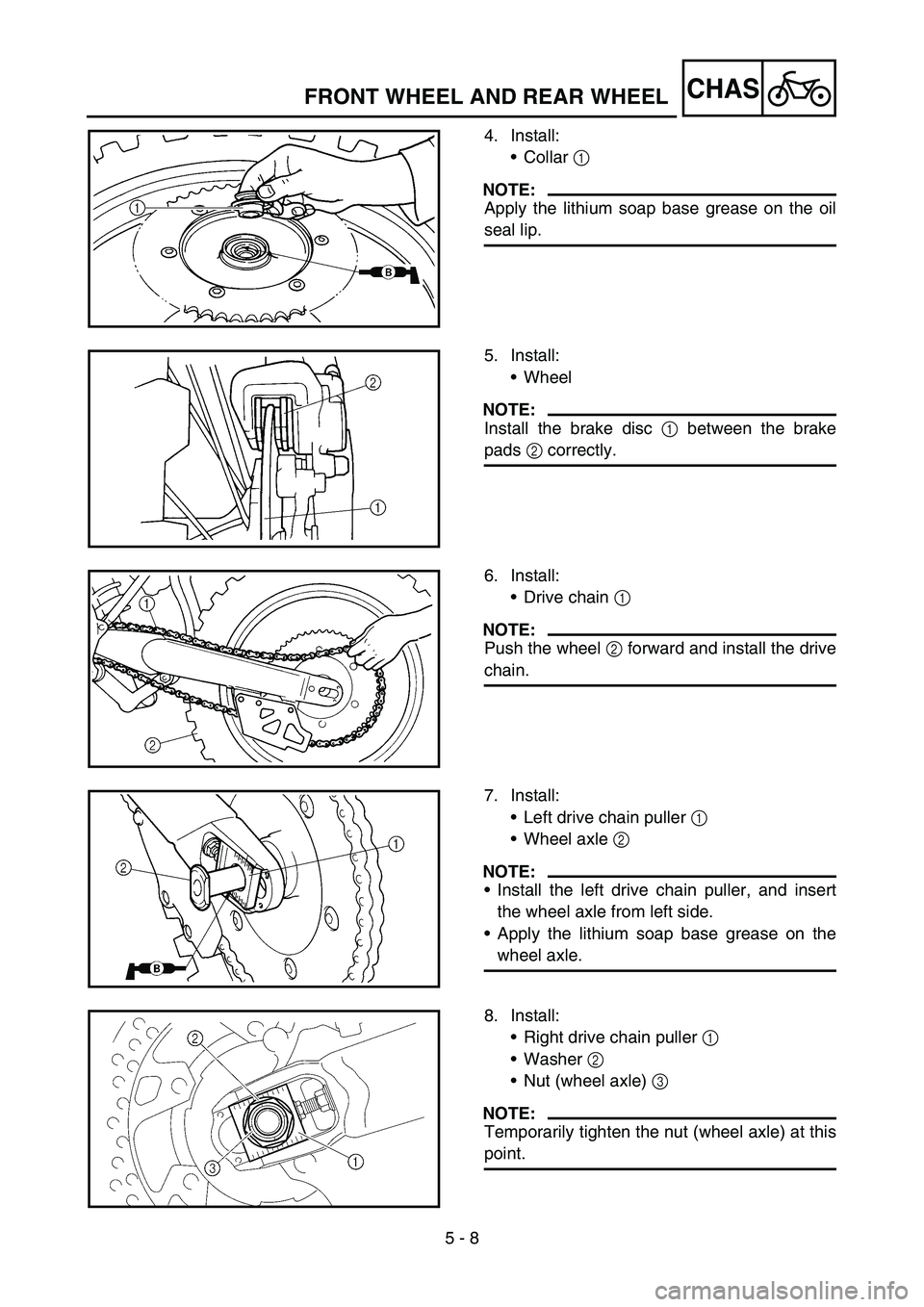

4. Install:

Collar 1

NOTE:

Apply the lithium soap base grease on the oil

seal lip.

FRONT WHEEL AND REAR WHEEL

5. Install:

Wheel

NOTE:

Install the brake disc 1 between the brake

pads 2 correctly.

6. Install:

Drive chain 1

NOTE:

Push the wheel 2 forward and install the drive

chain.

7. Install:

Left drive chain puller 1

Wheel axle 2

NOTE:

Install the left drive chain puller, and insert

the wheel axle from left side.

Apply the lithium soap base grease on the

wheel axle.

8. Install:

Right drive chain puller 1

Washer 2

Nut (wheel axle) 3

NOTE:

Temporarily tighten the nut (wheel axle) at this

point.

