fuel YAMAHA YZ250F 2007 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: YZ250F, Model: YAMAHA YZ250F 2007Pages: 676, PDF Size: 21.24 MB

Page 60 of 676

1 - 15

GEN

INFO

STARTING AND BREAK-IN

6. Return the cold starter knob to its original

position and run the engine at 3,000 ~

5,000 r/min for 1 or 2 minutes.

NOTE:

Since this model is equipped with an accelera-

tor pump, if the engine is raced (the throttle

opened and closed), the air/fuel mixture will be

too rich and the engine may stall. Also unlike a

two-stroke engine, this model can idle.

CAUTION:

Do not warm up the engine for extended

periods of time.

Page 64 of 676

1 - 17

GEN

INFO

STARTING AND BREAK-IN

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank

with the fuel.

2. Perform the pre-operation checks on the

machine.

3. Start and warm up the engine. Check the

idle speed, and check the operation of the

controls and the engine stop switch. Then,

restart the engine and check its operation

within no more than 5 minutes after it is

restarted.

4. Operate the machine in the lower gears at

moderate throttle openings for five to eight

minutes.

5. Check how the engine runs when the

machine is ridden with the throttle 1/4 to 1/2

open (low to medium speed) for about one

hour.

6. Restart the engine and check the operation

of the machine throughout its entire operat-

ing range. Restart the machine and oper-

ate it for about 10 to 15 more minutes. The

machine will now be ready to race.

CAUTION:

After the break-in or before each race,

you must check the entire machine for

loose fittings and fasteners as per

“TORQUE-CHECK POINTS”.

Tighten all such fasteners as required.

When any of the following parts have

been replaced, they must be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in operation is

necessary.

PISTON, RING, VALVES, CAMSHAFTS

AND GEARS:

These parts require about 30 minutes of

break-in operation at half-throttle or less.

Observe the condition of the engine care-

fully during operation.

