fuel YAMAHA YZ250F 2007 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: YZ250F, Model: YAMAHA YZ250F 2007Pages: 676, PDF Size: 21.24 MB

Page 172 of 676

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

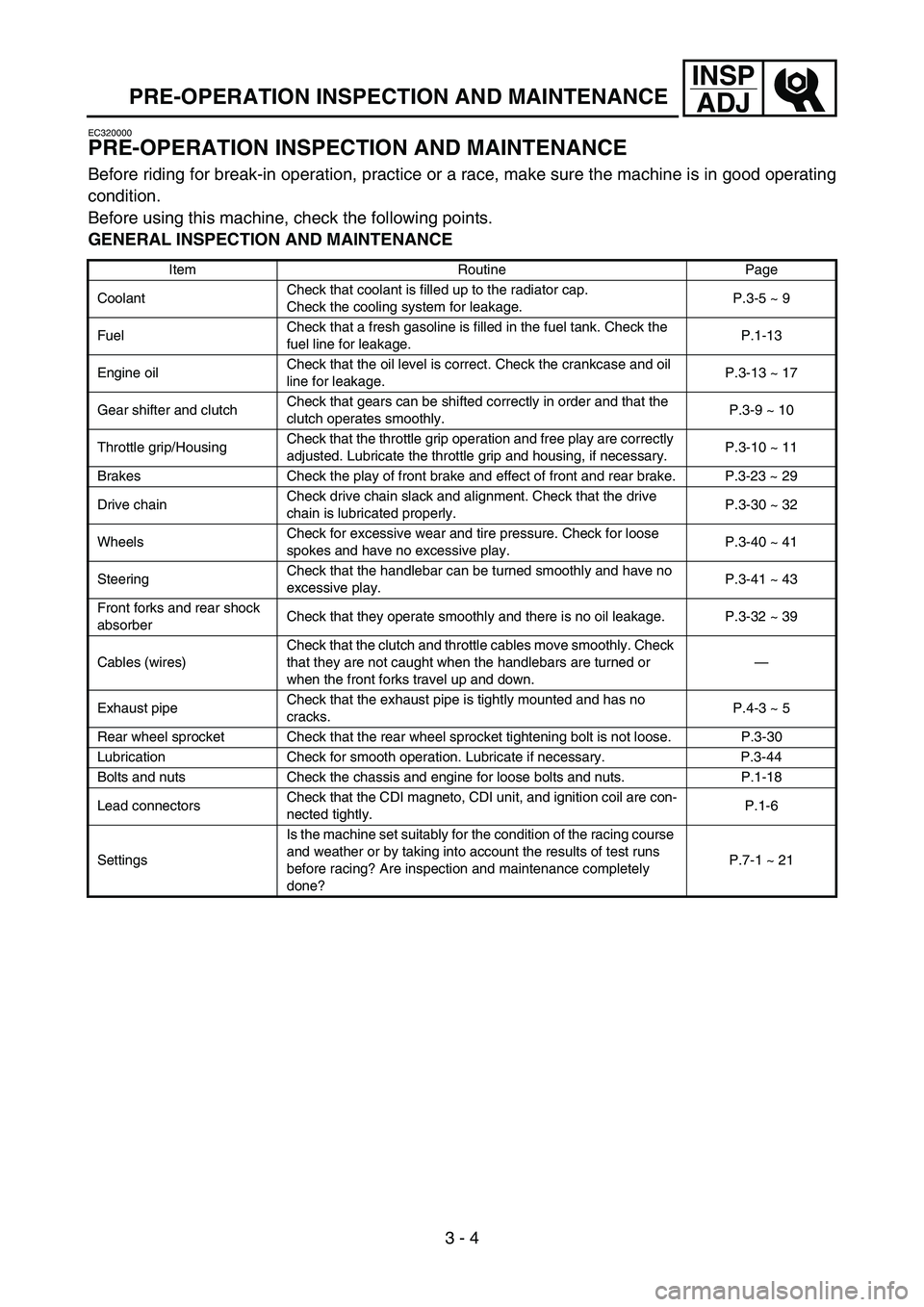

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-13

Engine oilCheck that the oil level is correct. Check the crankcase and oil

line for leakage.P.3-13 ~ 17

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9 ~ 10

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-23 ~ 29

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-30 ~ 32

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-40 ~ 41

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-41 ~ 43

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-32 ~ 39

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-3 ~ 5

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-30

Lubrication Check for smooth operation. Lubricate if necessary. P.3-44

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-18

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 21

Page 200 of 676

3 - 17

INSP

ADJ

OIL PRESSURE INSPECTION

1. Check:

Oil pressure

Checking steps:

Slightly loosen the oil pressure check bolt

1.

Start the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt. If no oil comes out after one minute,

turn the engine off so it will not seize.

Check oil passages and oil pump for dam-

age or leakage.

Start the engine after solving the prob-

lem(s) and recheck the oil pressure.

Tighten the oil pressure check bolt.

T R..

