ignition YAMAHA YZ250F 2010 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ250F, Model: YAMAHA YZ250F 2010Pages: 196, PDF Size: 13.74 MB

Page 74 of 196

3-24

ELECTRICAL

ELECTRICAL

CHECKING THE SPARK PLUG

1. Remove:• Spark plug

2. Inspect:

• Electrode "1"Wear/damage →Replace.

• Insulator color "2"

Normal condition is a medium to

light tan color.

Distinctly different color →Check

the engine condition.

When the engine runs for many hours

at low speeds, the spark plug insula-

tor will become sooty, even if the en-

gine and carburetor are in good

operating condition.

3. Measure: • Plug gap "a"Use a wire gauge or thickness

gauge.

Out of specification →Regap.

4. Clean the plug with a spark plug cleaner if necessary.

5. Tighten: • Spark plug

• Before installing a spark plug, clean the gasket surface and plug sur-

face.

• Finger-tighten "a" the spark plug before torquing to specification "b".

CHECKING THE IGNITION TIMING

1. Remove:• Timing mark accessing screw "1"

2. Attach: • Timing light

• Digital tachometerTo the ignition coil lead (orange

lead"1").

3. Adjust: • Engine idling speedRefer to "ADJUSTING THE EN-

GINE IDLING SPEED" section.

4. Check: • Ignition timingVisually check the stationary

pointer "a" is within the firing

range "b" on the rotor.

Incorrect firing range →Check ro-

tor and pickup assembly.

5. Install: • Timing mark accessing screw

Spark plug gap:

0.7–0.8 mm

(0.028–0.031 in)

Spark plug: 13 Nm (1.3 m•kg, 9.4

ft•lb)

Timing light:

