radiator YAMAHA YZ250F 2009 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ250F, Model: YAMAHA YZ250F 2009Pages: 190, PDF Size: 12.83 MB

Page 43 of 190

2-21

CABLE ROUTING DIAGRAM

E. Fasten the neutral switch lead,

CDI magneto lead, radiator

breather hose and clutch cable

over the radiator mounting boss.

F. Pass the radiator breather hose

in front of the radiator, on the left

of the chassis, and then be-

tween the frame and radiator

hose 4.

G. Fasten the sub-wire harness

and engine stop switch lead to

the CDI unit bracket at the white-

taped portion of the subwire har-

ness and with the clamp ends

facing downward.

H. Locate the clamp ends in the ar-

rowed range.

I. Fasten the neutral switch lead

and CDI magneto lead over the

hump of the frame.

J. Fasten the hot starter cable and

throttle cable onto the frame.

K. Fasten the throttle position sen-

sor lead and the hot starter ca-

ble.

L. Locate the clamp between the

hot starter cable protector and

rubber cap.

M. Locate the clamp ends under

the throttle cable, and after

clamping, leave the other end as

is and do not cut it. [clamp:L=

270mm (10.6 in)]

Page 44 of 190

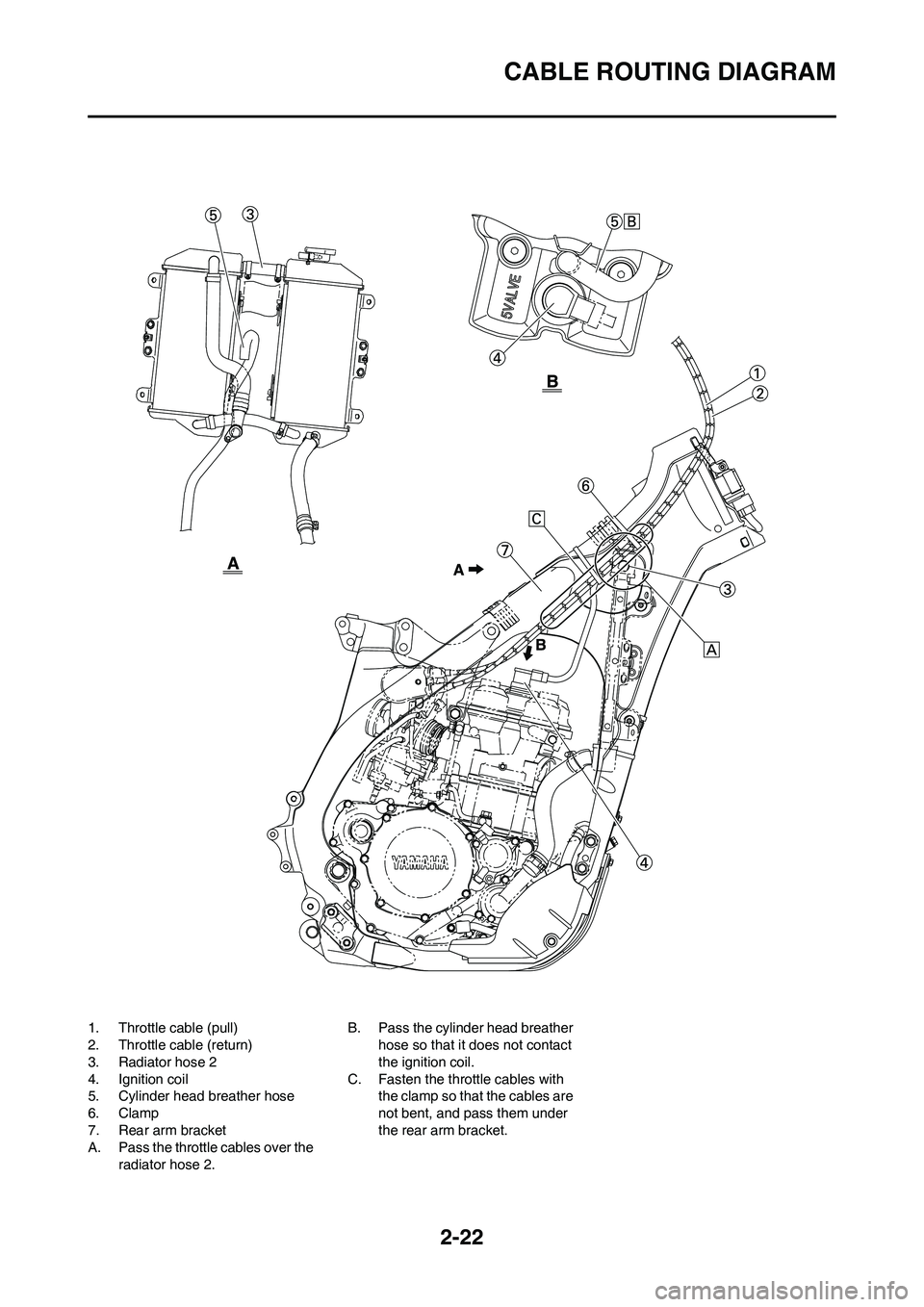

2-22

CABLE ROUTING DIAGRAM

1. Throttle cable (pull)

2. Throttle cable (return)

3. Radiator hose 2

4. Ignition coil

5. Cylinder head breather hose

6. Clamp

7. Rear arm bracket

A. Pass the throttle cables over the

radiator hose 2. B. Pass the cylinder head breather

hose so that it does not contact

the ignition coil.

C. Fasten the throttle cables with

the clamp so that the cables are

not bent, and pass them under

the rear arm bracket.

