oil YAMAHA YZ250F 2005 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ250F, Model: YAMAHA YZ250F 2005Pages: 668, PDF Size: 15.74 MB

Page 370 of 668

4 - 58

ENG

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

REMOVAL POINTS

Impeller shaft

1. Remove:

Impeller 1

Washer 2

Impeller shaft 3

NOTE:

Hold the impeller shaft on its width across the

flats a with spanners, etc. and remove the

impeller.

EC4G3210

Oil seal

NOTE:

It is not necessary to disassemble the water

pump, unless there is an abnormality such as

excessive change in coolant level, discolora-

tion of coolant, or milky transmission oil.

1. Remove:

Bearing 1

2. Remove:

Oil seal 1

INSPECTION

Oil delivery pipe

1. Inspect:

Oil delivery pipe 1

Bend/damage → Replace.

Clogged → Blow.

Page 372 of 668

4 - 59

ENG

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

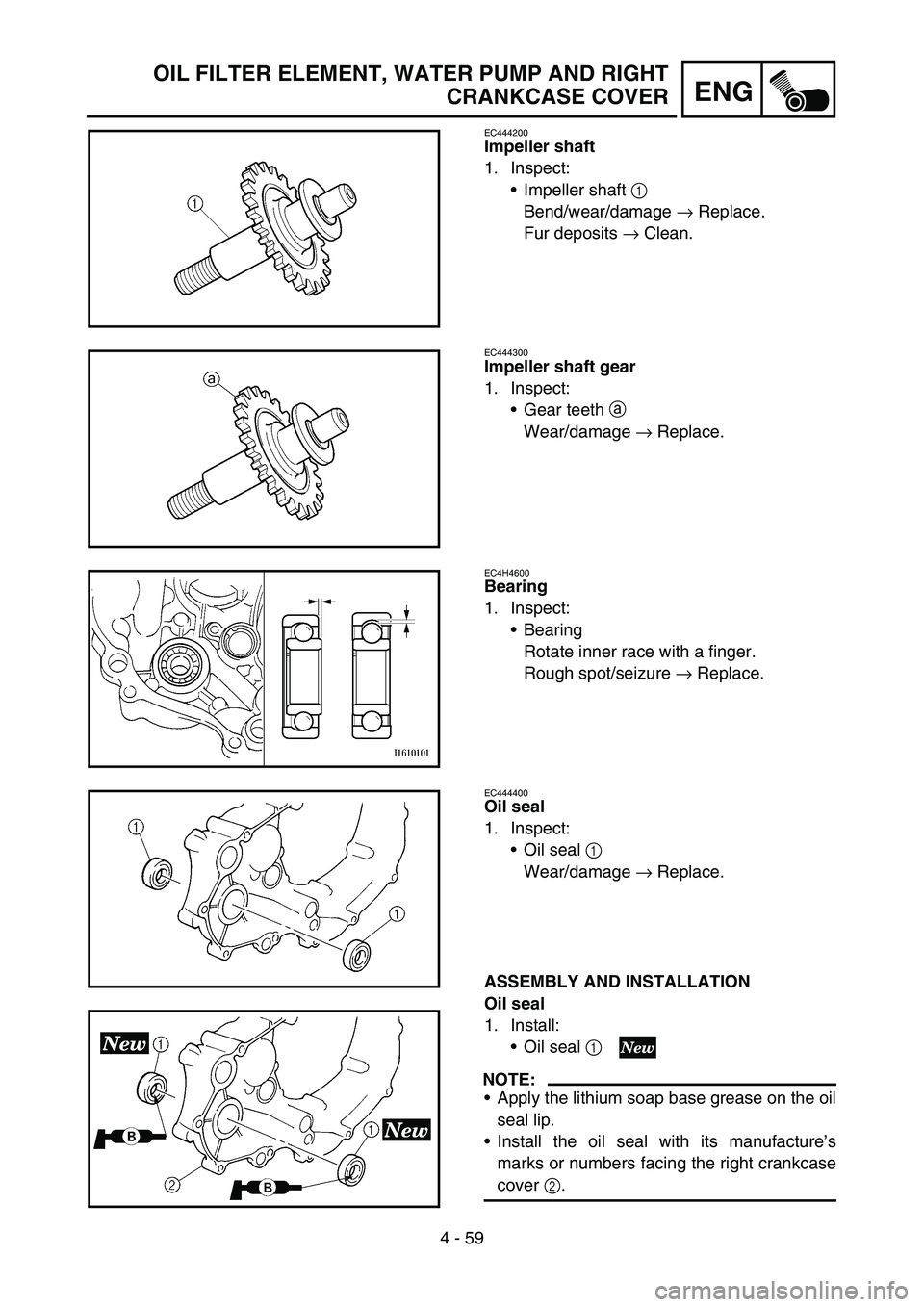

EC444200

Impeller shaft

1. Inspect:

Impeller shaft 1

Bend/wear/damage → Replace.

Fur deposits → Clean.

EC444300

Impeller shaft gear

1. Inspect:

Gear teeth a

Wear/damage → Replace.

EC4H4600

Bearing

1. Inspect:

Bearing

Rotate inner race with a finger.

Rough spot/seizure → Replace.

EC444400

Oil seal

1. Inspect:

Oil seal 1

Wear/damage → Replace.

ASSEMBLY AND INSTALLATION

Oil seal

1. Install:

Oil seal 1

NOTE:

Apply the lithium soap base grease on the oil

seal lip.

