ABS YAMAHA YZ250F 2008 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ250F, Model: YAMAHA YZ250F 2008Pages: 192, PDF-Größe: 7.03 MB

Page 10 of 192

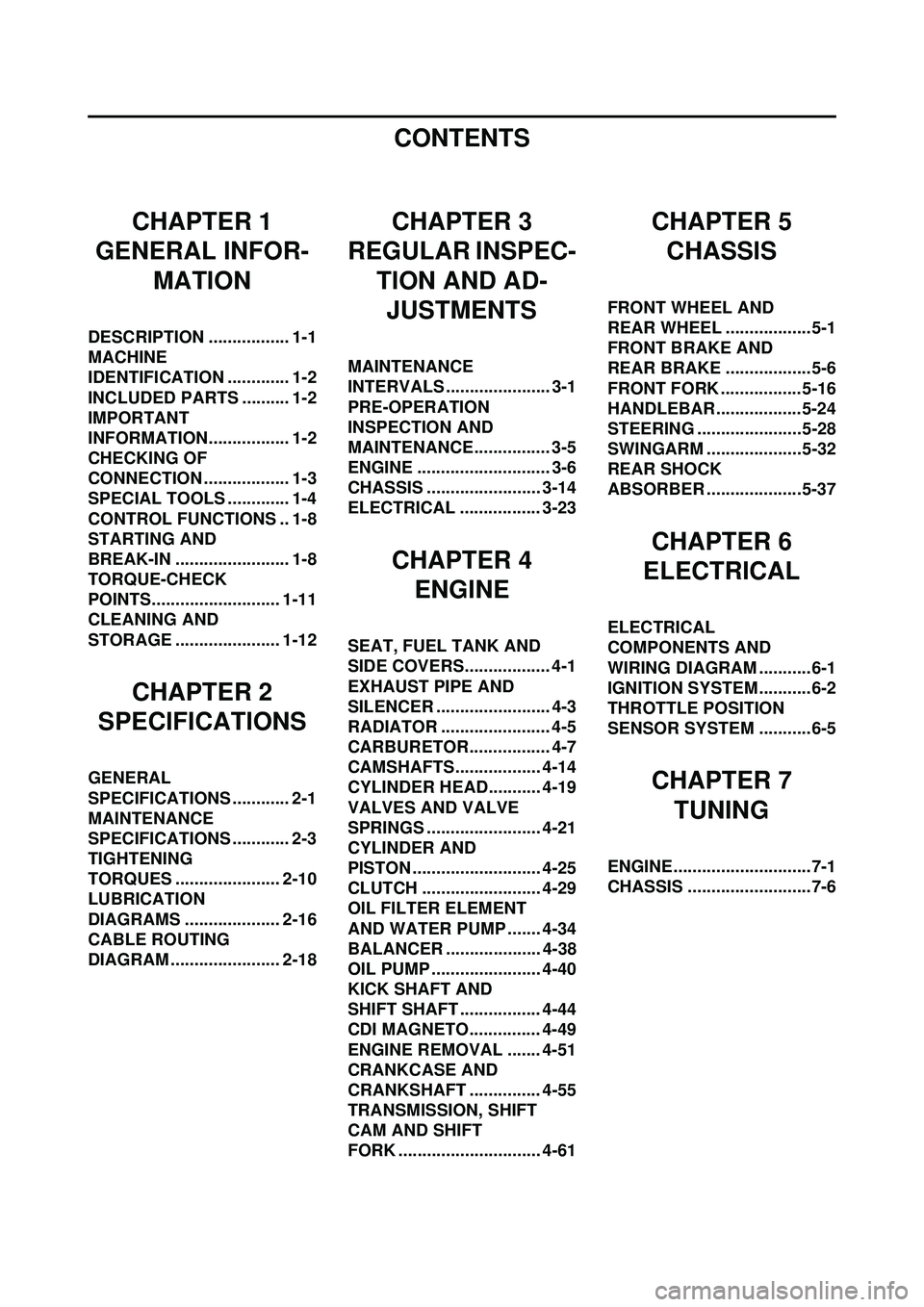

CONTENTS

CHAPTER 1

GENERAL INFOR-

MATION

DESCRIPTION ................. 1-1

MACHINE

IDENTIFICATION ............. 1-2

INCLUDED PARTS .......... 1-2

IMPORTANT

INFORMATION................. 1-2

CHECKING OF

CONNECTION .................. 1-3

SPECIAL TOOLS ............. 1-4

CONTROL FUNCTIONS .. 1-8

STARTING AND

BREAK-IN ........................ 1-8

TORQUE-CHECK

POINTS........................... 1-11

CLEANING AND

STORAGE ...................... 1-12

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-10

LUBRICATION

DIAGRAMS .................... 2-16

CABLE ROUTING

DIAGRAM ....................... 2-18

CHAPTER 3

REGULAR INSPEC-

TION AND AD-JUSTMENTS

MAINTENANCE

INTERVALS ...................... 3-1

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-5

ENGINE ............................ 3-6

CHASSIS ........................ 3-14

ELECTRICAL ................. 3-23

CHAPTER 4 ENGINE

SEAT, FUEL TANK AND

SIDE COVERS.................. 4-1

EXHAUST PIPE AND

SILENCER ........................ 4-3

RADIATOR ....................... 4-5

CARBURETOR................. 4-7

CAMSHAFTS.................. 4-14

CYLINDER HEAD........... 4-19

VALVES AND VALVE

SPRINGS ........................ 4-21

CYLINDER AND

PISTON ........................... 4-25

CLUTCH ......................... 4-29

OIL FILTER ELEMENT

AND WATER PUMP ....... 4-34

BALANCER .................... 4-38