Page 502 of 668

5 - 24

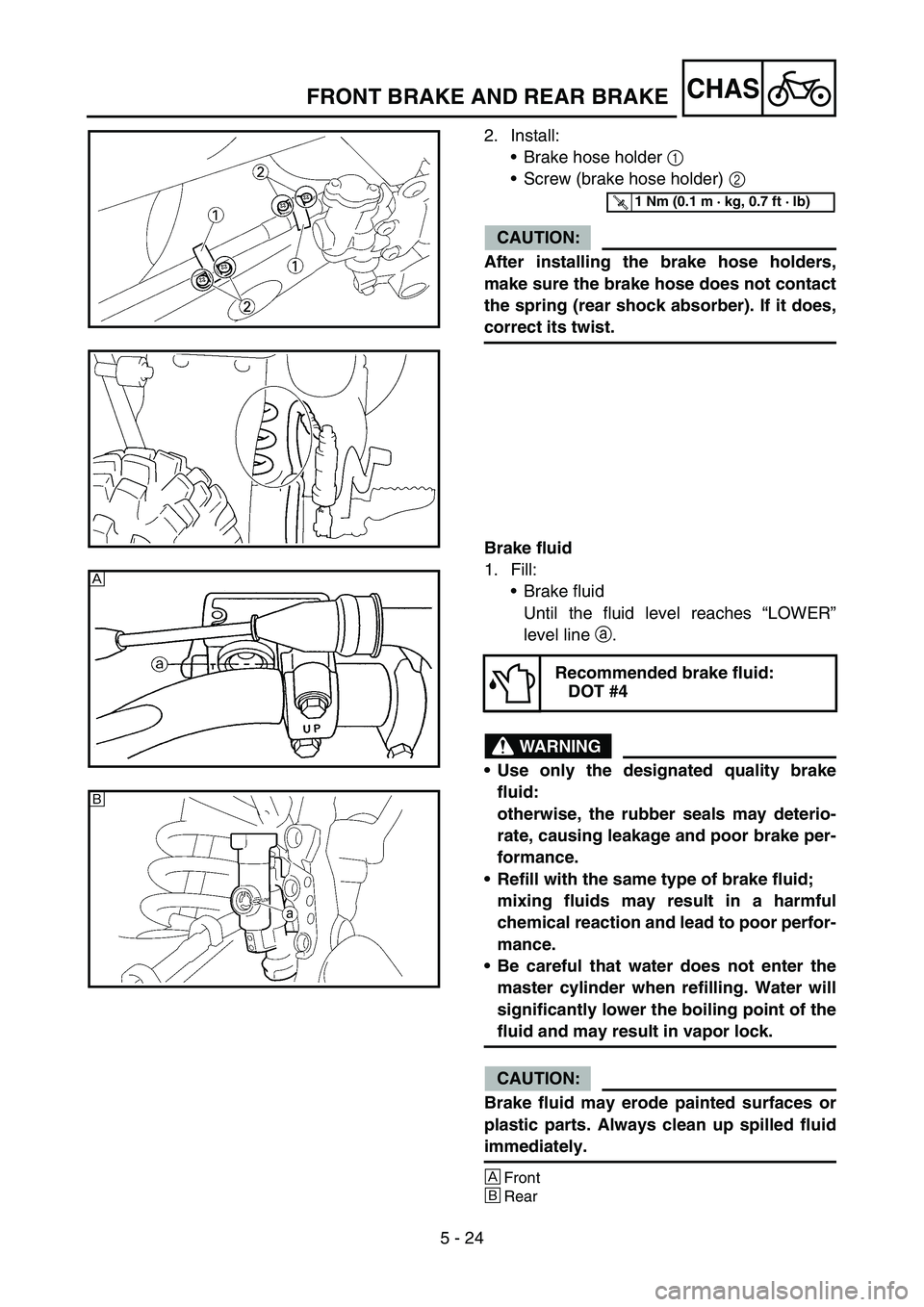

CHASFRONT BRAKE AND REAR BRAKE

2. Install:

Brake hose holder 1

Screw (brake hose holder) 2

CAUTION:

After installing the brake hose holders,

make sure the brake hose does not contact

the spring (rear shock absorber). If it does,

correct its twist.

Brake fluid

1. Fill:

Brake fluid

Until the fluid level reaches “LOWER”

level line a.

WARNING

Use only the designated quality brake

fluid:

otherwise, the rubber seals may deterio-

rate, causing leakage and poor brake per-

formance.

Refill with the same type of brake fluid;

mixing fluids may result in a harmful

chemical reaction and lead to poor perfor-

mance.

Be careful that water does not enter the

master cylinder when refilling. Water will

significantly lower the boiling point of the

fluid and may result in vapor lock.

CAUTION:

Brake fluid may erode painted surfaces or

plastic parts. Always clean up spilled fluid

immediately.

