oil change YAMAHA YZ250F 2009 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2009, Model line: YZ250F, Model: YAMAHA YZ250F 2009Pages: 190, PDF Size: 12.83 MB

Page 6 of 190

FOREWORD

INTRODUCTION

Congratulations on your purchase of

a Yamaha YZ series. This model is

the culmination of Yamaha's vast ex-

perience in the production of paceset-

ting racing machines. It represents

the highest grade of craftsmanship

and reliability that have made Yama-

ha a leader.

This manual explains operation, in-

spection, basic maintenance and tun-

ing of your machine. If you have any

questions about this manual or your

machine, please contact your Yama-

ha dealer.

Yamaha continually seeks advance-

ments in product design and quality.

Therefore, while this manual contains

the most current product information

available at the time of printing, there

may be minor discrepancies between

your machine and this manual. If you

have any questions concerning this

manual, please consult your Yamaha

dealer.

PLEASE READ THIS MANUAL

CAREFULLY AND COMPLETELY

BEFORE OPERATING THIS MA-

CHINE. DO NOT ATTEMPT TO OP-

ERATE THIS MACHINE UNTIL YOU

HAVE ATTAINED A SATISFACTO-

RY KNOWLEDGE OF ITS CON-

TROLS AND OPERATING

FEATURES AND UNTIL YOU HAVE

BEEN TRAINED IN SAFE AND

PROPER RIDING TECHNIQUES.

REGULAR INSPECTIONS AND

CAREFUL MAINTENANCE,

ALONG WITH GOOD RIDING

SKILLS, WILL ENSURE THAT YOU

SAFETY ENJOY THE CAPABILI-

TIES AND THE RELIABILITY OF

THIS MACHINE.

IMPORTANT MANUAL

INFORMATION

Particularly important information is

distinguished in this manual by the

following notations.

This is the safety alert symbol. It is

used to alert you to potential per-

sonal injury hazards. Obey all safe-

ty messages that follow this

symbol to avoid possible injury or

death. A WARNING indicates a hazardous

situation which, if not avoided,

could result in death or serious in-

jury.

A NOTICE indicates special pre-

cautions that must be taken to

avoid damage to the vehicle or oth-

er property.

A TIP provides key information to

make procedures easier or clearer.

SAFETY INFORMATION

THIS MACHINE IS DESIGNED

STRICTLY FOR COMPETITION

USE, ONLY ON A CLOSED

COURSE. It is illegal for this machine

to be operated on any public street,

road, or highway. Off-road use on

public lands may also be illegal.

Please check local regulations before

riding.

• THIS MACHINE IS TO BE OPER-

ATED BY AN EXPERIENCED RID-

ER ONLY.

Do not attempt to operate this ma-

chine at maximum power until you

are totally familiar with its character-

istics.

• THIS MACHINE IS DESIGNED TO

BE RIDDEN BY THE OPERATOR

ONLY.

Do not carry passengers on this

machine.

• ALWAYS WEAR PROTECTIVE

APPAREL.

When operating this machine, al-

ways wear an approved helmet with

goggles or a face shield. Also wear

heavy boots, gloves, and protective

clothing. Always wear proper fitting

clothing that will not be caught in

any of the moving parts or controls

of the machine.

• ALWAYS MAINTAIN YOUR MA-

CHINE IN PROPER WORKING

ORDER.

For safety and reliability, the ma-

chine must be properly maintained.

Always perform the pre-operation

checks indicated in this manual.

Correcting a mechanical problem

before you ride may prevent an ac-

cident.

• GASOLINE IS HIGHLY FLAMMA-

BLE.

Always turn off the engine while re-

fueling. Take care to not spill any

gasoline on the engine or exhaust

system. Never refuel in the vicinity of an open flame, or while smoking.

• GASOLINE CAN CAUSE INJURY.

If you should swallow some gaso-

line, inhale excess gasoline vapors,

or allow any gasoline to get into

your eyes, contact a doctor immedi-

ately. If any gasoline spills onto

your skin or clothing, immediately

wash skin areas with soap and wa-

ter, and change your clothes.

• ONLY OPERATE THE MACHINE

IN AN AREA WITH ADEQUATE

VENTILATION.

Never start the engine or let it run

for any length of time in an enclosed

area. Exhaust fumes are poison-

ous. These fumes contain carbon

monoxide, which by itself is odor-

less and colorless. Carbon monox-

ide is a dangerous gas which can

cause unconsciousness or can be

lethal.

• PARK THE MACHINE CAREFUL-

LY; TURN OFF THE ENGINE.

