brake fluid YAMAHA YZ250F 2008 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ250F, Model: YAMAHA YZ250F 2008Pages: 192, PDF-Größe: 7.03 MB

Page 8 of 192

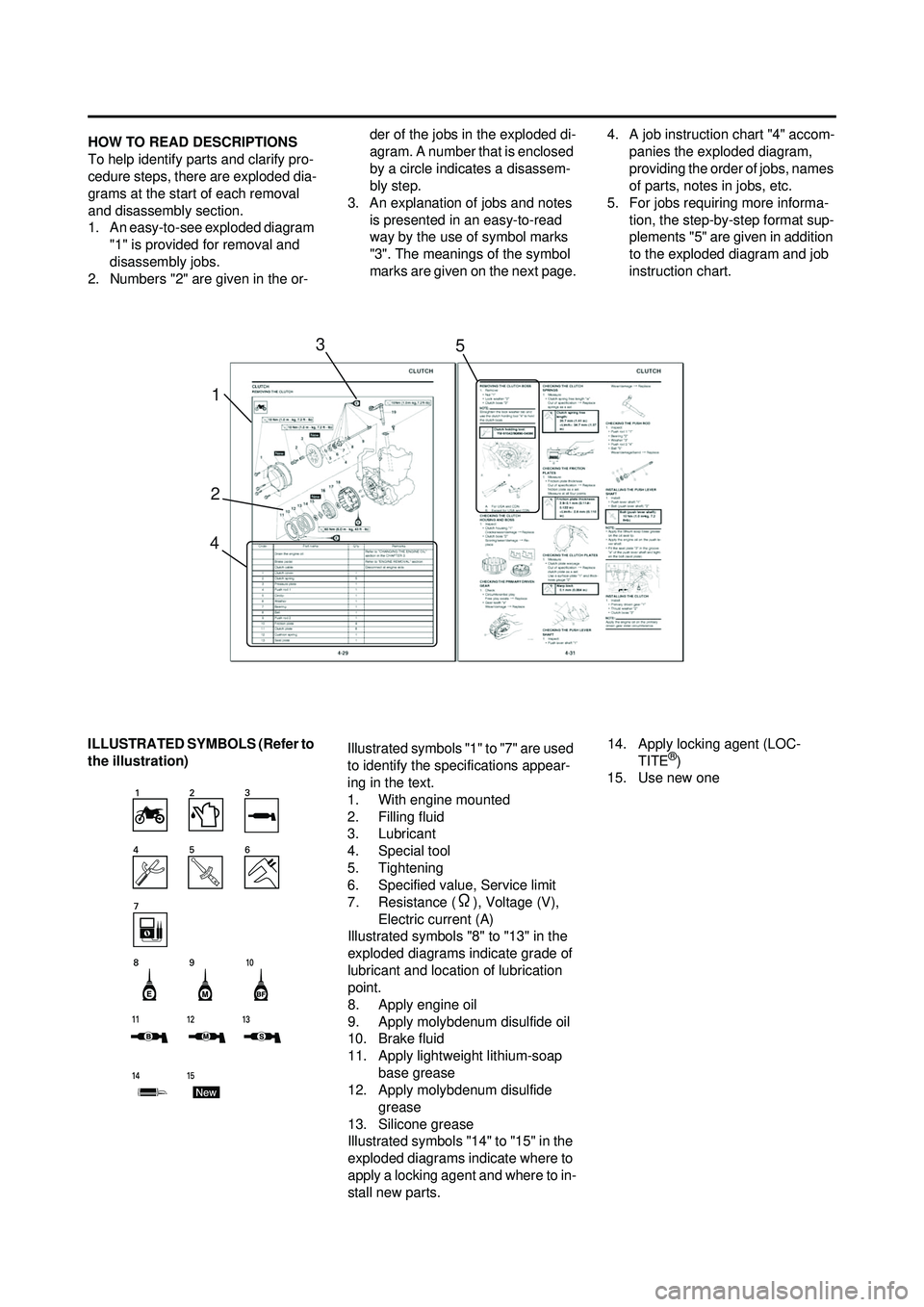

HOW TO READ DESCRIPTIONS

To help identify parts and clarify pro-

cedure steps, there are exploded dia-

grams at the start of each removal

and disassembly section.

1. An easy-to-see exploded diagram "1" is provided for removal and

disassembly jobs.

2. Numbers "2" are given in the or- der of the jobs in the exploded di-

agram. A number that is enclosed

by a circle indicates a disassem-

bly step.

3. An explanation of jobs and notes is presented in an easy-to-read

way by the use of symbol marks

"3". The meanings of the symbol

marks are given on the next page. 4. A job instruction chart "4" accom-

panies the exploded diagram,

providing the order of jobs, names

of parts, notes in jobs, etc.

5. For jobs requiring more informa- tion, the step-by-step format sup-

plements "5" are given in addition

to the exploded diagram and job

instruction chart.

ILLUSTRATED SYMBOLS (Refer to

the illustration) Illustrated symbols "1" to "7" are used

to identify the specifications appear-

ing in the text.

1. With engine mounted

2. Filling fluid

3. Lubricant

4. Special tool

5. Tightening

6. Specified value, Service limit

7. Resistance (

Ω), Voltage (V),

Electric current (A)

Illustrated symbols "8" to "13" in the

exploded diagrams indicate grade of

lubricant and location of lubrication

point.

8. Apply engine oil

9. Apply molybdenum disulfide oil

10. Brake fluid

11. Apply lightweight lithium-soap

base grease

12. Apply molybdenum disulfide

grease

13. Silicone grease

Illustrated symbols "14" to "15" in the

exploded diagrams indicate where to

apply a locking agent and where to in-

stall new parts. 14. Apply locking agent (LOC-

TITE

®)