OIL PUMP ....................... 4-40

KICK SHAFT AND

SHIFT SHAFT ................. 4-44

CDI MAGNETO............... 4-49

ENGINE REMOVAL ....... 4-51

CRANKCASE AND

CRANKSHAFT ............... 4-55

TRANSMISSION, SHIFT

CAM AND SHIFT

FORK .............................. 4-61

CHAPTER 5CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................5-1

FRONT BRAKE AND

REAR BRAKE ..................5-6

FRONT FORK ................. 5-16

HANDLEBAR..................5-24

STEERING ......................5-28

SWINGARM ....................5-32

REAR SHOCK

ABSORBER ....................5-37

CHAPTER 6

ELECTRICAL

ELECTRICAL

COMPONENTS AND

WIRING DIAGRAM ...........6-1

IGNITION SYSTEM...........6-2

THROTTLE POSITION

SENSOR SYSTEM ...........6-5

CHAPTER 7

TUNING

ENGINE.............................7-1

CHASSIS ..........................7-6

Page 21 of 192

1-11

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Concerning the tightening torque, refer to "TIGHTENING TORQUES" section in the CHAPTER 2.

Frame constructionFrame to rear frame

Combined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Installation of rear shock absorber Rear shock absorber to frame

Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle

Tightening of axle holder

Rear Tightening of wheel axle Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel system Fuel tank to fuel cock

Lubrication system Tightening of oil hose clamp

Page 24 of 192

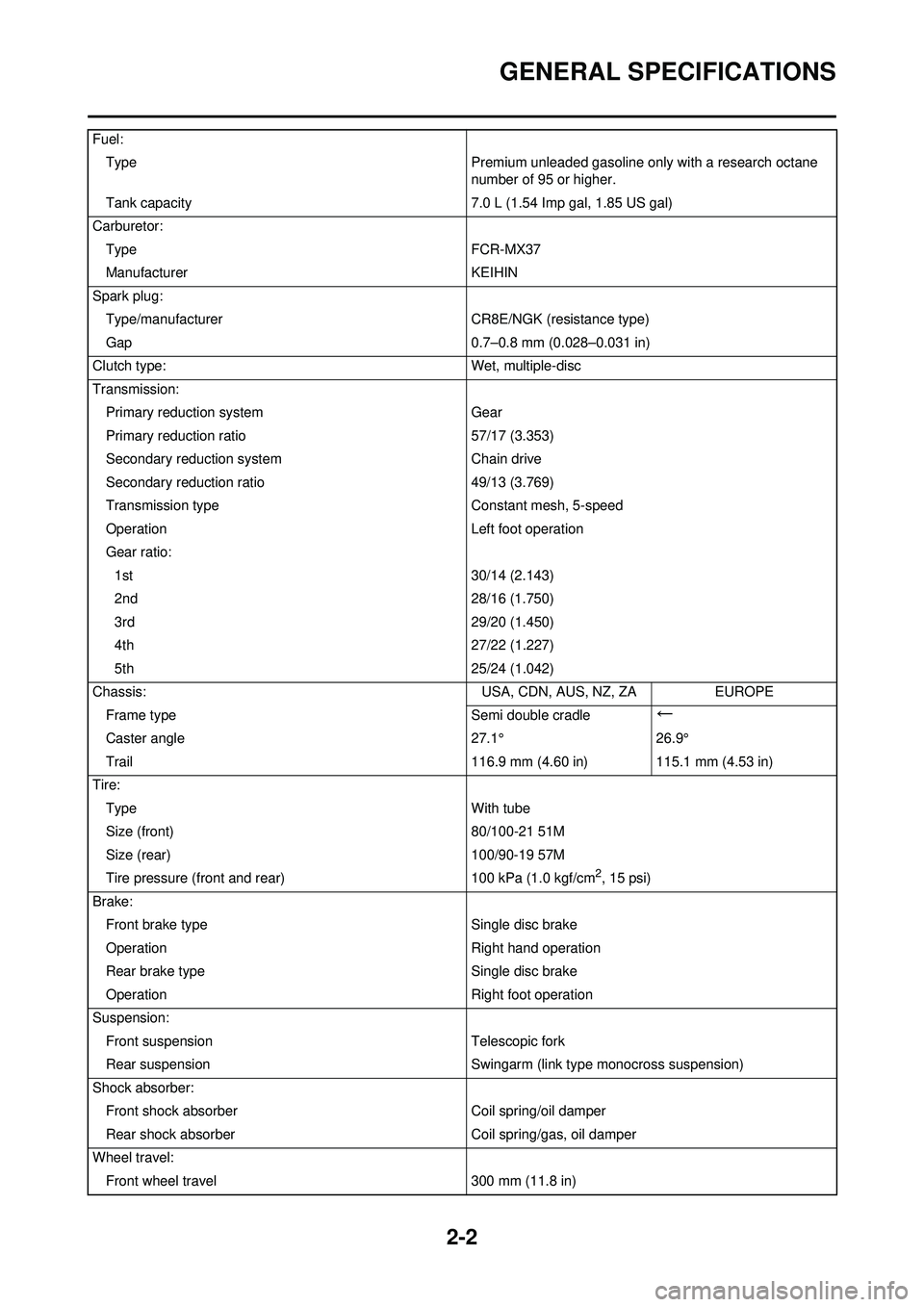

2-2

GENERAL SPECIFICATIONS

Fuel:Type Premium unleaded gasoline only with a research octane

number of 95 or higher.