Page 48 of 190

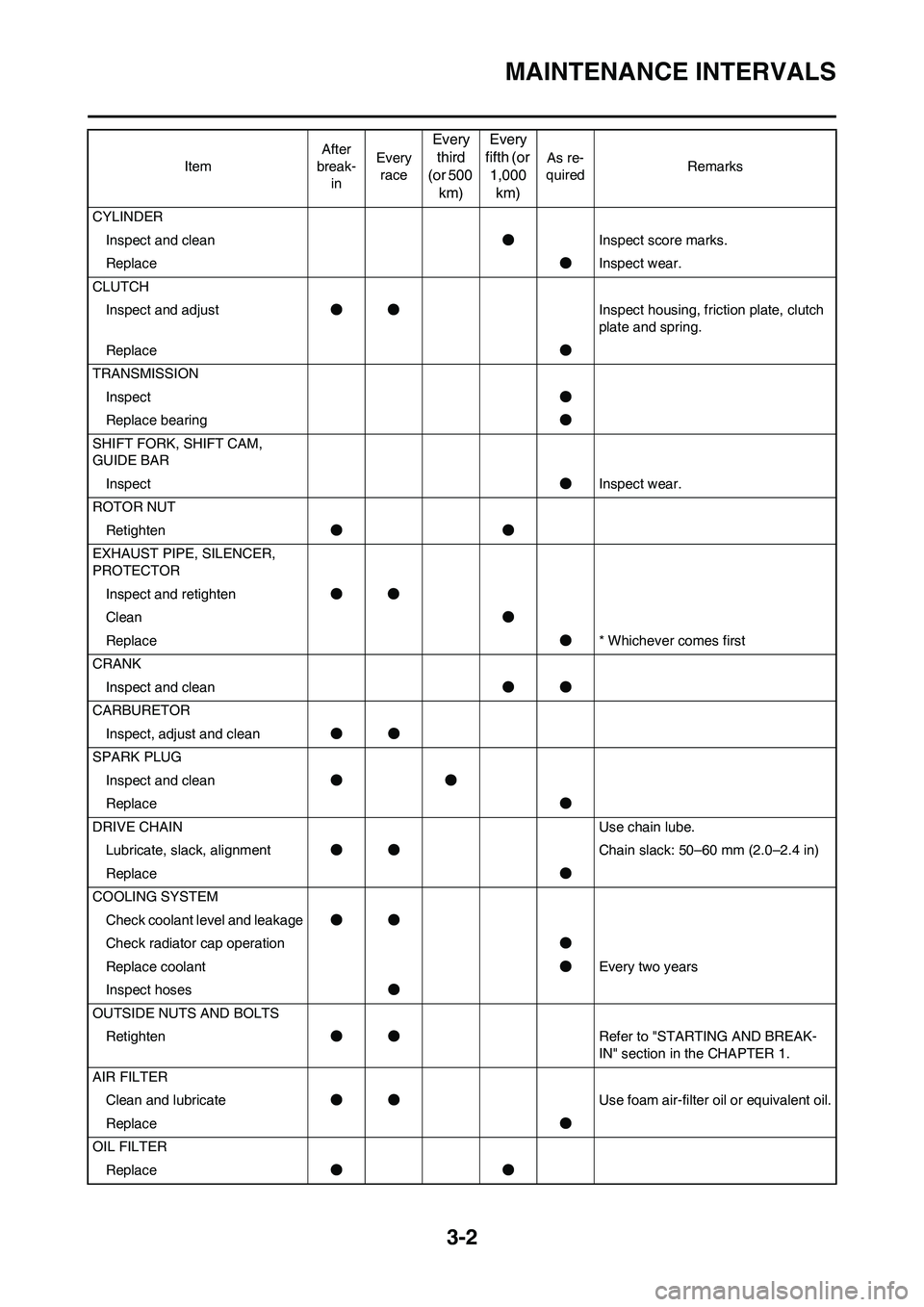

3-2

MAINTENANCE INTERVALS

CYLINDER

Inspect and clean●Inspect score marks.

Replace●Inspect wear.

CLUTCH

Inspect and adjust●●Inspect housing, friction plate, clutch

plate and spring.

Replace●

TRANSMISSION

Inspect●

Replace bearing●

SHIFT FORK, SHIFT CAM,

GUIDE BAR

Inspect●Inspect wear.

ROTOR NUT

Retighten●●

EXHAUST PIPE, SILENCER,

PROTECTOR

Inspect and retighten●●

Clean●

Replace●* Whichever comes first

CRANK

Inspect and clean●●

CARBURETOR

Inspect, adjust and clean●●

SPARK PLUG

Inspect and clean●●

Replace●

DRIVE CHAIN Use chain lube.

Lubricate, slack, alignment●●Chain slack: 50–60 mm (2.0–2.4 in)

Replace●

COOLING SYSTEM

Check coolant level and leakage●●

Check radiator cap operation●

Replace coolant●Every two years

Inspect hoses●

OUTSIDE NUTS AND BOLTS

Retighten●●Refer to "STARTING AND BREAK-

IN" section in the CHAPTER 1.

AIR FILTER

Clean and lubricate●●Use foam air-filter oil or equivalent oil.