Install the oil seal with its manufacture’s

marks or numbers facing the right crankcase

cover 2.

Page 374 of 668

4 - 60

ENG

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

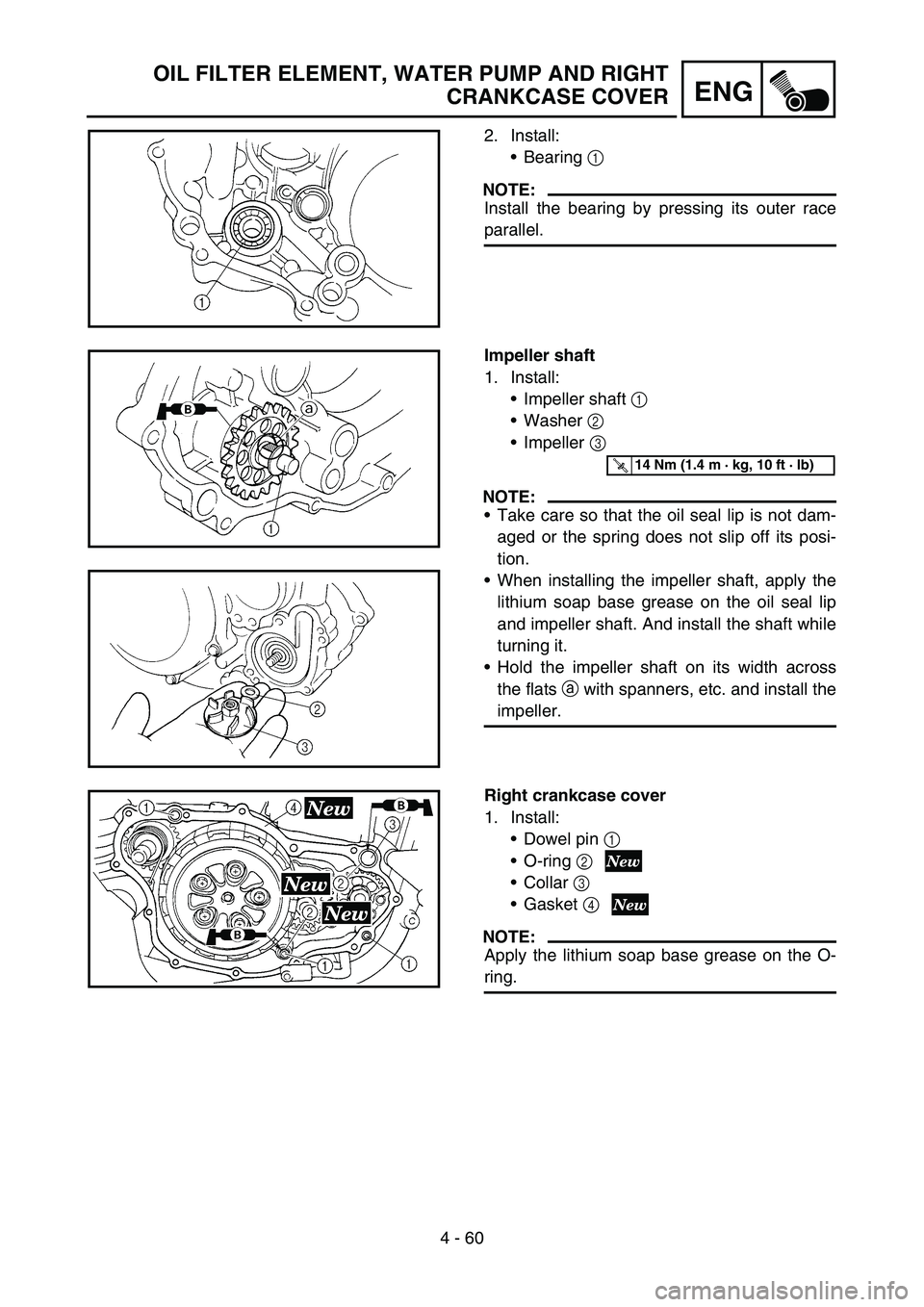

2. Install:

Bearing 1

NOTE:

Install the bearing by pressing its outer race

parallel.

Impeller shaft

1. Install:

Impeller shaft 1

Washer 2

Impeller 3

NOTE:

Take care so that the oil seal lip is not dam-

aged or the spring does not slip off its posi-

tion.

When installing the impeller shaft, apply the

lithium soap base grease on the oil seal lip

and impeller shaft. And install the shaft while

turning it.

Hold the impeller shaft on its width across

the flats a with spanners, etc. and install the

impeller.

T R..14 Nm (1.4 m · kg, 10 ft · lb)

Right crankcase cover

1. Install:

Dowel pin 1

O-ring 2

Collar 3

Gasket 4

NOTE:

Apply the lithium soap base grease on the O-

ring.