Page 66 of 676

GEN

INFO

1 - 18

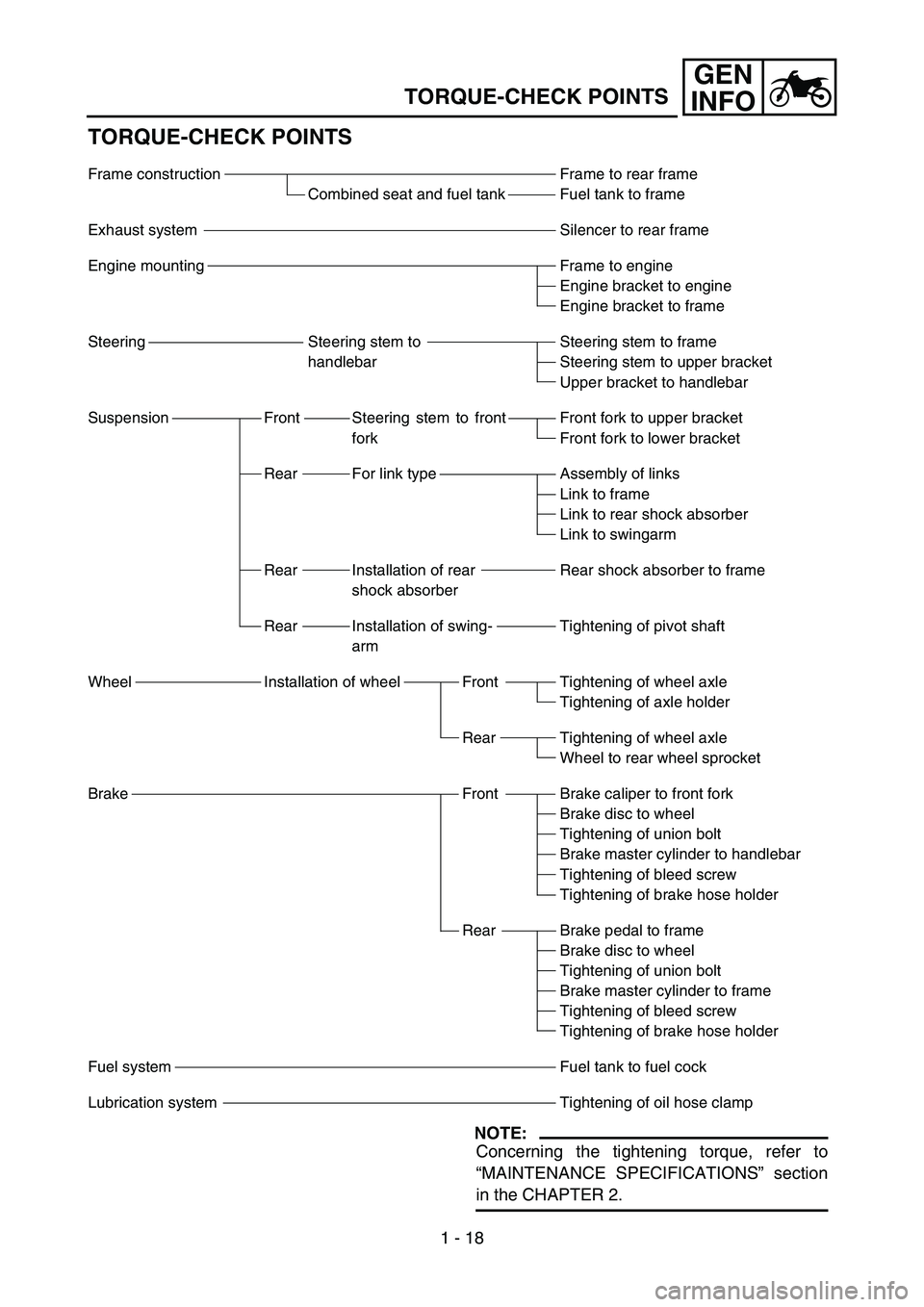

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Frame construction

Combined seat and fuel tank

Exhaust system

Engine mounting

Steering Steering stem to

handlebar

Suspension Front Steering stem to front

fork

Rear For link type

Rear Installation of rear

shock absorber

Rear Installation of swing-

arm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel system

Lubrication systemFrame to rear frame

Fuel tank to frame

Silencer to rear frame

Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Front fork to upper bracket

Front fork to lower bracket

Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Rear shock absorber to frame

Tightening of pivot shaft

Tightening of wheel axle

Tightening of axle holder

Tightening of wheel axle

Wheel to rear wheel sprocket

Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel tank to fuel cock

Tightening of oil hose clamp

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Page 72 of 676

1 - 20

GEN

INFO

CLEANING AND STORAGE

EC1B2001

STORAGE

If your machine is to be stored for 60 days or

more, some preventive measures must be

taken to avoid deterioration. After cleaning the

machine thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and the car-

buretor float bowl.

2. Remove the spark plug, pour a tablespoon

of SAE 10W-30 motor oil in the spark plug

hole, and reinstall the plug. With the engine

stop switch pushed in, kick the engine over

several times to coat the cylinder walls with

oil.

3. Remove the drive chain, clean it thoroughly

with solvent, and lubricate it. Reinstall the

chain or store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If the machine is to be stored in a humid or

salt-air environment, coat all exposed

metal surfaces with a film of light oil. Do not

apply oil to rubber parts or the seat cover.

NOTE:

Make any necessary repairs before the

machine is stored.