Oil pressure check bolt:

10 Nm (1.0 m kg, 7.2 ft lb)

PILOT SCREW ADJUSTMENT

1. Adjust:

Pilot screw 1

* Except for USA and CDNAdjustment steps:

NOTE:

To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot screw has

been individually set at the factory. Before

adjusting the pilot screw, turn it in fully and

count the number of turns. Record this num-

ber as the factory-set number of turns out.

Turn in the pilot screw until it is lightly

seated.

Turn out the pilot screw by the factory-set

number of turns.

Pilot screw (example):

1-7/8 turns out

* 2-1/8 turns out

OIL PRESSURE INSPECTION/

PILOT SCREW ADJUSTMENT

Page 202 of 676

3 - 18

INSP

ADJ

ENGINE IDLING SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it up.

2. Adjust:

Engine idling speed

Adjustment steps:

Adjust the pilot screw.

Refer to “PILOT SCREW ADJUSTMENT”

section.

Turn the throttle stop screw 1 until the

specified engine idling speed.

NOTE:

Using a digital engine tachometer for idle

speed adjustment, detect the engine idling

speed by bringing the sensing element c of

the engine tachometer close to the ignition

coil 2.

To increase idle speed → Turn the throt-

tle stop screw 1 in a.

To decrease idle speed → Turn the throt-

tle stop screw 1 out b.

Engine idling speed:

1,900 ~ 2,100 r/min

c2

VALVE CLEARANCE INSPECTION AND

ADJUSTMENT

NOTE:

The valve clearance should be adjusted

when the engine is cool to the touch.

The piston must be at Top Dead Center

(T.D.C.) on compression stroke to check or

adjust the valve clearance.

1. Remove:

Seat

Fuel tank

Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section in the CHAPTER 4.