Tank capacity 7.0 L (1.54 Imp gal, 1.85 US gal)

Carburetor: Type FCR-MX37

Manufacturer KEIHIN

Spark plug: Type/manufacturer CR8E/NGK (resistance type)

Gap 0.7–0.8 mm (0.028–0.031 in)

Clutch type: Wet, multiple-disc

Transmission: Primary reduction system Gear

Primary reduction ratio 57/17 (3.353)

Secondary reduction system Chain drive

Secondary reduction ratio 49/13 (3.769)

Transmission type Constant mesh, 5-speed

Operation Left foot operation

Gear ratio: 1st 30/14 (2.143)

2nd 28/16 (1.750)

3rd 29/20 (1.450)

4th 27/22 (1.227)

5th 25/24 (1.042)

Chassis: USA, CDN, AUS, NZ, ZAEUROPE

Frame type Semi double cradle

←

Caster angle27.1°26.9°

Trail 116.9 mm (4.60 in) 115.1 mm (4.53 in)

Tire: Type With tube

Size (front) 80/100-21 51M

Size (rear) 100/90-19 57M

Tire pressure (front and rear) 100 kPa (1.0 kgf/cm

2, 15 psi)

Brake: Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension: Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber: Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel: Front wheel travel 300 mm (11.8 in)

