CARB YAMAHA YZ250F 2009 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ250F, Model: YAMAHA YZ250F 2009Pages: 190, PDF Size: 12.83 MB

Page 82 of 190

4-12

CARBURETOR

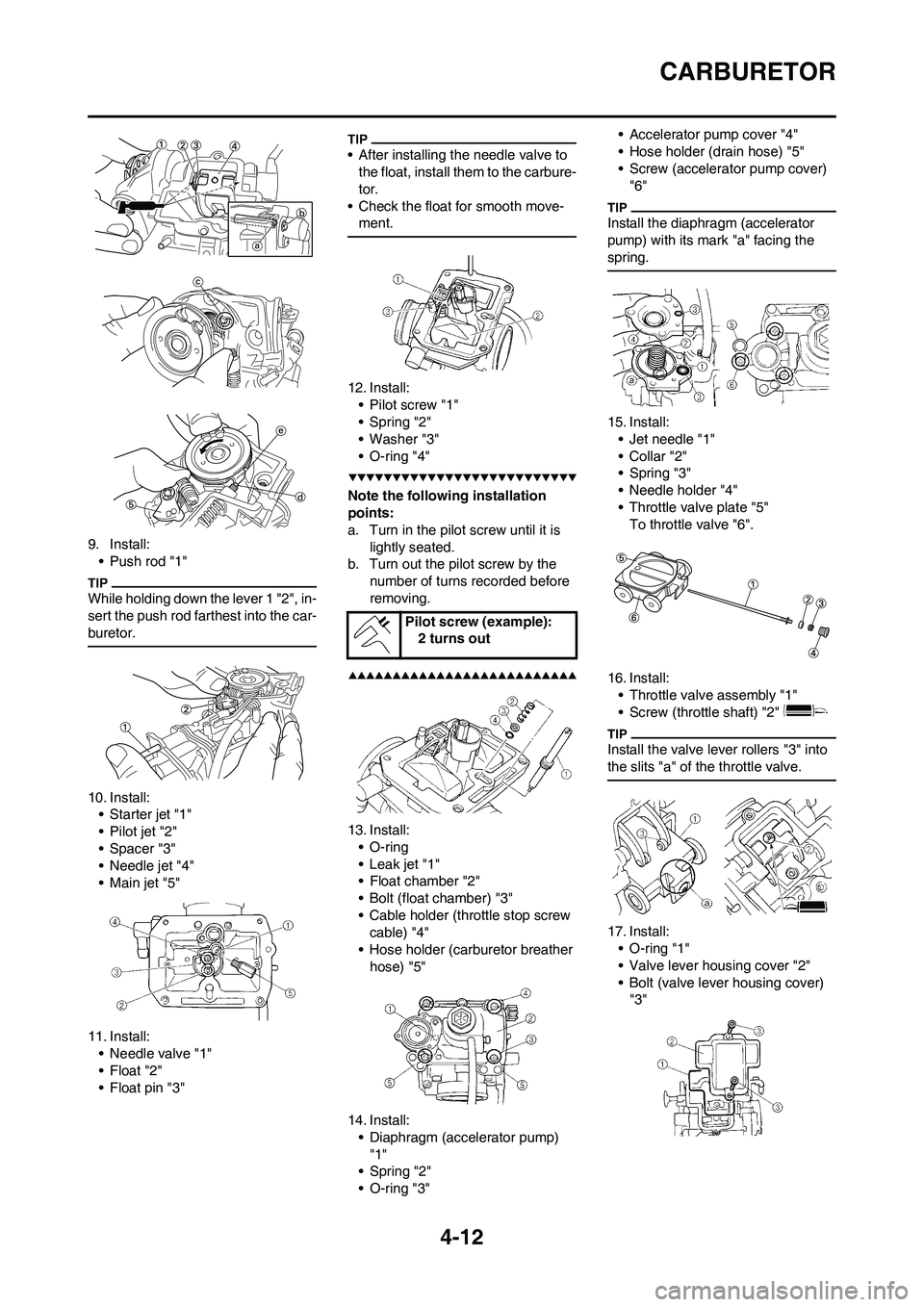

9. Install:

• Push rod "1"

While holding down the lever 1 "2", in-

sert the push rod farthest into the car-

buretor.

10. Install:

• Starter jet "1"

• Pilot jet "2"

• Spacer "3"

• Needle jet "4"

•Main jet "5"

11. Install:

• Needle valve "1"

•Float "2"

• Float pin "3"

• After installing the needle valve to

the float, install them to the carbure-

tor.

• Check the float for smooth move-

ment.

12. Install:

• Pilot screw "1"

• Spring "2"

•Washer "3"

• O-ring "4"

Note the following installation

points:

a. Turn in the pilot screw until it is

lightly seated.

b. Turn out the pilot screw by the

number of turns recorded before

removing.

13. Install:

• O-ring

•Leak jet "1"

• Float chamber "2"

• Bolt (float chamber) "3"

• Cable holder (throttle stop screw

cable) "4"

• Hose holder (carburetor breather

hose) "5"

14. Install:

• Diaphragm (accelerator pump)

"1"

• Spring "2"

• O-ring "3"• Accelerator pump cover "4"

• Hose holder (drain hose) "5"

• Screw (accelerator pump cover)

"6"

Install the diaphragm (accelerator

pump) with its mark "a" facing the

spring.

15. Install:

•Jet needle "1"

•Collar "2"

• Spring "3"

• Needle holder "4"

• Throttle valve plate "5"

To throttle valve "6".

16. Install:

• Throttle valve assembly "1"

• Screw (throttle shaft) "2"

Install the valve lever rollers "3" into

the slits "a" of the throttle valve.

17. Install:

• O-ring "1"

• Valve lever housing cover "2"

• Bolt (valve lever housing cover)

"3"

Pilot screw (example):