ENGINE IDLING SPEED ADJUSTMENT/

VALVE CLEARANCE INSPECTION AND ADJUSTMENT

Page 252 of 676

3 - 42

INSP

ADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

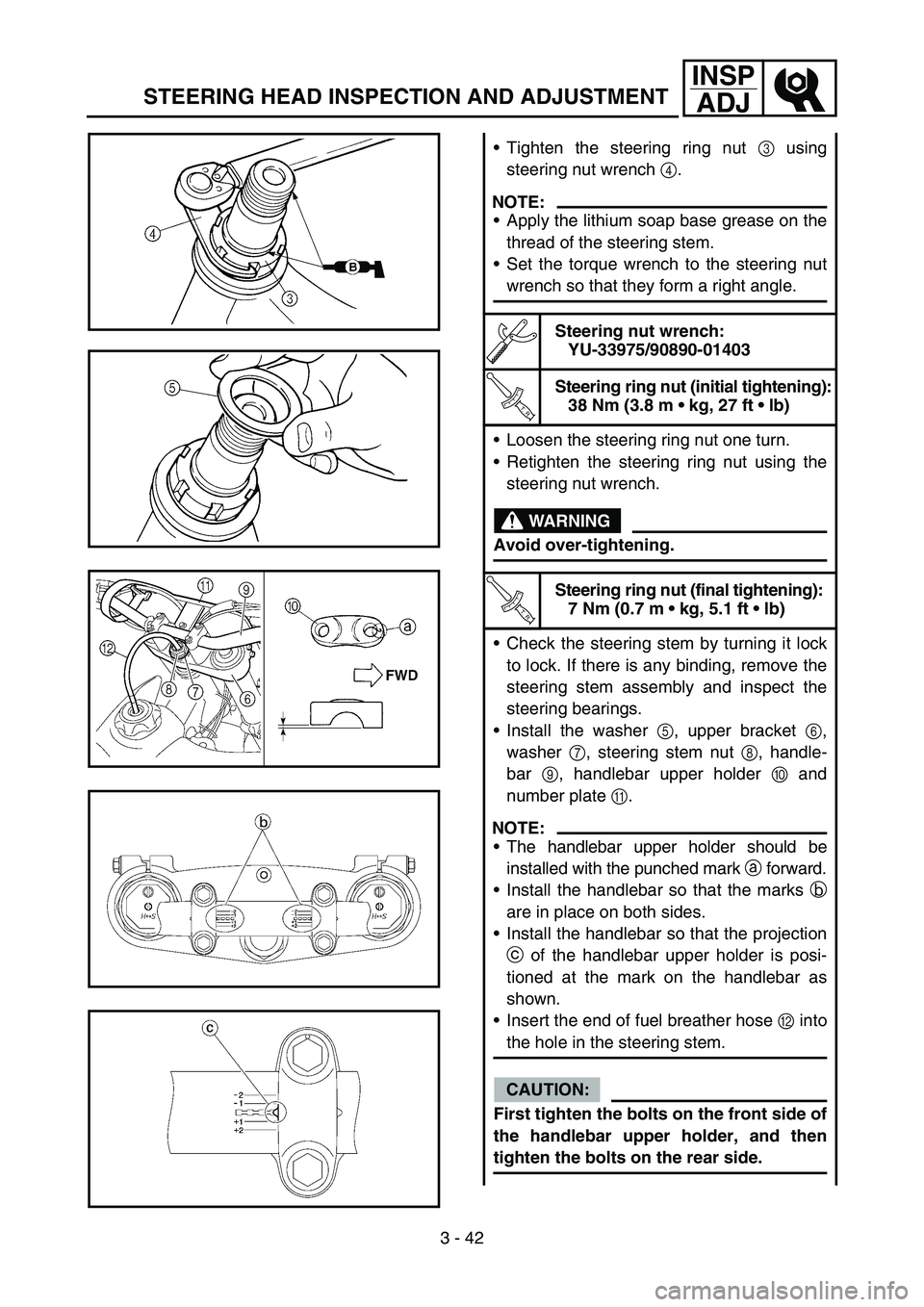

Tighten the steering ring nut 3 using

steering nut wrench 4.

NOTE:

Apply the lithium soap base grease on the

thread of the steering stem.

Set the torque wrench to the steering nut

wrench so that they form a right angle.

Steering nut wrench:

YU-33975/90890-01403

T R..

Steering ring nut (initial tightening):

38 Nm (3.8 m kg, 27 ft lb)

Loosen the steering ring nut one turn.

Retighten the steering ring nut using the

steering nut wrench.

WARNING

Avoid over-tightening.

T R..

Steering ring nut (final tightening):

7 Nm (0.7 m kg, 5.1 ft lb)

Check the steering stem by turning it lock

to lock. If there is any binding, remove the

steering stem assembly and inspect the

steering bearings.

Install the washer 5, upper bracket 6,

washer 7, steering stem nut 8, handle-

bar 9, handlebar upper holder 0 and

number plate A.

NOTE:

The handlebar upper holder should be

installed with the punched mark a forward.

Install the handlebar so that the marks b

are in place on both sides.

Install the handlebar so that the projection

c of the handlebar upper holder is posi-

tioned at the mark on the handlebar as

shown.

Insert the end of fuel breather hose B into

the hole in the steering stem.

CAUTION:

First tighten the bolts on the front side of

the handlebar upper holder, and then

tighten the bolts on the rear side.