Replace●

OIL FILTER

Replace●● ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

Page 51 of 190

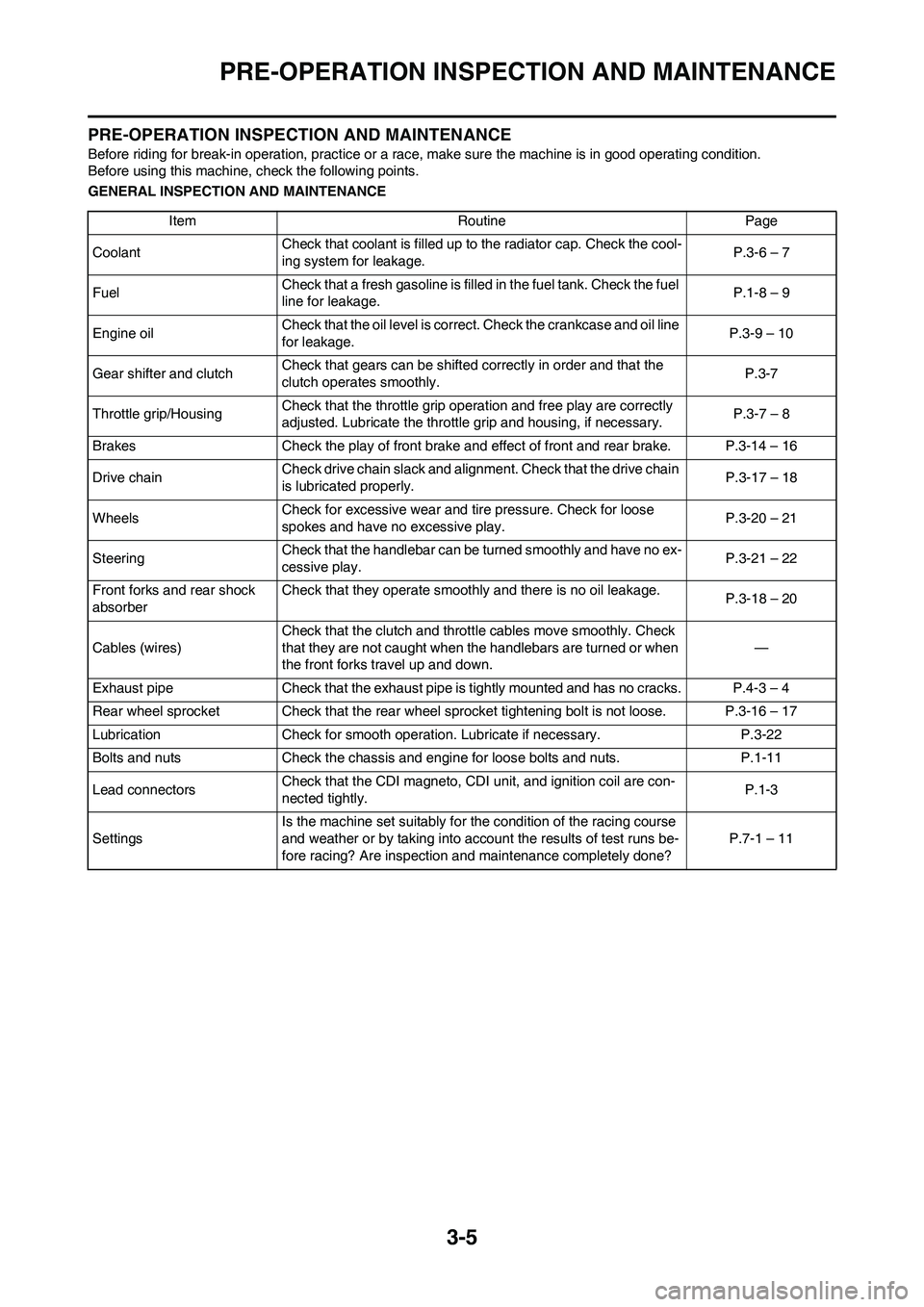

3-5

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage.P.3-6 – 7

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the fuel

line for leakage.P.1-8 – 9

Engine oilCheck that the oil level is correct. Check the crankcase and oil line

for leakage.P.3-9 – 10

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-7

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-7 – 8

Brakes Check the play of front brake and effect of front and rear brake. P.3-14 – 16

Drive chainCheck drive chain slack and alignment. Check that the drive chain

is lubricated properly.P.3-17 – 18

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-20 – 21

SteeringCheck that the handlebar can be turned smoothly and have no ex-

cessive play.P.3-21 – 22

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage.

P.3-18 – 20

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipe Check that the exhaust pipe is tightly mounted and has no cracks. P.4-3 – 4