Page 30 of 192

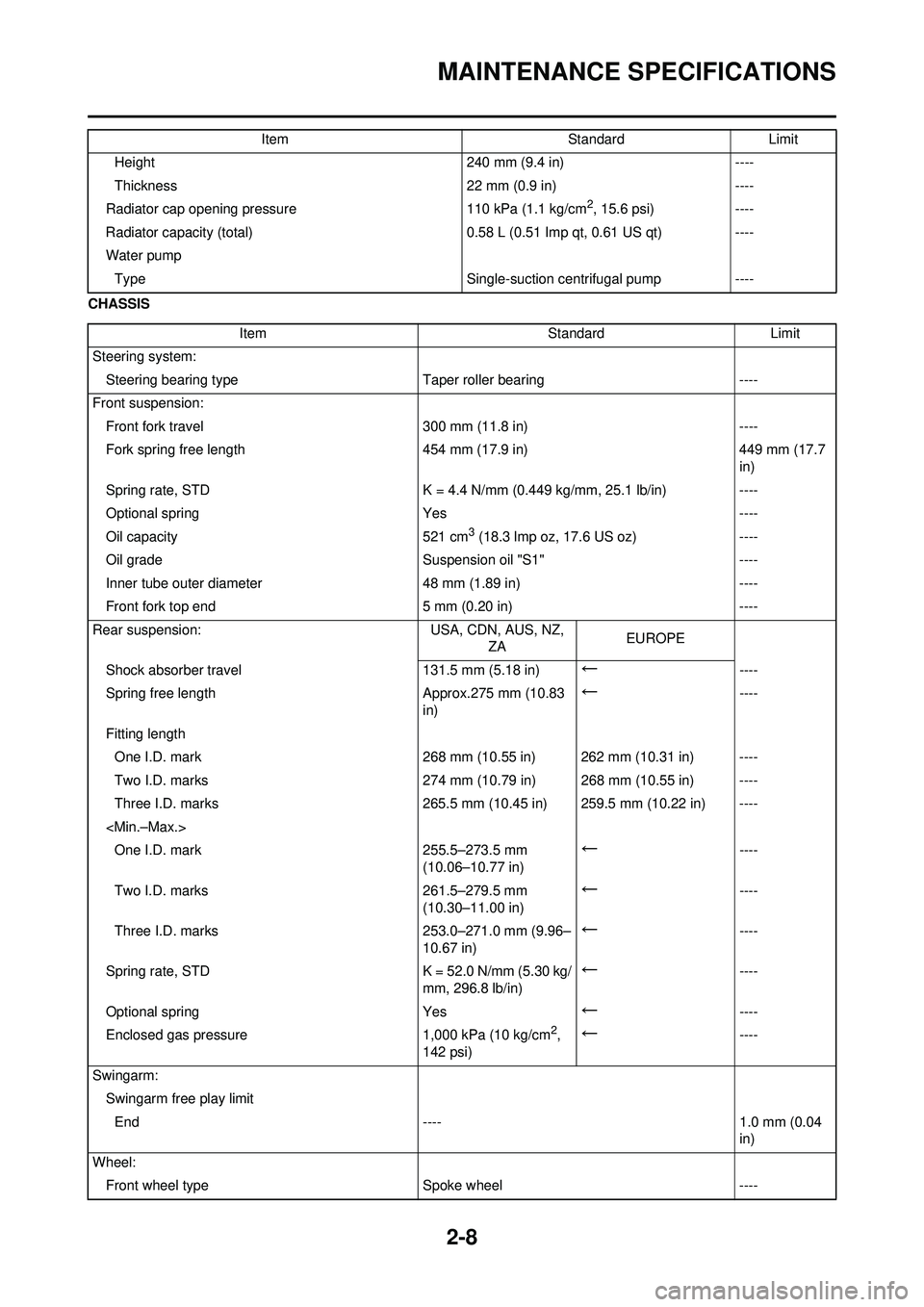

2-8

MAINTENANCE SPECIFICATIONS

CHASSISHeight

240 mm (9.4 in)----

Thickness 22 mm (0.9 in)----

Radiator cap opening pressure 110 kPa (1.1 kg/cm

2, 15.6 psi)----

Radiator capacity (total) 0.58 L (0.51 Imp qt, 0.61 US qt)----

Water pump Type Single-suction centrifugal pump----

Item

StandardLimit

Item StandardLimit

Steering system: Steering bearing type Taper roller bearing----

Front suspension: Front fork travel 300 mm (11.8 in)----

Fork spring free length 454 mm (17.9 in)449 mm (17.7

in)

Spring rate, STD K = 4.4 N/mm (0.449 kg/mm, 25.1 lb/in)----

Optional spring Yes----

Oil capacity 521 cm

3 (18.3 lmp oz, 17.6 US oz)----

Oil grade Suspension oil "S1"----

Inner tube outer diameter 48 mm (1.89 in)----

Front fork top end 5 mm (0.20 in)----

Rear suspension: USA, CDN, AUS, NZ,

ZA EUROPE

Shock absorber travel 131.5 mm (5.18 in)

←----

Spring free length Approx.275 mm (10.83 in)

←----

Fitting length One I.D. mark 268 mm (10.55 in) 262 mm (10.31 in) ----

Two I.D. marks 274 mm (10.79 in) 268 mm (10.55 in) ----

Three I.D. marks 265.5 mm (10.45 in) 259.5 mm (10.22 in) ----

←----

Two I.D. marks 261.5–279.5 mm

(10.30–11.00 in)

←----

Three I.D. marks 253.0–271.0 mm (9.96–

10.67 in)

←----

Spring rate, STD K = 52.0 N/mm (5.30 kg/ mm, 296.8 lb/in)

←----

Optional spring Yes

←----

Enclosed gas pressure 1,000 kPa (10 kg/cm

2,

142 psi)←----

Swingarm: Swingarm free play limitEnd ---- 1.0 mm (0.04 in)