15. Use new one

1

2 3

4 5

Page 31 of 192

2-9

MAINTENANCE SPECIFICATIONS

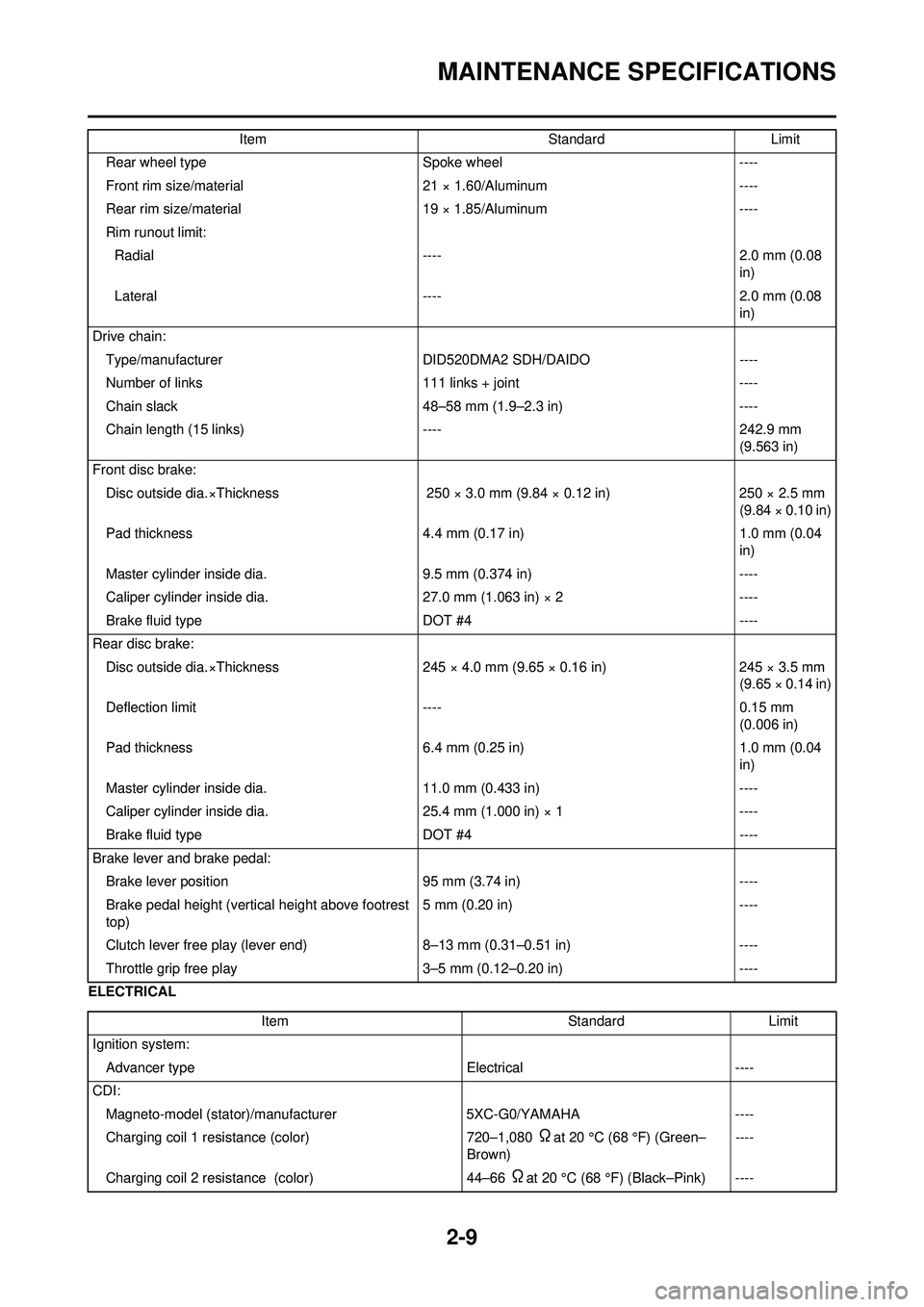

ELECTRICALRear wheel type

Spoke wheel----

Front rim size/material 21 × 1.60/Aluminum----

Rear rim size/material 19 × 1.85/Aluminum----

Rim runout limit: Radial ---- 2.0 mm (0.08

in)

Lateral ---- 2.0 mm (0.08

in)

Drive chain: Type/manufacturer DID520DMA2 SDH/DAIDO ----

Number of links 111 links + joint----

Chain slack 48–58 mm (1.9–2.3 in)----

Chain length (15 links) ----242.9 mm

(9.563 in)

Front disc brake: Disc outside dia.×Thickness 250 × 3.0 mm (9.84 × 0.12 in)250 × 2.5 mm

(9.84 × 0.10 in)

Pad thickness 4.4 mm (0.17 in)1.0 mm (0.04

in)

Master cylinder inside dia. 9.5 mm (0.374 in)----

Caliper cylinder inside dia. 27.0 mm (1.063 in) × 2----

Brake fluid type DOT #4----

Rear disc brake: Disc outside dia.×Thickness 245 × 4.0 mm (9.65 × 0.16 in)245 × 3.5 mm

(9.65 × 0.14 in)

Deflection limit ----0.15 mm

(0.006 in)

Pad thickness 6.4 mm (0.25 in)1.0 mm (0.04

in)

Master cylinder inside dia. 11.0 mm (0.433 in)----

Caliper cylinder inside dia. 25.4 mm (1.000 in) × 1----

Brake fluid type DOT #4----

Brake lever and brake pedal: Brake lever position 95 mm (3.74 in)----

Brake pedal height (vertical height above footrest

top) 5 mm (0.20 in)

----

Clutch lever free play (lever end) 8–13 mm (0.31–0.51 in)----

Throttle grip free play 3–5 mm (0.12–0.20 in)----

Item

StandardLimit

Item StandardLimit

Ignition system: Advancer type Electrical----

CDI: Magneto-model (stator)/manufacturer 5XC-G0/YAMAHA----

Charging coil 1 resistance (color) 720–1,080

Ωat 20 °C (68 °F) (Green–

Brown) ----

Charging coil 2 resistance (color) 44–66

Ωat 20 °C (68 °F) (Black–Pink) ----

Page 49 of 192

3-3

MAINTENANCE INTERVALS

OIL STRAINERClean

●

FRAMEClean and inspect

●●

FUEL TANK, COCKClean and inspect

●●

BRAKESAdjust lever position and pedal

height

●●

Lubricate pivot point●●

Check brake disc surface●●

Check fluid level and leakage●●

Retighten brake disc bolts, cali-

per bolts, master cylinder bolts

and union bolts●●

Replace pads●

Replace brake fluid●Every one year

FRONT FORKS Inspect and adjust

●●

Replace oil●●Suspension oil "S1"

Replace oil seal

●

FRONT FORK OIL SEAL AND

DUST SEAL Clean and lube

●●Lithium base grease

PROTECTOR GUIDE Replace

●

REAR SHOCK ABSORBERInspect and adjust

●●

Lube●

(After rain

ride)

●Molybdenum disulfide grease

Replace spring seat

●Every one year

Retighten

●●

DRIVE CHAIN GUIDE AND

ROLLERS Inspect

●●

SWINGARMInspect, lube and retighten

●●Molybdenum disulfide grease

RELAY ARM, CONNECTING

ROD Inspect, lube and retighten

●●Molybdenum disulfide grease

STEERING HEAD Inspect free play and retighten

●●

Clean and lube●Lithium base grease

Replace bearing

●

Item After

break-

in Every

race

Every third

(or 500 km) Every

fifth (or 1,000 km)