YM-33277-A/90890-

03141

Page 125 of 196

4-51

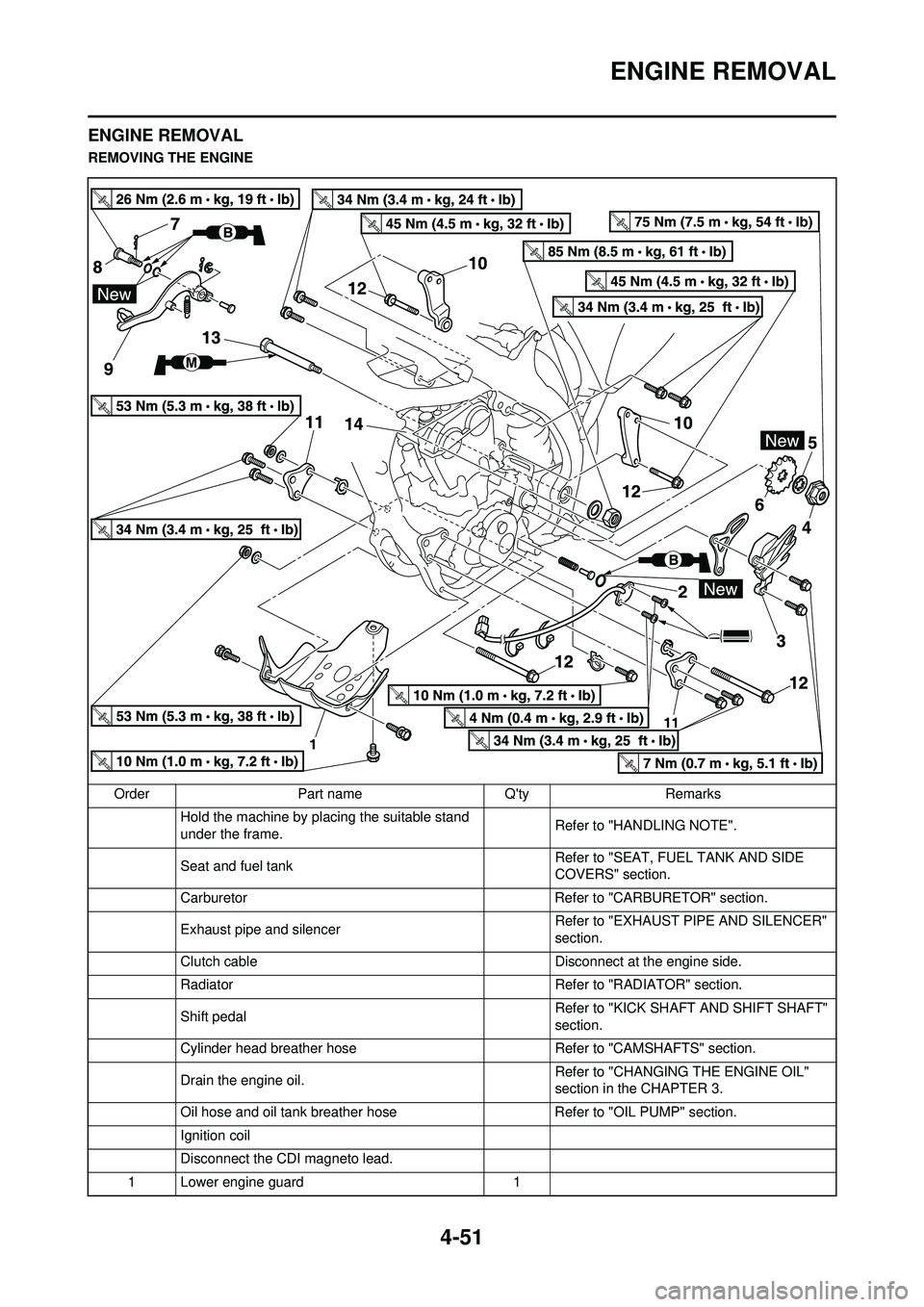

ENGINE REMOVAL

ENGINE REMOVAL

REMOVING THE ENGINEOrder Part name Q'ty Remarks Hold the machine by placing the suitable stand

under the frame. Refer to "HANDLING NOTE".

Seat and fuel tank Refer to "SEAT, FUEL TANK AND SIDE

COVERS" section.

Carburetor Refer to "CARBURETOR" section.

Exhaust pipe and silencer Refer to "EXHAUST PIPE AND SILENCER"

section.

Clutch cable Disconnect at the engine side.

Radiator Refer to "RADIATOR" section.

Shift pedal Refer to "KICK SHAFT AND SHIFT SHAFT"

section.

Cylinder head breather hose Refer to "CAMSHAFTS" section.

Drain the engine oil. Refer to "CHANGING THE ENGINE OIL"

section in the CHAPTER 3.

Oil hose and oil tank breather ho seRefer to "OIL PUMP" section.

Ignition coil

Disconnect the CDI magneto lead.