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-16 – 17

Lubrication Check for smooth operation. Lubricate if necessary. P.3-22

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-11

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-3

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs be-

fore racing? Are inspection and maintenance completely done?P.7-1 – 11

Page 52 of 190

3-6

ENGINE

ENGINE

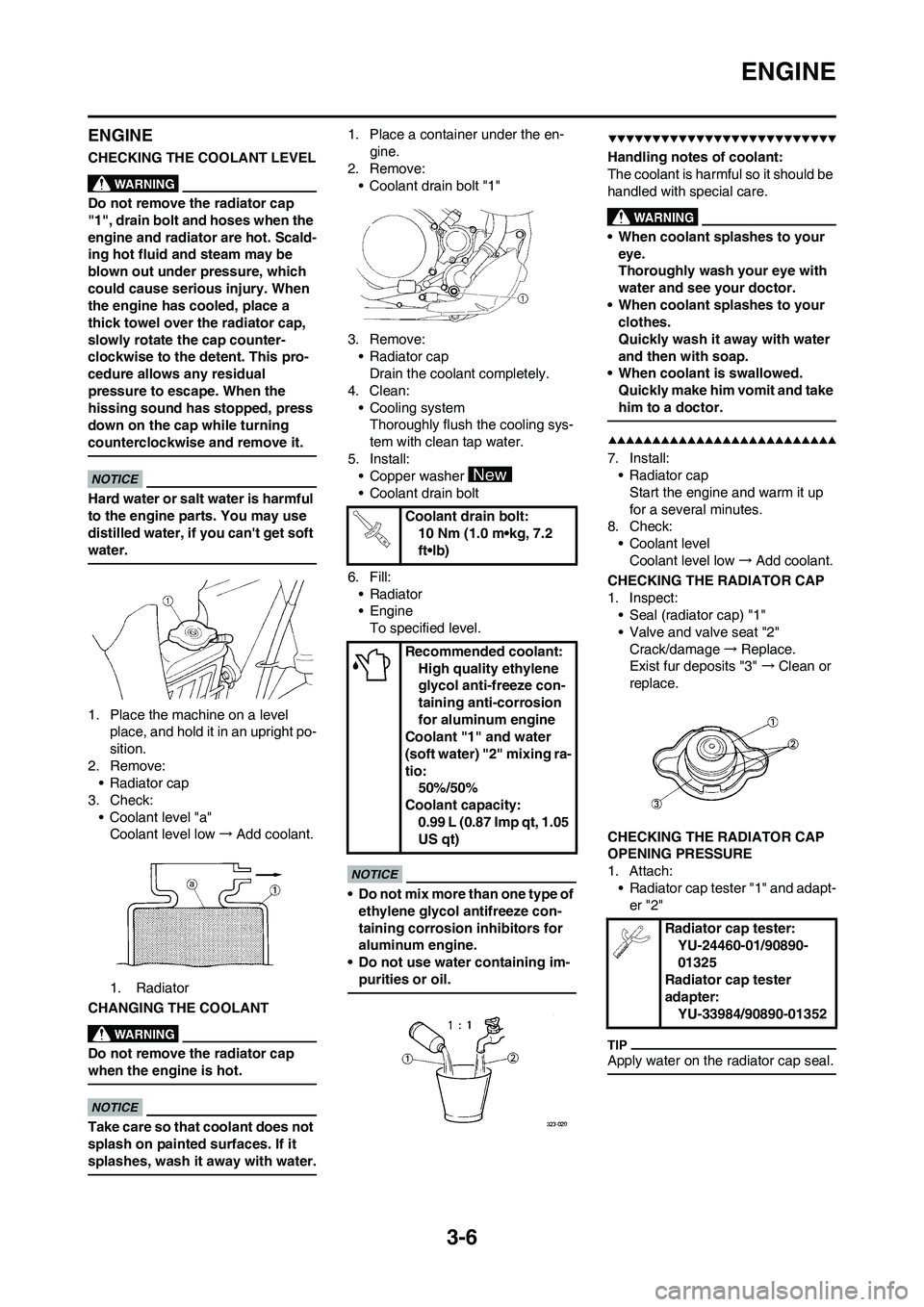

CHECKING THE COOLANT LEVEL

Do not remove the radiator cap

"1", drain bolt and hoses when the

engine and radiator are hot. Scald-

ing hot fluid and steam may be

blown out under pressure, which

could cause serious injury. When

the engine has cooled, place a

thick towel over the radiator cap,

slowly rotate the cap counter-

clockwise to the detent. This pro-

cedure allows any residual

pressure to escape. When the

hissing sound has stopped, press

down on the cap while turning

counterclockwise and remove it.

Hard water or salt water is harmful

to the engine parts. You may use

distilled water, if you can't get soft

water.

1. Place the machine on a level

place, and hold it in an upright po-

sition.

2. Remove:

• Radiator cap

3. Check:

• Coolant level "a"

Coolant level low→Add coolant.

1. Radiator

CHANGING THE COOLANT

Do not remove the radiator cap

when the engine is hot.

Take care so that coolant does not

splash on painted surfaces. If it

splashes, wash it away with water.

1. Place a container under the en-

gine.

2. Remove:

• Coolant drain bolt "1"

3. Remove:

•Radiator cap

Drain the coolant completely.

4. Clean:

• Cooling system

Thoroughly flush the cooling sys-

tem with clean tap water.

5. Install:

• Copper washer

• Coolant drain bolt

6. Fill:

•Radiator

•Engine

To specified level.

• Do not mix more than one type of

ethylene glycol antifreeze con-

taining corrosion inhibitors for

aluminum engine.

• Do not use water containing im-

purities or oil.

Handling notes of coolant:

The coolant is harmful so it should be

handled with special care.

• When coolant splashes to your

eye.

Thoroughly wash your eye with

water and see your doctor.

• When coolant splashes to your

clothes.

Quickly wash it away with water

and then with soap.

• When coolant is swallowed.

Quickly make him vomit and take

him to a doctor.

7. Install:

•Radiator cap

Start the engine and warm it up

for a several minutes.

8. Check:

• Coolant level

Coolant level low→Add coolant.