2 turns out

Page 83 of 190

4-13

CARBURETOR

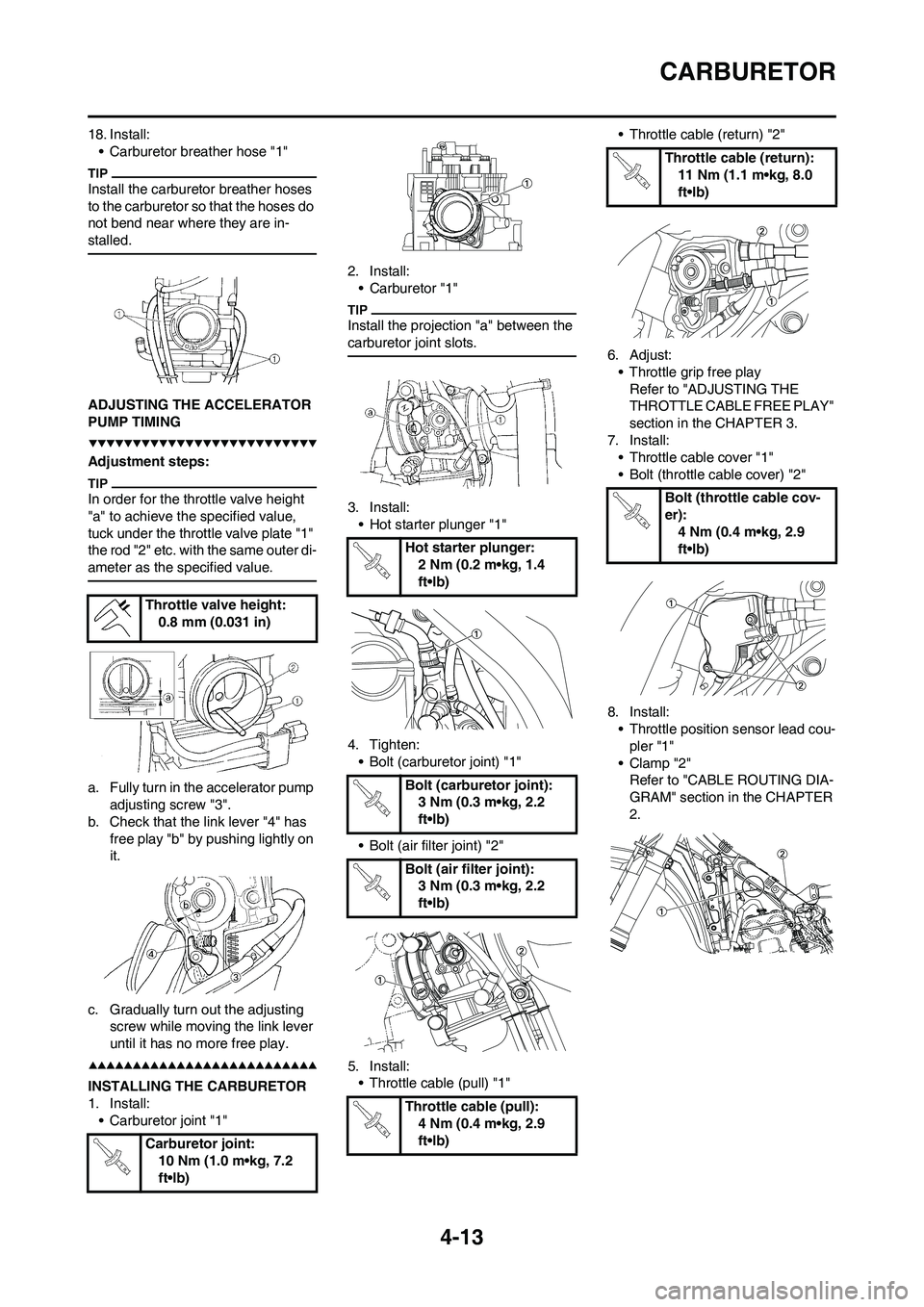

18. Install:

• Carburetor breather hose "1"

Install the carburetor breather hoses

to the carburetor so that the hoses do

not bend near where they are in-

stalled.

ADJUSTING THE ACCELERATOR

PUMP TIMING

Adjustment steps:

In order for the throttle valve height

"a" to achieve the specified value,

tuck under the throttle valve plate "1"

the rod "2" etc. with the same outer di-

ameter as the specified value.

a. Fully turn in the accelerator pump

adjusting screw "3".

b. Check that the link lever "4" has

free play "b" by pushing lightly on

it.

c. Gradually turn out the adjusting

screw while moving the link lever

until it has no more free play.

INSTALLING THE CARBURETOR

1. Install:

• Carburetor joint "1"2. Install:

• Carburetor "1"

Install the projection "a" between the

carburetor joint slots.

3. Install:

• Hot starter plunger "1"

4. Tighten:

• Bolt (carburetor joint) "1"

• Bolt (air filter joint) "2"

5. Install:

• Throttle cable (pull) "1"• Throttle cable (return) "2"

6. Adjust:

• Throttle grip free play

Refer to "ADJUSTING THE

THROTTLE CABLE FREE PLAY"

section in the CHAPTER 3.

7. Install:

• Throttle cable cover "1"

• Bolt (throttle cable cover) "2"

8. Install:

• Throttle position sensor lead cou-

pler "1"

•Clamp "2"

Refer to "CABLE ROUTING DIA-

GRAM" section in the CHAPTER

2. Throttle valve height:

0.8 mm (0.031 in)

Carburetor joint:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Hot starter plunger:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Bolt (carburetor joint):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (air filter joint):

3 Nm (0.3 m•kg, 2.2

ft•lb)

Throttle cable (pull):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Throttle cable (return):

11 Nm (1.1 m•kg, 8.0

ft•lb)