Page 376 of 668

4 - 61

ENG

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

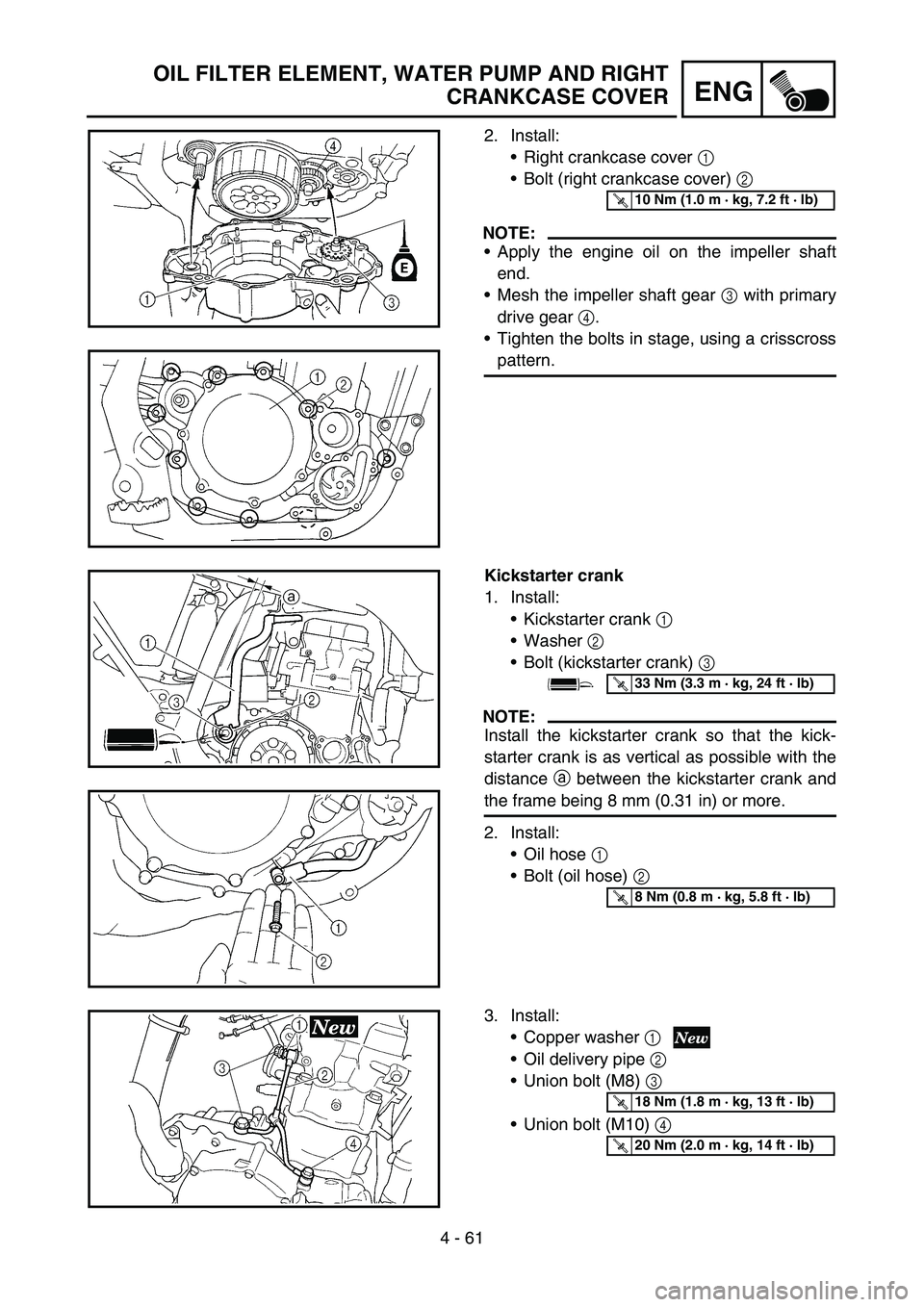

2. Install:

Right crankcase cover 1

Bolt (right crankcase cover) 2

NOTE:

Apply the engine oil on the impeller shaft

end.

Mesh the impeller shaft gear 3 with primary

drive gear 4.

Tighten the bolts in stage, using a crisscross

pattern.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Kickstarter crank

1. Install:

Kickstarter crank 1

Washer 2

Bolt (kickstarter crank) 3

NOTE:

Install the kickstarter crank so that the kick-

starter crank is as vertical as possible with the

distance a between the kickstarter crank and

the frame being 8 mm (0.31 in) or more.

2. Install:

Oil hose 1

Bolt (oil hose) 2

T R..33 Nm (3.3 m · kg, 24 ft · lb)

T R..8 Nm (0.8 m · kg, 5.8 ft · lb)

3. Install:

Copper washer 1

Oil delivery pipe 2

Union bolt (M8) 3

Union bolt (M10) 4

T R..18 Nm (1.8 m · kg, 13 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 378 of 668