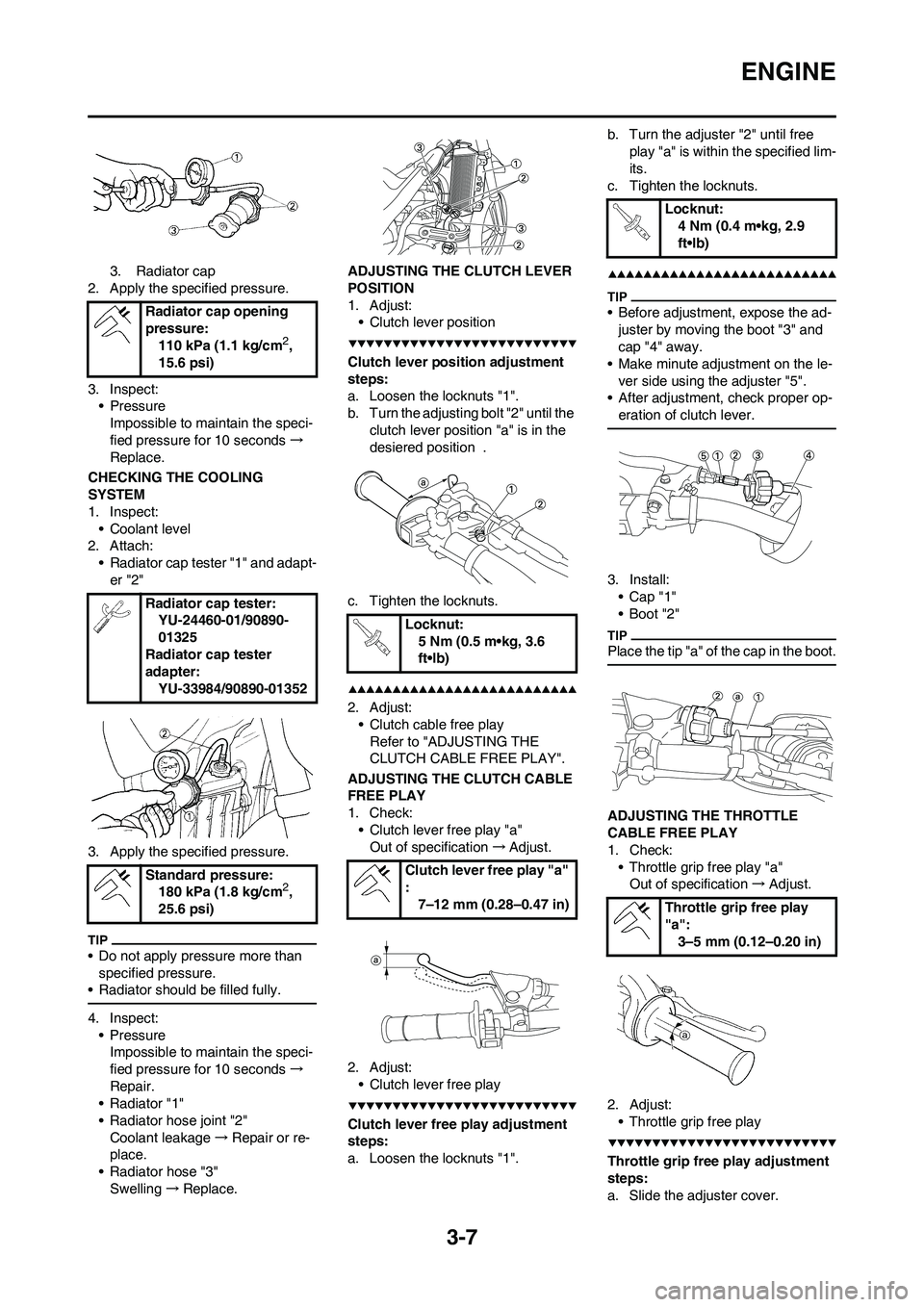

CHECKING THE RADIATOR CAP

1. Inspect:

• Seal (radiator cap) "1"

• Valve and valve seat "2"

Crack/damage→Replace.

Exist fur deposits "3" →Clean or

replace.

CHECKING THE RADIATOR CAP

OPENING PRESSURE

1. Attach:

• Radiator cap tester "1" and adapt-

er "2"

Apply water on the radiator cap seal.

Coolant drain bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Recommended coolant:

High quality ethylene

glycol anti-freeze con-

taining anti-corrosion

for aluminum engine

Coolant "1" and water

(soft water) "2" mixing ra-

tio:

50%/50%

Coolant capacity:

0.99 L (0.87 Imp qt, 1.05

US qt)

Radiator cap tester:

YU-24460-01/90890-

01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Page 53 of 190

3-7

ENGINE

3. Radiator cap

2. Apply the specified pressure.

3. Inspect:

•Pressure

Impossible to maintain the speci-

fied pressure for 10 seconds→

Replace.

CHECKING THE COOLING

SYSTEM

1. Inspect:

• Coolant level

2. Attach:

• Radiator cap tester "1" and adapt-

er "2"

3. Apply the specified pressure.

• Do not apply pressure more than

specified pressure.

• Radiator should be filled fully.

4. Inspect:

•Pressure

Impossible to maintain the speci-

fied pressure for 10 seconds→

Repair.

• Radiator "1"

• Radiator hose joint "2"

Coolant leakage→Repair or re-

place.

• Radiator hose "3"

Swelling→Replace.ADJUSTING THE CLUTCH LEVER

POSITION

1. Adjust:

• Clutch lever position

Clutch lever position adjustment

steps:

a. Loosen the locknuts "1".

b. Turn the adjusting bolt "2" until the

clutch lever position "a" is in the

desiered position .

c. Tighten the locknuts.

2. Adjust:

• Clutch cable free play

Refer to "ADJUSTING THE

CLUTCH CABLE FREE PLAY".

ADJUSTING THE CLUTCH CABLE

FREE PLAY

1. Check:

• Clutch lever free play "a"

Out of specification→Adjust.

2. Adjust:

• Clutch lever free play

Clutch lever free play adjustment

steps:

a. Loosen the locknuts "1".b. Turn the adjuster "2" until free

play "a" is within the specified lim-

its.

c. Tighten the locknuts.

• Before adjustment, expose the ad-

juster by moving the boot "3" and

cap "4" away.

• Make minute adjustment on the le-

ver side using the adjuster "5".

• After adjustment, check proper op-

eration of clutch lever.

3. Install:

•Cap "1"

•Boot "2"

Place the tip "a" of the cap in the boot.

ADJUSTING THE THROTTLE

CABLE FREE PLAY

1. Check:

• Throttle grip free play "a"

Out of specification→Adjust.