Always turn off the engine if you are

going to leave the machine. Do not

park the machine on a slope or soft

ground as it may fall over.

• THE ENGINE, EXHAUST PIPE,

MUFFLER, AND OIL TANK WILL

BE VERY HOT AFTER THE EN-

GINE HAS BEEN RUN.

Be careful not to touch them or to

allow any clothing item to contact

them during inspection or repair.

• PROPERLY SECURE THE MA-

CHINE BEFORE TRANSPORTING

IT.

When transporting the machine in

another vehicle, always be sure it is

properly secured and in an upright

position and that the fuel cock is in

the "OFF" position. Otherwise, fuel

may leak out of the carburetor or

fuel tank.

F.I.M. MACHINE WEIGHTS

Weights of machines without fuel

The minimum weights for motocross

machines are:

for the class 125 cc:

minimum 88 kg (194 lb)

for the class 250 cc:

minimum 98 kg (216 lb)

for the class 500 cc:

minimum 102 kg (225 lb)

In modifying your machine (e.g., for

weight reduction), take note of the

above limits of weight.

Page 11 of 190

1-1

DESCRIPTION

GENERAL INFORMATION

DESCRIPTION

• The machine you have purchased may differ slightly from those shown in the following.

• Designs and specifications are subject to change without notice.

1. Clutch lever

2. Hot starter lever

3. Front brake lever

4. Throttle grip

5. Radiator cap

6. Fuel tank cap

7. Engine stop switch

8. Kickstarter crank

9. Fuel tank

10. Radiator

11. Coolant drain bolt

12. Rear brake pedal

13. Valve joint14. Fuel cock

15. Cold starter knob