As re-

quired Remarks

Page 60 of 192

3-14

CHASSIS

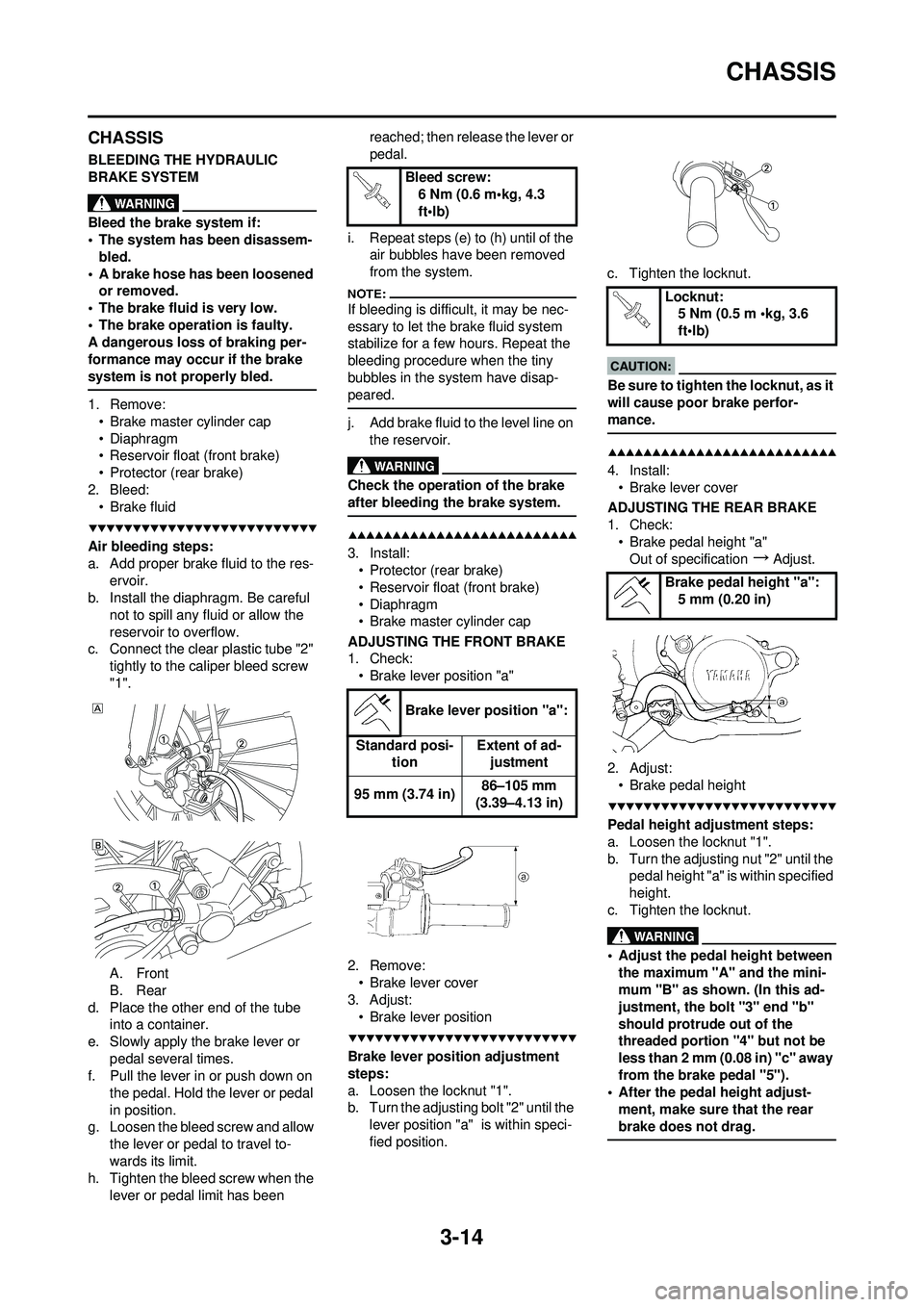

CHASSIS

BLEEDING THE HYDRAULIC

BRAKE SYSTEM

Bleed the brake system if:

• The system has been disassem-bled.

• A brake hose has been loosened or removed.

• The brake fluid is very low.

• The brake operation is faulty.

A dangerous loss of braking per-

formance may occur if the brake

system is not properly bled.

1. Remove: • Brake master cylinder cap

• Diaphragm

• Reservoir float (front brake)

• Protector (rear brake)

2. Bleed: • Brake fluid

Air bleeding steps:

a. Add proper brake fluid to the res-

ervoir.

b. Install the diaphragm. Be careful

not to spill any fluid or allow the

reservoir to overflow.

c. Connect the clear plastic tube "2"

tightly to the caliper bleed screw

"1".

A. Front

B. Rear

d. Place the other end of the tube into a container.

e. Slowly apply the brake lever or pedal several times.

f. Pull the lever in or push down on

the pedal. Hold the lever or pedal

in position.

g. Loosen the bleed screw and allow

the lever or pedal to travel to-

wards its limit.

h. Tighten the bleed screw when the

lever or pedal limit has been reached; then release the lever or

pedal.

i. Repeat steps (e) to (h) until of the air bubbles have been removed

from the system.

If bleeding is difficult, it may be nec-

essary to let the brake fluid system

stabilize for a few hours. Repeat the

bleeding procedure when the tiny

bubbles in the system have disap-

peared.

j. Add brake fluid to the level line on

the reservoir.

Check the operation of the brake

after bleeding the brake system.

3. Install:• Protector (rear brake)

• Reservoir float (front brake)

• Diaphragm

• Brake master cylinder cap

ADJUSTING THE FRONT BRAKE

1. Check: • Brake lever position "a"

2. Remove: • Brake lever cover

3. Adjust: • Brake lever position

Brake lever position adjustment

steps:

a. Loosen the locknut "1".

b. Turn the adjusting bolt "2" until the lever position "a" is within speci-

fied position. c. Tighten the locknut.

Be sure to tighten the locknut, as it

will cause poor brake perfor-

mance.

4. Install:

• Brake lever cover

ADJUSTING THE REAR BRAKE

1. Check: • Brake pedal height "a"Out of specification

→Adjust.

2. Adjust: • Brake pedal height

Pedal height adjustment steps:

a. Loosen the locknut "1".

b. Turn the adjusting nut "2" until the pedal height "a" is within specified

height.

c. Tighten the locknut.

• Adjust the pedal height between the maximum "A" and the mini-

mum "B" as shown. (In this ad-

justment, the bolt "3" end "b"

should protrude out of the

threaded portion "4" but not be

less than 2 mm (0.08 in) "c" away

from the brake pedal "5").