1 Lower engine guard 1

Page 178 of 196

6-2

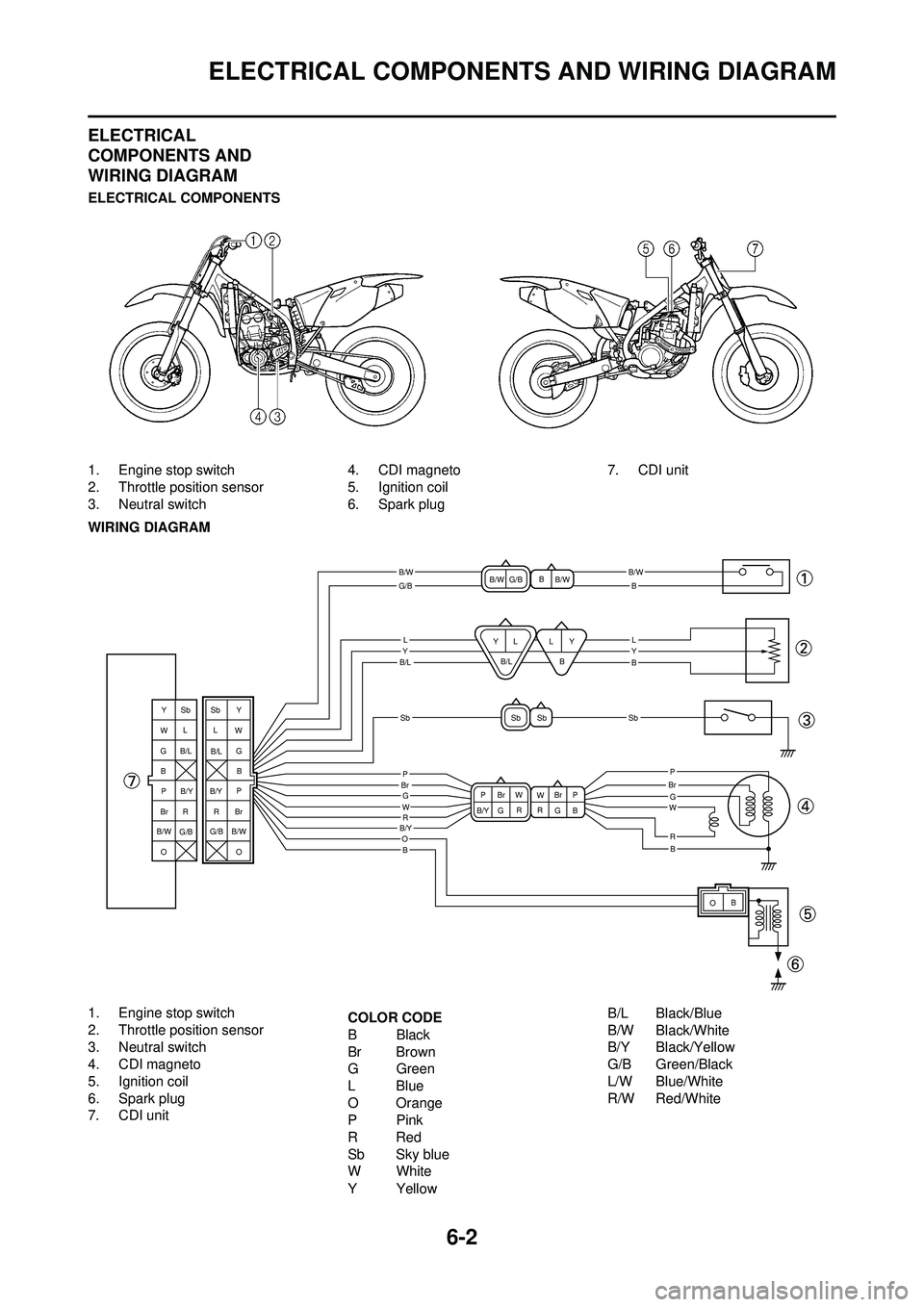

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

ELECTRICAL

COMPONENTS AND

WIRING DIAGRAM

ELECTRICAL COMPONENTS

1. Engine stop switch

2. Throttle position sensor

3. Neutral switch4. CDI magneto

5. Ignition coil

6. Spark plug 7. CDI unit

WIRING DIAGRAM

1. Engine stop switch

2. Throttle position sensor

3. Neutral switch

4. CDI magneto

5. Ignition coil

6. Spark plug

7. CDI unit COLOR CODE

BBlack

Br Brown

GGreen

LBlue

O Orange

PPink

RRed

Sb Sky blue

WWhite

YYellow B/L Black/Blue

B/W Black/White

B/Y Black/Yellow

G/B Green/Black

L/W Blue/White

R/W Red/White

B/WB/W

B/L

B/Y

SbSb

G/B

LYLY

P

B

B

B

B

G

O

WR

P

GW

R

P

B

Br W

W

B/Y G Br

G

RR

OB

Sb Sb

Y

Y

W Y

W

GG B

P P

Br BrRR

O L

B

Sb Y

LL

B/L

B/W

B/W

G/B

B

B

B/L

L

Sb

B/L

G/B