16. Drive chain

17. Air filter

18. Oil level check window

19. Shift pedal

20. Front fork

1

Page 23 of 190

2-1

GENERAL SPECIFICATIONS

SPECIFICATIONS

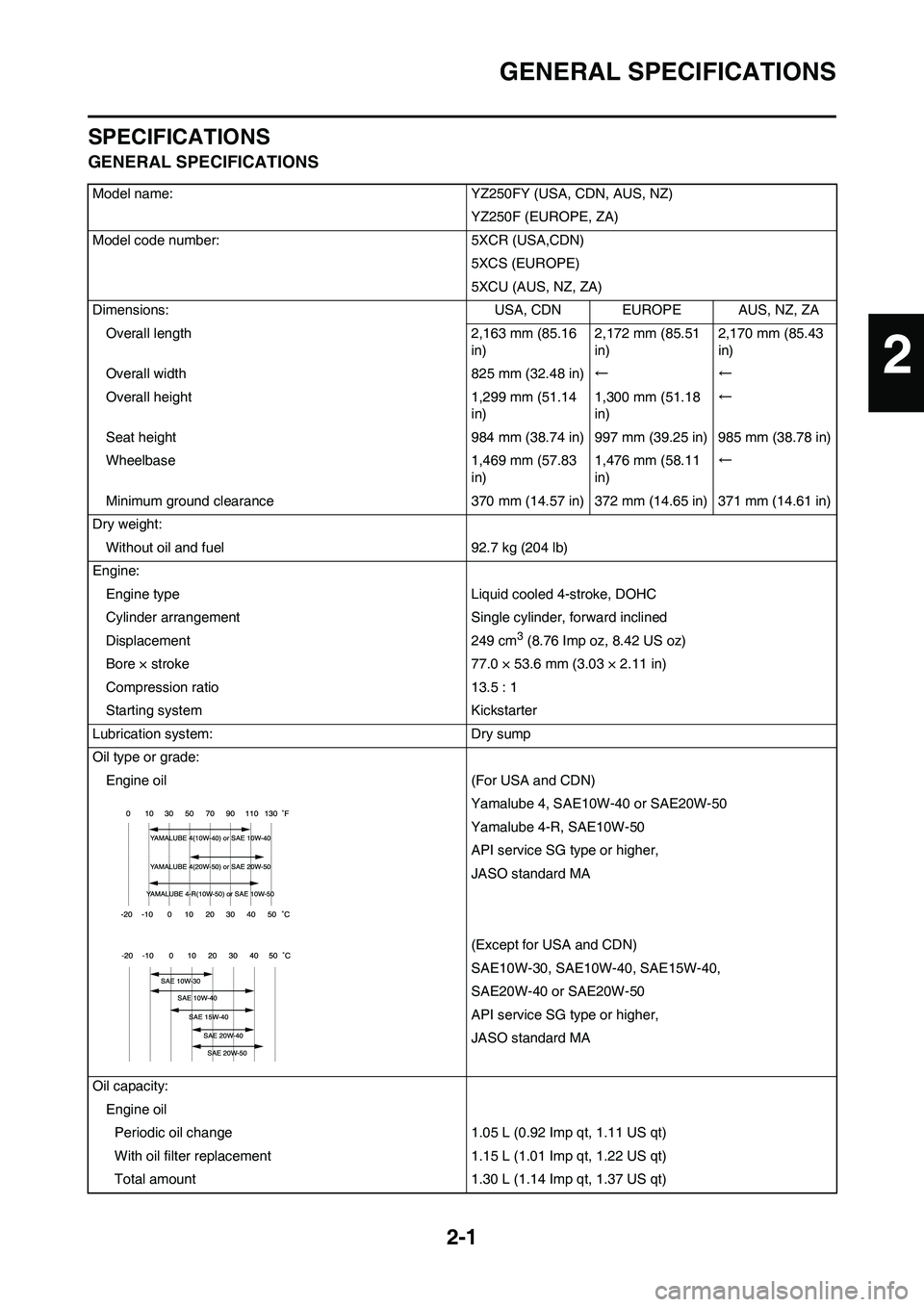

GENERAL SPECIFICATIONS

Model name: YZ250FY (USA, CDN, AUS, NZ)

YZ250F (EUROPE, ZA)

Model code number: 5XCR (USA,CDN)

5XCS (EUROPE)

5XCU (AUS, NZ, ZA)

Dimensions: USA, CDN EUROPE AUS, NZ, ZA

Overall length 2,163 mm (85.16

in)2,172 mm (85.51

in)2,170 mm (85.43

in)

Overall width 825 mm (32.48 in)←←

Overall height 1,299 mm (51.14

in)1,300 mm (51.18

in)←

Seat height 984 mm (38.74 in) 997 mm (39.25 in) 985 mm (38.78 in)

Wheelbase 1,469 mm (57.83

in)1,476 mm (58.11

in)←

Minimum ground clearance 370 mm (14.57 in) 372 mm (14.65 in) 371 mm (14.61 in)

Dry weight:

Without oil and fuel 92.7 kg (204 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 249 cm

3 (8.76 Imp oz, 8.42 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 13.5 : 1

Starting system Kickstarter

Lubrication system: Dry sump

Oil type or grade:

Engine oil (For USA and CDN)

Yamalube 4, SAE10W-40 or SAE20W-50

Yamalube 4-R, SAE10W-50

API service SG type or higher,

JASO standard MA

(Except for USA and CDN)

SAE10W-30, SAE10W-40, SAE15W-40,

SAE20W-40 or SAE20W-50

API service SG type or higher,

JASO standard MA

Oil capacity:

Engine oil

Periodic oil change 1.05 L (0.92 Imp qt, 1.11 US qt)

With oil filter replacement 1.15 L (1.01 Imp qt, 1.22 US qt)

Total amount 1.30 L (1.14 Imp qt, 1.37 US qt)