2. Adjust:

• Throttle grip free play

Throttle grip free play adjustment

steps:

a. Slide the adjuster cover. Radiator cap opening

pressure:

110 kPa (1.1 kg/cm

2,

15.6 psi)

Radiator cap tester:

YU-24460-01/90890-

01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Standard pressure:

180 kPa (1.8 kg/cm

2,

25.6 psi)

Locknut:

5 Nm (0.5 m•kg, 3.6

ft•lb)

Clutch lever free play "a"

:

7–12 mm (0.28–0.47 in)

Locknut:

4 Nm (0.4 m•kg, 2.9

ft•lb)

Throttle grip free play

"a":

3–5 mm (0.12–0.20 in)

Page 75 of 190

4-5

RADIATOR

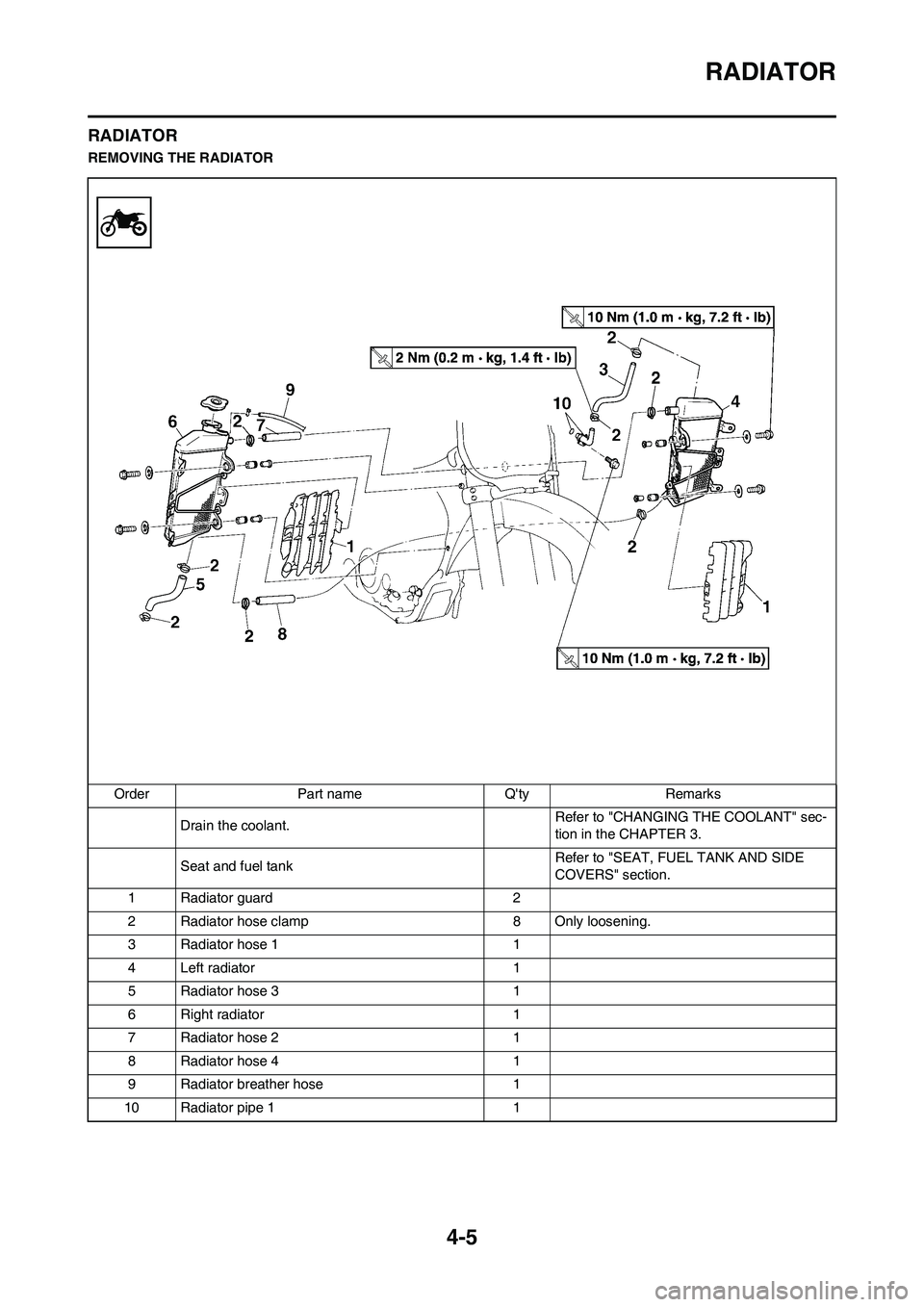

RADIATOR

REMOVING THE RADIATOR

Order Part name Q'ty Remarks

Drain the coolant.Refer to "CHANGING THE COOLANT" sec-

tion in the CHAPTER 3.

Seat and fuel tankRefer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

1 Radiator guard 2

2 Radiator hose clamp 8 Only loosening.

3 Radiator hose 1 1

4 Left radiator 1

5 Radiator hose 3 1

6 Right radiator 1

7 Radiator hose 2 1

8 Radiator hose 4 1

9 Radiator breather hose 1

10 Radiator pipe 1 1

Page 76 of 190

4-6

RADIATOR

HANDLING NOTE

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot fluid and steam

may be blown out under pressure,

which could cause serious injury.

When the engine has cooled, open

the radiator cap by the following

procedure:

Place a thick rag, like a towel, over

the radiator cap, slowly rotate the

cap counterclockwise to the de-

tent. This procedure allows any re-

sidual pressure to escape. When

the hissing sound has stopped,

press down on the cap while turn-

ing counterclockwise and remove

it.