G/B B/Y

B/Y

B/W O

B/W

BrBrP

Page 179 of 196

6-3

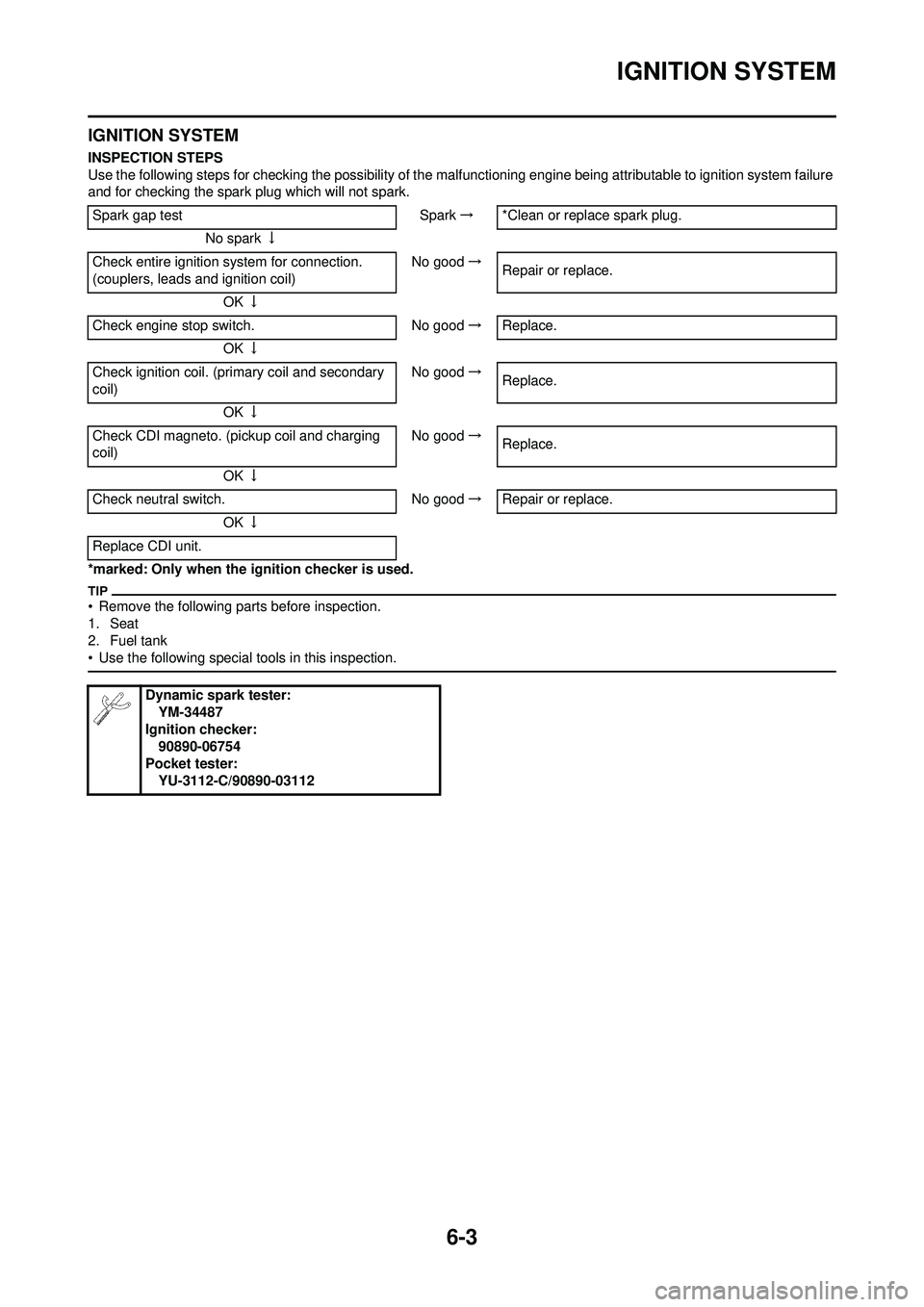

IGNITION SYSTEM

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to ignition system failure

and for checking the spark plug which will not spark.

*marked: Only when the ignition checker is used.

• Remove the following parts before inspection.

1. Seat

2. Fuel tank

• Use the following special tools in this inspection.

Spark gap test Spark→ *Clean or replace spark plug.

No spark ↓

Check entire ignition system for connection.

(couplers, leads and ignition coil) No good

→

Repair or replace.

OK ↓

Check engine stop switch. No good→Replace.

OK ↓

Check ignition coil. (primary coil and secondary

coil) No good

→

Replace.

OK ↓

Check CDI magneto. (pickup coil and charging

coil) No good

→

Replace.

OK ↓

Check neutral switch. No good→Repair or replace.

OK ↓

Replace CDI unit.