• After the pedal height adjust-

ment, make sure that the rear

brake does not drag.

Bleed screw: 6 Nm (0.6 m•kg, 4.3

ft•lb)

Brake lever position "a":

Standard posi- tion Extent of ad-

justment

95 mm (3.74 in) 86–105 mm

(3.39–4.13 in)

Locknut: 5 Nm (0.5 m •kg, 3.6

ft•lb)

Brake pedal height "a": 5 mm (0.20 in)

Page 61 of 192

3-15

CHASSIS

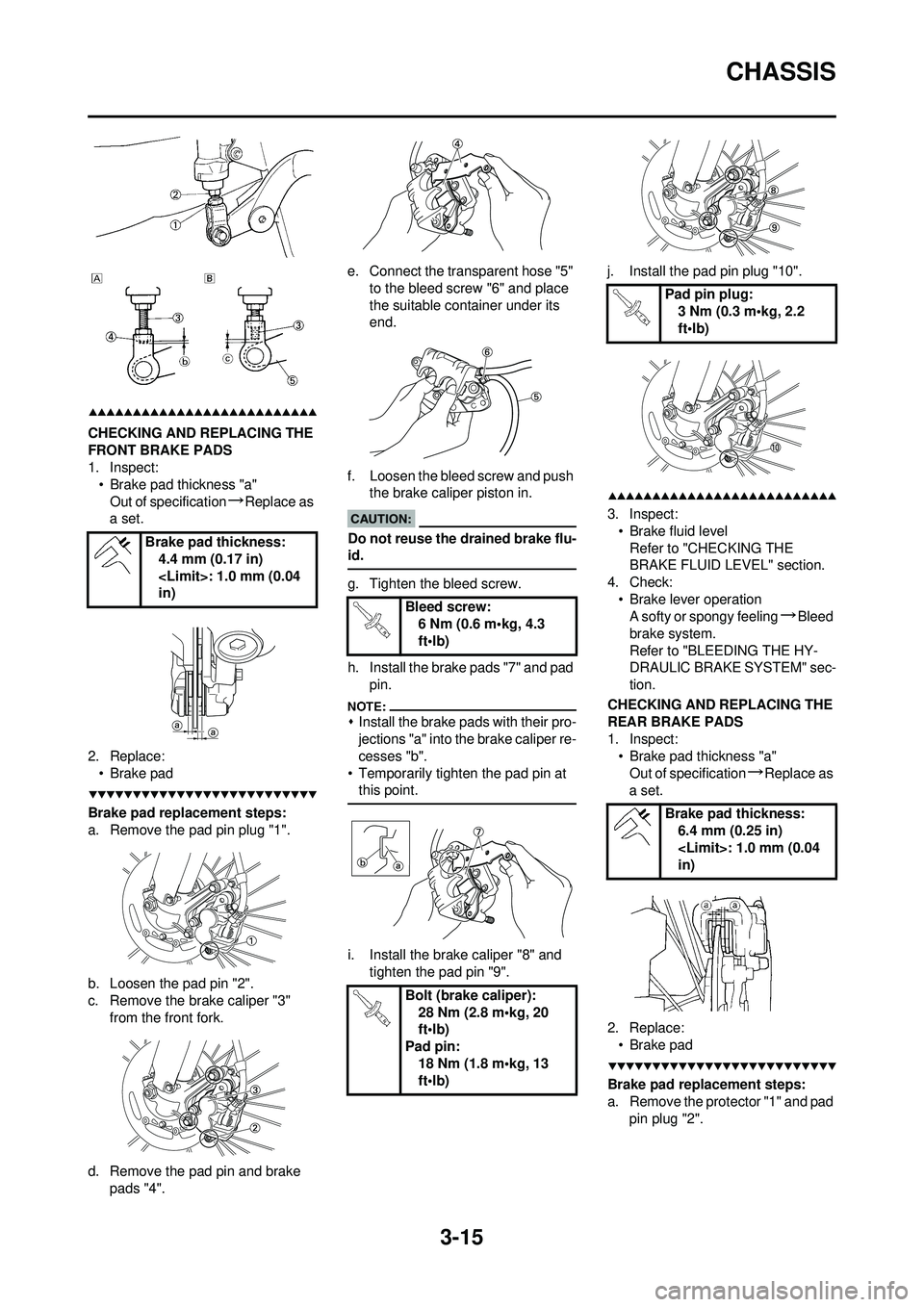

CHECKING AND REPLACING THE

FRONT BRAKE PADS

1. Inspect:• Brake pad thickness "a"Out of specification

→Replace as

a set.

2. Replace: •Brake pad

Brake pad replacement steps:

a. Remove the pad pin plug "1".

b. Loosen the pad pin "2".

c. Remove the brake caliper "3" from the front fork.

d. Remove the pad pin and brake pads "4". e. Connect the transparent hose "5"

to the bleed screw "6" and place

the suitable container under its

end.

f. Loosen the bleed screw and push the brake caliper piston in.

Do not reuse the drained brake flu-

id.

g. Tighten the bleed screw.

h. Install the brake pads "7" and pad

pin.

�ŒInstall the brake pads with their pro-

jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at this point.

i. Install the brake caliper "8" and

tighten the pad pin "9". j. Install the pad pin plug "10".

3. Inspect:

• Brake fluid levelRefer to "CHECKING THE

BRAKE FLUID LEVEL" section.

4. Check: • Brake lever operationA softy or spongy feeling

→Bleed

brake system.

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion.

CHECKING AND REPLACING THE

REAR BRAKE PADS

1. Inspect: • Brake pad thickness "a"

Out of specification

→Replace as

a set.

2. Replace: • Brake pad

Brake pad replacement steps:

a. Remove the protector "1" and pad pin plug "2".