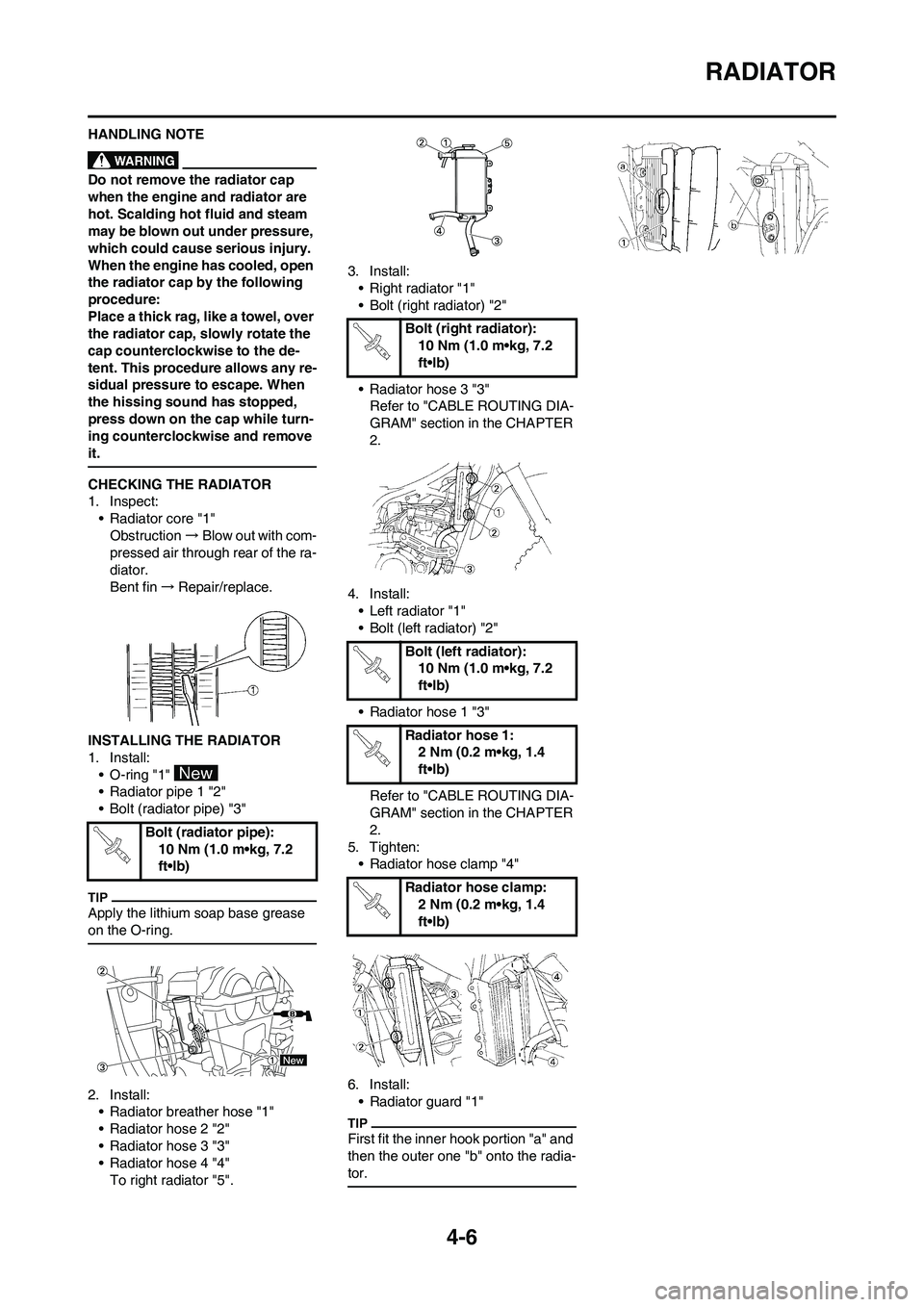

CHECKING THE RADIATOR

1. Inspect:

• Radiator core "1"

Obstruction→Blow out with com-

pressed air through rear of the ra-

diator.

Bent fin→Repair/replace.

INSTALLING THE RADIATOR

1. Install:

• O-ring "1"

• Radiator pipe 1 "2"

• Bolt (radiator pipe) "3"

Apply the lithium soap base grease

on the O-ring.

2. Install:

• Radiator breather hose "1"

• Radiator hose 2 "2"

• Radiator hose 3 "3"

• Radiator hose 4 "4"

To right radiator "5".3. Install:

• Right radiator "1"

• Bolt (right radiator) "2"

• Radiator hose 3 "3"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

4. Install:

• Left radiator "1"

• Bolt (left radiator) "2"

• Radiator hose 1 "3"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2.

5. Tighten:

• Radiator hose clamp "4"

6. Install:

• Radiator guard "1"

First fit the inner hook portion "a" and

then the outer one "b" onto the radia-

tor.

Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (right radiator):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (left radiator):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Radiator hose 1:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Radiator hose clamp:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Page 89 of 190