Dynamic spark tester: YM-34487

Ignition checker:

90890-06754

Pocket tester:

YU-3112-C/90890-03112

Page 180 of 196

6-4

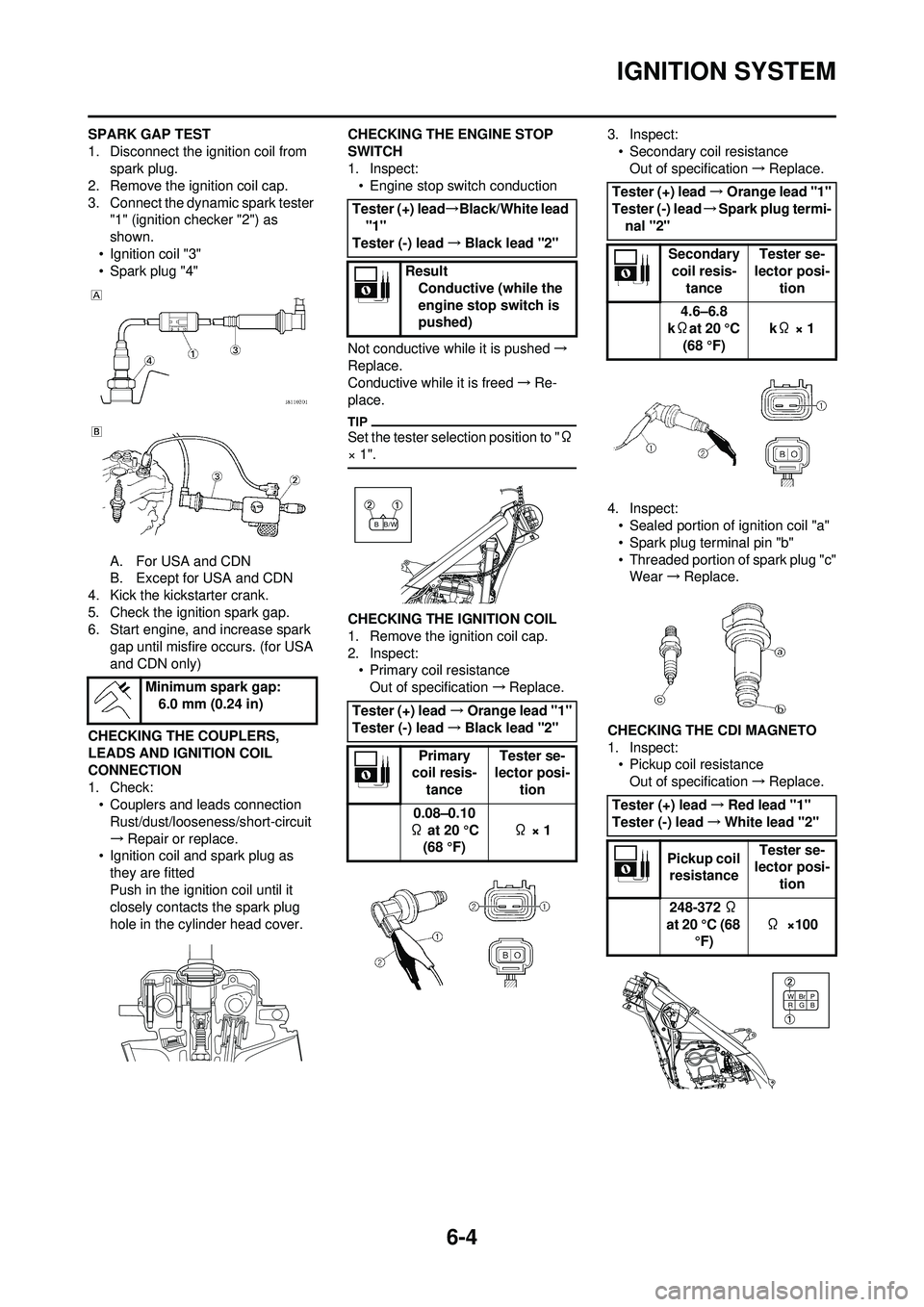

IGNITION SYSTEM

SPARK GAP TEST

1. Disconnect the ignition coil from spark plug.

2. Remove the ignition coil cap.

3. Connect the dynamic spark tester "1" (ignition ch ecker "2") as

shown.