Brake pad thickness:

4.4 mm (0.17 in)

in)

Bleed screw:6 Nm (0.6 m•kg, 4.3

ft•lb)

Bolt (brake caliper): 28 Nm (2.8 m•kg, 20

ft•lb)

Pad pin: 18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug:3 Nm (0.3 m•kg, 2.2

ft•lb)

Brake pad thickness: 6.4 mm (0.25 in)

in)

Page 62 of 192

3-16

CHASSIS

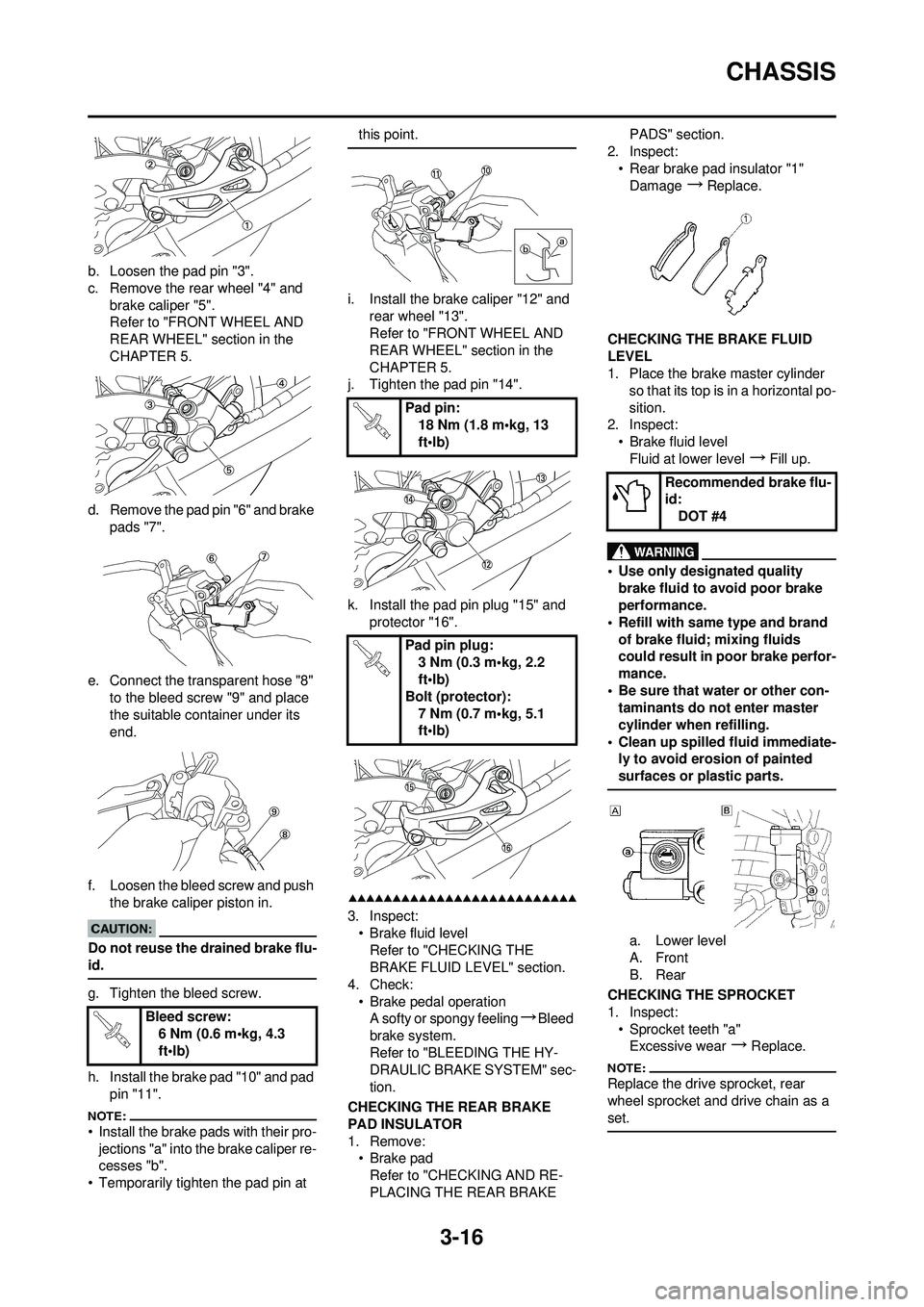

b. Loosen the pad pin "3".

c. Remove the rear wheel "4" and brake caliper "5".

Refer to "FRONT WHEEL AND

REAR WHEEL" section in the

CHAPTER 5.

d. Remove the pad pin "6" and brake pads "7".

e. Connect the transparent hose "8" to the bleed screw "9" and place

the suitable container under its

end.

f. Loosen the bleed screw and push the brake caliper piston in.

Do not reuse the drained brake flu-

id.

g. Tighten the bleed screw.

h. Install the brake pad "10" and pad pin "11".

• Install the brake pads with their pro-jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at this point.

i. Install the brake caliper "12" and

rear wheel "13".

Refer to "FRONT WHEEL AND

REAR WHEEL" section in the

CHAPTER 5.

j. Tighten the pad pin "14".

k. Install the pad pin plug "15" and

protector "16".

3. Inspect:• Brake fluid levelRefer to "CHECKING THE

BRAKE FLUID LEVEL" section.

4. Check: • Brake pedal operationA softy or spongy feeling

→Bleed

brake system.

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion.

CHECKING THE REAR BRAKE

PAD INSULATOR

1. Remove: •Brake pad

Refer to "CHECKING AND RE-

PLACING THE REAR BRAKE PADS" section.

2. Inspect: • Rear brake pad insulator "1"Damage

→Replace.

CHECKING THE BRAKE FLUID

LEVEL

1. Place the brake master cylinder so that its top is in a horizontal po-

sition.

2. Inspect:

• Brake fluid levelFluid at lower level

→Fill up.

• Use only designated quality brake fluid to avoid poor brake

performance.

• Refill with same type and brand of brake fluid; mixing fluids

could result in poor brake perfor-

mance.

• Be sure that water or other con- taminants do not enter master

cylinder when refilling.

• Clean up spilled fluid immediate- ly to avoid erosion of painted

surfaces or plastic parts.

a. Lower level

A. Front

B. Rear

CHECKING THE SPROCKET

1. Inspect: • Sprocket teeth "a"Excessive wear

→Replace.

Replace the drive sprocket, rear

wheel sprocket and drive chain as a

set.

Bleed screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Pad pin:18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug: 3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (protector): 7 Nm (0.7 m•kg, 5.1

ft•lb)