Wheel: Front wheel type Spoke wheel----

Page 35 of 192

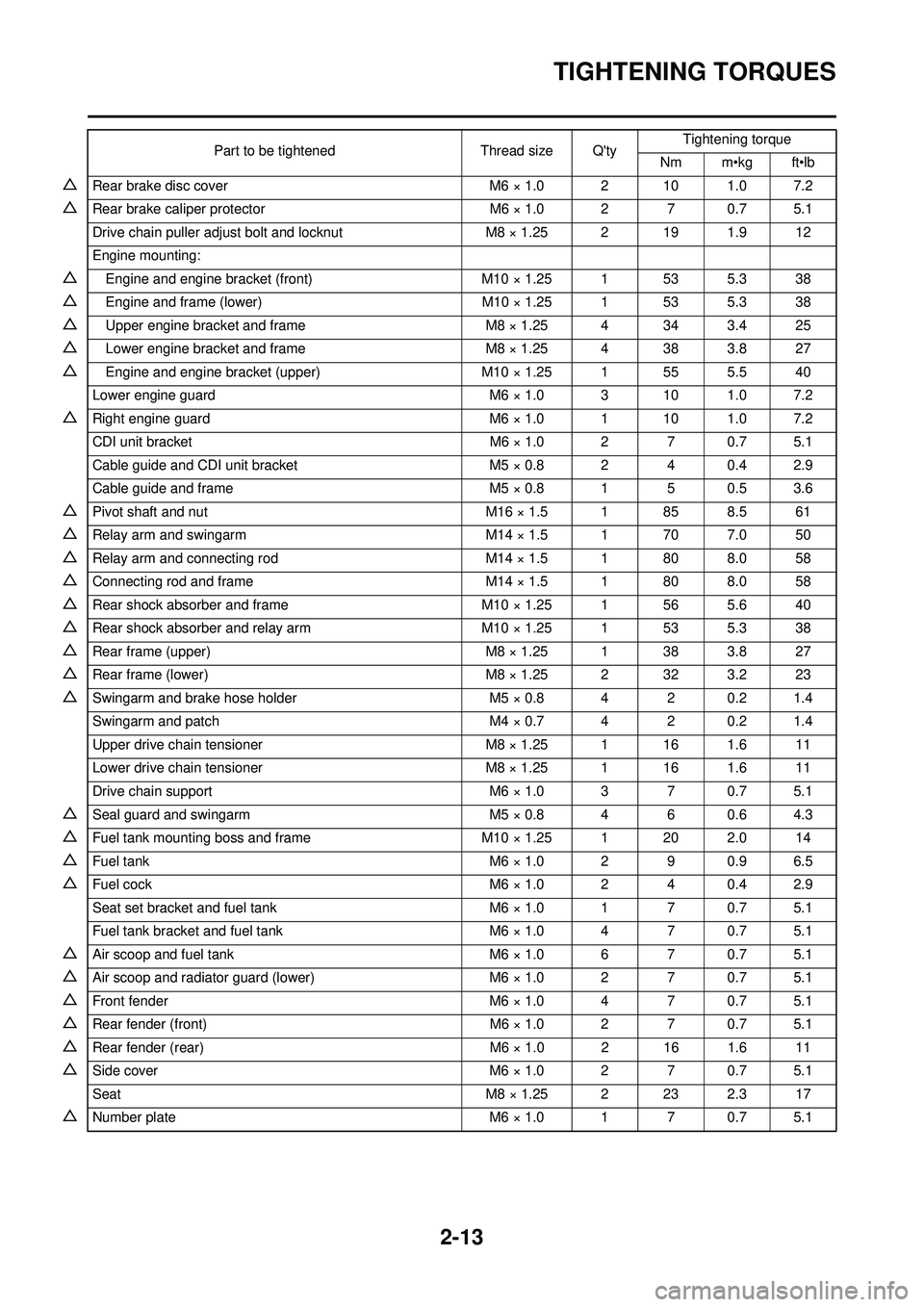

2-13

TIGHTENING TORQUES

△Rear brake disc coverM6 × 1.0 2 10 1.0 7.2

△Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 19 1.9 12

Engine mounting:

△Engine and engine bracket (front) M10 × 1.25 1 53 5.3 38

△Engine and frame (lower) M10 × 1.25 1 53 5.3 38

△Upper engine bracket and frame M8 × 1.25 4 34 3.4 25

△Lower engine bracket and frameM8 × 1.25 4 38 3.8 27

△Engine and engine bracket (upper)M10 × 1.25 1 55 5.5 40

Lower engine guard M6 × 1.0 3 10 1.0 7.2

△Right engine guardM6 × 1.0 1 10 1.0 7.2

CDI unit bracket M6 × 1.0 2 7 0.7 5.1

Cable guide and CDI unit bracket M5 × 0.8 2 4 0.4 2.9

Cable guide and frame M5 × 0.8 1 5 0.5 3.6

△Pivot shaft and nutM16 × 1.5 1 85 8.5 61

△Relay arm and swingarmM14 × 1.5 1 70 7.0 50

△Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

△Connecting rod and frame M14 × 1.5 1 80 8.0 58

△Rear shock absorber and frameM10 × 1.25 1 56 5.6 40

△Rear shock absorber and relay armM10 × 1.25 1 53 5.3 38

△Rear frame (upper) M8 × 1.25 1 38 3.8 27

△Rear frame (lower) M8 × 1.25 2 32 3.2 23

△Swingarm and brake hose holder M5 × 0.8 4 2 0.2 1.4

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 16 1.6 11

Lower drive chain tensioner M8 × 1.25 1 16 1.6 11

Drive chain support M6 × 1.0 3 7 0.7 5.1

△Seal guard and swingarmM5 × 0.8 4 6 0.6 4.3

△Fuel tank mounting boss and frameM10 × 1.25 1 20 2.0 14

△Fuel tank M6 × 1.0 2 9 0.9 6.5

△Fuel cockM6 × 1.0 2 4 0.4 2.9

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

△Air scoop and fuel tankM6 × 1.0 6 7 0.7 5.1

△Air scoop and radiator guard (lower) M6 × 1.0 2 7 0.7 5.1

△Front fenderM6 × 1.0 4 7 0.7 5.1

△Rear fender (front) M6 × 1.0 2 7 0.7 5.1

△Rear fender (rear) M6 × 1.0 2 16 1.6 11

△Side coverM6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 23 2.3 17

△Number plate M6 × 1.0 1 7 0.7 5.1

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 41 of 192

2-19

CABLE ROUTING DIAGRAM

F. Pass the clutch cable in front of the radiator mounting boss.

G. Pass the fuel hose between the hot starter cable and throttle po-

sition sensor lead.

H. Pass the carburetor breater hos- es so that they are not pinched

between the upper engine

bracket and carburetor.

I. Pass the carburetor breather

hoses and overflow hose so that

all there hoses do not contact

the rear shock absorber.