• Ignition coil "3"

• Spark plug "4"

A. For USA and CDN

B. Except for USA and CDN

4. Kick the kickstarter crank.

5. Check the ignition spark gap.

6. Start engine, and increase spark gap until misfire occurs. (for USA

and CDN only)

CHECKING THE COUPLERS,

LEADS AND IGNITION COIL

CONNECTION

1. Check: • Couplers and leads connection

Rust/dust/looseness/short-circuit

→ Repair or replace.

• Ignition coil and spark plug as

they are fitted

Push in the ignition coil until it

closely contacts the spark plug

hole in the cylinder head cover. CHECKING THE ENGINE STOP

SWITCH

1. Inspect:

• Engine stop switch conduction

Not conductive while it is pushed →

Replace.

Conductive while it is freed →Re-

place.

Set the tester selection position to " Ω

× 1".

CHECKING THE IGNITION COIL

1. Remove the ignition coil cap.

2. Inspect: • Primary coil resistance

Out of specification →Replace. 3. Inspect:

• Secondary coil resistanceOut of specification →Replace.

4. Inspect: • Sealed portion of ignition coil "a"

• Spark plug terminal pin "b"

• Threaded portion of spark plug "c"Wear →Replace.

CHECKING THE CDI MAGNETO

1. Inspect: • Pickup coil resistance

Out of specification →Replace.

Minimum spark gap:

6.0 mm (0.24 in)

Tester (+) lead →Black/White lead

"1"

Tester (-) lead →Black lead "2"

Result Conductive (while the

engine stop switch is

pushed)

Tester (+) lead →Orange lead "1"

Tester (-) lead →Black lead "2"

Primary

coil resis-

tance Tester se-

lector posi-

tion

0.08–0.10

Ω at 20 °C (68 °F) Ω × 1

/W

BB

Tester (+) lead →Orange lead "1"

Tester (-) lead →Spark plug termi-

nal "2"

Secondary coil resis- tance Tester se-

lector posi- tion

4.6–6.8

k Ωat 20 °C

(68 °F) k

Ω × 1

Tester (+) lead →Red lead "1"

Tester (-) lead →White lead "2"

