wheel YAMAHA YZ250F 2008 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ250F, Model: YAMAHA YZ250F 2008Pages: 192, PDF Size: 7.03 MB

Page 144 of 192

5-12

FRONT BRAKE AND REAR BRAKE

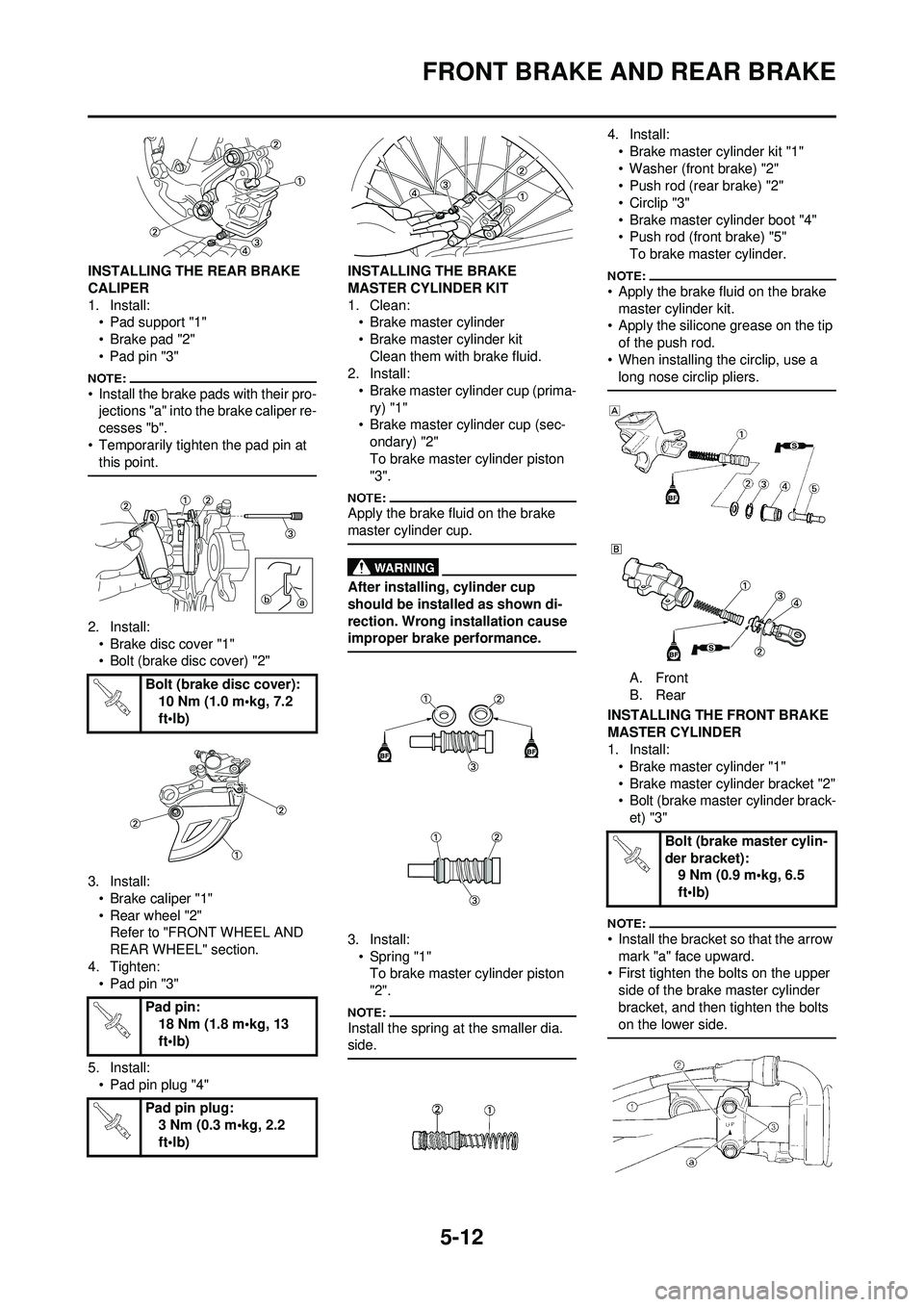

INSTALLING THE REAR BRAKE

CALIPER

1. Install:• Pad support "1"

• Brake pad "2"

• Pad pin "3"

• Install the brake pads with their pro-jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at this point.