Bolt (throttle cable cov-

er):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 89 of 190

4-19

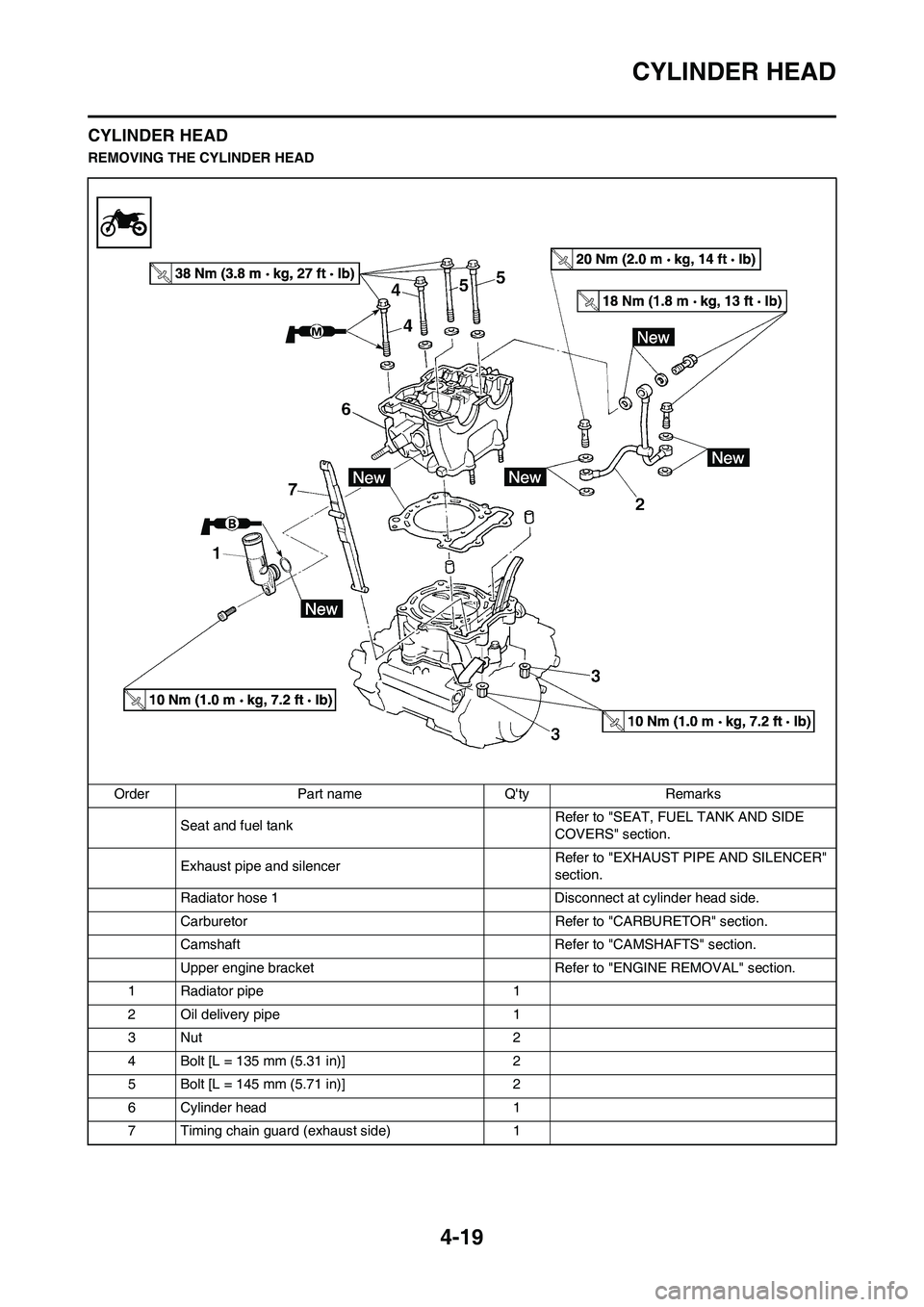

CYLINDER HEAD

CYLINDER HEAD

REMOVING THE CYLINDER HEAD

Order Part name Q'ty Remarks

Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Exhaust pipe and silencerRefer to "EXHAUST PIPE AND SILENCER"

section.

Radiator hose 1 Disconnect at cylinder head side.

Carburetor Refer to "CARBURETOR" section.

Camshaft Refer to "CAMSHAFTS" section.

Upper engine bracket Refer to "ENGINE REMOVAL" section.

1 Radiator pipe 1

2 Oil delivery pipe 1

3Nut 2

4 Bolt [L = 135 mm (5.31 in)] 2

5 Bolt [L = 145 mm (5.71 in)] 2

6 Cylinder head 1

7 Timing chain guard (exhaust side) 1

Page 90 of 190

4-20

CYLINDER HEAD

CHECKING THE CYLINDER HEAD

1. Eliminate:

• Carbon deposits (from the com-

bustion chambers)

Use a rounded scraper.

Do not use a sharp instrument to

avoid damaging or scratching:

• Spark plug threads

•Valve seats

2. Inspect:

• Cylinder head

Scratches/damage→Replace.

3. Measure:

• Cylinder head warpage

Out of specification→Resurface.

Warpage measurement and resur-

facing steps:

a. Place a straightedge and a feeler

gauge across the cylinder head.

b. Use a feeler gauge to measure

the warpage.

c. If the warpage is out of specifica-

tion, resurface the cylinder head.

d. Place a 400–600 grit wet sandpa-

per on the surface plate, and re-

surface the head using a figure-

eight sanding pattern.

To ensure an even surface rotate the

cylinder head several times.

INSTALLING THE CYLINDER

HEAD

1. Install:

• Dowel pin "1"

• Cylinder head gasket "2"

• Timing chain guide (exhaust side)

"3"

• Cylinder head "4"

While pulling up the timing chain, in-

stall the timing chain guide (exhaust

side) and cylinder head.

2. Install:

•Washer "1"

• Cable guide "2"

• Bolts [L = 145 mm (5.71 in)] "3"

• Bolts [L = 135 mm (5.31 in)] "4"

•Nuts "5"

• Apply the molybdenum disulfide

grease on the thread and contact

surface of the bolts.

• Follow the numerical order shown

in the illustration. Tighten the bolts

and nuts in two stages.

3. Install:

• Copper washer "1"

• Oil delivery pipe "2"

• Union bolt (M8) "3"

• Union bolt (M10) "4"

4. Install:

• Radiator pipe "1"

• Bolt (radiator pipe) "2" Cylinder head warpage:

Less than 0.05 mm

(0.002 in)

Bolts [L = 145 mm (5.71

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Bolts [L = 135 mm (5.31

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Nuts:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Union bolt (M8):

18 Nm (1.8 m•kg, 13

ft•lb)

