torque YAMAHA YZ250F 2010 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ250F, Model: YAMAHA YZ250F 2010Pages: 196, PDF Size: 13.74 MB

Page 10 of 196

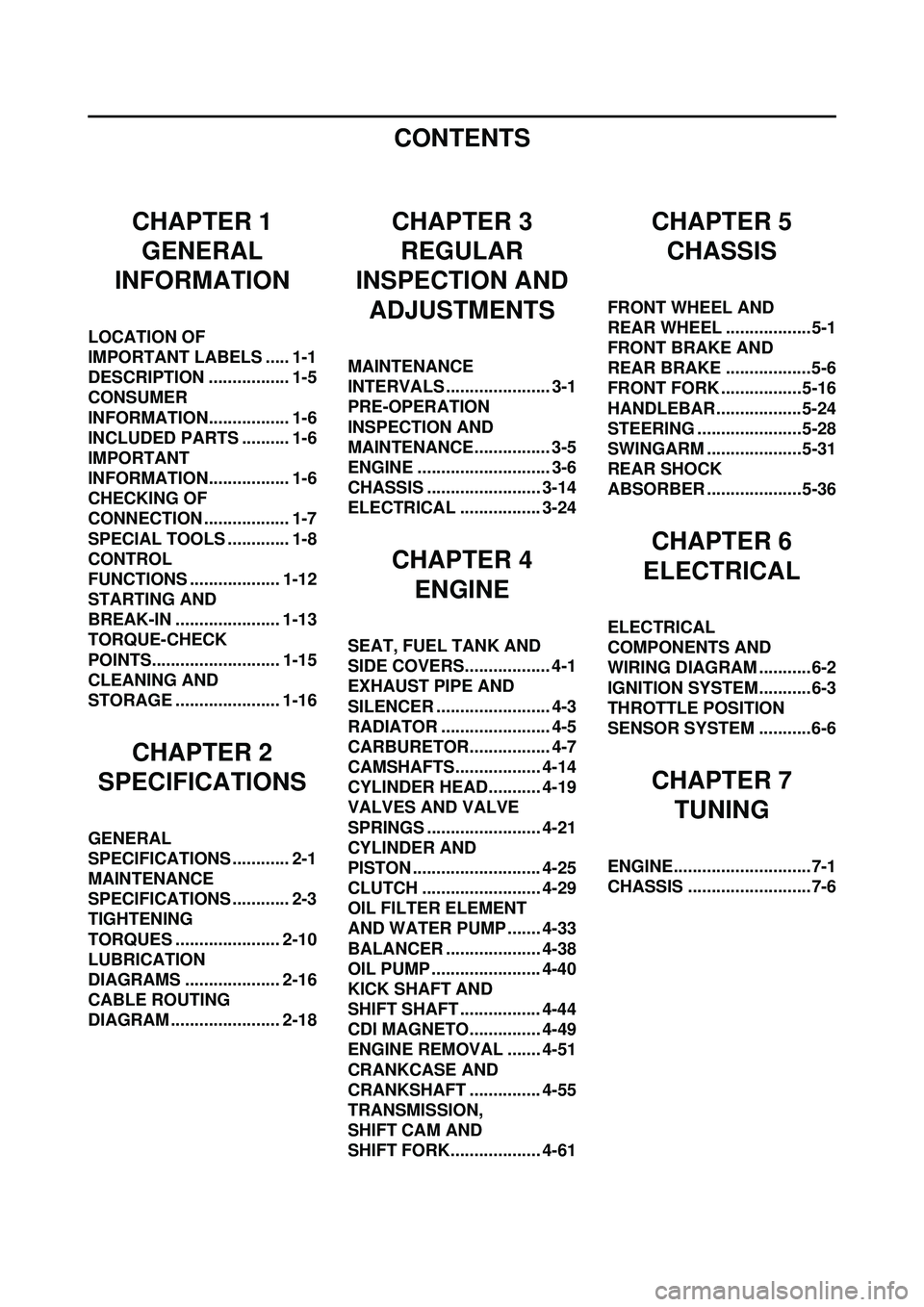

CONTENTS

CHAPTER 1GENERAL

INFORMATION

LOCATION OF

IMPORTANT LABELS ..... 1-1

DESCRIPTION ................. 1-5

CONSUMER

INFORMATION................. 1-6

INCLUDED PARTS .......... 1-6

IMPORTANT

INFORMATION................. 1-6

CHECKING OF

CONNECTION .................. 1-7

SPECIAL TOOLS ............. 1-8

CONTROL

FUNCTIONS ................... 1-12

STARTING AND

BREAK-IN ...................... 1-13

TORQUE-CHECK

POINTS........................... 1-15

CLEANING AND

STORAGE ...................... 1-16

CHAPTER 2

SPECIFICATIONS

GENERAL

SPECIFICATIONS ............ 2-1

MAINTENANCE

SPECIFICATIONS ............ 2-3

TIGHTENING

TORQUES ...................... 2-10

LUBRICATION

DIAGRAMS .................... 2-16

CABLE ROUTING

DIAGRAM ....................... 2-18

CHAPTER 3 REGULAR

INSPECTION AND ADJUSTMENTS

MAINTENANCE

INTERVALS ...................... 3-1

PRE-OPERATION

INSPECTION AND

MAINTENANCE................ 3-5

ENGINE ............................ 3-6

CHASSIS ........................ 3-14

ELECTRICAL ................. 3-24

CHAPTER 4 ENGINE

SEAT, FUEL TANK AND

SIDE COVERS.................. 4-1

EXHAUST PIPE AND

SILENCER ........................ 4-3

RADIATOR ....................... 4-5

CARBURETOR................. 4-7

CAMSHAFTS.................. 4-14

CYLINDER HEAD........... 4-19

VALVES AND VALVE

SPRINGS ........................ 4-21

CYLINDER AND

PISTON ........................... 4-25

CLUTCH ......................... 4-29

OIL FILTER ELEMENT

AND WATER PUMP ....... 4-33

BALANCER .................... 4-38

OIL PUMP ....................... 4-40

KICK SHAFT AND

SHIFT SHAFT ................. 4-44

CDI MAGNETO............... 4-49

ENGINE REMOVAL ....... 4-51

CRANKCASE AND

CRANKSHAFT ............... 4-55

TRANSMISSION,

SHIFT CAM AND

SHIFT FORK................... 4-61