Page 45 of 192

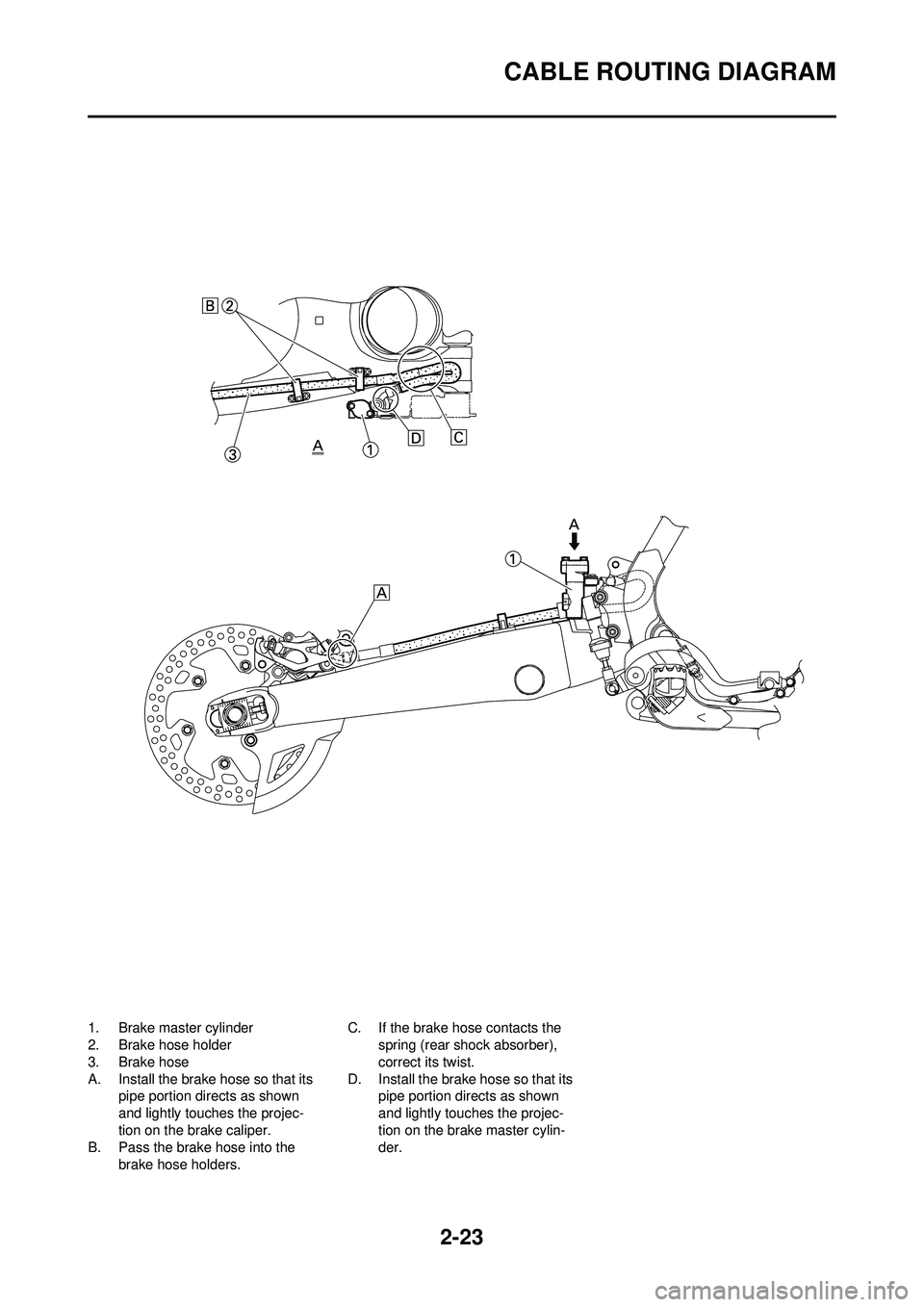

2-23

CABLE ROUTING DIAGRAM

1. Brake master cylinder

2. Brake hose holder

3. Brake hose

A. Install the brake hose so that its pipe portion directs as shown

and lightly touches the projec-

tion on the brake caliper.

B. Pass the brake hose into the

brake hose holders. C. If the brake hose contacts the

spring (rear shock absorber),

correct its twist.

D. Install the brake hose so that its pipe portion directs as shown

and lightly touches the projec-

tion on the brake master cylin-

der.

Page 49 of 192

3-3

MAINTENANCE INTERVALS

OIL STRAINERClean

●

FRAMEClean and inspect

●●

FUEL TANK, COCKClean and inspect

●●

BRAKESAdjust lever position and pedal

height

●●

Lubricate pivot point●●

Check brake disc surface●●

Check fluid level and leakage●●

Retighten brake disc bolts, cali-

per bolts, master cylinder bolts

and union bolts●●

Replace pads●

Replace brake fluid●Every one year

FRONT FORKS Inspect and adjust

●●

Replace oil●●Suspension oil "S1"

Replace oil seal

●

FRONT FORK OIL SEAL AND

DUST SEAL Clean and lube

●●Lithium base grease

PROTECTOR GUIDE Replace

●

REAR SHOCK ABSORBERInspect and adjust

●●

Lube●

(After rain

ride)

●Molybdenum disulfide grease

Replace spring seat

●Every one year

Retighten

●●

DRIVE CHAIN GUIDE AND

ROLLERS Inspect

●●

SWINGARMInspect, lube and retighten

●●Molybdenum disulfide grease

RELAY ARM, CONNECTING

ROD Inspect, lube and retighten

●●Molybdenum disulfide grease

STEERING HEAD Inspect free play and retighten

●●

Clean and lube●Lithium base grease

Replace bearing

●

Item After

break-

in Every

race

Every third

(or 500 km) Every

fifth (or 1,000 km)