Union bolt (M10):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 93 of 190

4-23

VALVES AND VALVE SPRINGS

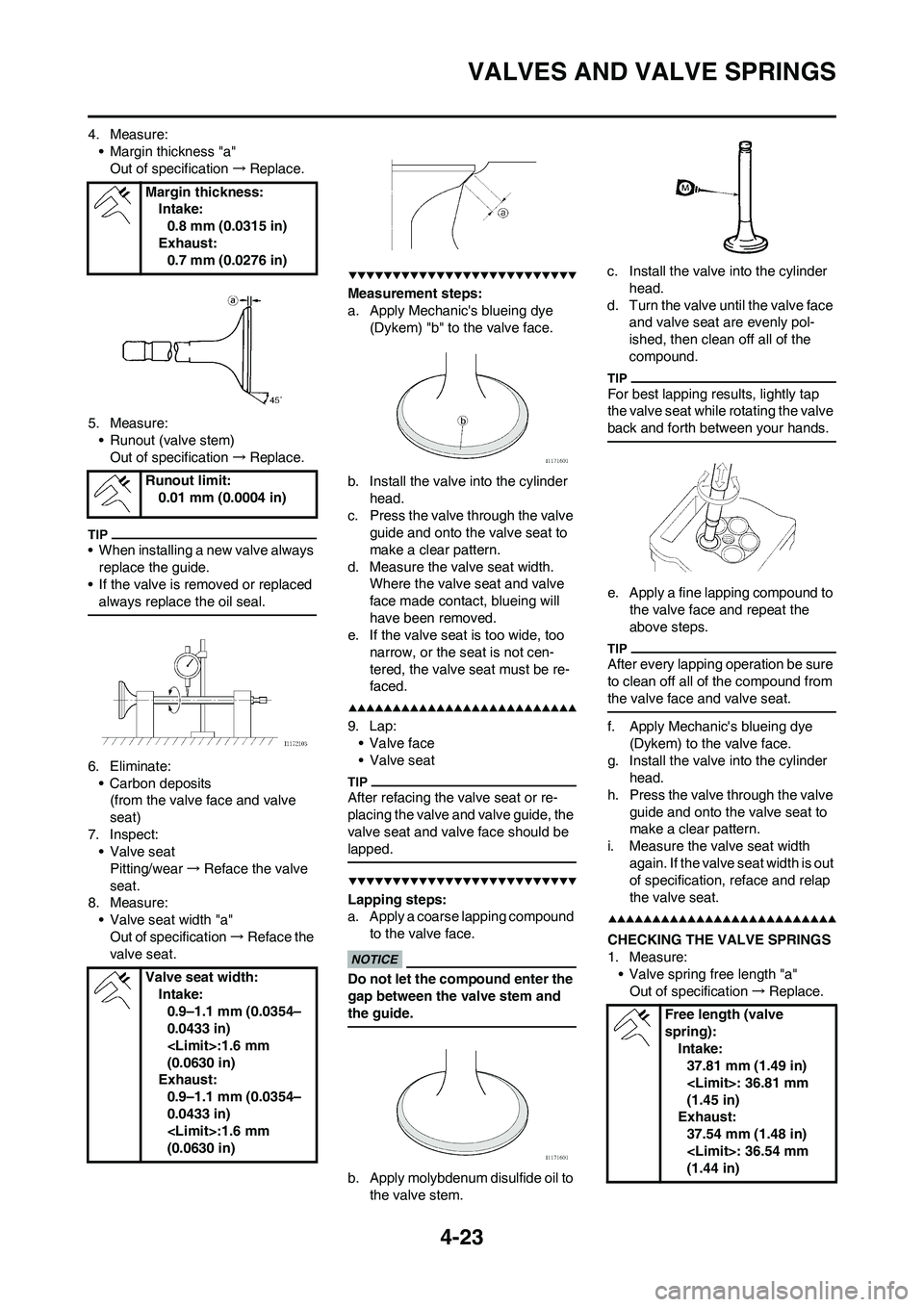

4. Measure:

• Margin thickness "a"

Out of specification→Replace.

5. Measure:

• Runout (valve stem)

Out of specification→Replace.

• When installing a new valve always

replace the guide.

• If the valve is removed or replaced

always replace the oil seal.

6. Eliminate:

• Carbon deposits

(from the valve face and valve

seat)

7. Inspect:

•Valve seat

Pitting/wear→Reface the valve

seat.

8. Measure:

• Valve seat width "a"

Out of specification→Reface the

valve seat.

Measurement steps:

a. Apply Mechanic's blueing dye

(Dykem) "b" to the valve face.

b. Install the valve into the cylinder

head.

c. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

d. Measure the valve seat width.

Where the valve seat and valve

face made contact, blueing will

have been removed.

e. If the valve seat is too wide, too

narrow, or the seat is not cen-

tered, the valve seat must be re-

faced.

9. Lap:

• Valve face

• Valve seat

After refacing the valve seat or re-

placing the valve and valve guide, the

valve seat and valve face should be

lapped.

Lapping steps:

a. Apply a coarse lapping compound

to the valve face.

Do not let the compound enter the

gap between the valve stem and

the guide.

b. Apply molybdenum disulfide oil to

the valve stem.c. Install the valve into the cylinder

head.

d. Turn the valve until the valve face

and valve seat are evenly pol-

ished, then clean off all of the

compound.

For best lapping results, lightly tap

the valve seat while rotating the valve

back and forth between your hands.

e. Apply a fine lapping compound to

the valve face and repeat the

above steps.

After every lapping operation be sure

to clean off all of the compound from

the valve face and valve seat.

f. Apply Mechanic's blueing dye

(Dykem) to the valve face.

g. Install the valve into the cylinder

head.

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification→Replace. Margin thickness:

Intake:

0.8 mm (0.0315 in)

Exhaust:

0.7 mm (0.0276 in)

Runout limit:

0.01 mm (0.0004 in)

Valve seat width:

Intake:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Exhaust:

0.9–1.1 mm (0.0354–

0.0433 in)

(0.0630 in)

Free length (valve

spring):

Intake:

37.81 mm (1.49 in)

(1.45 in)

Exhaust:

37.54 mm (1.48 in)

(1.44 in)