Page 262 of 676

4 - 1

ENG

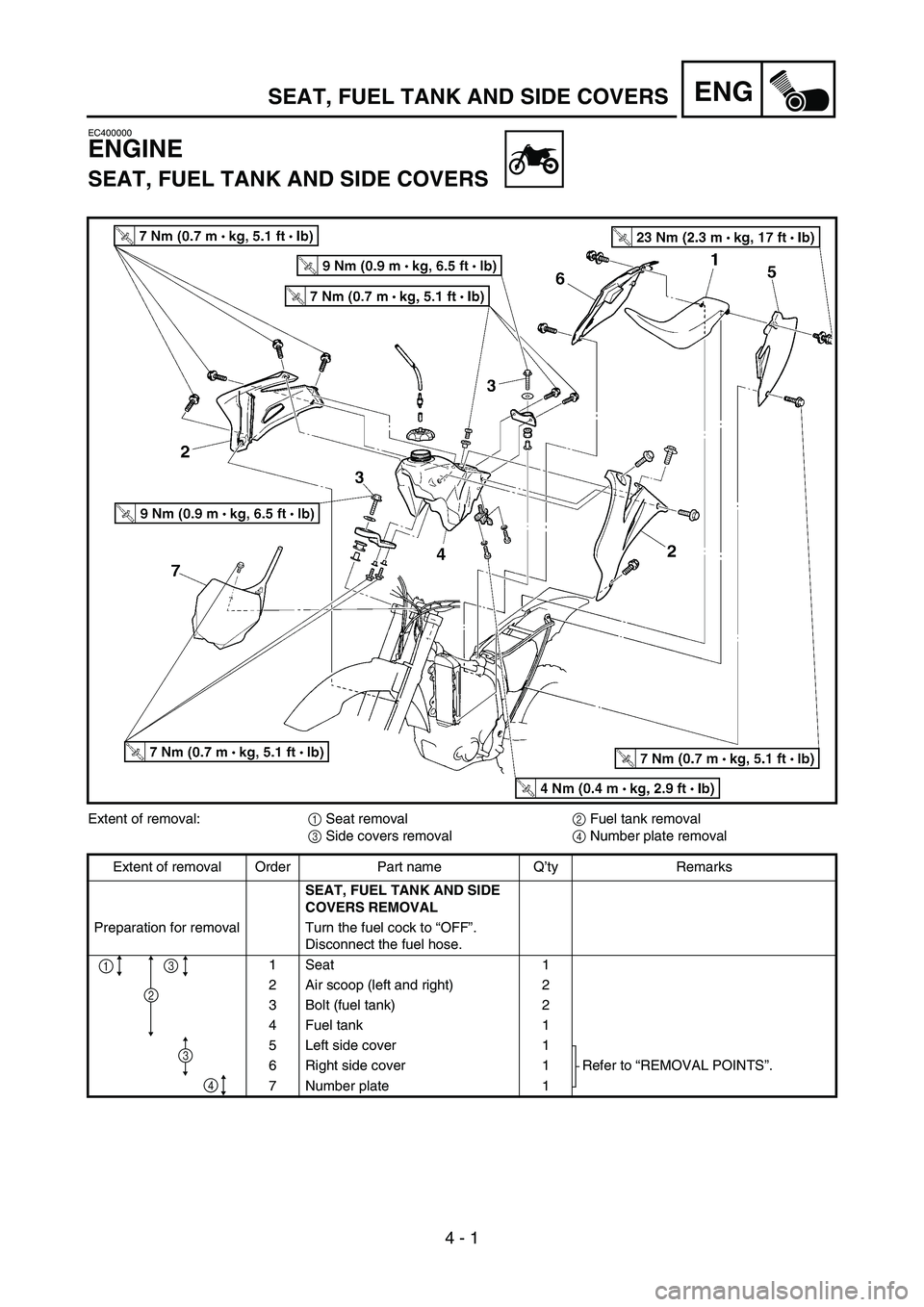

EC400000

ENGINE

SEAT, FUEL TANK AND SIDE COVERS

Extent of removal:

1 Seat removal

2 Fuel tank removal

3 Side covers removal

4 Number plate removal

Extent of removal Order Part name Q’ty Remarks

SEAT, FUEL TANK AND SIDE

COVERS REMOVAL

Preparation for removal Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1Seat 1