As re-

quired Remarks

Page 51 of 192

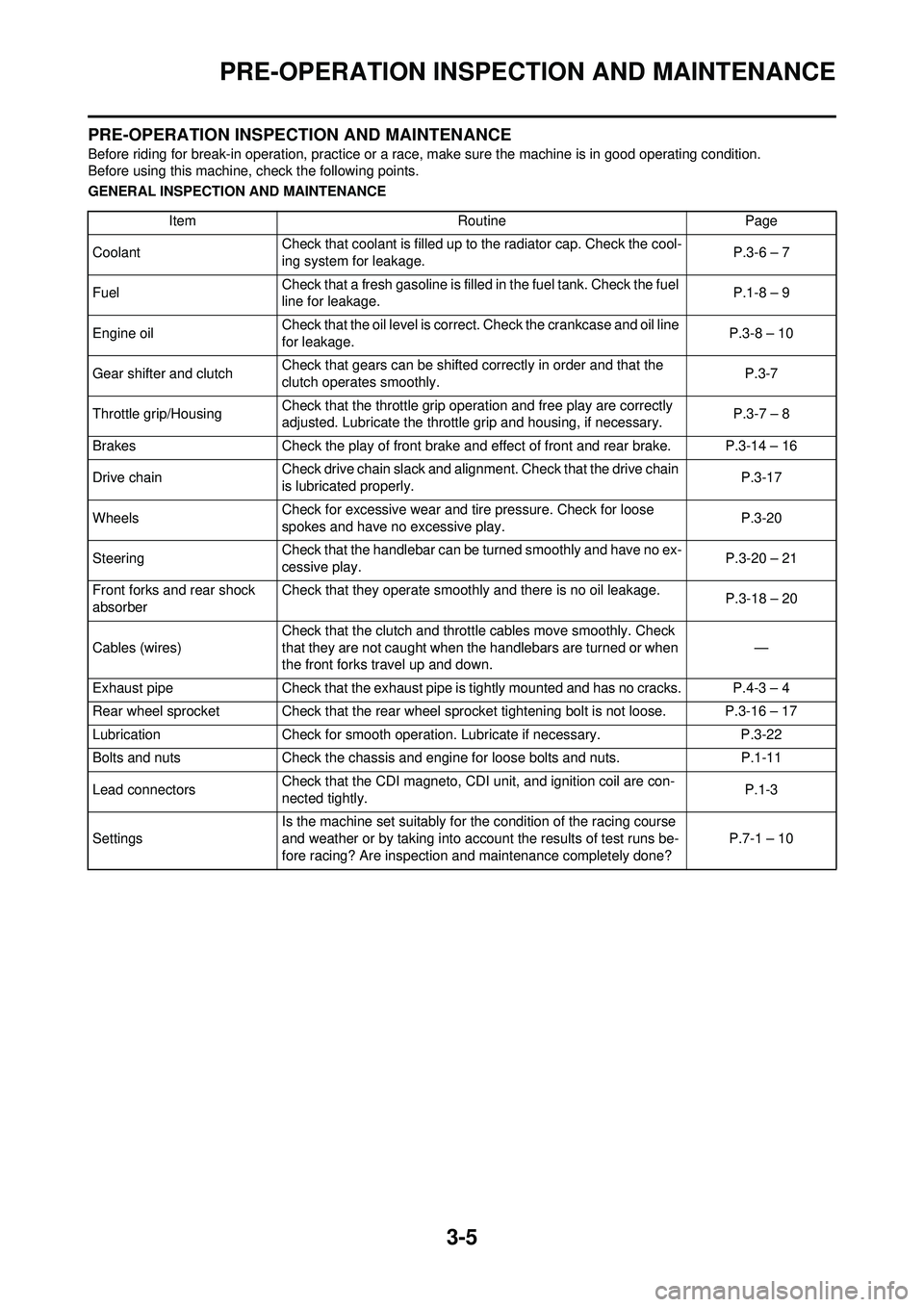

3-5

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCEItem RoutinePage

Coolant Check that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage. P.3-6 – 7

Fuel Check that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage. P.1-8 – 9

Engine oil Check that the oil level is correct. Check the crankcase and oil line

for leakage. P.3-8 – 10

Gear shifter and clutch Check that gears can be shifted correctly in order and that the

clutch operates smoothly. P.3-7

Throttle grip/Housing Check that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary. P.3-7 – 8

Brakes Check the play of front brake and effect of front and rear brake. P.3-14 – 16

Drive chain Check drive chain slack and alignment. Check that the drive chain

is lubricated properly. P.3-17

Wheels Check for excessive wear and tire pressure. Check for loose

spokes and have no excessive play. P.3-20

Steering Check that the handlebar can be turned smoothly and have no ex-

cessive play. P.3-20 – 21

Front forks and rear shock

absorber Check that they operate smoothly and there is no oil leakage.

P.3-18 – 20

Cables (wires) Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.

—

Exhaust pipe Check that the exhaust pipe is tightly mounted and has no cracks. P.4-3 – 4

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-16 – 17

Lubrication Check for smooth operation. Lubricate if necessary. P.3-22

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-11

Lead connectors Check that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly. P.1-3

Settings Is the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs be-

fore racing? Are inspection and maintenance completely done?