Page 96 of 190

4-26

CYLINDER AND PISTON

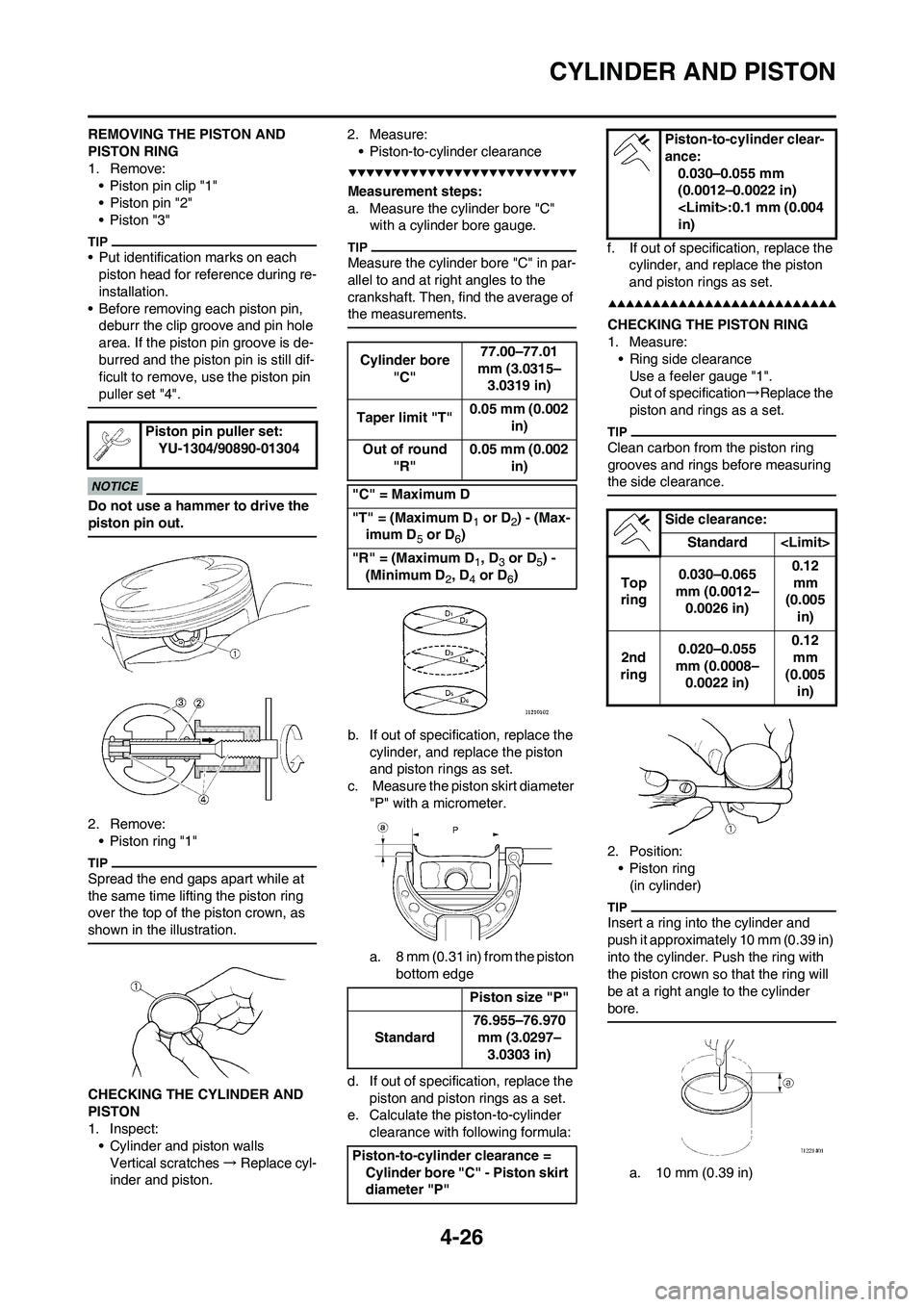

REMOVING THE PISTON AND

PISTON RING

1. Remove:

• Piston pin clip "1"

• Piston pin "2"

•Piston "3"

• Put identification marks on each

piston head for reference during re-

installation.

• Before removing each piston pin,

deburr the clip groove and pin hole

area. If the piston pin groove is de-

burred and the piston pin is still dif-

ficult to remove, use the piston pin

puller set "4".

Do not use a hammer to drive the

piston pin out.

2. Remove:

• Piston ring "1"

Spread the end gaps apart while at

the same time lifting the piston ring

over the top of the piston crown, as

shown in the illustration.

CHECKING THE CYLINDER AND

PISTON

1. Inspect:

• Cylinder and piston walls

Vertical scratches→Replace cyl-

inder and piston.2. Measure:

• Piston-to-cylinder clearance

Measurement steps:

a. Measure the cylinder bore "C"

with a cylinder bore gauge.

Measure the cylinder bore "C" in par-

allel to and at right angles to the

crankshaft. Then, find the average of

the measurements.

b. If out of specification, replace the

cylinder, and replace the piston

and piston rings as set.

c. Measure the piston skirt diameter

"P" with a micrometer.

a. 8 mm (0.31 in) from the piston

bottom edge

d. If out of specification, replace the

piston and piston rings as a set.

e. Calculate the piston-to-cylinder

clearance with following formula:f. If out of specification, replace the

cylinder, and replace the piston

and piston rings as set.

CHECKING THE PISTON RING

1. Measure:

• Ring side clearance

Use a feeler gauge "1".

Out of specification→Replace the

piston and rings as a set.

Clean carbon from the piston ring

grooves and rings before measuring

the side clearance.

2. Position:

• Piston ring

(in cylinder)

Insert a ring into the cylinder and

push it approximately 10 mm (0.39 in)

into the cylinder. Push the ring with

the piston crown so that the ring will

be at a right angle to the cylinder

bore.

a. 10 mm (0.39 in) Piston pin puller set:

YU-1304/90890-01304

Cylinder bore

"C"77.00–77.01

mm (3.0315–

3.0319 in)

Taper limit "T"0.05 mm (0.002

in)

Out of round

"R"0.05 mm (0.002

in)

"C" = Maximum D

"T" = (Maximum D

1 or D2) - (Max-

imum D

5 or D6)

"R" = (Maximum D

1, D3 or D5) -

(Minimum D

2, D4 or D6)

Piston size "P"

Standard76.955–76.970

mm (3.0297–

3.0303 in)

Piston-to-cylinder clearance =

Cylinder bore "C" - Piston skirt

diameter "P"

Piston-to-cylinder clear-

ance:

0.030–0.055 mm

(0.0012–0.0022 in)

in)

Side clearance:

Standard

Top

ring0.030–0.065

mm (0.0012–

0.0026 in)0.12

mm

(0.005

in)

2nd

ring0.020–0.055

mm (0.0008–

0.0022 in)0.12

mm

(0.005

in)