2 Air scoop (left and right) 2

3 Bolt (fuel tank) 2

4 Fuel tank 1

5 Left side cover 1

Refer to “REMOVAL POINTS”. 6 Right side cover 1

7 Number plate 1

4

2

1

3

3

SEAT, FUEL TANK AND SIDE COVERS

4

Page 264 of 676

4 - 2

ENG

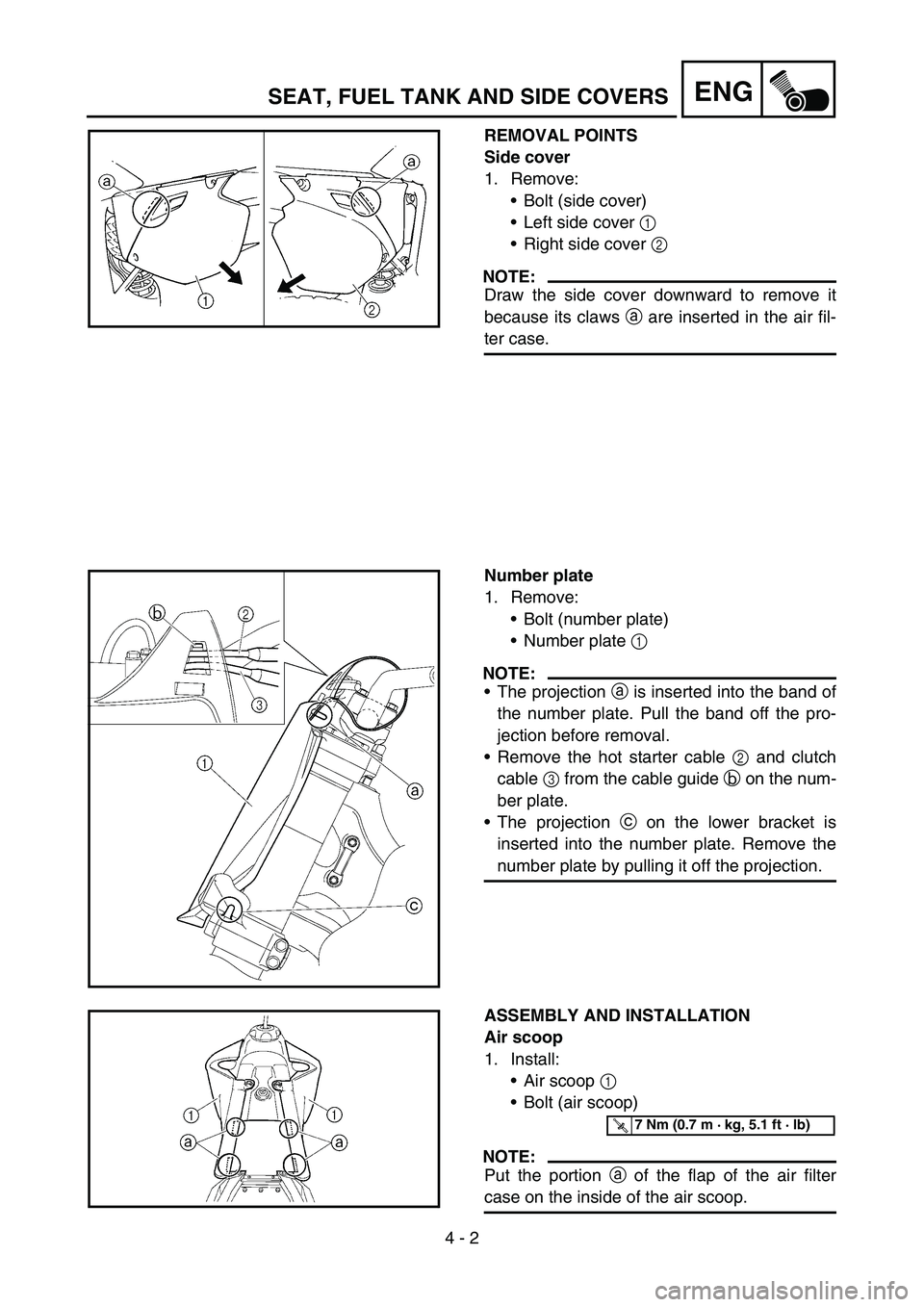

REMOVAL POINTS

Side cover

1. Remove:

Bolt (side cover)

Left side cover 1

Right side cover 2

NOTE:

Draw the side cover downward to remove it

because its claws a are inserted in the air fil-

ter case.

Number plate

1. Remove:

Bolt (number plate)

Number plate 1

NOTE:

The projection a is inserted into the band of

the number plate. Pull the band off the pro-

jection before removal.

Remove the hot starter cable 2 and clutch

cable 3 from the cable guide b on the num-

ber plate.

The projection c on the lower bracket is

inserted into the number plate. Remove the

number plate by pulling it off the projection.

ASSEMBLY AND INSTALLATION

Air scoop

1. Install:

Air scoop 1

Bolt (air scoop)

NOTE:

Put the portion a of the flap of the air filter

case on the inside of the air scoop.

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

SEAT, FUEL TANK AND SIDE COVERS

Page 266 of 676

4 - 3

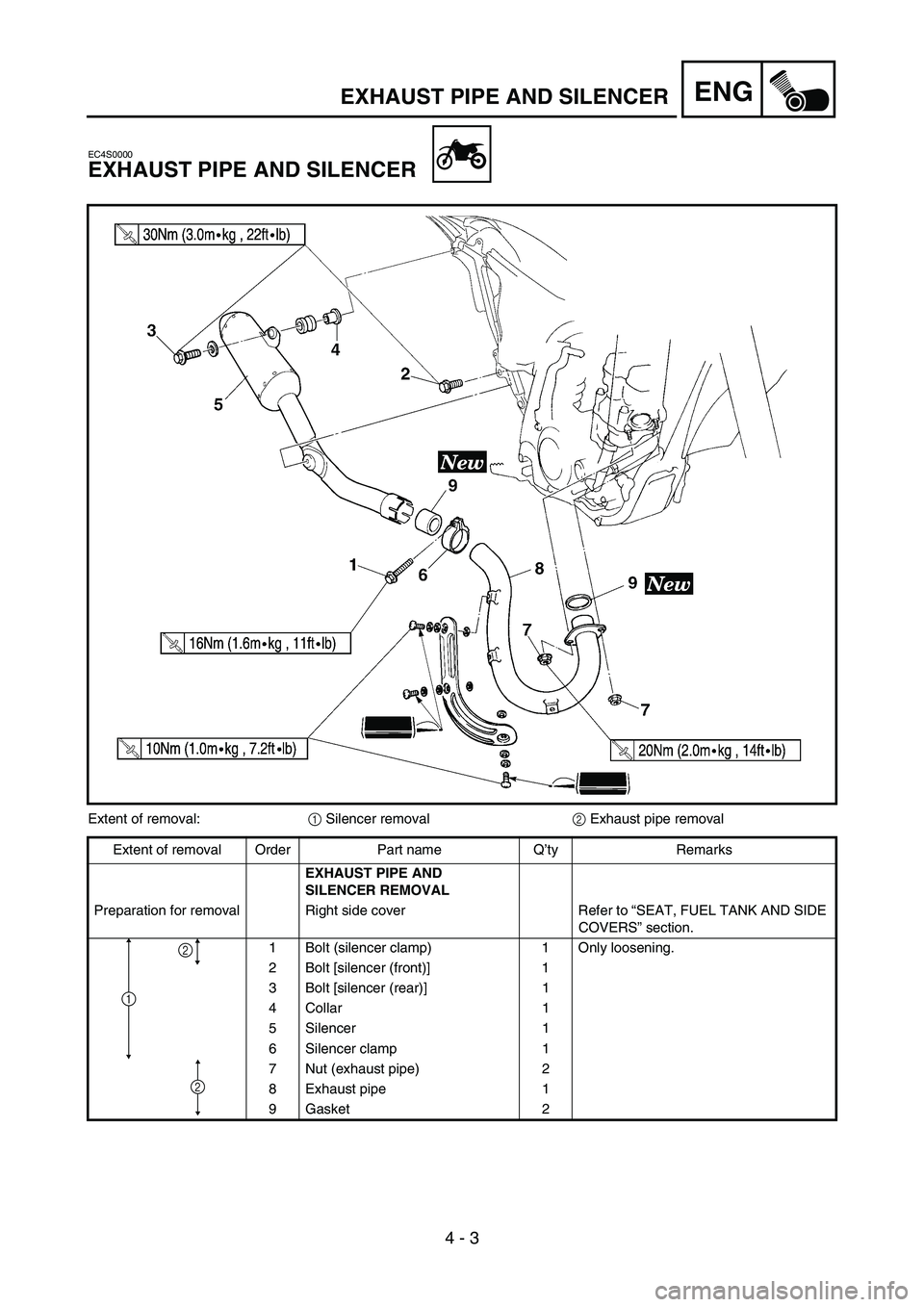

ENGEXHAUST PIPE AND SILENCER

EC4S0000

EXHAUST PIPE AND SILENCER

Extent of removal:

1 Silencer removal

2 Exhaust pipe removal

Extent of removal Order Part name Q’ty Remarks

EXHAUST PIPE AND

SILENCER REMOVAL

Preparation for removal Right side cover Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

1 Bolt (silencer clamp) 1 Only loosening.

2 Bolt [silencer (front)] 1

3 Bolt [silencer (rear)] 1

4 Collar 1

5 Silencer 1

6 Silencer clamp 1

7 Nut (exhaust pipe) 2

8 Exhaust pipe 1

9 Gasket 2

2

1

2

Page 272 of 676

4 - 6

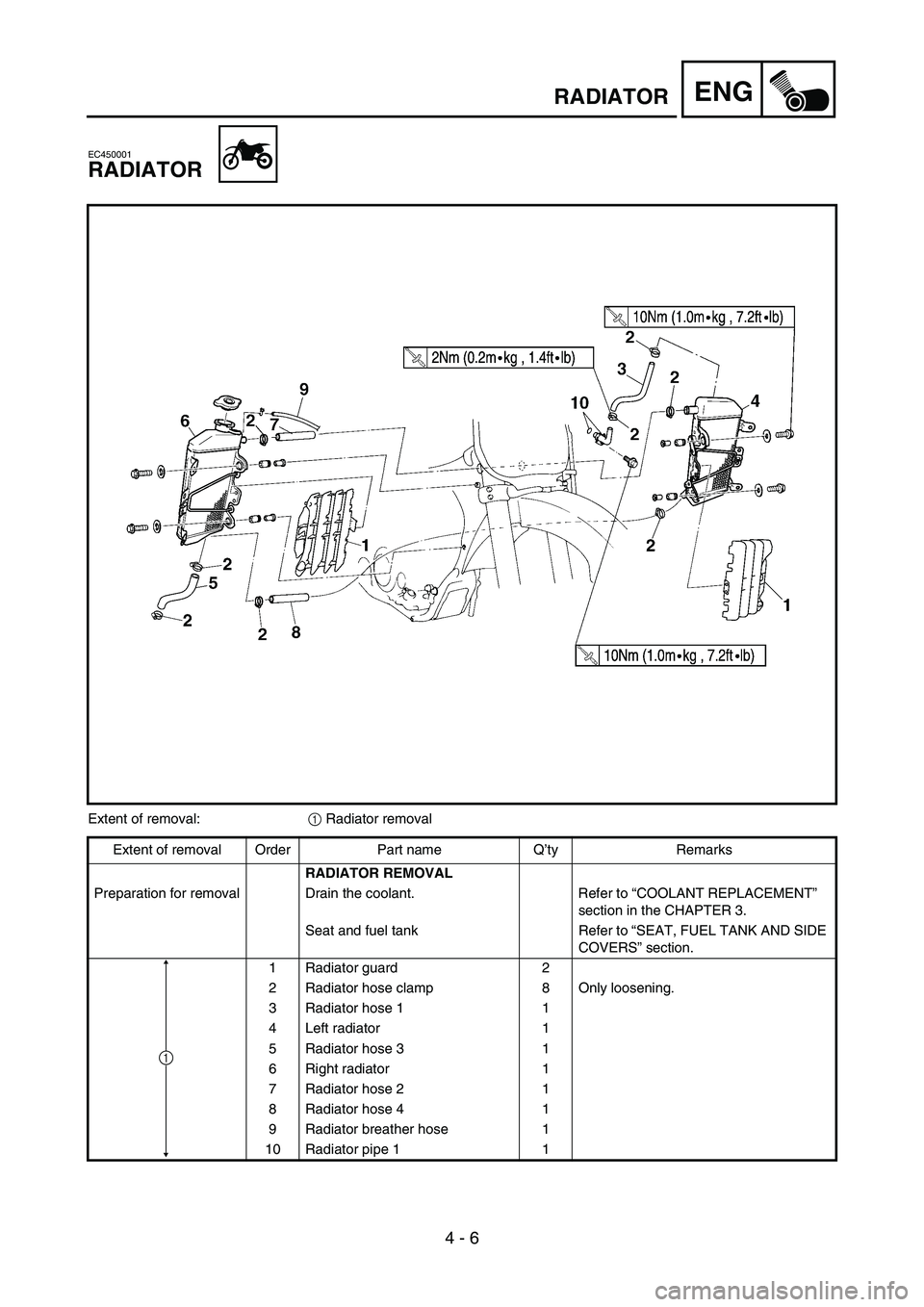

ENGRADIATOR

EC450001

RADIATOR

Extent of removal:

1 Radiator removal

Extent of removal Order Part name Q’ty Remarks

RADIATOR REMOVAL

Preparation for removal Drain the coolant. Refer to “COOLANT REPLACEMENT”

section in the CHAPTER 3.

Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

1 Radiator guard 2

2 Radiator hose clamp 8 Only loosening.

3 Radiator hose 1 1

4 Left radiator 1

5 Radiator hose 3 1

6 Right radiator 1

7 Radiator hose 2 1

8 Radiator hose 4 1

9 Radiator breather hose 1

10 Radiator pipe 1 1

1

Page 278 of 676

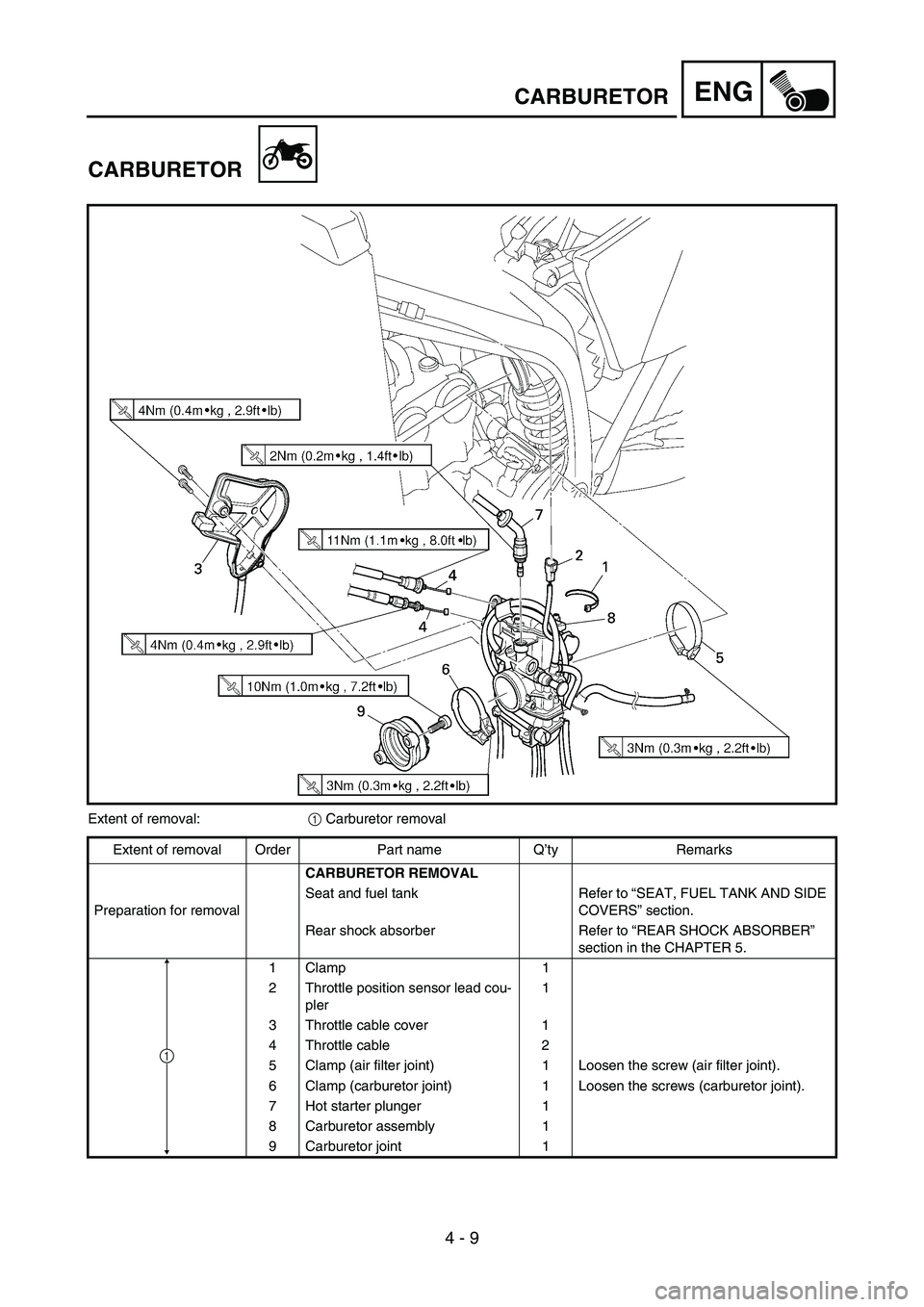

4 - 9

ENGCARBURETOR

CARBURETOR

Extent of removal:

1 Carburetor removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalCARBURETOR REMOVAL

Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Rear shock absorber Refer to “REAR SHOCK ABSORBER”

section in the CHAPTER 5.