Page 74 of 676

SPEC

2 - 1

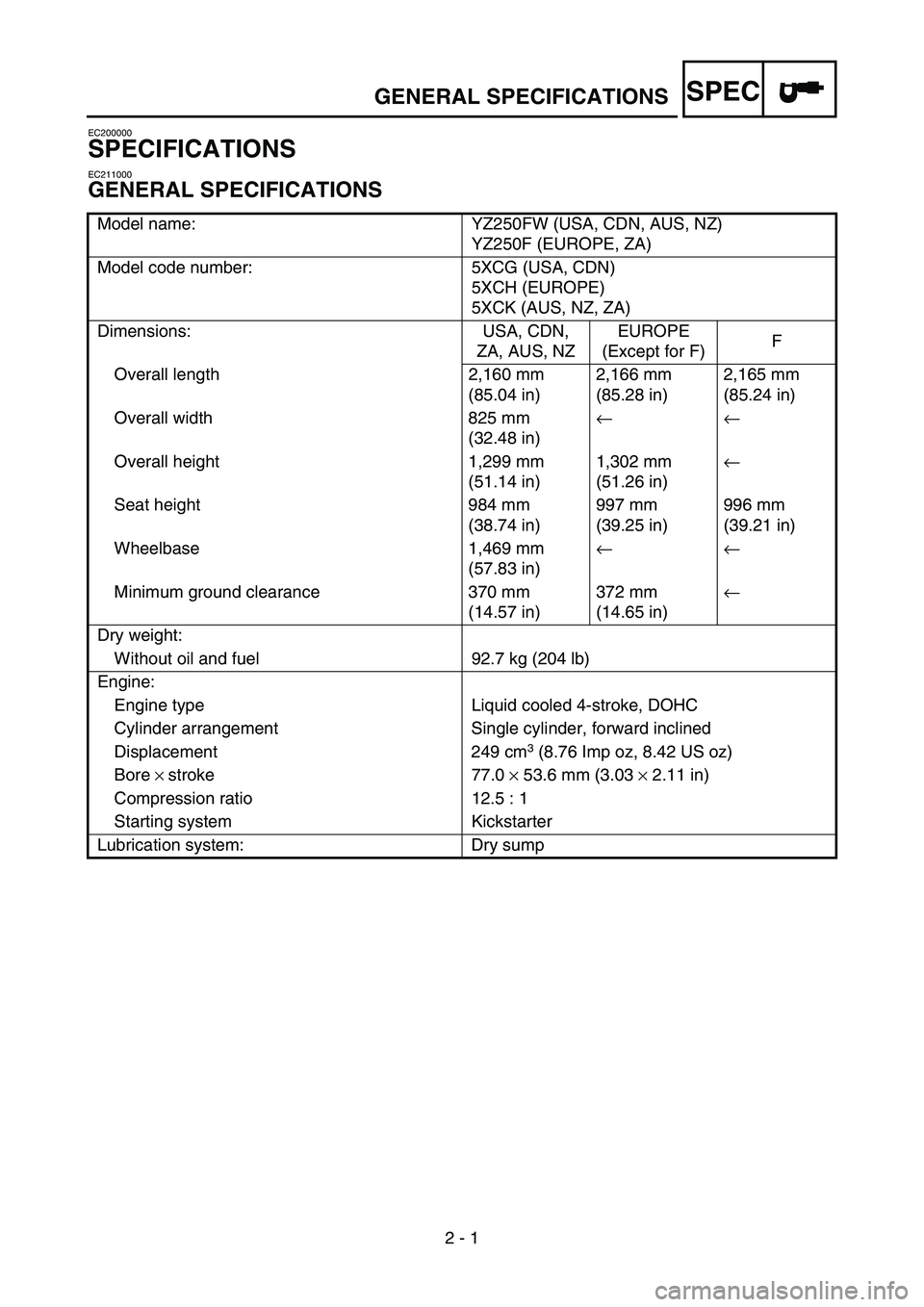

EC200000

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: YZ250FW (USA, CDN, AUS, NZ)

YZ250F (EUROPE, ZA)

Model code number: 5XCG (USA, CDN)

5XCH (EUROPE)

5XCK (AUS, NZ, ZA)

Dimensions: USA, CDN,

ZA, AUS, NZEUROPE

(Except for F)F

Overall length 2,160 mm

(85.04 in)2,166 mm

(85.28 in)2,165 mm

(85.24 in)

Overall width 825 mm

(32.48 in)← ←

Overall height 1,299 mm

(51.14 in)1,302 mm

(51.26 in)←

Seat height 984 mm

(38.74 in)997 mm

(39.25 in)996 mm

(39.21 in)

Wheelbase 1,469 mm

(57.83 in)← ←

Minimum ground clearance 370 mm

(14.57 in)372 mm

(14.65 in)←

Dry weight:

Without oil and fuel 92.7 kg (204 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 249 cm

3 (8.76 Imp oz, 8.42 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 12.5 : 1