È

Front

ÉRear

Recommended brake fluid:

DOT #4

T R..1 Nm (0.1 m · kg, 0.7 ft · lb)

È

É

Page 508 of 668

5 - 27

CHASFRONT FORK

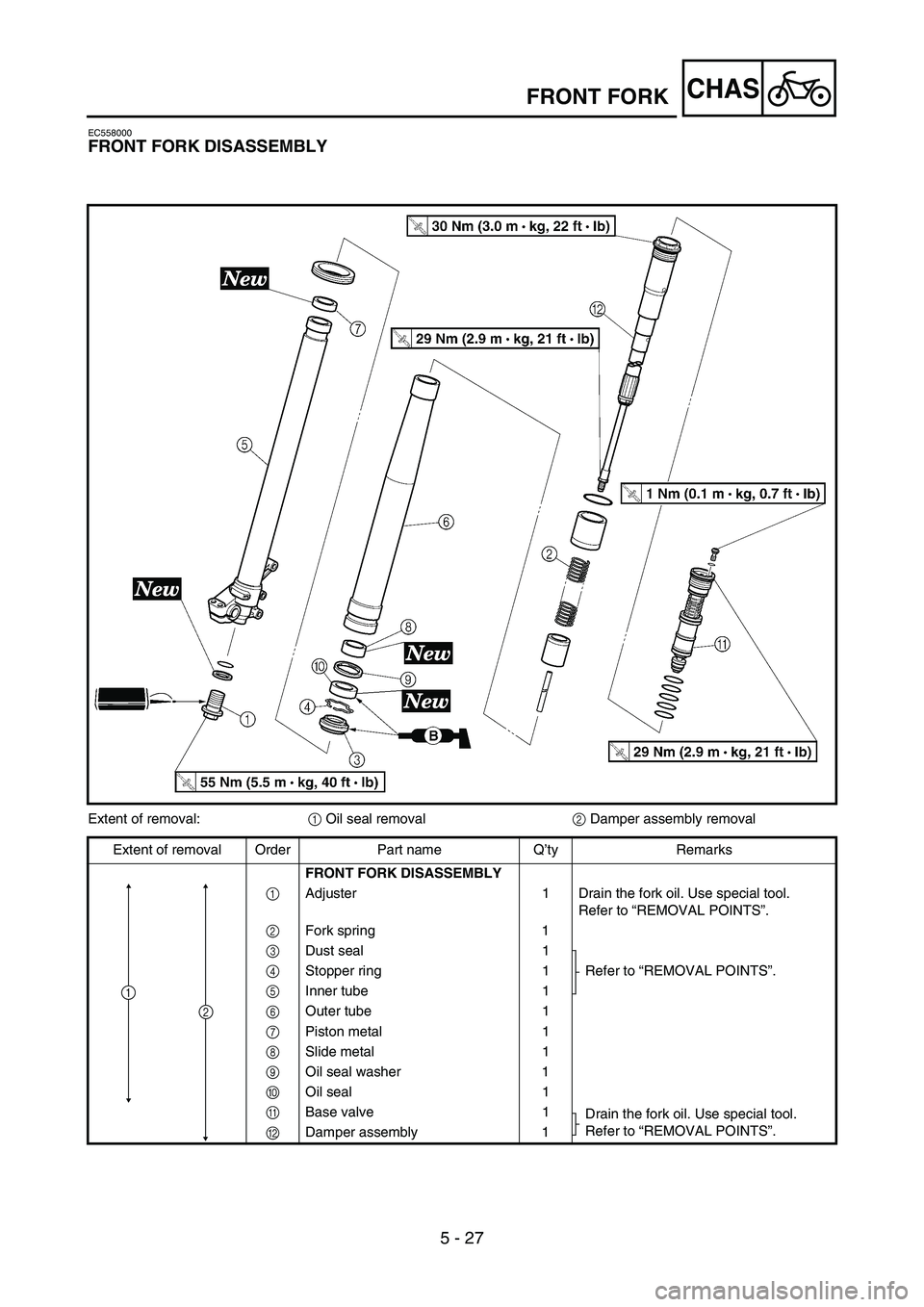

EC558000

FRONT FORK DISASSEMBLY

Extent of removal:

1 Oil seal removal

2 Damper assembly removal

Extent of removal Order Part name Q’ty Remarks

FRONT FORK DISASSEMBLY

1Adjuster 1 Drain the fork oil. Use special tool.

Refer to “REMOVAL POINTS”.

2Fork spring 1

3Dust seal 1

Refer to “REMOVAL POINTS”.

4Stopper ring 1

5Inner tube 1

6Outer tube 1

7Piston metal 1

8Slide metal 1

9Oil seal washer 1

0Oil seal 1

ABase valve 1

Drain the fork oil. Use special tool.

Refer to “REMOVAL POINTS”.

