wheel alignment YAMAHA YZ250F 2008 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2008, Model line: YZ250F, Model: YAMAHA YZ250F 2008Pages: 192, PDF Size: 7.03 MB

Page 51 of 192

3-5

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCEItem RoutinePage

Coolant Check that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage. P.3-6 – 7

Fuel Check that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage. P.1-8 – 9

Engine oil Check that the oil level is correct. Check the crankcase and oil line

for leakage. P.3-8 – 10

Gear shifter and clutch Check that gears can be shifted correctly in order and that the

clutch operates smoothly. P.3-7

Throttle grip/Housing Check that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary. P.3-7 – 8

Brakes Check the play of front brake and effect of front and rear brake. P.3-14 – 16

Drive chain Check drive chain slack and alignment. Check that the drive chain

is lubricated properly. P.3-17

Wheels Check for excessive wear and tire pressure. Check for loose

spokes and have no excessive play. P.3-20

Steering Check that the handlebar can be turned smoothly and have no ex-

cessive play. P.3-20 – 21

Front forks and rear shock

absorber Check that they operate smoothly and there is no oil leakage.

P.3-18 – 20

Cables (wires) Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.

—

Exhaust pipe Check that the exhaust pipe is tightly mounted and has no cracks. P.4-3 – 4

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-16 – 17

Lubrication Check for smooth operation. Lubricate if necessary. P.3-22

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-11

Lead connectors Check that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly. P.1-3

Settings Is the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs be-

fore racing? Are inspection and maintenance completely done?