2

Page 47 of 190

3-1

MAINTENANCE INTERVALS

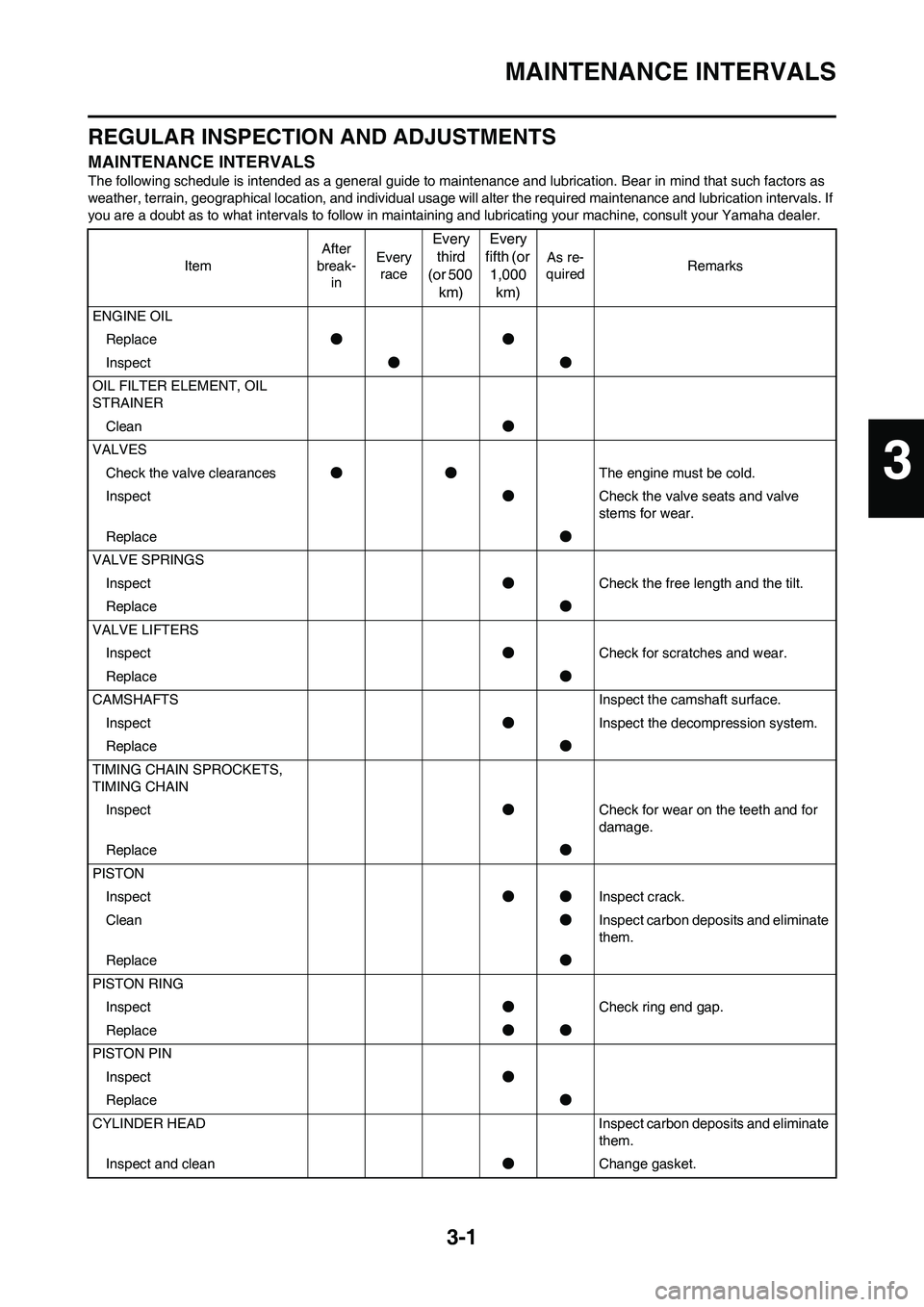

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals. If

you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-

inEvery

race

Every

third

(or 500

km)Every

fifth (or

1,000

km)

As re-

quiredRemarks

ENGINE OIL

Replace●●

Inspect●●

OIL FILTER ELEMENT, OIL

STRAINER

Clean●

VALVES

Check the valve clearances●●The engine must be cold.

Inspect●Check the valve seats and valve

stems for wear.

Replace●

VALVE SPRINGS

Inspect●Check the free length and the tilt.

Replace●

VALVE LIFTERS

Inspect●Check for scratches and wear.

Replace●

CAMSHAFTS Inspect the camshaft surface.

Inspect●Inspect the decompression system.

Replace●

TIMING CHAIN SPROCKETS,

TIMING CHAIN

Inspect●Check for wear on the teeth and for

damage.

Replace●

PISTON

Inspect●●Inspect crack.

Clean●Inspect carbon deposits and eliminate

them.

Replace●

PISTON RING

Inspect●Check ring end gap.

Replace●●

PISTON PIN

Inspect●

Replace●

CYLINDER HEAD Inspect carbon deposits and eliminate

them.

Inspect and clean●Change gasket.

3

Page 55 of 190

3-9

ENGINE

7. Install:

• Air filter element "1"

• Washer

• Fitting bolt

Align the projection "a" on filter guide

with the hole "b" in air filter case.