BDamper assembly 1

1

2

Page 510 of 668

5 - 28

CHASFRONT FORK

EC556000

HANDLING NOTE

NOTE:

The front fork requires careful attention. So it is

recommended that the front fork be maintained

at the dealers.

CAUTION:

To prevent an accidental explosion of air,

the following instructions should be

observed:

The front fork with a built-in piston rod

has a very sophisticated internal con-

struction and is particularly sensitive to

foreign material.

Use enough care not to allow any foreign

material to come in when the oil is

replaced or when the front fork is disas-

sembled and reassembled.

Before removing the base valves or front

forks, be sure to extract the air from the

air chamber completely.

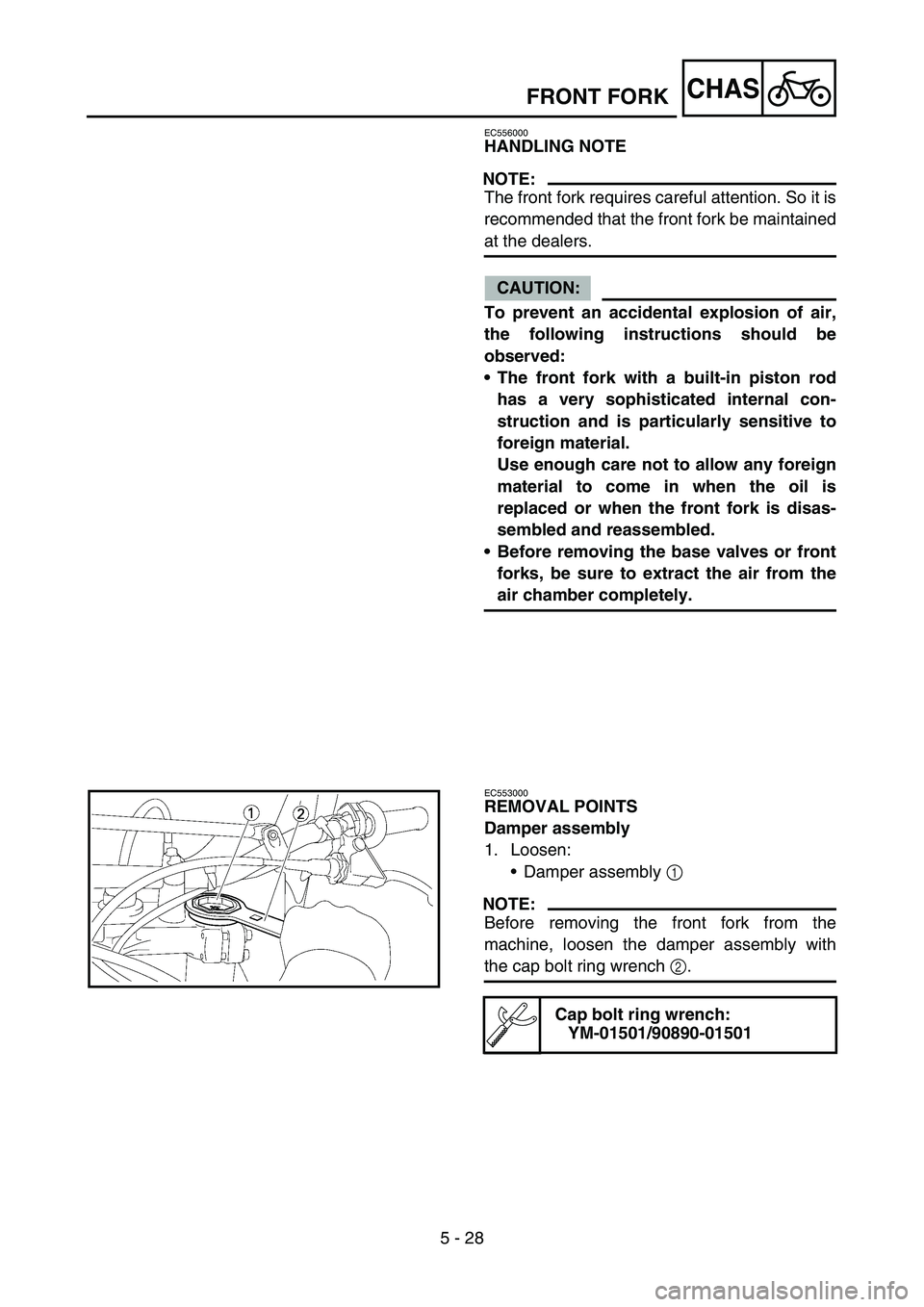

EC553000

REMOVAL POINTS

Damper assembly

1. Loosen:

Damper assembly 1

NOTE:

Before removing the front fork from the

machine, loosen the damper assembly with

the cap bolt ring wrench 2.

Cap bolt ring wrench:

YM-01501/90890-01501