2. Install:

• Brake disc cover "1"

• Bolt (brake disc cover) "2"

3. Install: • Brake caliper "1"

• Rear wheel "2"Refer to "FRONT WHEEL AND

REAR WHEEL" section.

4. Tighten: • Pad pin "3"

5. Install: • Pad pin plug "4" INSTALLING THE BRAKE

MASTER CYLINDER KIT

1. Clean:

• Brake master cylinder

• Brake master cylinder kit

Clean them with brake fluid.

2. Install:

• Brake master cylinder cup (prima-ry) "1"

• Brake master cylinder cup (sec-

ondary) "2"

To brake master cylinder piston

"3".

Apply the brake fluid on the brake

master cylinder cup.

After installing, cylinder cup

should be installed as shown di-

rection. Wrong installation cause

improper brake performance.

3. Install:• Spring "1"To brake master cylinder piston

"2".

Install the spring at the smaller dia.

side.

4. Install:

• Brake master cylinder kit "1"

• Washer (front brake) "2"

• Push rod (rear brake) "2"

•Circlip "3"

• Brake master cylinder boot "4"

• Push rod (front brake) "5"To brake master cylinder.

• Apply the brake fluid on the brake master cylinder kit.

• Apply the silicone grease on the tip

of the push rod.

• When installing the circlip, use a long nose circlip pliers.

A. Front

B. Rear

INSTALLING THE FRONT BRAKE

MASTER CYLINDER

1. Install: • Brake master cylinder "1"

• Brake master cylinder bracket "2"

• Bolt (brake master cylinder brack-et) "3"

• Install the bracket so that the arrow mark "a" face upward.

• First tighten the bolts on the upper

side of the brake master cylinder

bracket, and then tighten the bolts

on the lower side.

Bolt (brake disc cover): 10 Nm (1.0 m•kg, 7.2

ft•lb)

Pad pin: 18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug: 3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (brake master cylin-

der bracket):9 Nm (0.9 m•kg, 6.5

ft•lb)