Recommended brake flu-

id:DOT #4

Page 138 of 192

5-6

FRONT BRAKE AND REAR BRAKE

FRONT BRAKE AND REAR BRAKE

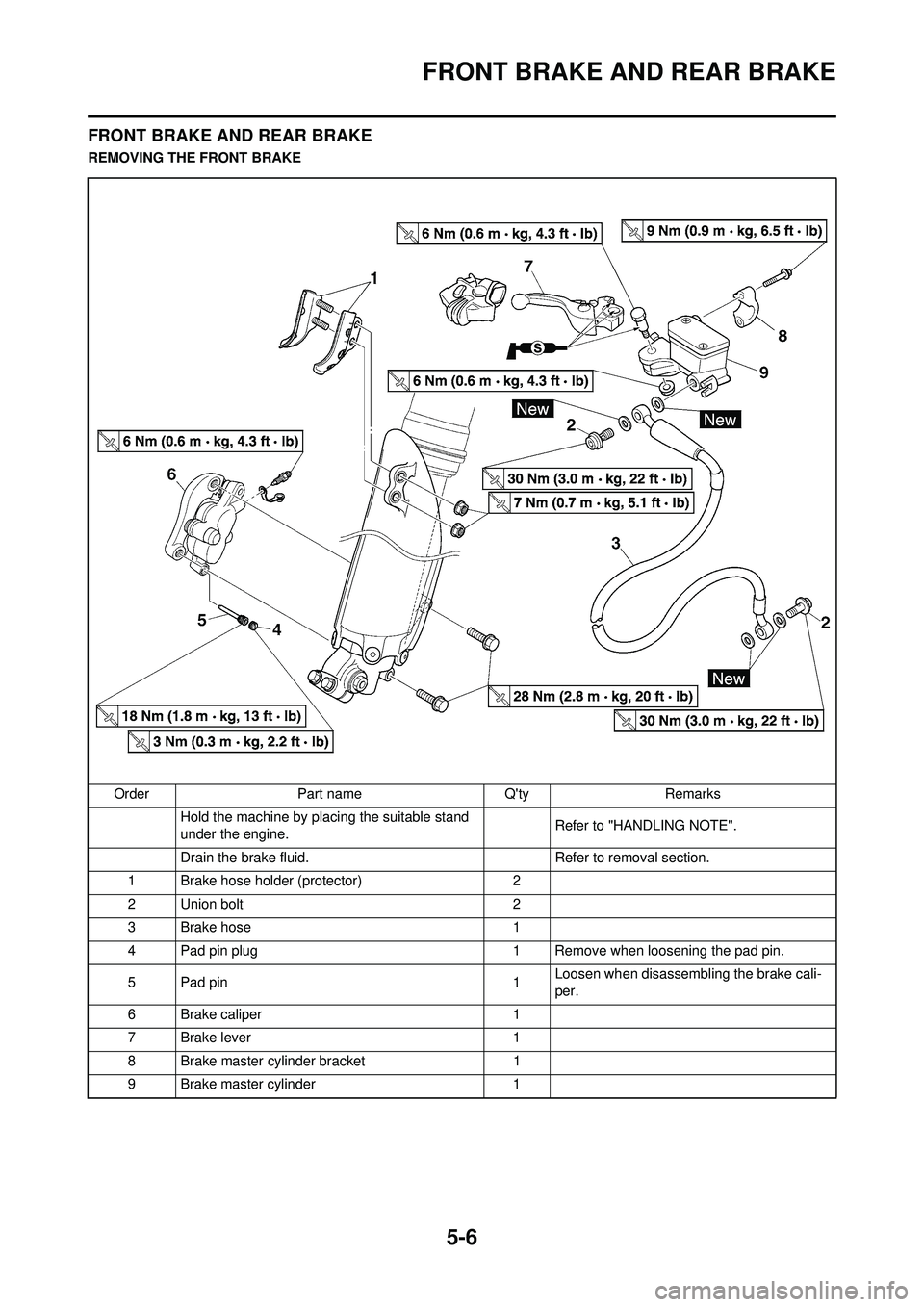

REMOVING THE FRONT BRAKEOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Drain the brake fluid. Refer to removal section.

1 Brake hose holder (protector) 2

2 Union bolt 2

3Brake hose 1

4 Pad pin plug 1 Remove when loosening the pad pin.

5 Pad pin 1Loosen when disassembling the brake cali-

per.

6 Brake caliper 1

7Brake lever 1

8 Brake master cylinder bracket 1

9 Brake master cylinder 1

Page 139 of 192

5-7

FRONT BRAKE AND REAR BRAKE

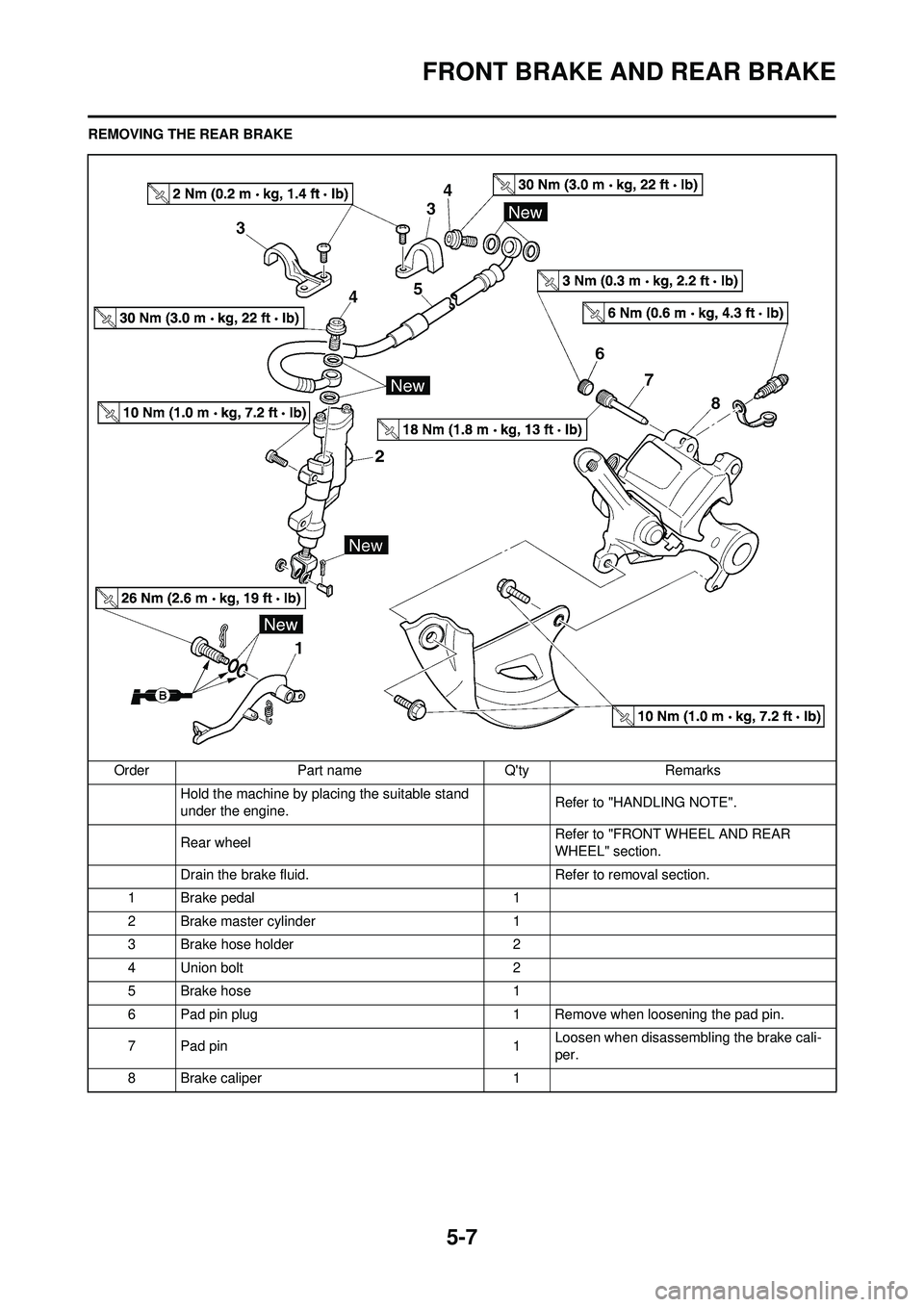

REMOVING THE REAR BRAKEOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Rear wheel Refer to "FRONT WHEEL AND REAR

WHEEL" section.