1Clamp 1

2 Throttle position sensor lead cou-

pler1

3 Throttle cable cover 1

4 Throttle cable 2

5 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

6 Clamp (carburetor joint) 1 Loosen the screws (carburetor joint).

7 Hot starter plunger 1

8 Carburetor assembly 1

9 Carburetor joint 1

1

Page 284 of 676

4 - 12

ENGCARBURETOR

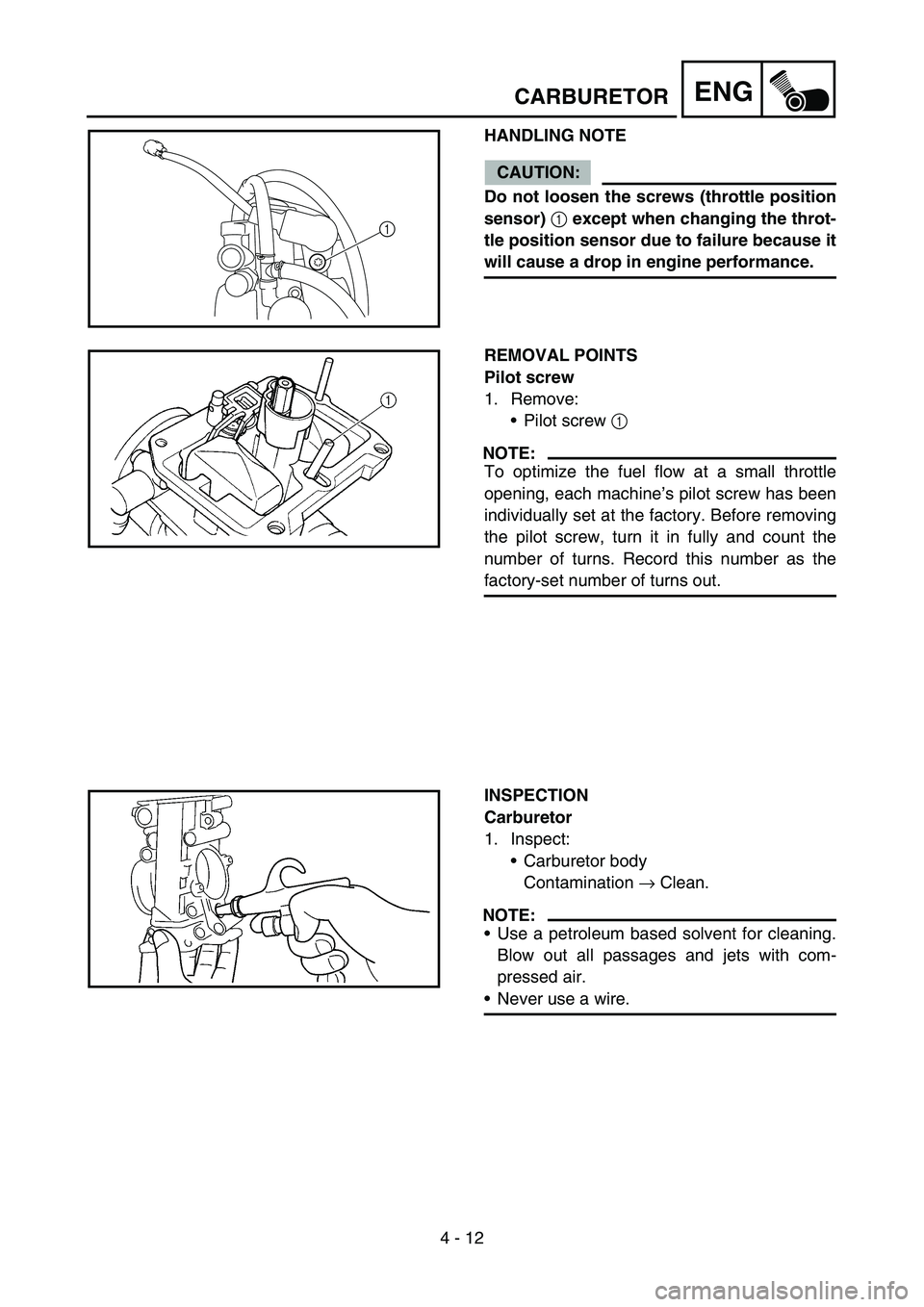

HANDLING NOTE

CAUTION:

Do not loosen the screws (throttle position

sensor)

1 except when changing the throt-

tle position sensor due to failure because it

will cause a drop in engine performance.

1

REMOVAL POINTS

Pilot screw

1. Remove:

Pilot screw 1

NOTE:

To optimize the fuel flow at a small throttle

opening, each machine’s pilot screw has been

individually set at the factory. Before removing

the pilot screw, turn it in fully and count the

number of turns. Record this number as the

factory-set number of turns out.

INSPECTION

Carburetor

1. Inspect:

Carburetor body

Contamination → Clean.

NOTE:

Use a petroleum based solvent for cleaning.

Blow out all passages and jets with com-

pressed air.

Never use a wire.