Page 148 of 192

5-16

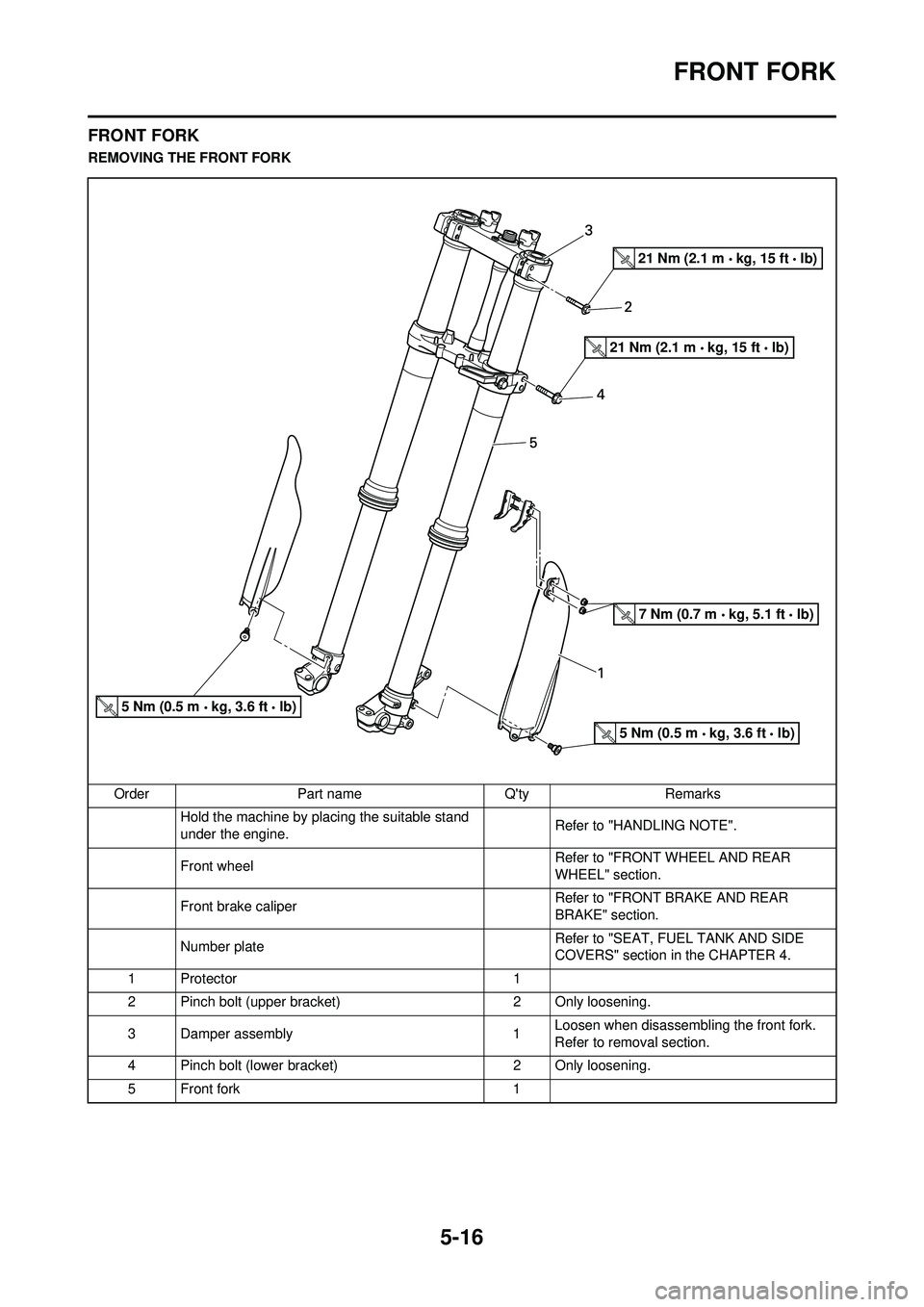

FRONT FORK

FRONT FORK

REMOVING THE FRONT FORKOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the engine. Refer to "HANDLING NOTE".

Front wheel Refer to "FRONT WHEEL AND REAR

WHEEL" section.

Front brake caliper Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Number plate Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section in the CHAPTER 4.

1Protector 1

2 Pinch bolt (upper bracket) 2 Only loosening.

3 Damper assembly 1Loosen when disassembling the front fork.

Refer to removal section.