4 - 62

ENG

OIL FILTER ELEMENT, WATER PUMP AND RIGHT

CRANKCASE COVER

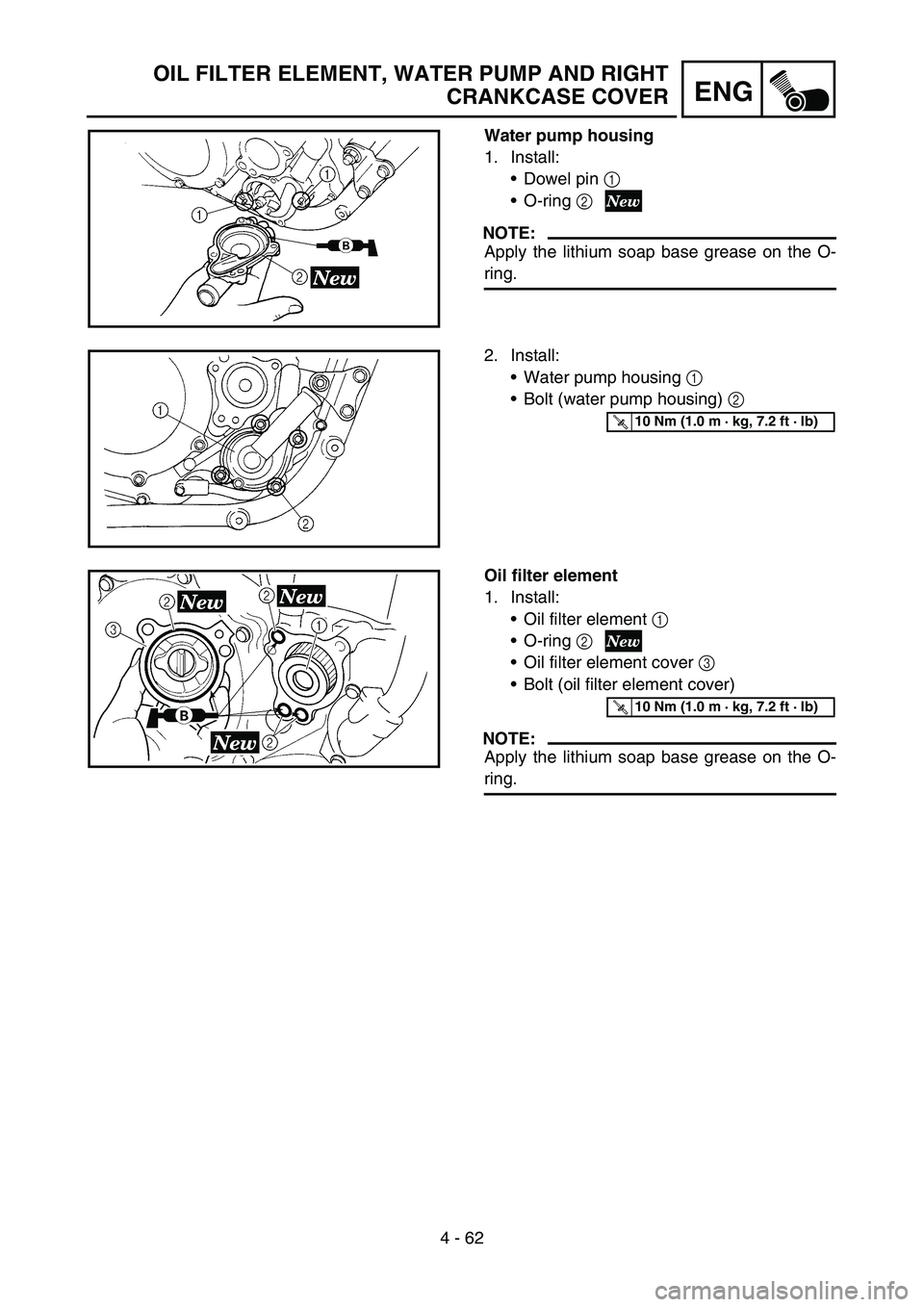

Water pump housing

1. Install:

Dowel pin 1

O-ring 2

NOTE:

Apply the lithium soap base grease on the O-

ring.

2. Install:

Water pump housing 1

Bolt (water pump housing) 2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Oil filter element

1. Install:

Oil filter element 1

O-ring 2

Oil filter element cover 3

Bolt (oil filter element cover)

NOTE:

Apply the lithium soap base grease on the O-

ring.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 380 of 668

4 - 63

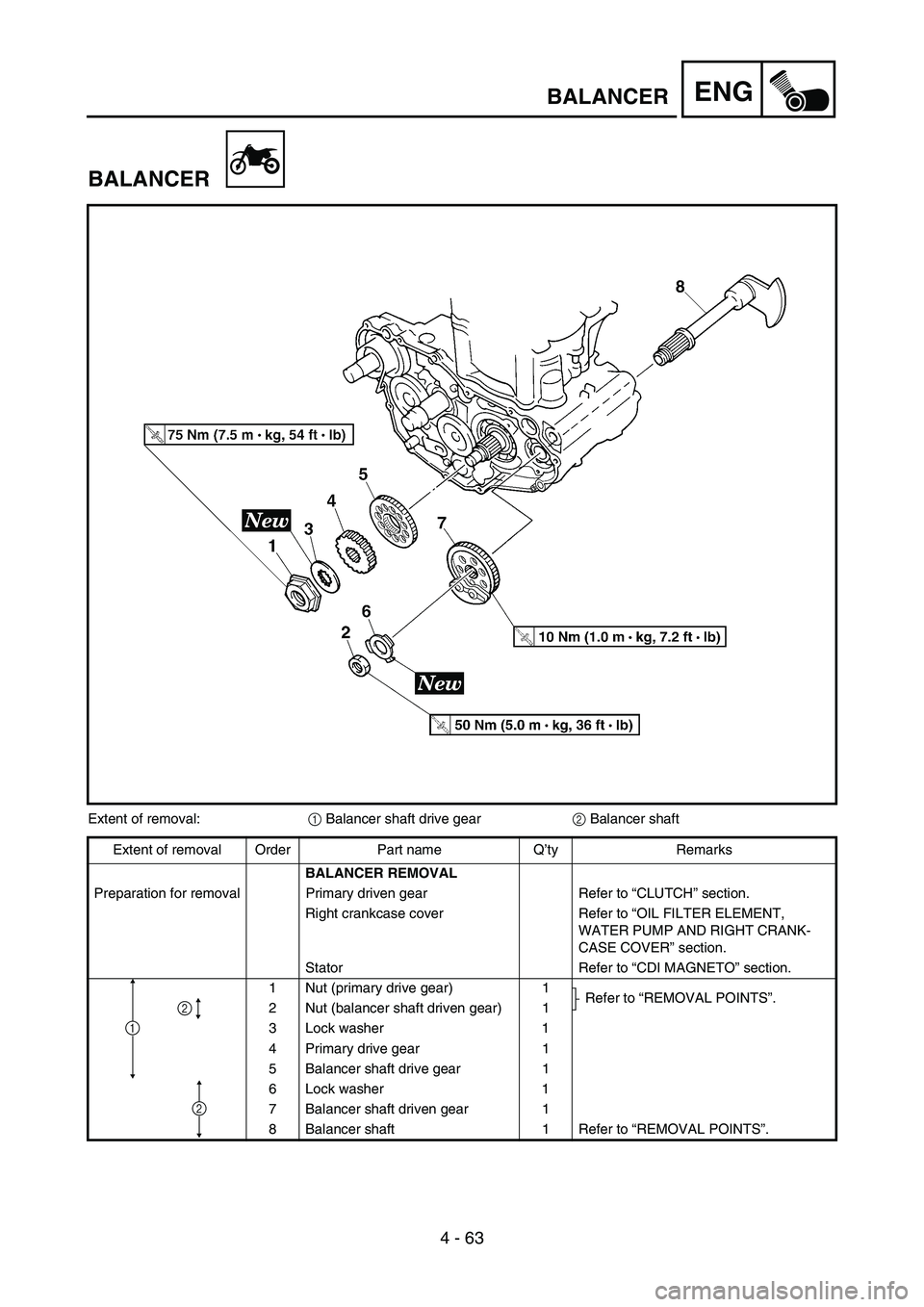

ENGBALANCER

BALANCER

Extent of removal:

1 Balancer shaft drive gear

2 Balancer shaft

Extent of removal Order Part name Q’ty Remarks

BALANCER REMOVAL

Preparation for removal Primary driven gear Refer to “CLUTCH” section.

Right crankcase cover Refer to “OIL FILTER ELEMENT,

WATER PUMP AND RIGHT CRANK-

CASE COVER” section.

Stator Refer to “CDI MAGNETO” section.

1 Nut (primary drive gear) 1

Refer to “REMOVAL POINTS”.