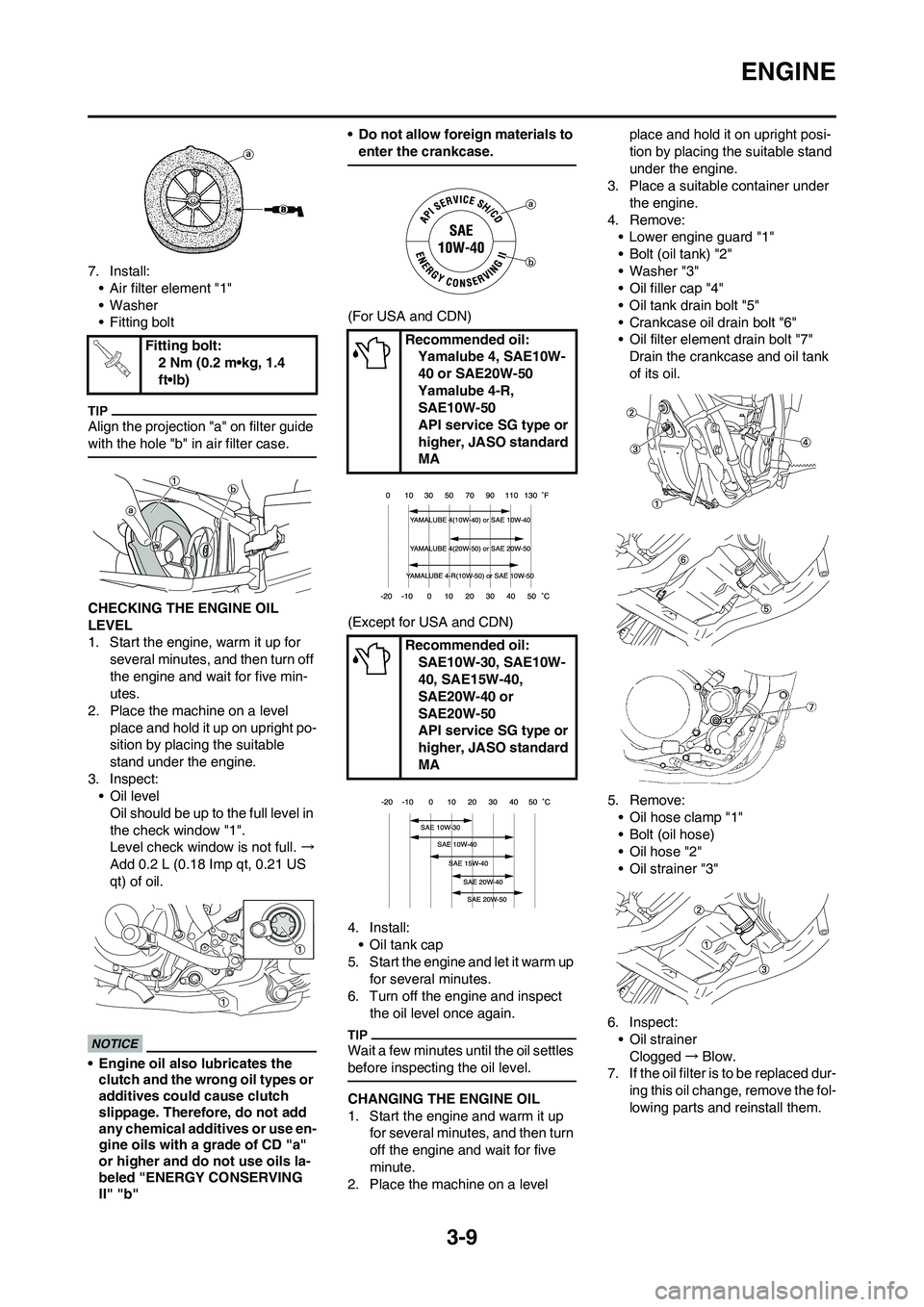

CHECKING THE ENGINE OIL

LEVEL

1. Start the engine, warm it up for

several minutes, and then turn off

the engine and wait for five min-

utes.

2. Place the machine on a level

place and hold it up on upright po-

sition by placing the suitable

stand under the engine.

3. Inspect:

• Oil level

Oil should be up to the full level in

the check window "1".

Level check window is not full. →

Add 0.2 L (0.18 Imp qt, 0.21 US

qt) of oil.

• Engine oil also lubricates the

clutch and the wrong oil types or

additives could cause clutch

slippage. Therefore, do not add

any chemical additives or use en-

gine oils with a grade of CD "a"

or higher and do not use oils la-

beled "ENERGY CONSERVING

II" "b"• Do not allow foreign materials to

enter the crankcase.

(For USA and CDN)

(Except for USA and CDN)

4. Install:

• Oil tank cap

5. Start the engine and let it warm up

for several minutes.

6. Turn off the engine and inspect

the oil level once again.

Wait a few minutes until the oil settles

before inspecting the oil level.

CHANGING THE ENGINE OIL

1. Start the engine and warm it up

for several minutes, and then turn

off the engine and wait for five

minute.

2. Place the machine on a level place and hold it on upright posi-

tion by placing the suitable stand

under the engine.

3. Place a suitable container under

the engine.

4. Remove:

• Lower engine guard "1"

• Bolt (oil tank) "2"

• Washer "3"

• Oil filler cap "4"

• Oil tank drain bolt "5"

• Crankcase oil drain bolt "6"

• Oil filter element drain bolt "7"

Drain the crankcase and oil tank

of its oil.