4 Pinch bolt (lower bracket) 2 Only loosening.

5 Front fork 1

21 Nm (2.1 m kg, 15 ft lb)

21 Nm (2.1 m kg, 15 ft lb)

5 Nm (0.5 m kg, 3.6 ft lb)

5 Nm (0.5 m kg, 3.6 ft lb)

7 Nm (0.7 m kg, 5.1 ft lb)

Page 186 of 192

7-6

CHASSIS

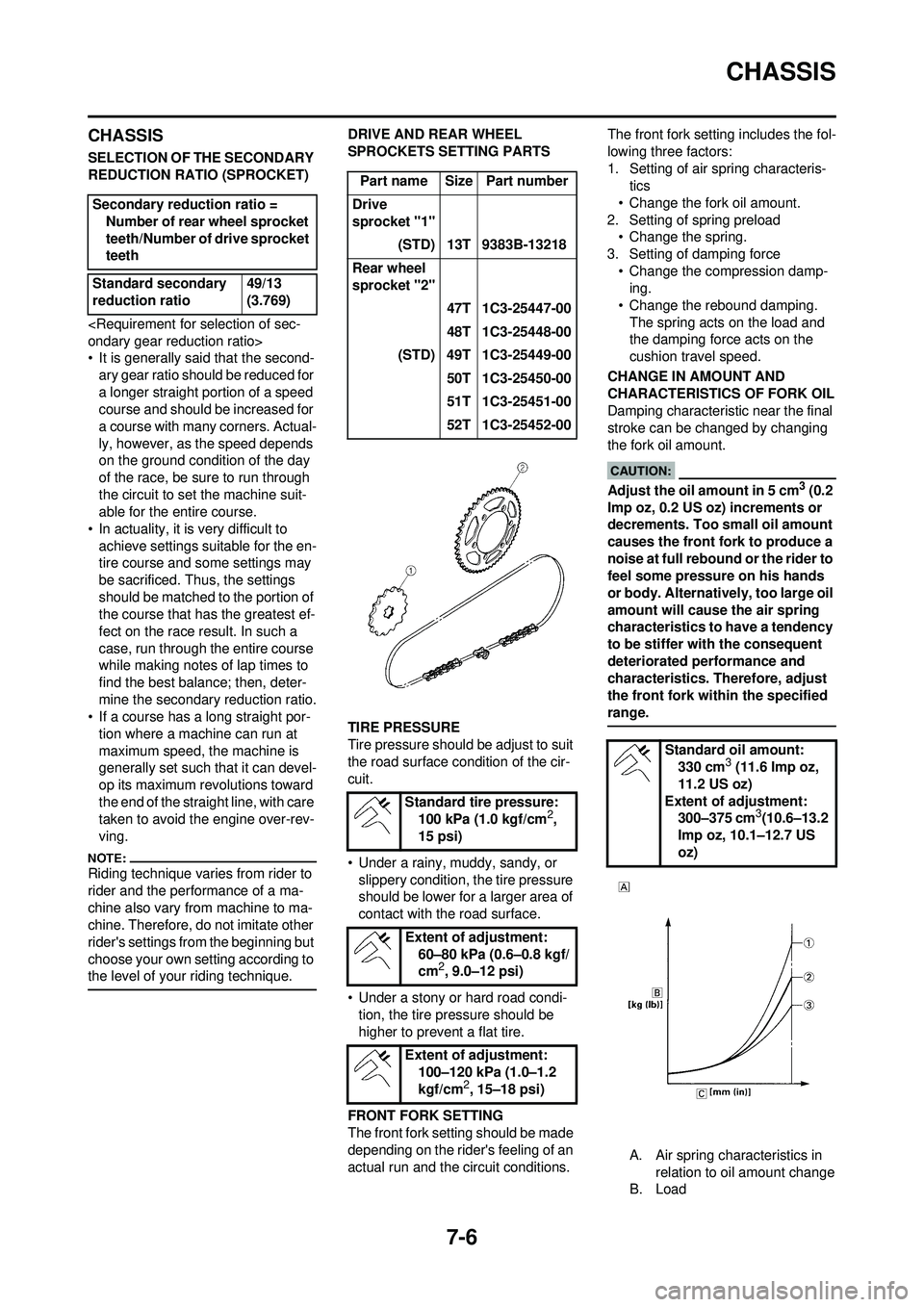

CHASSIS

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

• It is generally said that the second-ary gear ratio should be reduced for

a longer straight portion of a speed

course and should be increased for

a course with many corners. Actual-

ly, however, as the speed depends

on the ground condition of the day

of the race, be sure to run through

the circuit to set the machine suit-

able for the entire course.

• In actuality, it is very difficult to achieve settings suitable for the en-

tire course and some settings may

be sacrificed. Thus, the settings

should be matched to the portion of

the course that has the greatest ef-

fect on the race result. In such a

case, run through the entire course

while making notes of lap times to

find the best balance; then, deter-

mine the secondary reduction ratio.

• If a course has a long straight por-

tion where a machine can run at

maximum speed, the machine is

generally set such that it can devel-

op its maximum revolutions toward

the end of the straight line, with care

taken to avoid the engine over-rev-

ving.

Riding technique varies from rider to

rider and the performance of a ma-

chine also vary from machine to ma-

chine. Therefore, do not imitate other

rider's settings from the beginning but

choose your own setting according to

the level of your riding technique.

DRIVE AND REAR WHEEL

SPROCKETS SETTING PARTS

TIRE PRESSURE

Tire pressure should be adjust to suit

the road surface condition of the cir-

cuit.

• Under a rainy, muddy, sandy, or slippery condition, the tire pressure

should be lower for a larger area of

contact with the road surface.

• Under a stony or hard road condi- tion, the tire pressure should be

higher to prevent a flat tire.

FRONT FORK SETTING

The front fork setting should be made

depending on the rider's feeling of an

actual run and the circuit conditions. The front fork setting includes the fol-

lowing three factors:

1. Setting of air spring characteris-

tics

• Change the fork oil amount.

2. Setting of spring preload • Change the spring.

3. Setting of damping force • Change the compression damp-ing.

• Change the rebound damping. The spring acts on the load and

the damping force acts on the

cushion travel speed.

CHANGE IN AMOUNT AND

CHARACTERISTICS OF FORK OIL

Damping characteristic near the final

stroke can be changed by changing

the fork oil amount.

Adjust the oil amount in 5 cm3 (0.2

Imp oz, 0.2 US oz) increments or

decrements. Too small oil amount

causes the front fork to produce a

noise at full rebound or the rider to

feel some pressure on his hands

or body. Alternatively, too large oil

amount will cause the air spring

characteristics to have a tendency

to be stiffer with the consequent

deteriorated performance and

characteristics. Therefore, adjust

the front fork within the specified

range.