Starting system Kickstarter

Lubrication system: Dry sump

2

GENERAL SPECIFICATIONS

Page 75 of 676

SPEC

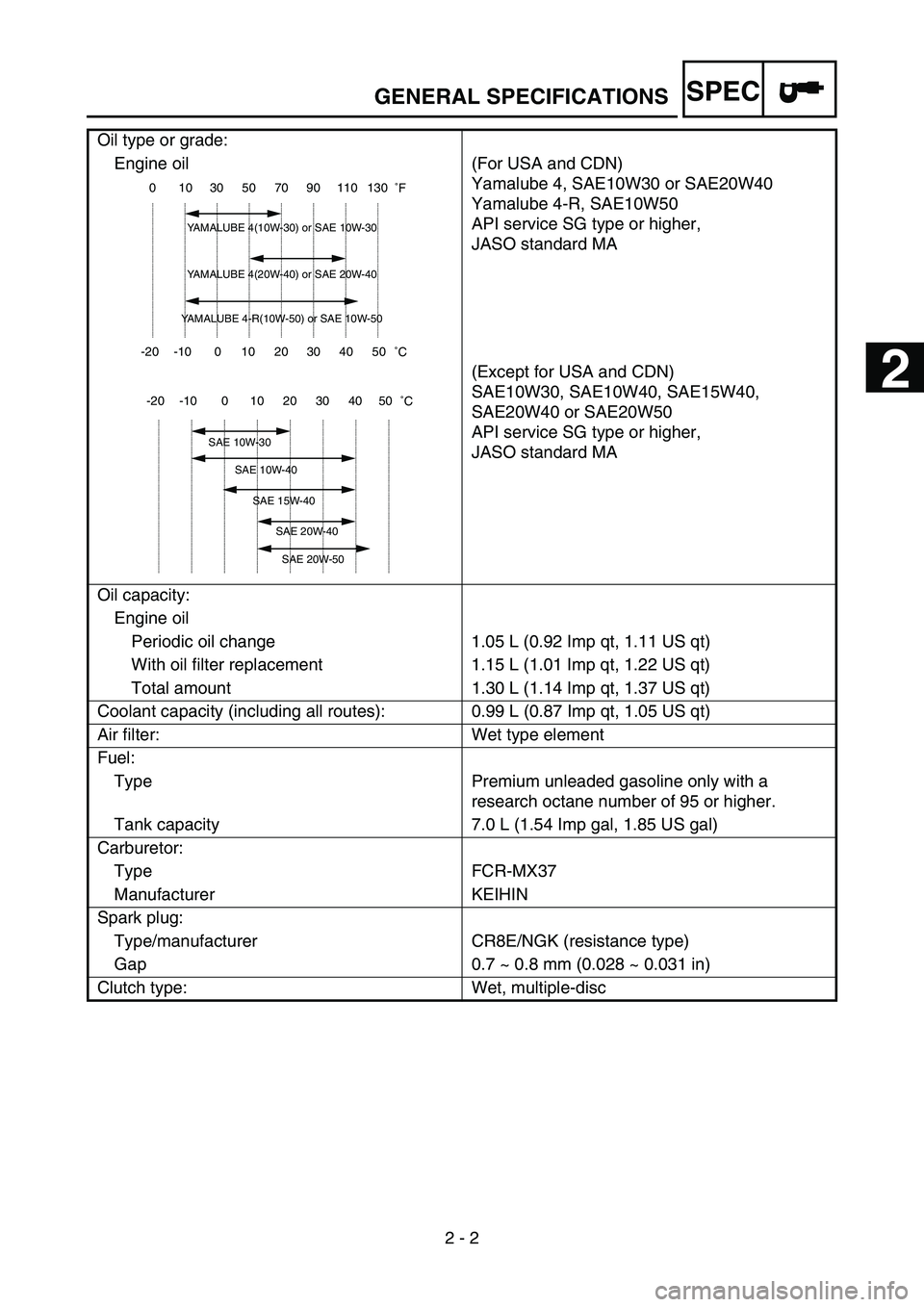

2 - 2 Oil type or grade:

Engine oil (For USA and CDN)

Yamalube 4, SAE10W30 or SAE20W40

Yamalube 4-R, SAE10W50

API service SG type or higher,

JASO standard MA

(Except for USA and CDN)

SAE10W30, SAE10W40, SAE15W40,

SAE20W40 or SAE20W50

API service SG type or higher,

JASO standard MA

Oil capacity:

Engine oil

Periodic oil change 1.05 L (0.92 Imp qt, 1.11 US qt)

With oil filter replacement 1.15 L (1.01 Imp qt, 1.22 US qt)

Total amount 1.30 L (1.14 Imp qt, 1.37 US qt)

Coolant capacity (including all routes): 0.99 L (0.87 Imp qt, 1.05 US qt)

Air filter: Wet type element

Fuel:

Type Premium unleaded gasoline only with a

research octane number of 95 or higher.