Drain the brake fluid. Refer to removal section.

1 Brake pedal 1

2 Brake master cylinder 1

3 Brake hose holder 2

4 Union bolt 2

5Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7 Pad pin 1Loosen when disassembling the brake cali-

per.

8 Brake caliper 1

Page 142 of 192

5-10

FRONT BRAKE AND REAR BRAKE

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

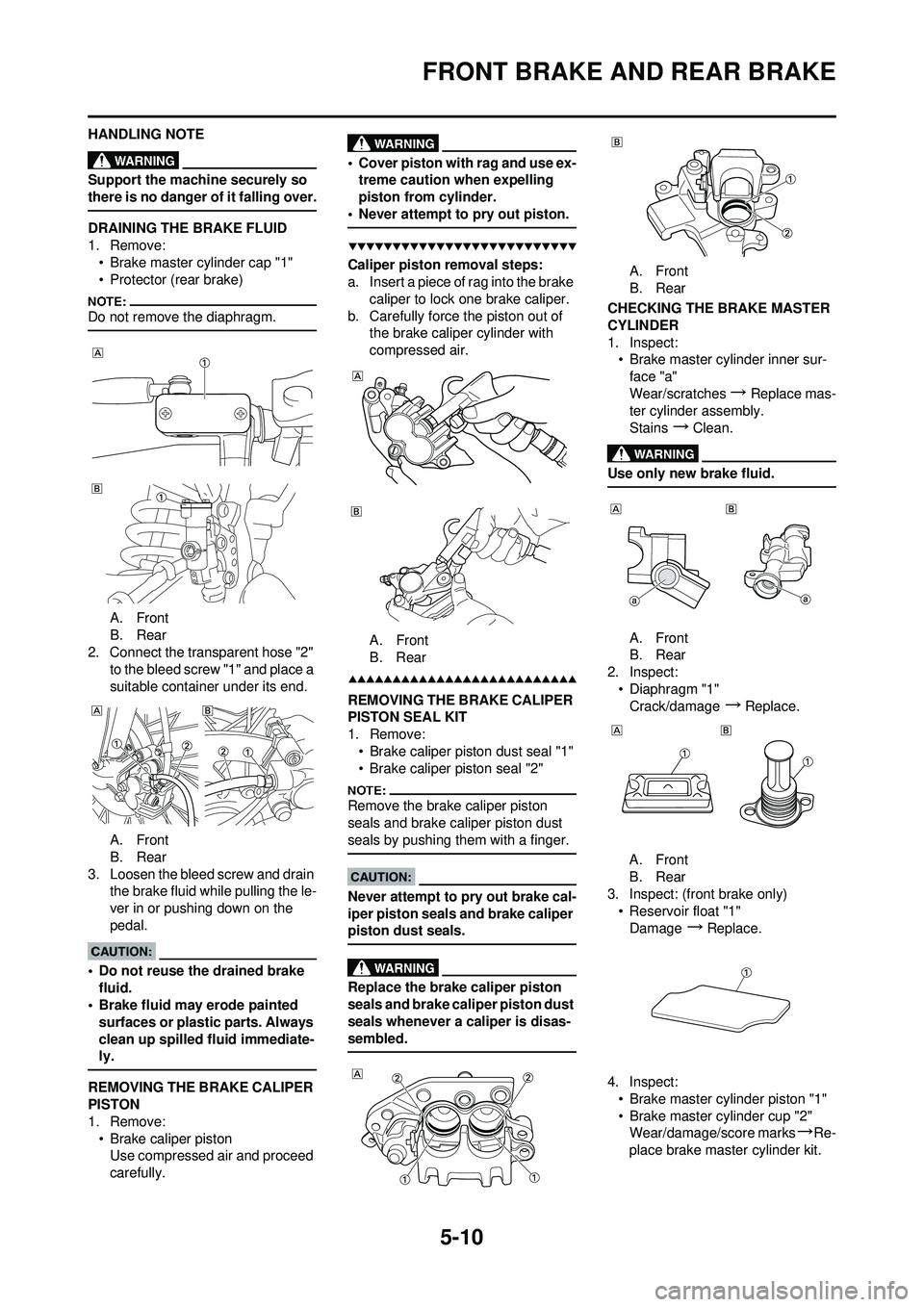

DRAINING THE BRAKE FLUID

1. Remove:• Brake master cylinder cap "1"

• Protector (rear brake)

Do not remove the diaphragm.

A. Front

B. Rear

2. Connect the transparent hose "2" to the bleed screw "1" and place a

suitable container under its end.

A. Front

B. Rear

3. Loosen the bleed screw and drain the brake fluid while pulling the le-

ver in or pushing down on the

pedal.

• Do not reuse the drained brake

fluid.

• Brake fluid may erode painted

surfaces or plastic parts. Always

clean up spilled fluid immediate-

ly.

REMOVING THE BRAKE CALIPER

PISTON

1. Remove:• Brake caliper pistonUse compressed air and proceed

carefully.

• Cover piston with rag and use ex-treme caution when expelling

piston from cylinder.

• Never attempt to pry out piston.

Caliper piston removal steps:

a. Insert a piece of rag into the brake caliper to lock one brake caliper.

b. Carefully force the piston out of the brake caliper cylinder with

compressed air.

A. Front

B. Rear

REMOVING THE BRAKE CALIPER

PISTON SEAL KIT

1. Remove:

• Brake caliper piston dust seal "1"

• Brake caliper piston seal "2"

Remove the brake caliper piston

seals and brake caliper piston dust

seals by pushing them with a finger.

Never attempt to pry out brake cal-

iper piston seals and brake caliper

piston dust seals.

Replace the brake caliper piston

seals and brake caliper piston dust

seals whenever a caliper is disas-

sembled.

A. Front

B. Rear

CHECKING THE BRAKE MASTER

CYLINDER

1. Inspect: • Brake master cylinder inner sur-

face "a"

Wear/scratches

→ Replace mas-

ter cylinder assembly.