A. Air spring characteristics in relation to oil amount change

B. Load

Secondary reduction ratio =

Number of rear wheel sprocket

teeth/Number of drive sprocket

teeth

Standard secondary

reduction ratio 49/13

(3.769)

Part name Size Part number

Drive

sprocket "1" (STD) 13T 9383B-13218

Rear wheel

sprocket "2" 47T 1C3-25447-00

48T 1C3-25448-00

(STD) 49T 1C3-25449-00 50T 1C3-25450-00

51T 1C3-25451-00

52T 1C3-25452-00

Standard tire pressure: 100 kPa (1.0 kgf/cm

2,

15 psi)

Extent of adjustment: 60–80 kPa (0.6–0.8 kgf/

cm

2, 9.0–12 psi)

Extent of adjustment: 100–120 kPa (1.0–1.2

kgf/cm

2, 15–18 psi)

Standard oil amount:330 cm3 (11.6 Imp oz,

11.2 US oz)

Extent of adjustment: 300–375 cm

3(10.6–13.2

Imp oz, 10.1–12.7 US

oz)

Page 187 of 192

7-7

CHASSIS

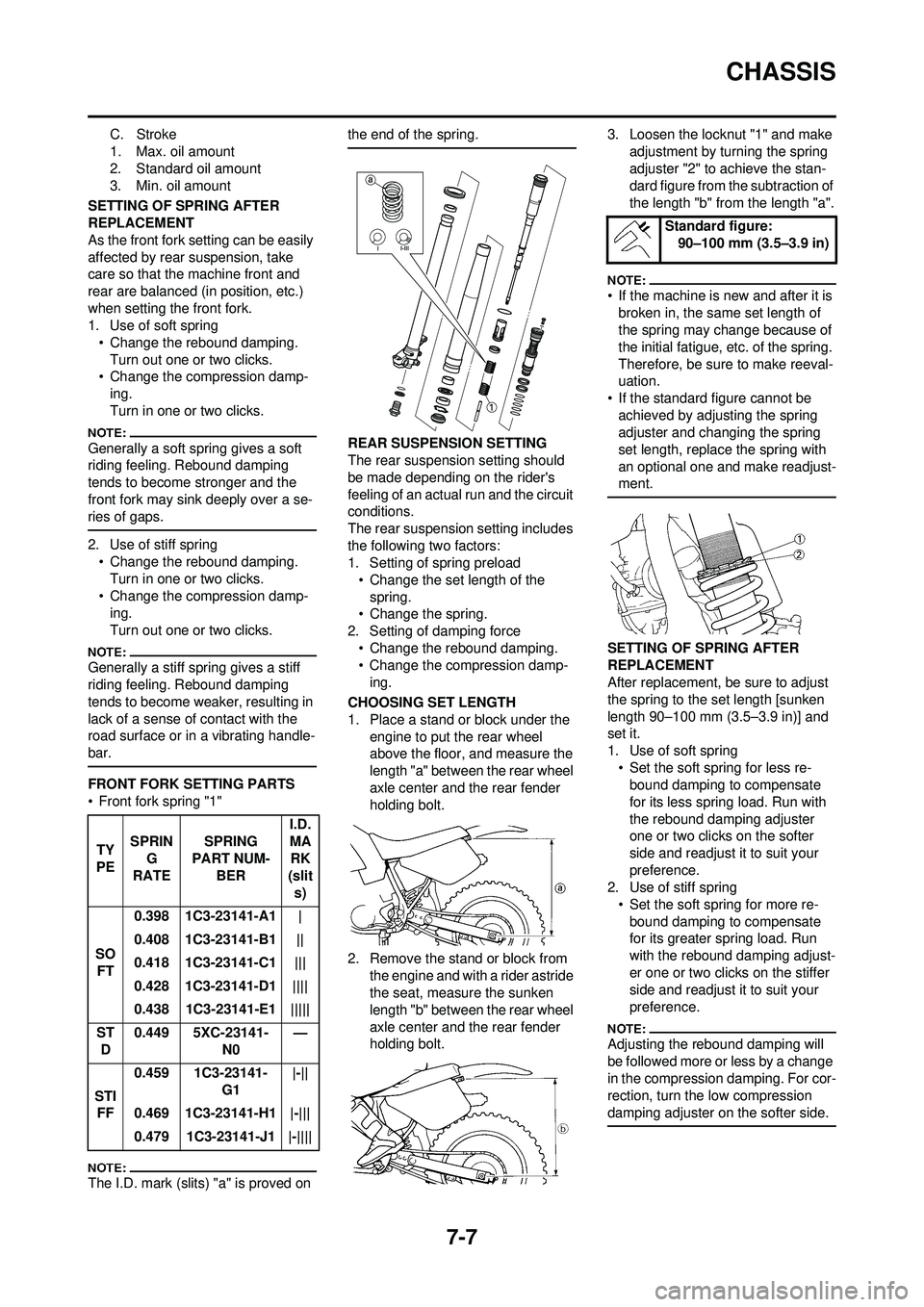

C. Stroke

1. Max. oil amount

2. Standard oil amount

3. Min. oil amount

SETTING OF SPRING AFTER

REPLACEMENT

As the front fork setting can be easily

affected by rear suspension, take

care so that the machine front and

rear are balanced (in position, etc.)

when setting the front fork.

1. Use of soft spring • Change the rebound damping.Turn out one or two clicks.

• Change the compression damp-

ing.

Turn in one or two clicks.

Generally a soft spring gives a soft

riding feeling. Rebound damping

tends to become stronger and the

front fork may sink deeply over a se-

ries of gaps.

2. Use of stiff spring• Change the rebound damping.Turn in one or two clicks.

• Change the compression damp-

ing.

Turn out one or two clicks.

Generally a stiff spring gives a stiff

riding feeling. Rebound damping

tends to become weaker, resulting in

lack of a sense of contact with the

road surface or in a vibrating handle-

bar.

FRONT FORK SETTING PARTS

• Front fork spring "1"

The I.D. mark (slits) "a" is proved on the end of the spring.

REAR SUSPENSION SETTING

The rear suspension setting should

be made depending on the rider's

feeling of an actual run and the circuit

conditions.

The rear suspension setting includes

the following two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force • Change the rebound damping.