Tank capacity 7.0 L (1.54 Imp gal, 1.85 US gal)

Carburetor:

Type FCR-MX37

Manufacturer KEIHIN

Spark plug:

Type/manufacturer CR8E/NGK (resistance type)

Gap 0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

Clutch type: Wet, multiple-disc

-20 -10 0 10 20 30 40 50

˚C 0 10 30 50 70 90 110 130

˚F

YAMALUBE 4(10W-30) or SAE 10W-30

YAMALUBE 4(20W-40) or SAE 20W-40

YAMALUBE 4-R(10W-50) or SAE 10W-50

-20 -10 0 10 20 30 40 50

˚C

SAE 10W-30

SAE 10W-40

SAE 15W-40

SAE 20W-40

SAE 20W-50

GENERAL SPECIFICATIONS

2

Page 88 of 676

SPEC

2 - 15

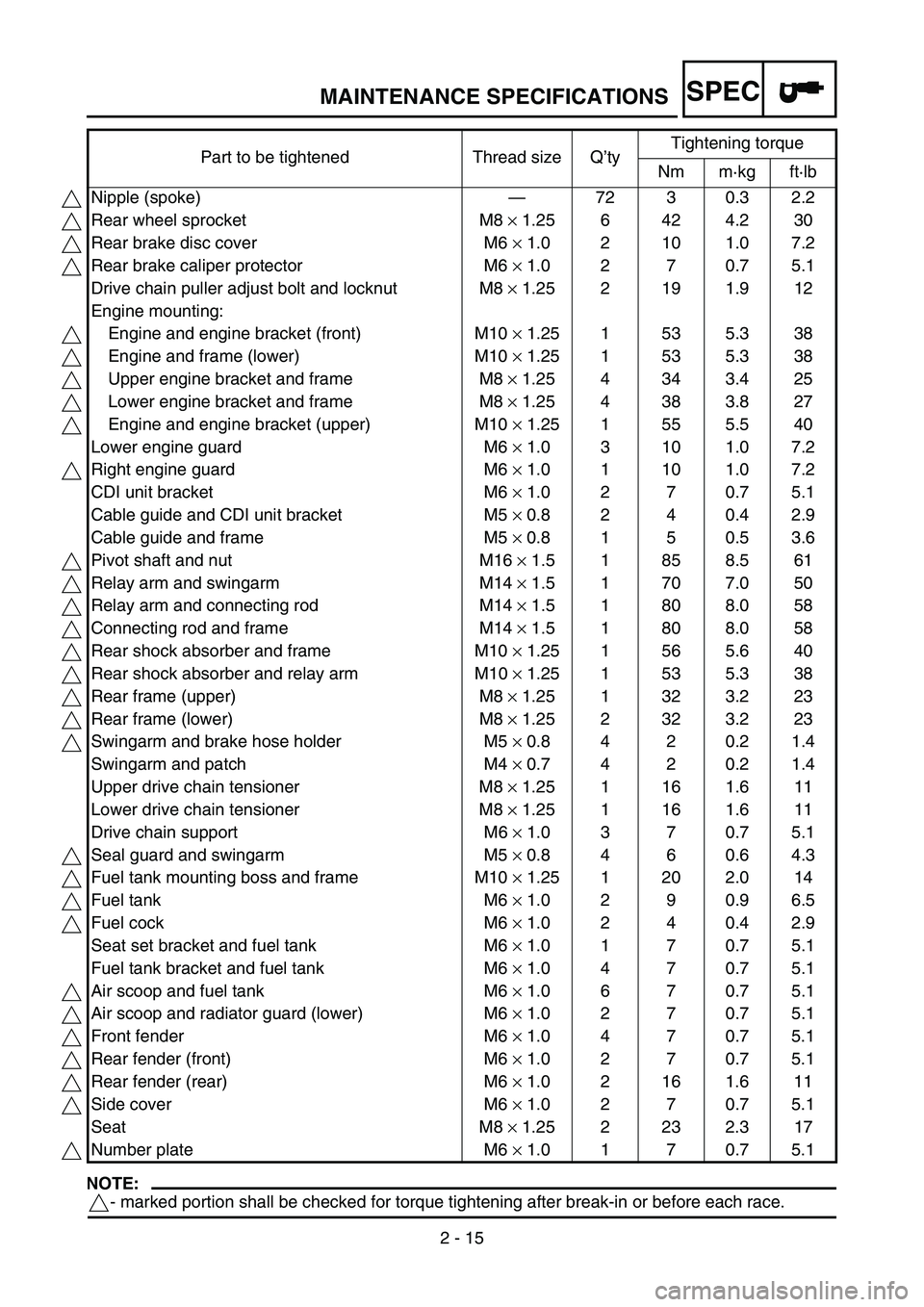

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race.Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Nipple (spoke)—72 3 0.3 2.2