Page 119 of 190

4-49

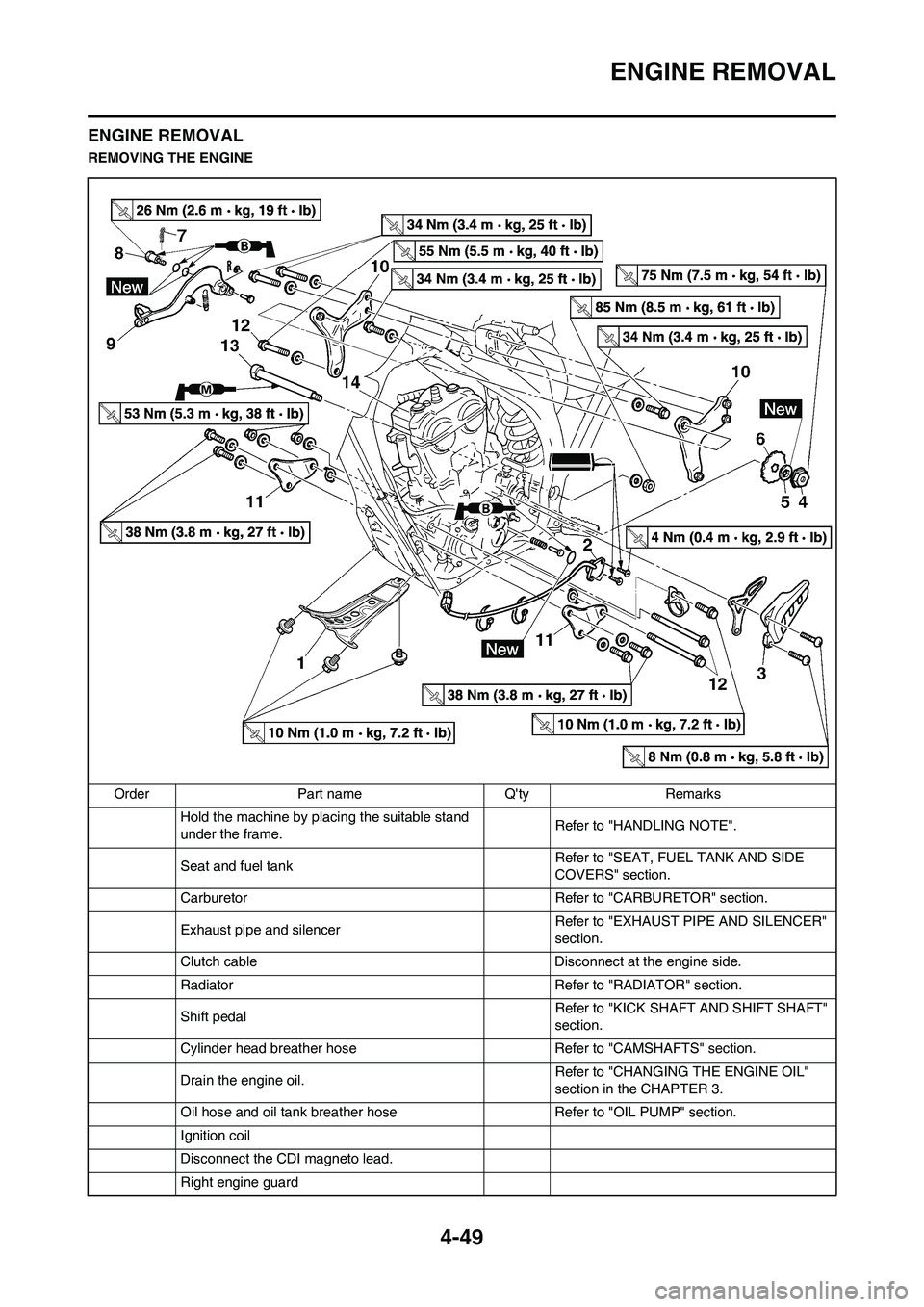

ENGINE REMOVAL

ENGINE REMOVAL

REMOVING THE ENGINE

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the frame.Refer to "HANDLING NOTE".

Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Carburetor Refer to "CARBURETOR" section.

Exhaust pipe and silencer Refer to "EXHAUST PIPE AND SILENCER"

section.

Clutch cable Disconnect at the engine side.

Radiator Refer to "RADIATOR" section.

Shift pedalRefer to "KICK SHAFT AND SHIFT SHAFT"

section.

Cylinder head breather hose Refer to "CAMSHAFTS" section.

Drain the engine oil.Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Oil hose and oil tank breather hose Refer to "OIL PUMP" section.

Ignition coil

Disconnect the CDI magneto lead.

Right engine guard

Page 176 of 190

6-7

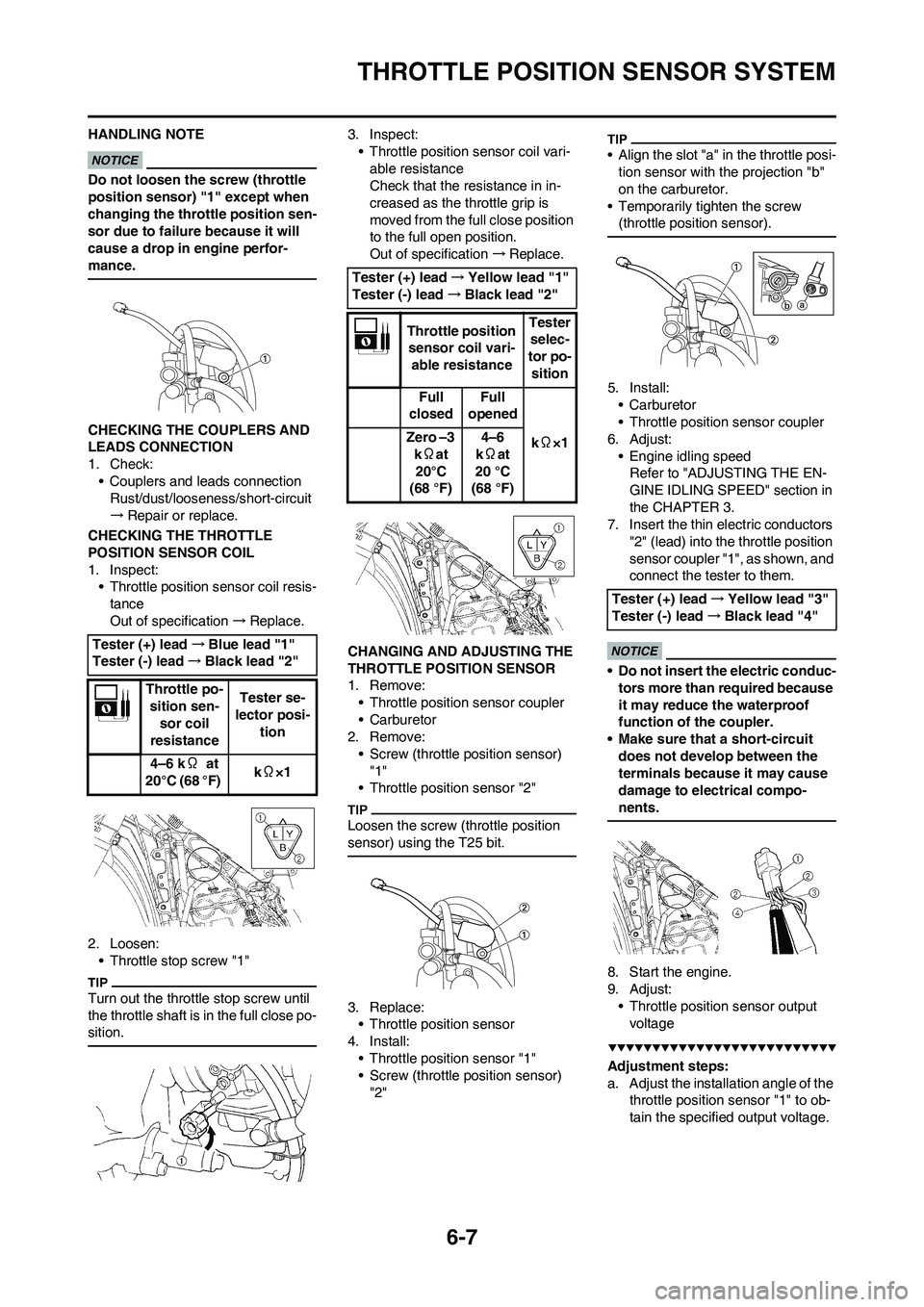

THROTTLE POSITION SENSOR SYSTEM

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

CHECKING THE COUPLERS AND

LEADS CONNECTION

1. Check:

• Couplers and leads connection

Rust/dust/looseness/short-circuit

→Repair or replace.

CHECKING THE THROTTLE

POSITION SENSOR COIL

1. Inspect:

• Throttle position sensor coil resis-

tance

Out of specification→Replace.

2. Loosen:

• Throttle stop screw "1"

Turn out the throttle stop screw until

the throttle shaft is in the full close po-

sition.

3. Inspect:

• Throttle position sensor coil vari-

able resistance

Check that the resistance in in-

creased as the throttle grip is

moved from the full close position

to the full open position.

Out of specification→Replace.

CHANGING AND ADJUSTING THE

THROTTLE POSITION SENSOR

1. Remove:

• Throttle position sensor coupler

•Carburetor

2. Remove:

• Screw (throttle position sensor)

"1"

• Throttle position sensor "2"

Loosen the screw (throttle position

sensor) using the T25 bit.

3. Replace:

• Throttle position sensor

4. Install:

• Throttle position sensor "1"

• Screw (throttle position sensor)

"2"

• Align the slot "a" in the throttle posi-

tion sensor with the projection "b"

on the carburetor.