P.7-1 – 10

Page 64 of 192

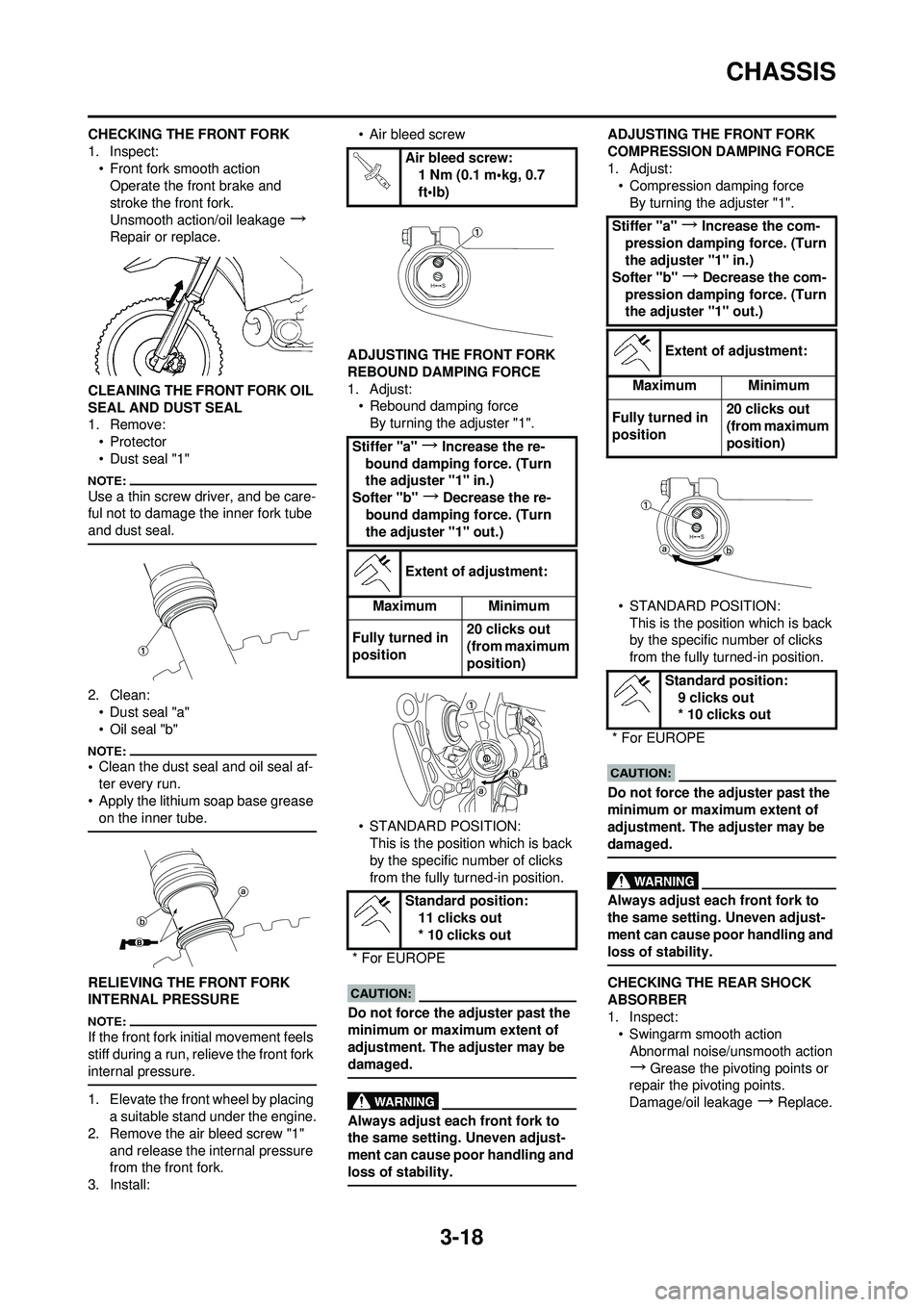

3-18

CHASSIS

CHECKING THE FRONT FORK

1. Inspect:• Front fork smooth actionOperate the front brake and

stroke the front fork.

Unsmooth action/oil leakage

→

Repair or replace.

CLEANING THE FRONT FORK OIL

SEAL AND DUST SEAL

1. Remove: •Protector

• Dust seal "1"

Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:• Dust seal "a"

•Oil seal "b"

•Clean the dust seal and oil seal af-

ter every run.

• Apply the lithium soap base grease

on the inner tube.

RELIEVING THE FRONT FORK

INTERNAL PRESSURE

If the front fork initial movement feels

stiff during a run, relieve the front fork

internal pressure.

1. Elevate the front wheel by placing a suitable stand under the engine.

2. Remove the air bleed screw "1" and release the internal pressure

from the front fork.

3. Install: • Air bleed screw

ADJUSTING THE FRONT FORK

REBOUND DAMPING FORCE

1. Adjust: • Rebound damping force

By turning the adjuster "1".

• STANDARD POSITION: This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

ADJUSTING THE FRONT FORK

COMPRESSION DAMPING FORCE

1. Adjust:• Compression damping force

By turning the adjuster "1".

• STANDARD POSITION: This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:• Swingarm smooth action

Abnormal noise/unsmooth action

→Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage

→Replace.

Air bleed screw:

1 Nm (0.1 m•kg, 0.7

ft•lb)

Stiffer "a"

→Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b"

→Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 11 clicks out

* 10 clicks out

* For EUROPE

Stiffer "a" →Increase the com-

pression damping force. (Turn

the adjuster "1" in.)

Softer "b"

→Decrease the com-

pression damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position 20 clicks out

(from maximum

position)

Standard position: 9 clicks out

* 10 clicks out

* For EUROPE