• Change the compression damp-ing.

CHOOSING SET LENGTH

1. Place a stand or block under the engine to put the rear wheel

above the floor, and measure the

length "a" between the rear wheel

axle center and the rear fender

holding bolt.

2. Remove the stand or block from the engine and with a rider astride

the seat, measure the sunken

length "b" between the rear wheel

axle center and the rear fender

holding bolt. 3. Loosen the locknut "1" and make

adjustment by turning the spring

adjuster "2" to achieve the stan-

dard figure from the subtraction of

the length "b" from the length "a".

• If the machine is new and after it is broken in, the same set length of

the spring may change because of

the initial fatigue, etc. of the spring.

Therefore, be sure to make reeval-

uation.

• If the standard figure cannot be achieved by adjusting the spring

adjuster and changing the spring

set length, replace the spring with

an optional one and make readjust-

ment.

SETTING OF SPRING AFTER

REPLACEMENT

After replacement, be sure to adjust

the spring to the set length [sunken

length 90–100 mm (3.5–3.9 in)] and

set it.

1. Use of soft spring• Set the soft spring for less re-bound damping to compensate

for its less spring load. Run with

the rebound damping adjuster

one or two clicks on the softer

side and readjust it to suit your

preference.

2. Use of stiff spring

• Set the soft spring for more re-bound damping to compensate

for its greater spring load. Run

with the rebound damping adjust-

er one or two clicks on the stiffer

side and readjust it to suit your

preference.

Adjusting the rebound damping will

be followed more or less by a change

in the compression damping. For cor-

rection, turn the low compression

damping adjuster on the softer side.

TY

PE SPRIN

G

RATE SPRING

PART NUM- BER I.D.

MA

RK

(slit

s)

SO FT 0.398 1C3-23141-A1 |

0.408 1C3-23141-B1 ||

0.418 1C3-23141-C1 |||

0.428 1C3-23141-D1 ||||

0.438 1C3-23141-E1 |||||

ST D 0.449 5XC-23141-

N0—

STI FF 0.459 1C3-23141-

G1|-||

0.469 1C3-23141-H1 |-|||

0.479 1C3-23141-J1 |-||||

Standard figure: 90–100 mm (3.5–3.9 in)