5. Remove:

• Oil hose clamp "1"

• Bolt (oil hose)

•Oil hose "2"

• Oil strainer "3"

6. Inspect:

• Oil strainer

Clogged→Blow.

7. If the oil filter is to be replaced dur-

ing this oil change, remove the fol-

lowing parts and reinstall them. Fitting bolt:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Recommended oil:

Yamalube 4, SAE10W-

40 or SAE20W-50

Yamalube 4-R,

SAE10W-50

API service SG type or

higher, JASO standard

MA

Recommended oil:

SAE10W-30, SAE10W-

40, SAE15W-40,

SAE20W-40 or

SAE20W-50

API service SG type or

higher, JASO standard

MA

4

Page 56 of 190

3-10

ENGINE

Replacement steps:

a. Remove the oil filter element cov-

er "1" and oil filter element "2".

b. Check the O-rings "3", if cracked

or damaged, replace them with a

new one.

c. Install the oil filter element and oil

filter element cover.

8. Install:

• O-ring "1"

• Oil strainer "2"

•Oil hose

• Bolt (oil hose)

• Oil hose clamp

9. Install:

• Copper washer

• Oil filter element drain bolt

• Crankcase oil drain bolt• Oil tank drain bolt

• Lower engine guard

10. Fill:

• Engine oil

11. Check:

• Oil leakage

12. Install:

• Oil filler cap

• Washer (oil tank)

• Bolt (oil tank)

13. Check:

• Engine oil level

CHECKING THE OIL PRESSURE

1. Check:

• Oil pressure

Checking steps:

a. Slightly loosen the oil pressure

check bolt "1".

b. Start the engine and keep it idling

until oil starts to seep from the oil

pressure check bolt. If no oil

comes out after one minute, turn

the engine off so it will not seize.

c. Check oil passages and oil pump

for damage or leakage.

d. Start the engine after solving the

problem(s) and recheck the oil

pressure.e. Tighten the oil pressure check

bolt.

ADJUSTING THE PILOT SCREW

1. Adjust:

•Pilot screw "1"

Adjustment steps:

To optimize the fuel flow at a smaller

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before adjusting the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

a. Turn in the pilot screw until it is

lightly seated.

b. Turn out the pilot screw by the

factory-set number of turns.

ADJUSTING THE ENGINE IDLING

SPEED

1. Start the engine and thoroughly

warm it up.

2. Adjust:

• Engine idling speed

Adjustment steps:

a. Adjust the pilot screw.

Refer to "ADJUSTING THE PI-

LOT SCREW" section.

b. Turn the throttle stop screw "1"

until the specified engine idling

speed. Oil filter element cover:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil strainer:

9 Nm (0.9 m•kg, 6.5

ft•lb)

Bolt (oil hose):

8 Nm (0.8 m•kg, 5.8

ft•lb)

Oil hose clamp:

2 Nm (0.2 m•kg, 1.4

ft•lb)

Oil filter element drain

bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Crankcase oil drain bolt:

20 Nm (2.0 m•kg, 14

ft•lb)

Oil tank drain bolt:

18 Nm (1.8 m•kg, 13

ft•lb)

Lower engine guard:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Oil quantity:

Periodic oil change:

1.05 L (0.92 Imp qt,

1.11 US qt)

With oil filter replace-

ment:

1.15 L (1.01 Imp qt,

1.22 US qt)

Total amount:

1.30 L (1.14 Imp qt,

1.37 US qt)

Bolt (oil tank):

7 Nm (0.7 m•kg, 5.1

ft•lb)

Oil pressure check bolt:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Pilot screw (example):

2 turns out

Page 65 of 190

3-19

CHASSIS

• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Swingarm smooth action

Abnormal noise/unsmooth action

→Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage→Replace.

ADJUSTING THE REAR SHOCK

ABSORBER SPRING PRELOAD

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Remove:

• Rear frame

3. Measure:

• Spring fitting length

The I.D. mark "a" is marked at the end

of the spring.

4. Adjust:

• Spring preload

Adjustment steps:

a. Loosen the locknut "1".

b. Loosen the adjuster "2" until there

is some clearance between the

spring and adjuster.

c. Measure the spring free length

"a".

d. Turn the adjuster "2".

• Be sure to remove all dirt and mud

from around the locknut and adjust-

er before adjustment.

• The length of the spring (installed)

changes 1.5 mm (0.06 in) per turn

of the adjuster.

Never attempt to turn the adjuster

beyond the maximum or minimum

setting.

e. Tighten the locknut.