Pickup coil resistance Tester se-

lector posi-

tion

248-372 Ω

at 20 °C (68 °F) Ω

×100

B

WBr

G P

R

Page 181 of 196

6-5

IGNITION SYSTEM

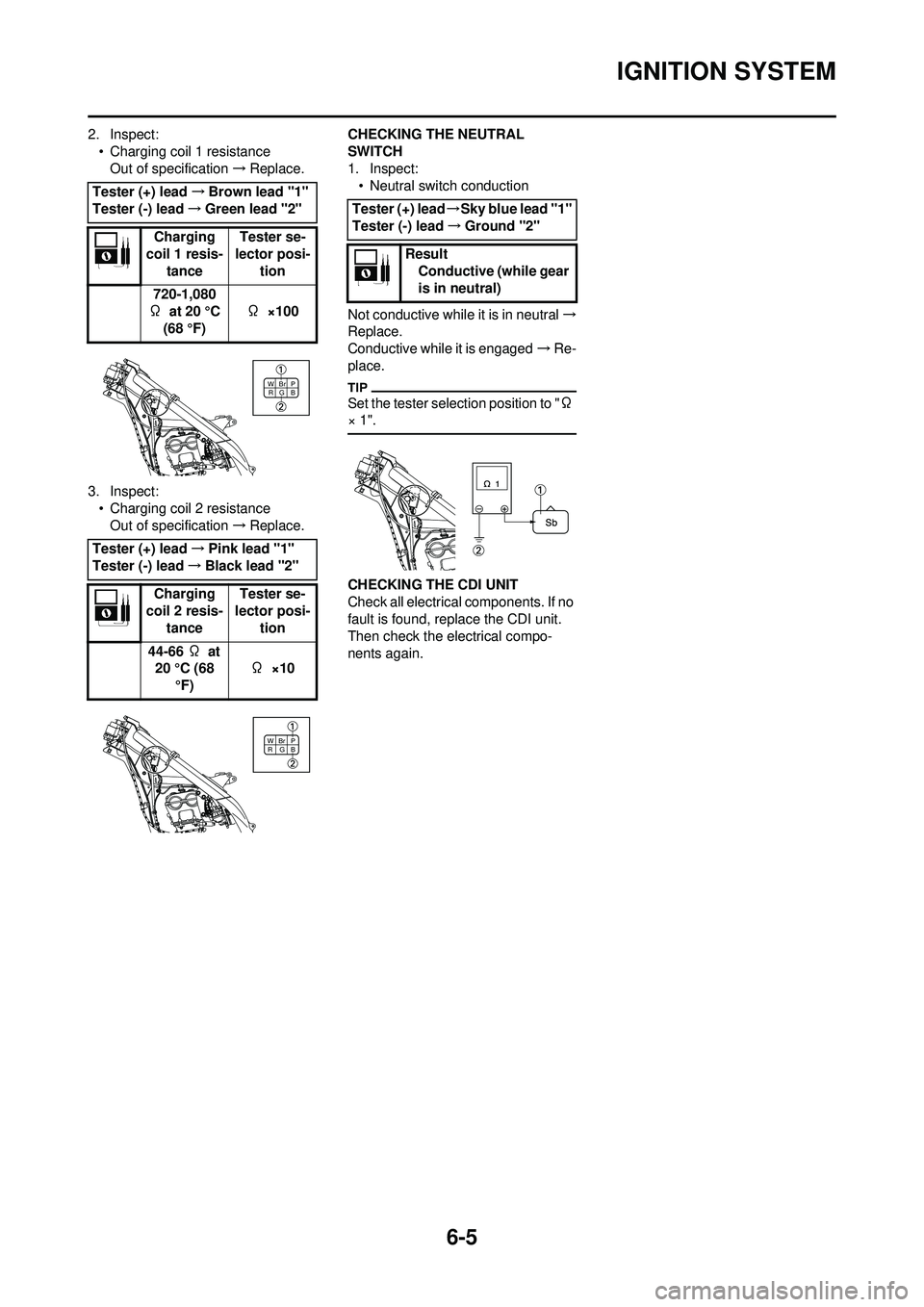

2. Inspect:• Charging coil 1 resistanceOut of specification →Replace.

3. Inspect: • Charging coil 2 resistanceOut of specification →Replace. CHECKING THE NEUTRAL

SWITCH

1. Inspect:

• Neutral switch conduction

Not conductive while it is in neutral →

Replace.

Conductive while it is engaged →Re-

place.

Set the tester selection position to " Ω

× 1".

CHECKING THE CDI UNIT

Check all electrical components. If no

fault is found, replace the CDI unit.

Then check the electrical compo-

nents again.

Tester (+) lead

→Brown lead "1"

Tester (-) lead →Green lead "2"

Charging

coil 1 resis- tance Tester se-

lector posi- tion

720-1,080

Ω at 20 °C

(68 °F) Ω

×100

Tester (+) lead →Pink lead "1"

Tester (-) lead →Black lead "2"

Charging

coil 2 resis- tance Tester se-

lector posi- tion

44-66 Ω at

20 °C (68 °F) Ω ×10

B

WBr

G P

R

B

WBr

GP

R

Tester (+) lead →Sky blue lead "1"

Tester (-) lead →Ground "2"

Result Conductive (while gear

is in neutral)

Page 182 of 196

6-6

THROTTLE POSITION SENSOR SYSTEM

THROTTLE POSITION SENSOR SYSTEM

INSPECTION STEPS

If the throttle position sensor will not operate, use the following inspection steps.

*marked: Refer to "IGN ITION SYSTEM" section.

Use the following special tools in this inspection.

Check entire ignition system for connection. No good →Repair or replace.

OK ↓

Check throttle position sensor. (Throttle position

sensor coil) No good

→

Replace.

OK ↓

*Check CDI magneto. (Charging coil) No good→Replace.

OK ↓

Check CDI unit. (Throttle position sensor input

voltage) No good

→

Replace.

Pocket tester:

YU-3112-C/90890-03112