Rear wheel sprocket M8 × 1.25 6 42 4.2 30

Rear brake disc cover M6 × 1.0 2 10 1.0 7.2

Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 19 1.9 12

Engine mounting:

Engine and engine bracket (front) M10 × 1.25 1 53 5.3 38

Engine and frame (lower) M10 × 1.25 1 53 5.3 38

Upper engine bracket and frame M8 × 1.25 4 34 3.4 25

Lower engine bracket and frame M8 × 1.25 4 38 3.8 27

Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

Lower engine guard M6 × 1.0 3 10 1.0 7.2

Right engine guard M6 × 1.0 1 10 1.0 7.2

CDI unit bracket M6 × 1.0 2 7 0.7 5.1

Cable guide and CDI unit bracket M5 × 0.8 2 4 0.4 2.9

Cable guide and frame M5 × 0.8 1 5 0.5 3.6

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 70 7.0 50

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame (lower) M8 × 1.25 2 32 3.2 23

Swingarm and brake hose holder M5 × 0.8 4 2 0.2 1.4

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 16 1.6 11

Lower drive chain tensioner M8 × 1.25 1 16 1.6 11

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank mounting boss and frame M10 × 1.25 1 20 2.0 14

Fuel tank M6 × 1.0 2 9 0.9 6.5

Fuel cock M6 × 1.0 2 4 0.4 2.9

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator guard (lower) M6 × 1.0 2 7 0.7 5.1

Front fender M6 × 1.0 4 7 0.7 5.1

Rear fender (front) M6 × 1.0 2 7 0.7 5.1

Rear fender (rear) M6 × 1.0 2 16 1.6 11

Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 23 2.3 17

Number plate M6 × 1.0 1 7 0.7 5.1

MAINTENANCE SPECIFICATIONS

Page 146 of 676

2 - 20

SPECCABLE ROUTING DIAGRAM

EC240000

CABLE ROUTING DIAGRAM

1Fuel tank breather hose

2Radiator hose 1

3Connector cover

4Cylinder head breather hose

5Radiator hose 4

6Clutch cable

7Throttle position sensor lead

8Carburetor breather hose

9Upper engine bracket0Hot starter cable

AFuel hose

BCarburetor overflow hose

Page 148 of 676

2 - 21

SPEC

ÈInsert the end of the fuel tank breather hose into

the hole in the steering stem.

ÉInstall the connector cover so that it does not

come in between the radiator hose 1 and radia-

tor.

ÊAligh the paint mark on the cylinder head

breather hose with the front end of the hose

guide.

ËPass the cylinder head breather hose on the out-

side of the radiator hose 1 and then between the

radiator 4 and frame.ÌPass the clutch cable through the cable guide.

ÍPass the clutch cable in front of the radiator

mounting boss.

ÎPass the fuel hose between the hot starter cable

and throttle position sensor lead.

ÏPass the carburetor breater hoses so that they

are not pinched between the upper engine

bracket and carburetor.

ÐPass the carburetor breather hoses and over-

flow hose so that all there hoses do not contact

the rear shock absorber.