Stains

→Clean.

Use only new brake fluid.

A. Front

B. Rear

2. Inspect: • Diaphragm "1"Crack/damage

→Replace.

A. Front

B. Rear

3. Inspect: (front brake only)

• Reservoir float "1"Damage

→Replace.

4. Inspect: • Brake master cylinder piston "1"

• Brake master cylinder cup "2"Wear/damage/score marks

→Re-

place brake master cylinder kit.

Page 143 of 192

5-11

FRONT BRAKE AND REAR BRAKE

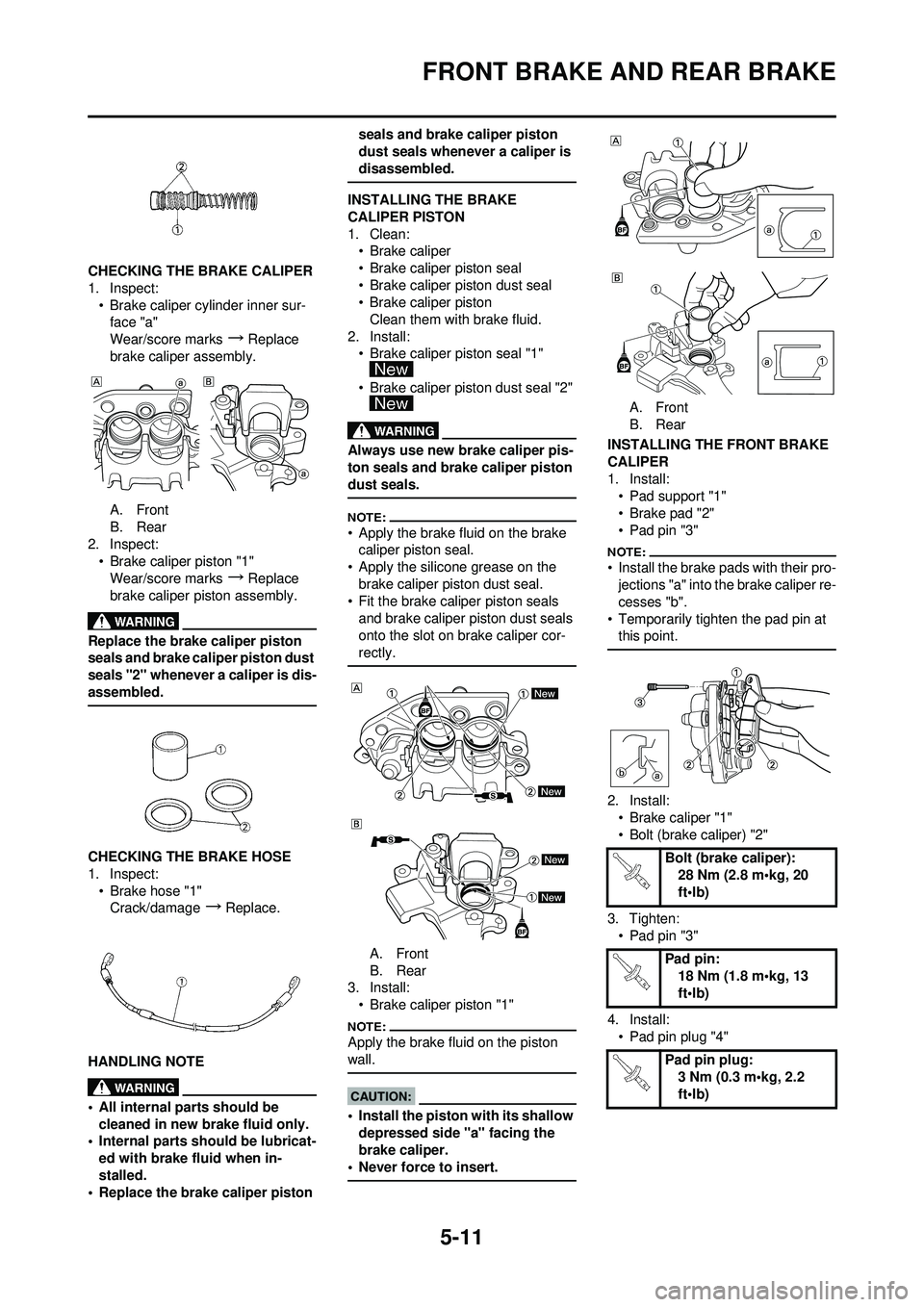

CHECKING THE BRAKE CALIPER

1. Inspect:• Brake caliper cylinder inner sur-face "a"

Wear/score marks

→Replace

brake caliper assembly.

A. Front

B. Rear

2. Inspect: • Brake caliper piston "1"

Wear/score marks

→Replace

brake caliper piston assembly.

Replace the brake caliper piston

seals and brake caliper piston dust

seals "2" whenever a caliper is dis-

assembled.

CHECKING THE BRAKE HOSE

1. Inspect: •Brake hose "1"Crack/damage

→Replace.

HANDLING NOTE

• All internal parts should be cleaned in new brake fluid only.

• Internal parts should be lubricat-

ed with brake fluid when in-

stalled.

• Replace the brake caliper piston seals and brake caliper piston

dust seals whenever a caliper is

disassembled.

INSTALLING THE BRAKE

CALIPER PISTON

1. Clean:

• Brake caliper

• Brake caliper piston seal

• Brake caliper piston dust seal

• Brake caliper piston

Clean them with brake fluid.

2. Install: • Brake caliper piston seal "1"

• Brake caliper piston dust seal "2"

Always use new brake caliper pis-

ton seals and brake caliper piston

dust seals.

• Apply the brake fluid on the brake caliper piston seal.

• Apply the silicone grease on the brake caliper piston dust seal.

• Fit the brake caliper piston seals and brake caliper piston dust seals

onto the slot on brake caliper cor-

rectly.

A. Front

B. Rear

3. Install:

• Brake caliper piston "1"

Apply the brake fluid on the piston

wall.

• Install the piston with its shallow depressed side "a" facing the

brake caliper.

• Never force to insert.

A. Front

B. Rear

INSTALLING THE FRONT BRAKE

CALIPER

1. Install: • Pad support "1"

• Brake pad "2"

• Pad pin "3"

• Install the brake pads with their pro-jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at this point.

2. Install:

• Brake caliper "1"

• Bolt (brake caliper) "2"

3. Tighten: • Pad pin "3"

4. Install: • Pad pin plug "4"

Bolt (brake caliper): 28 Nm (2.8 m•kg, 20

ft•lb)

Pad pin: 18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug: 3 Nm (0.3 m•kg, 2.2

ft•lb)