5. Install:

• Rear frame (upper)

• Rear frame (lower)

ADJUSTING THE REAR SHOCK

ABSORBER REBOUND DAMPING

FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1". Standard position:

9 clicks out

Standard fitting length:

I.D. MARK/

Q'TYLength

Yellow/1 251 mm

(9.98 in)

* 248 mm

(9.76 in)

* Except for USA and CDN

Stiffer →Increase the spring pre-

load. (Turn the adjuster "2" in.)

Softer→Decrease the spring pre-

load. (Turn the adjuster "2"

out.)

Extent of adjustment:

Maximum Minimum

Position in

which the

spring is turned

in 13 mm (0.51

in) from its free

length.Position in

which the

spring is turned

in 1.5 mm (0.06

in) from its free

length.

Locknut:

30 Nm (3.0 m•kg, 22

ft•lb)

Rear frame (upper):

38 Nm (3.8 m•kg, 27

ft•lb)

Rear frame (lower):

32 Nm (3.2 m•kg, 23

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Page 105 of 190

4-35

OIL FILTER ELEMENT AND WATER PUMP

REMOVING THE IMPELLER

SHAFT

1. Remove:

•Impeller "1"

• Washer "2"

• Impeller shaft "3"

Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and remove the impeller.

REMOVING THE OIL SEAL

It is not necessary to disassemble the

water pump, unless there is an abnor-

mality such as excessive change in

coolant level, discoloration of coolant,

or milky transmission oil.

1. Remove:

• Bearing "1"

2. Remove:

•Oil seal "1"

CHECKING THE OIL DELIVERY

PIPE

1. Inspect:

• Oil delivery pipe "1"

Bend/damage→Replace.

Clogged→Blow.CHECKING THE IMPELLER SHAFT

1. Inspect:

• Impeller shaft "1"

Bend/wear/damage→Replace.

Fur deposits→Clean.

CHECKING THE IMPELLER SHAFT

GEAR

1. Inspect:

• Gear teeth "a"

Wear/damage→Replace.

CHECKING THE BEARING

1. Inspect:

• Bearing

Rotate inner race with a finger.

Rough spot/seizure→Replace.

CHECKING THE OIL SEAL

1. Inspect:

• Oil seal "1"

Wear/damage→Replace.INSTALLING THE OIL SEAL

1. Install:

•Oil seal "1"

• Apply the lithium soap base grease

on the oil seal lip.

• Install the oil seal with its manufac-

ture's marks or numbers facing the

right crankcase cover "2".

2. Install:

• Bearing "1"

Install the bearing by pressing its out-

er race parallel.

INSTALLING THE IMPELLER

SHAFT

1. Install:

• Impeller shaft "1"

• Washer "2"

• Impeller "3"

• Take care so that the oil seal lip is

not damaged or the spring does not

slip off its position.

• When installing the impeller shaft,

apply the lithium soap base grease

on the oil seal lip and impeller shaft.

And install the shaft while turning it.

• Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and install the impeller.

Impeller:

14 Nm (1.4 m•kg, 10

ft•lb)

Page 156 of 190

5-25

HANDLEBAR

REMOVING THE BRAKE MASTER

CYLINDER

1. Remove:

• Brake master cylinder bracket "1"

• Brake master cylinder "2"

• Do not let the brake master cylin-

der hang on the brake hose.

• Keep the brake master cylinder

cap side horizontal to prevent air

from coming in.

REMOVING THE GRIP

1. Remove:

•Grip "1"

Blow in air between the handlebar or

tube guide and the grip. Then remove

the grip which has become loose.

CHECKING THE HANDLEBAR

1. Inspect:

• Handlebar "1"

Bends/cracks/damage→Re-

place.

Do not attempt to straighten a bent

handlebar as this may dangerous-

ly weaken the handlebar.

INSTALLING THE HANDLEBAR

1. Install:

• Handlebar lower holder "1"

• Washer "2"

• Nut (handlebar lower holder) "3"

• Be sure the side of the handlebar

lower holder having the greater dis-

tance "a" from the mounting bolt

center faces forward. And install it

in the hole "b" in the rear of the up-

per bracket.

• Apply the lithium soap base grease

on the thread of the handlebar low-

er holder.

• Change in the direction back to

front and installing position of the

handlebar lower holder allows the

front-to-rear offset amount of the

handlebar position to be changed.

• Do not tighten the nut yet.

A. Forward

2. Install:

• Handlebar "1"

• Handlebar upper holder "2"

• Bolt (handlebar upper holder) "3"

• The handlebar upper holder should

be installed with the punched mark

"a" forward.

• Install the handlebar so that the

marks "b" are in place on both

sides.