4-19

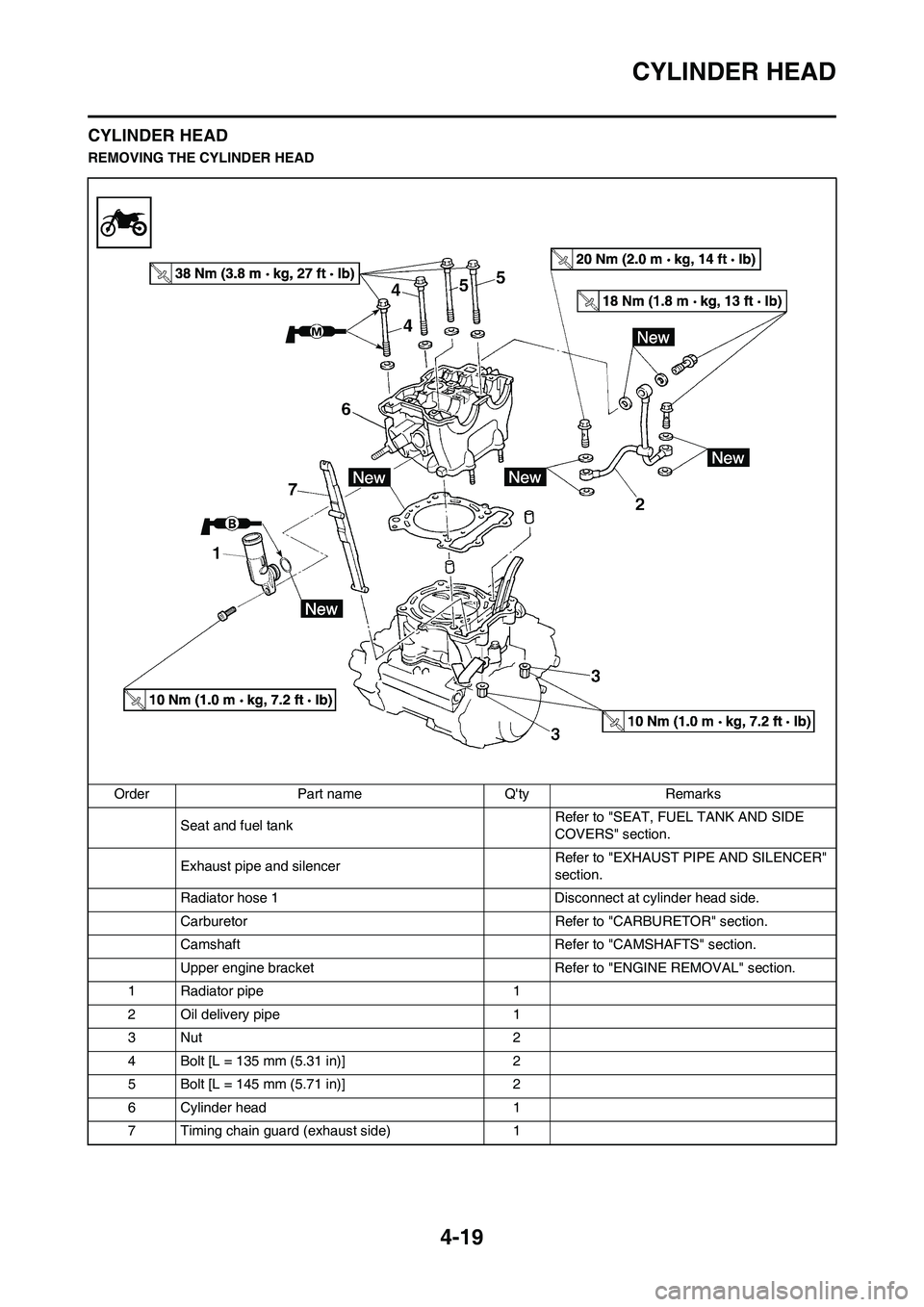

CYLINDER HEAD

CYLINDER HEAD

REMOVING THE CYLINDER HEAD

Order Part name Q'ty Remarks

Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Exhaust pipe and silencerRefer to "EXHAUST PIPE AND SILENCER"

section.

Radiator hose 1 Disconnect at cylinder head side.

Carburetor Refer to "CARBURETOR" section.

Camshaft Refer to "CAMSHAFTS" section.

Upper engine bracket Refer to "ENGINE REMOVAL" section.

1 Radiator pipe 1

2 Oil delivery pipe 1

3Nut 2

4 Bolt [L = 135 mm (5.31 in)] 2

5 Bolt [L = 145 mm (5.71 in)] 2

6 Cylinder head 1

7 Timing chain guard (exhaust side) 1

Page 90 of 190

4-20

CYLINDER HEAD

CHECKING THE CYLINDER HEAD

1. Eliminate:

• Carbon deposits (from the com-

bustion chambers)

Use a rounded scraper.

Do not use a sharp instrument to

avoid damaging or scratching:

• Spark plug threads

•Valve seats

2. Inspect:

• Cylinder head

Scratches/damage→Replace.

3. Measure:

• Cylinder head warpage

Out of specification→Resurface.

Warpage measurement and resur-

facing steps:

a. Place a straightedge and a feeler

gauge across the cylinder head.

b. Use a feeler gauge to measure

the warpage.

c. If the warpage is out of specifica-

tion, resurface the cylinder head.

d. Place a 400–600 grit wet sandpa-

per on the surface plate, and re-

surface the head using a figure-

eight sanding pattern.

To ensure an even surface rotate the

cylinder head several times.

INSTALLING THE CYLINDER

HEAD

1. Install:

• Dowel pin "1"

• Cylinder head gasket "2"

• Timing chain guide (exhaust side)

"3"

• Cylinder head "4"

While pulling up the timing chain, in-

stall the timing chain guide (exhaust

side) and cylinder head.

2. Install:

•Washer "1"

• Cable guide "2"

• Bolts [L = 145 mm (5.71 in)] "3"

• Bolts [L = 135 mm (5.31 in)] "4"

•Nuts "5"

• Apply the molybdenum disulfide

grease on the thread and contact

surface of the bolts.

• Follow the numerical order shown

in the illustration. Tighten the bolts

and nuts in two stages.

3. Install:

• Copper washer "1"

• Oil delivery pipe "2"

• Union bolt (M8) "3"

• Union bolt (M10) "4"

4. Install:

• Radiator pipe "1"

• Bolt (radiator pipe) "2" Cylinder head warpage:

Less than 0.05 mm

(0.002 in)

Bolts [L = 145 mm (5.71

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Bolts [L = 135 mm (5.31

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Nuts:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Union bolt (M8):

18 Nm (1.8 m•kg, 13

ft•lb)

Union bolt (M10):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)