CABLE ROUTING DIAGRAM

Page 161 of 676

3 - 2

INSP

ADJ

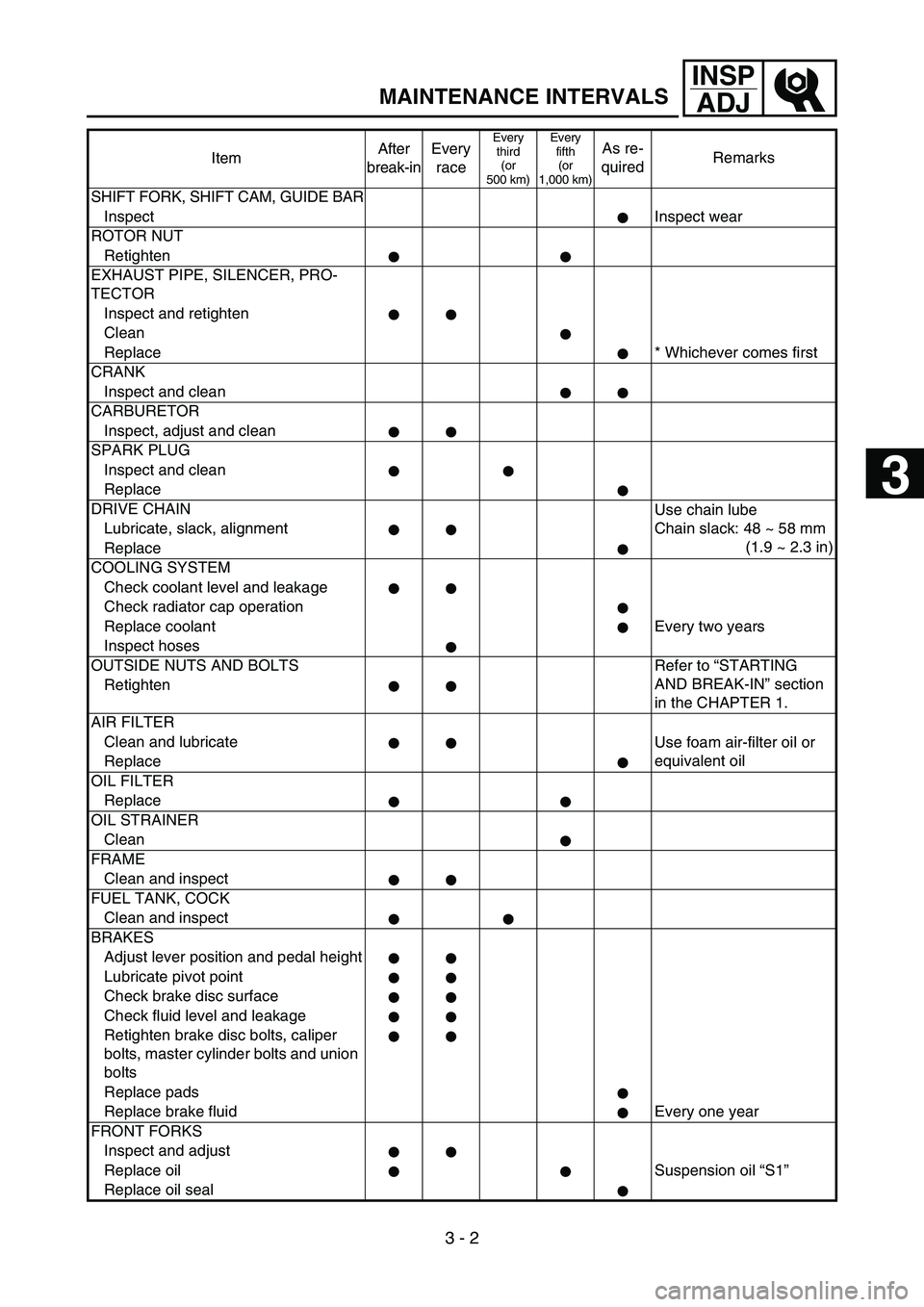

MAINTENANCE INTERVALS

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectInspect wear

ROTOR NUT

Retighten

EXHAUST PIPE, SILENCER, PRO-

TECTOR

Inspect and retighten

Clean

Replace * Whichever comes first

CRANK

Inspect and clean

CARBURETOR

Inspect, adjust and clean

SPARK PLUG

Inspect and clean

Replace

DRIVE CHAIN

Use chain lube

Chain slack: 48 ~ 58 mm

(1.9 ~ 2.3 in) Lubricate, slack, alignment

Replace

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant Every two years

Inspect hoses

OUTSIDE NUTS AND BOLTS Refer to “STARTING

AND BREAK-IN” section

in the CHAPTER 1. Retighten

AIR FILTER

Clean and lubricate

Use foam air-filter oil or

equivalent oil

Replace

OIL FILTER

Replace

OIL STRAINER

Clean

FRAME

Clean and inspect

FUEL TANK, COCK

Clean and inspect

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid Every one year

FRONT FORKS

Inspect and adjust

Replace oil Suspension oil “S1”

Replace oil sealItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

3