• Install the handlebar so that the pro-

jection "c" of the handlebar upper

holder is positioned at the mark on

the handlebar as shown.

• First tighten the bolts on the front

side of the handlebar upper holder,

and then tighten the bolts on the

rear side.

3. Tighten:

• Nut (handlebar lower holder) "1"

4. Install:

• Left grip "1"

Apply the adhesive to the handle-

bar "2".

• Before applying the adhesive, wipe

off grease or oil on the handlebar

surface "a" with a lacquer thinner.

• Install the left grip to the handlebar

so that the line "b" between the two

arrow marks faces straight upward.

Bolt (handlebar upper

holder):

28 Nm (2.8 m•kg, 20

ft•lb)

Nut (handlebar lower

holder):

34 Nm (3.4 m•kg, 24

ft•lb)

Page 183 of 190

7-6

CHASSIS

CHASSIS

SELECTION OF THE SECONDARY

REDUCTION RATIO (SPROCKET)

• It is generally said that the second-

ary gear ratio should be reduced for

a longer straight portion of a speed

course and should be increased for

a course with many corners. Actual-

ly, however, as the speed depends

on the ground condition of the day

of the race, be sure to run through

the circuit to set the machine suit-

able for the entire course.

• In actuality, it is very difficult to

achieve settings suitable for the en-

tire course and some settings may

be sacrificed. Thus, the settings

should be matched to the portion of

the course that has the greatest ef-

fect on the race result. In such a

case, run through the entire course

while making notes of lap times to

find the best balance; then, deter-

mine the secondary reduction ratio.

• If a course has a long straight por-

tion where a machine can run at

maximum speed, the machine is

generally set such that it can devel-

op its maximum revolutions toward

the end of the straight line, with care

taken to avoid the engine over-rev-

ving.

Riding technique varies from rider to

rider and the performance of a ma-

chine also vary from machine to ma-

chine. Therefore, do not imitate other

rider's settings from the beginning but

choose your own setting according to

the level of your riding technique.

DRIVE AND REAR WHEEL

SPROCKETS SETTING PARTS

TIRE PRESSURE

Tire pressure should be adjust to suit

the road surface condition of the cir-

cuit.

• Under a rainy, muddy, sandy, or

slippery condition, the tire pressure

should be lower for a larger area of

contact with the road surface.

• Under a stony or hard road condi-

tion, the tire pressure should be

higher to prevent a flat tire.FRONT FORK SETTING

The front fork setting should be made

depending on the rider's feeling of an

actual run and the circuit conditions.

The front fork setting includes the fol-

lowing three factors:

1. Setting of air spring characteris-

tics

• Change the fork oil amount.

2. Setting of spring preload

• Change the spring.

3. Setting of damping force

• Change the compression damp-

ing.

• Change the rebound damping.

The spring acts on the load and

the damping force acts on the

cushion travel speed.

CHANGE IN AMOUNT AND

CHARACTERISTICS OF FORK OIL

Damping characteristic near the final

stroke can be changed by changing

the fork oil amount.

Adjust the oil amount in 5 cm3 (0.2

Imp oz, 0.2 US oz) increments or

decrements. Too small oil amount

causes the front fork to produce a

noise at full rebound or the rider to

feel some pressure on his hands

or body. Alternatively, too large oil

amount will cause the air spring

characteristics to have a tendency

to be stiffer with the consequent

deteriorated performance and

characteristics. Therefore, adjust

the front fork within the specified

range.

Secondary reduction ratio =

Number of rear wheel sprocket

teeth/Number of drive sprocket

teeth

Standard secondary

reduction ratio49/13

(3.769)

* 51/13

(3.923)

* Except for USA and CDN

Part name Size Part number

Drive

sprocket "1"

(STD) 13T 9383B-13218

Rear wheel

sprocket "2"

47T 1C3-25447-00

48T 1C3-25448-00

(STD) 49T 1C3-25449-00

50T 1C3-25450-00

* (STD) 51T 1C3-25451-00

52T 1C3-25452-00

* Except for USA and CDN

Standard tire pressure:

100 kPa (1.0 kgf/cm

2,

15 psi)

Extent of adjustment:

60–80 kPa (0.6–0.8 kgf/

cm

2, 9.0–12 psi)

Extent of adjustment:

100–120 kPa (1.0–1.2

kgf/cm

2, 15–18 psi)

Standard oil amount:

330 cm3 (11.6 Imp oz,

11.2 US oz)

Extent of adjustment:

300–375 cm

3(10.6–13.2

Imp oz, 10.1–12.7 US

oz)