2 Nut (balancer shaft driven gear) 1

3 Lock washer 1

4 Primary drive gear 1

5 Balancer shaft drive gear 1

6 Lock washer 1

7 Balancer shaft driven gear 1

8 Balancer shaft 1 Refer to “REMOVAL POINTS”.

2

1

2

Page 384 of 668

4 - 65

ENGBALANCER

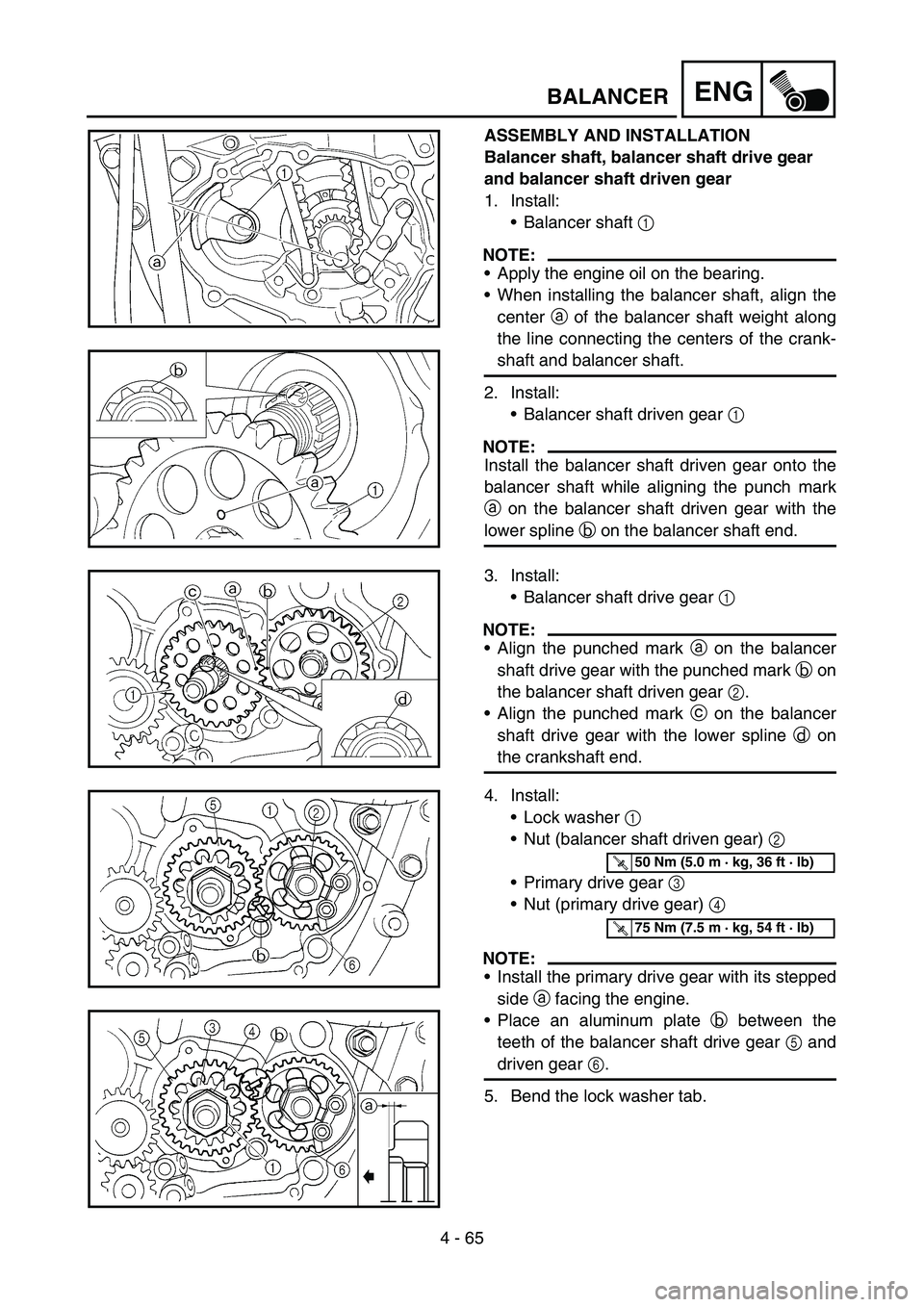

ASSEMBLY AND INSTALLATION

Balancer shaft, balancer shaft drive gear

and balancer shaft driven gear

1. Install:

Balancer shaft 1

NOTE:

Apply the engine oil on the bearing.

When installing the balancer shaft, align the

center a of the balancer shaft weight along

the line connecting the centers of the crank-

shaft and balancer shaft.

2. Install:

Balancer shaft driven gear 1

NOTE:

Install the balancer shaft driven gear onto the

balancer shaft while aligning the punch mark

a on the balancer shaft driven gear with the

lower spline b on the balancer shaft end.

3. Install:

Balancer shaft drive gear 1

NOTE:

Align the punched mark a on the balancer

shaft drive gear with the punched mark b on

the balancer shaft driven gear 2.

Align the punched mark c on the balancer

shaft drive gear with the lower spline d on

the crankshaft end.

4. Install:

Lock washer 1

Nut (balancer shaft driven gear) 2

Primary drive gear 3

Nut (primary drive gear) 4

NOTE:

Install the primary drive gear with its stepped

side a facing the engine.

Place an aluminum plate b between the

teeth of the balancer shaft drive gear 5 and

driven gear 6.

5. Bend the lock washer tab.

T R..50 Nm (5.0 m · kg, 36 ft · lb)

T R..75 Nm (7.5 m · kg, 54 ft · lb)