• Temporarily tighten the screw

(throttle position sensor).

5. Install:

•Carburetor

• Throttle position sensor coupler

6. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section in

the CHAPTER 3.

7. Insert the thin electric conductors

"2" (lead) into the throttle position

sensor coupler "1", as shown, and

connect the tester to them.

• Do not insert the electric conduc-

tors more than required because

it may reduce the waterproof

function of the coupler.

• Make sure that a short-circuit

does not develop between the

terminals because it may cause

damage to electrical compo-

nents.

8. Start the engine.

9. Adjust:

• Throttle position sensor output

voltage

Adjustment steps:

a. Adjust the installation angle of the

throttle position sensor "1" to ob-

tain the specified output voltage. Tester (+) lead→Blue lead "1"

Tester (-) lead→Black lead "2"

Throttle po-

sition sen-

sor coil

resistanceTester se-

lector posi-

tion

4–6 kΩ at

20°C (68 °F) kΩ×1

Tester (+) lead→Yellow lead "1"

Tester (-) lead→Black lead "2"

Throttle position

sensor coil vari-

able resistanceTester

selec-

tor po-

sition

Full

closedFull

opened

kΩ×1 Zero –3

kΩat

20°C

(68 °F)4–6

kΩat

20 °C

(68 °F)

Tester (+) lead→Yellow lead "3"

Tester (-) lead→Black lead "4"

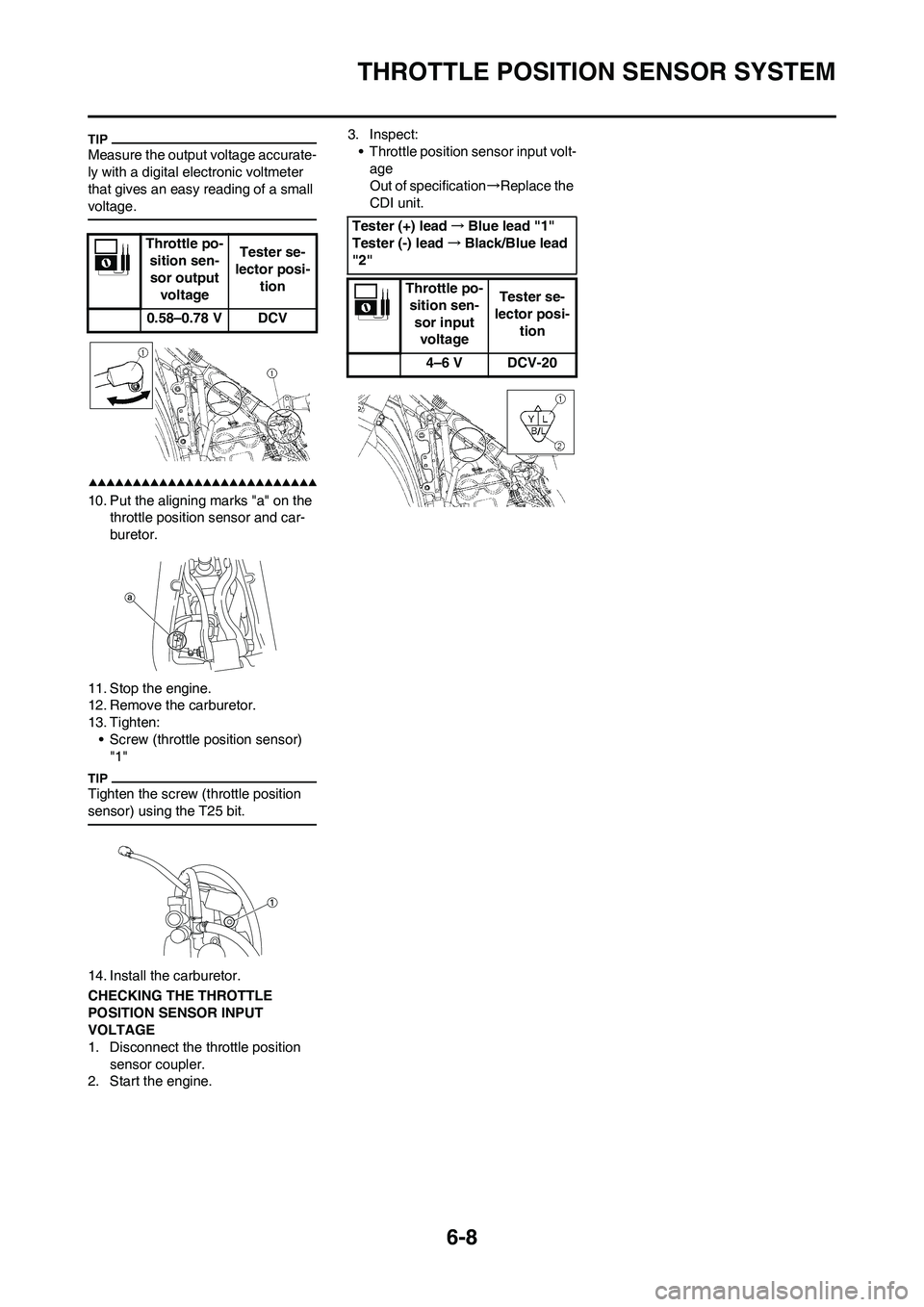

Page 177 of 190

6-8

THROTTLE POSITION SENSOR SYSTEM

Measure the output voltage accurate-

ly with a digital electronic voltmeter

that gives an easy reading of a small

voltage.

10. Put the aligning marks "a" on the

throttle position sensor and car-

buretor.

11. Stop the engine.

12. Remove the carburetor.

13. Tighten:

• Screw (throttle position sensor)

"1"

Tighten the screw (throttle position

sensor) using the T25 bit.

14. Install the carburetor.

CHECKING THE THROTTLE

POSITION SENSOR INPUT

VOLTAGE

1. Disconnect the throttle position

sensor coupler.

2. Start the engine.3. Inspect:

• Throttle position sensor input volt-

age

Out of specification→Replace the

CDI unit.

Throttle po-

sition sen-

sor output

voltageTester se-

lector posi-

tion

0.58–0.78 V DCV

Tester (+) lead→Blue lead "1"

Tester (-) lead→Black/Blue lead

"2"

Throttle po-

sition sen-

sor input

voltage Tester se-

lector posi-

tion

4–6 V DCV-20

Page 178 of 190

7-1

ENGINE

TUNING

ENGINE

CARBURETOR SETTING

• The air/fuel mixture will vary de-

pending on atmospheric conditions.

Therefore, it is necessary to take

into consideration the air pressure,

ambient temperature, humidity,

etc., when adjusting the carburetor.

• Perform a test run to check for prop-

er engine performance (e.g., throt-

tle response) and spark plug(-s)

discoloration or fouling. Use these

readings to determine the best pos-

sible carburetor setting.