P.7-1 – 10

Page 63 of 192

3-17

CHASSIS

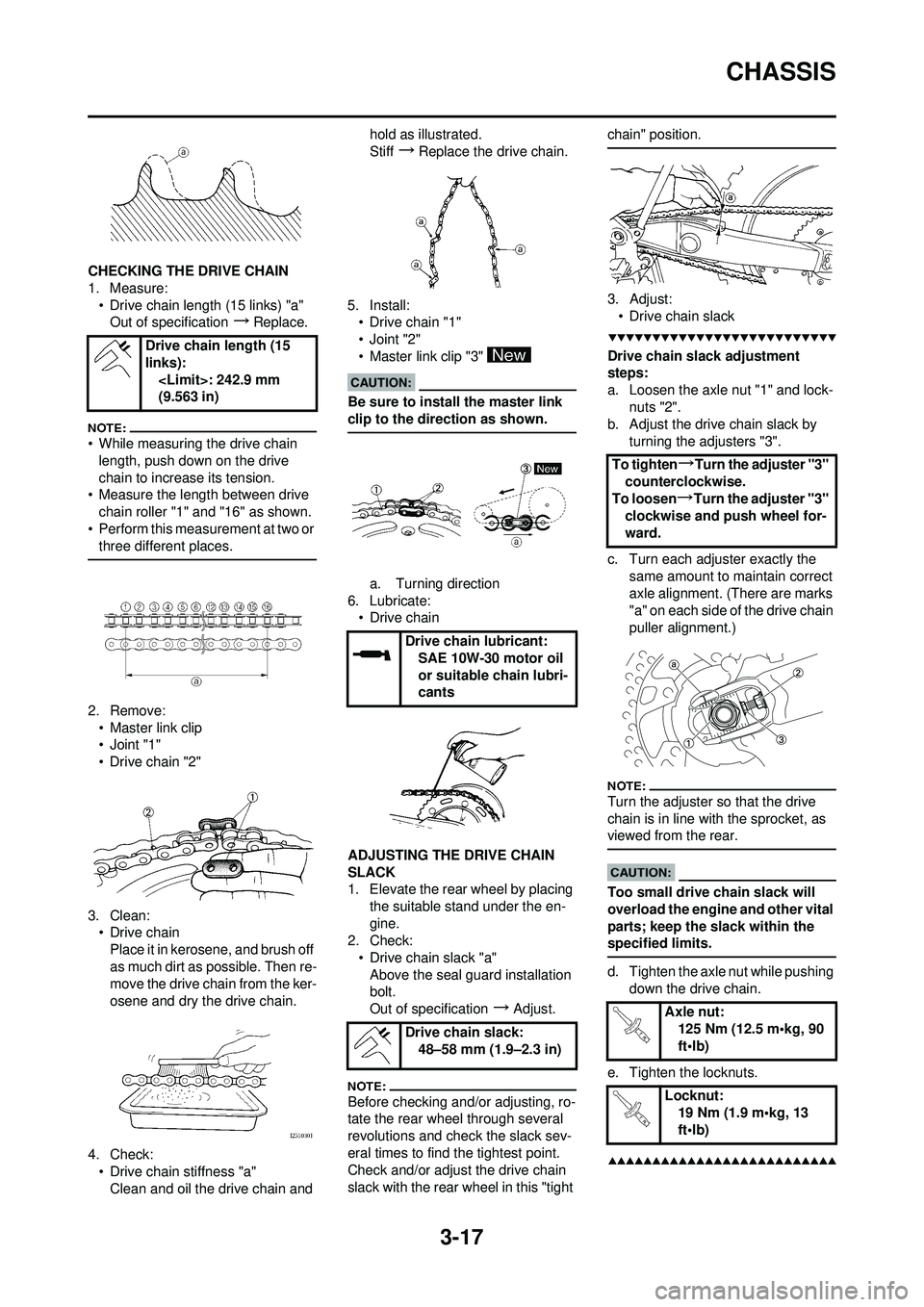

CHECKING THE DRIVE CHAIN

1. Measure:• Drive chain length (15 links) "a"Out of specification

→Replace.

• While measuring the drive chain

length, push down on the drive

chain to increase its tension.

• Measure the length between drive

chain roller "1" and "16" as shown.

• Perform this measurement at two or three different places.

2. Remove:

• Master link clip

•Joint "1"

• Drive chain "2"

3. Clean: • Drive chain

Place it in kerosene, and brush off

as much dirt as possible. Then re-

move the drive chain from the ker-

osene and dry the drive chain.

4. Check: • Drive chain stiffness "a"

Clean and oil the drive chain and hold as illustrated.

Stiff

→Replace the drive chain.

5. Install: • Drive chain "1"

• Joint "2"

• Master link clip "3"

Be sure to install the master link

clip to the direction as shown.

a. Turning direction

6. Lubricate: • Drive chain

ADJUSTING THE DRIVE CHAIN

SLACK

1. Elevate the rear wheel by placing the suitable stand under the en-

gine.

2. Check:

• Drive chain slack "a"Above the seal guard installation

bolt.

Out of specification

→Adjust.

Before checking and/or adjusting, ro-

tate the rear wheel through several

revolutions and check the slack sev-

eral times to find the tightest point.

Check and/or adjust the drive chain

slack with the rear wheel in this "tight chain" position.

3. Adjust:

• Drive chain slack

Drive chain slack adjustment

steps:

a. Loosen the axle nut "1" and lock- nuts "2".

b. Adjust the drive chain slack by

turning the adjusters "3".

c. Turn each adjuster exactly the same amount to maintain correct

axle alignment. (There are marks

"a" on each side of the drive chain

puller alignment.)

Turn the adjuster so that the drive

chain is in line with the sprocket, as

viewed from the rear.

Too small drive chain slack will

overload the engine and other vital

parts; keep the slack within the

specified limits.

d. Tighten the axle nut while pushing down the drive chain.

e. Tighten the locknuts.

Drive chain length (15

links):

(9.563 in)

Drive chain lubricant:SAE 10W-30 motor oil

or suitable chain lubri-

cants

Drive chain slack: 48–58 mm (1.9–2.3 in)

To tighten→Turn the adjuster "3"

counterclockwise.

To loosen

→Turn the adjuster "3"

clockwise and push wheel for-

ward.

Axle nut:125 Nm (12.5 m•kg, 90

ft•lb)

Locknut: 19 Nm (1.9 m•kg, 13

ft•lb)