Page 386 of 668

4 - 66

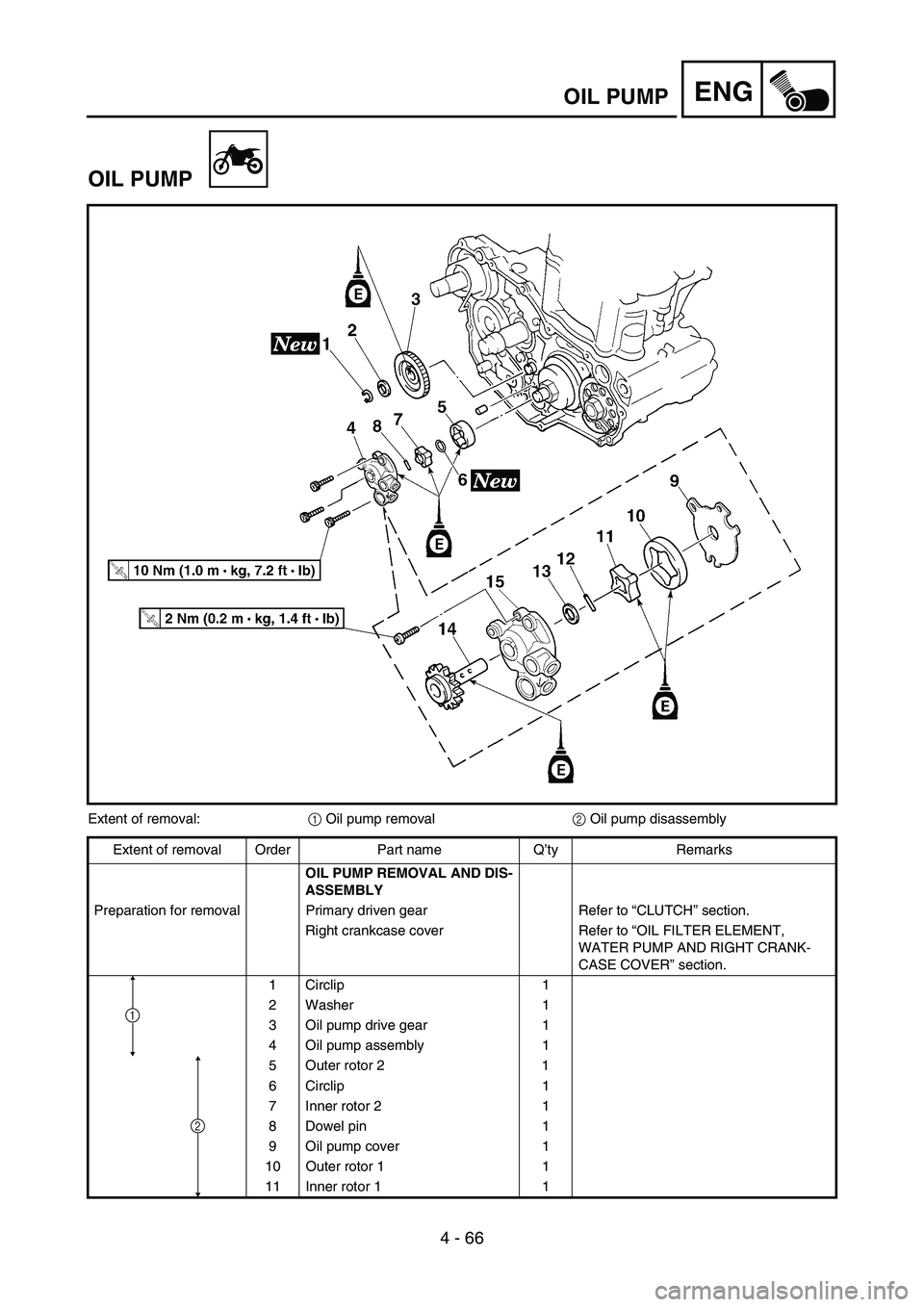

ENGOIL PUMP

OIL PUMP

Extent of removal:

1 Oil pump removal

2 Oil pump disassembly

Extent of removal Order Part name Q’ty Remarks

OIL PUMP REMOVAL AND DIS-

ASSEMBLY

Preparation for removal Primary driven gear Refer to “CLUTCH” section.

Right crankcase cover Refer to “OIL FILTER ELEMENT,

WATER PUMP AND RIGHT CRANK-

CASE COVER” section.