It is recommended to keep a record of

all carburetor settings and external

conditions (e.g., atmospheric condi-

tions, track/surface conditions, lap

times) to make future carburetor set-

ting easier.

• The carburetor is a part of the

fuel line. Therefore, be sure to in-

stall it in a wellventilated area,

away from flammable objects

and any sources of fire.

• Never look into the carburetor in-

take. Flames may shoot out from

the pipe if the engine backfires

while it is being started. Gasoline

may be discharged from the ac-

celerator pump nozzle when the

carburetor has been removed.

• The carburetor is extremely sen-

sitive to foreign matter (dirt,

sand, water, etc.). During instal-

lation, do not allow foreign mat-

ter to get into the carburetor.

• Always handle the carburetor

and its components carefully.

Even slight scratches, bends or

damage to carburetor parts may

prevent the carburetor from

functioning correctly. Carefully

perform all servicing with the ap-

propriate tools and without ap-

plying excessive force.

• When the engine is stopped or

when riding at no load, do not

open and close the throttle un-

necessarily. Otherwise, too

much fuel may be discharged,

starting may become difficult or

the engine may not run well.• After installing the carburetor,

check that the throttle operates

correctly and opens and closes

smoothly.

ATMOSPHERIC CONDITIONS AND

CARBURETOR SETTINGS

The air density (i.e., concentration of

oxygen in the air) determines the rich-

ness or leanness of the air/fuel mix-

ture.

• Higher temperature expands the air

with its resultant reduced density.

• Higher humidity reduces the

amount of oxygen in the air by so

much of the water vapor in the

same air.

• Lower atmospheric pressure (at a

high altitude) reduces the density of

the air.

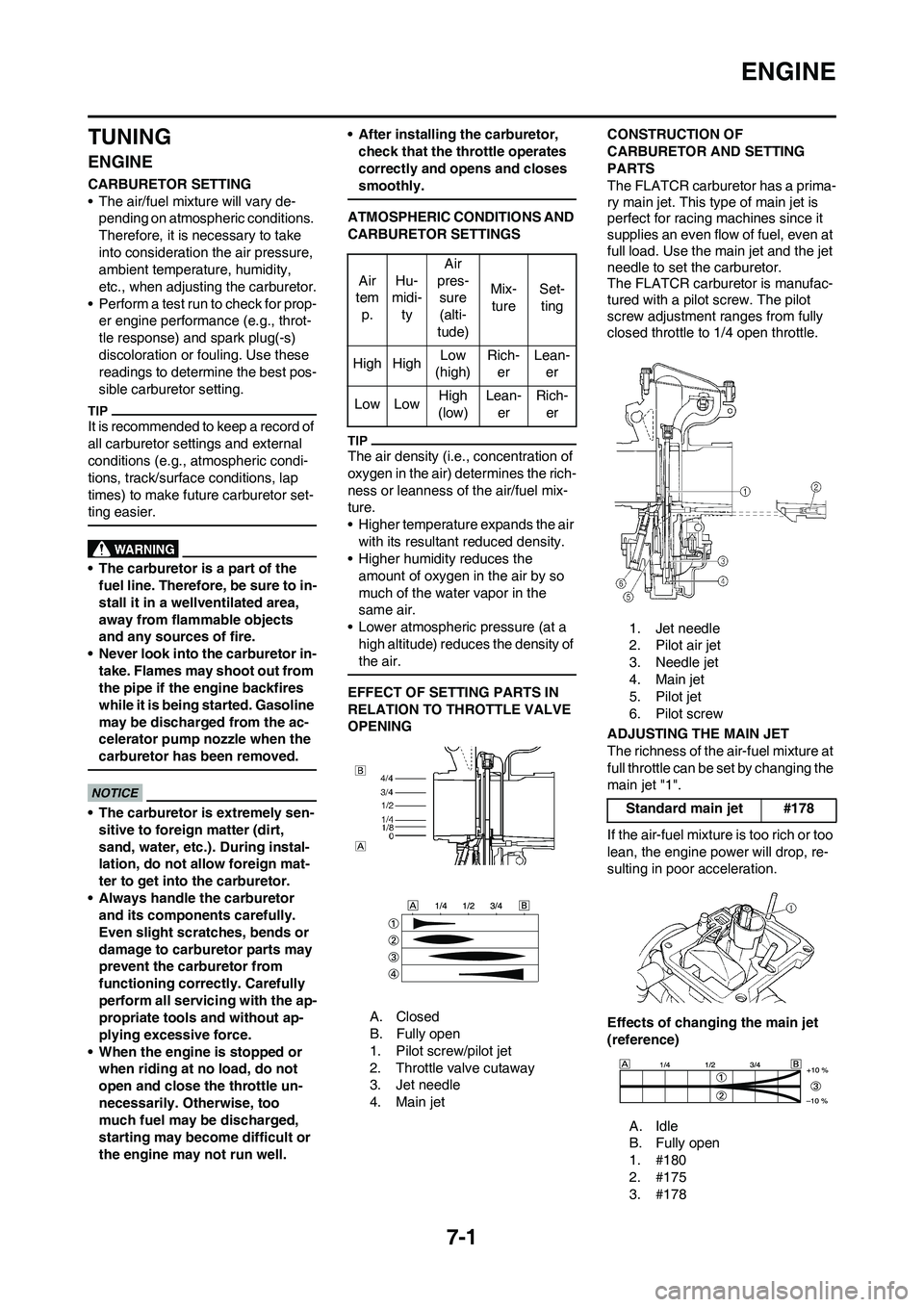

EFFECT OF SETTING PARTS IN

RELATION TO THROTTLE VALVE

OPENING

A. Closed

B. Fully open

1. Pilot screw/pilot jet

2. Throttle valve cutaway

3. Jet needle

4. Main jetCONSTRUCTION OF

CARBURETOR AND SETTING

PARTS

The FLATCR carburetor has a prima-

ry main jet. This type of main jet is

perfect for racing machines since it

supplies an even flow of fuel, even at

full load. Use the main jet and the jet

needle to set the carburetor.

The FLATCR carburetor is manufac-

tured with a pilot screw. The pilot

screw adjustment ranges from fully

closed throttle to 1/4 open throttle.

1. Jet needle

2. Pilot air jet

3. Needle jet

4. Main jet

5. Pilot jet

6. Pilot screw

ADJUSTING THE MAIN JET

The richness of the air-fuel mixture at

full throttle can be set by changing the

main jet "1".

If the air-fuel mixture is too rich or too

lean, the engine power will drop, re-

sulting in poor acceleration.

Effects of changing the main jet

(reference)

A. Idle

B. Fully open

1. #180

2. #175

3. #178 Air

tem

p.Hu-

midi-

tyAir

pres-

sure

(alti-

tude)Mix-

tureSet-

ting

High HighLow

(high)Rich-

erLean-

er

Low LowHigh

(low)Lean-

erRich-

er

Standard main jet #178