1 Circlip 1

2 Washer 1

3 Oil pump drive gear 1

4 Oil pump assembly 1

5 Outer rotor 2 1

6 Circlip 1

7 Inner rotor 2 1

8 Dowel pin 1

9 Oil pump cover 1

10 Outer rotor 1 1

11 Inner rotor 1 1

2

1

Page 388 of 668

4 - 67

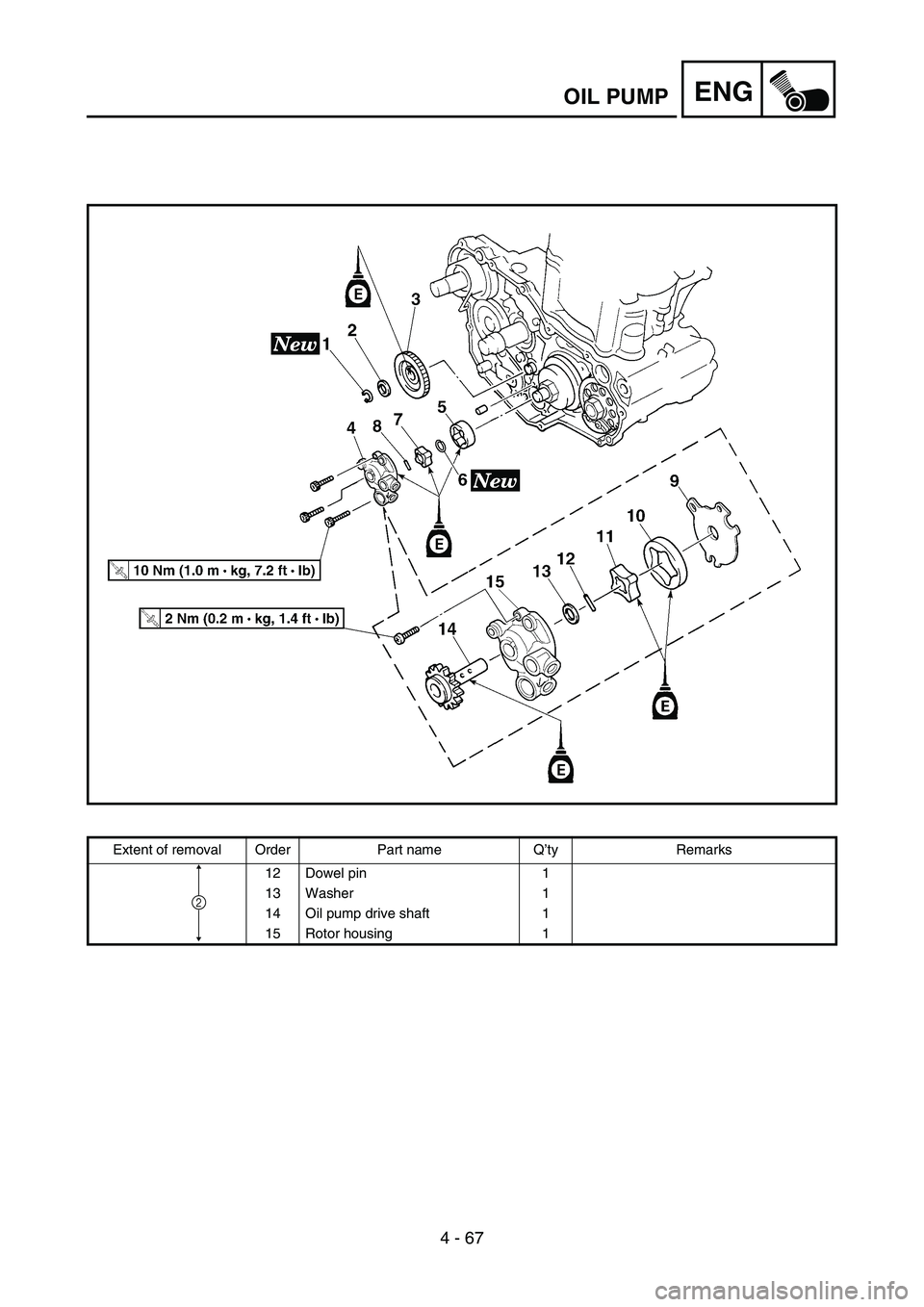

ENGOIL PUMP

Extent of removal Order Part name Q’ty Remarks

12 Dowel pin 1

13 Washer 1

14 Oil pump drive shaft 1

15 Rotor housing 1

2

Page 390 of 668

4 - 68

ENGOIL PUMP

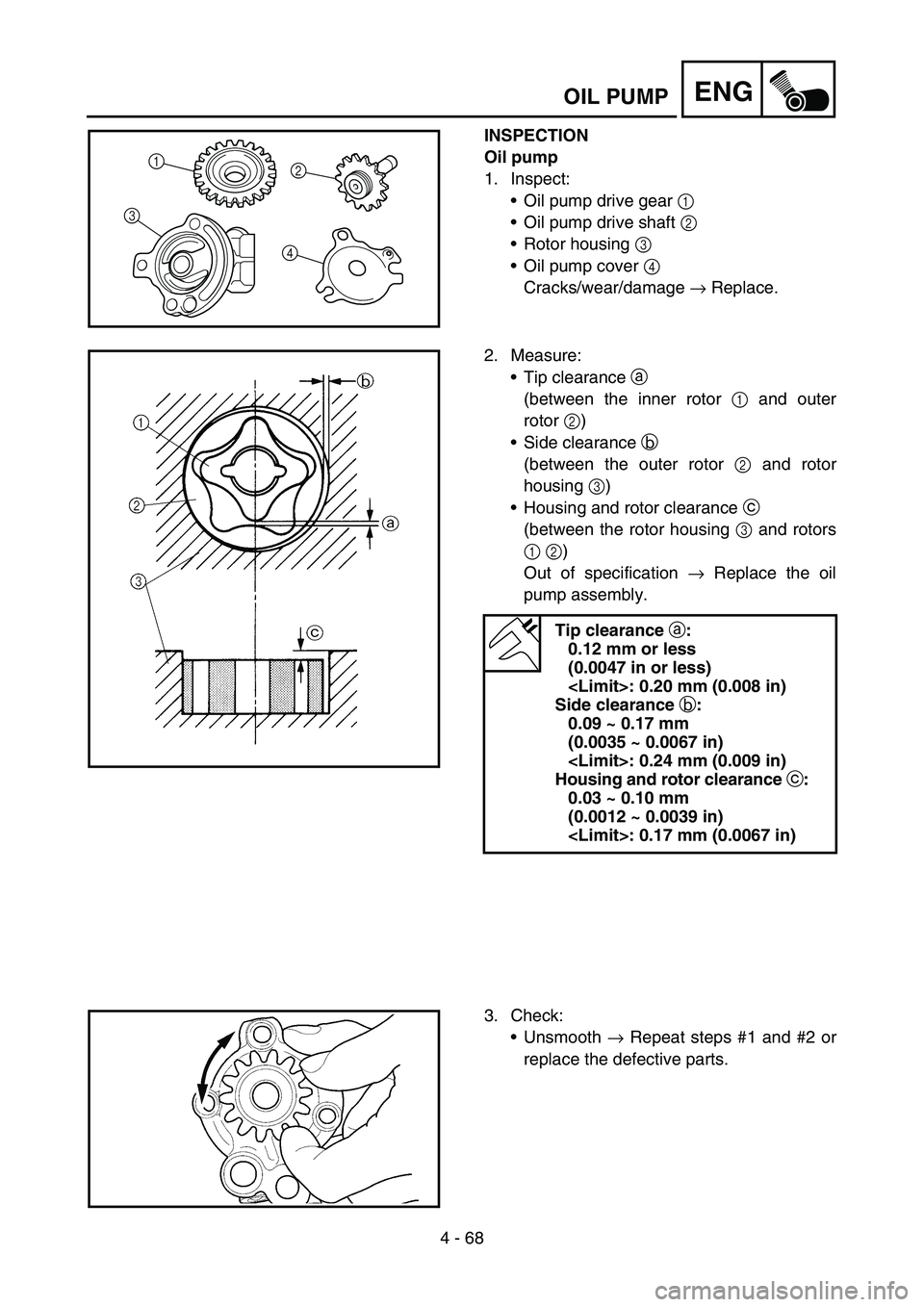

INSPECTION

Oil pump

1. Inspect:

Oil pump drive gear 1

Oil pump drive shaft 2

Rotor housing 3

Oil pump cover 4

Cracks/wear/damage → Replace.

1

32

4

2. Measure:

Tip clearance a

(between the inner rotor 1 and outer

rotor 2)

Side clearance b

(between the outer rotor 2 and rotor

housing 3)

Housing and rotor clearance c

(between the rotor housing 3 and rotors

1 2)

Out of specification → Replace the oil

pump assembly.

Tip clearance a:

0.12 mm or less

(0.0047 in or less)

Side clearance b:

0.09 ~ 0.17 mm

(0.0035 ~ 0.0067 in)

Housing and rotor clearance c:

0.03 ~ 0.10 mm

(0.0012 ~ 0.0039 in)

3. Check:

Unsmooth → Repeat steps #1 and #2 or

replace the defective parts.