CHAPTER 5CHASSIS

FRONT WHEEL AND

REAR WHEEL ..................5-1

FRONT BRAKE AND

REAR BRAKE ..................5-6

FRONT FORK .................5-16

HANDLEBAR..................5-24

STEERING ......................5-28

SWINGARM ....................5-31

REAR SHOCK

ABSORBER ....................5-36

CHAPTER 6

ELECTRICAL

ELECTRICAL

COMPONENTS AND

WIRING DIAGRAM ...........6-2

IGNITION SYSTEM...........6-3

THROTTLE POSITION

SENSOR SYSTEM ...........6-6

CHAPTER 7 TUNING

ENGINE.............................7-1

CHASSIS ..........................7-6

Page 24 of 196

1-14

STARTING AND BREAK-IN

BREAK-IN PROCEDURES

1. Before starting the engine, fill the fuel tank with the fuel.

2. Perform the pre-operation checks

on the machine.

3. Start and warm up the engine. Check the idle speed, and check

the operation of the controls and

the engine stop switch. Then, re-

start the engine and check its op-

eration within no more than 5

minutes after it is restarted.

4. Operate the machine in the lower

gears at moderate throttle open-

ings for five to eight minutes.

5. Check how the engine runs when

the machine is ridden with the

throttle 1/4 to 1/2 open (low to me-

dium speed) for about one hour.

6. Restart the engine and check the operation of the machine through-

out its entire oper ating range. Re-

start the machine and operate it

for about 10 to 15 more minutes.

The machine will now be ready to

race.

• After the break-in or before each race, you must check the entire

machine for loose fittings and

fasteners as per "TORQUE-

CHECK POINTS". Tighten all

such fasteners as required.

• When any of the following parts have been replaced, they must

be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in oper-

ation is necessary.

PISTON, RING, VALVES, CAM-

SHAFTS AND GEARS:

These parts require about 30

minutes of break-in operation at

half-throttle or le ss. Observe the

condition of the engine carefully

during operation.

Page 25 of 196

1-15

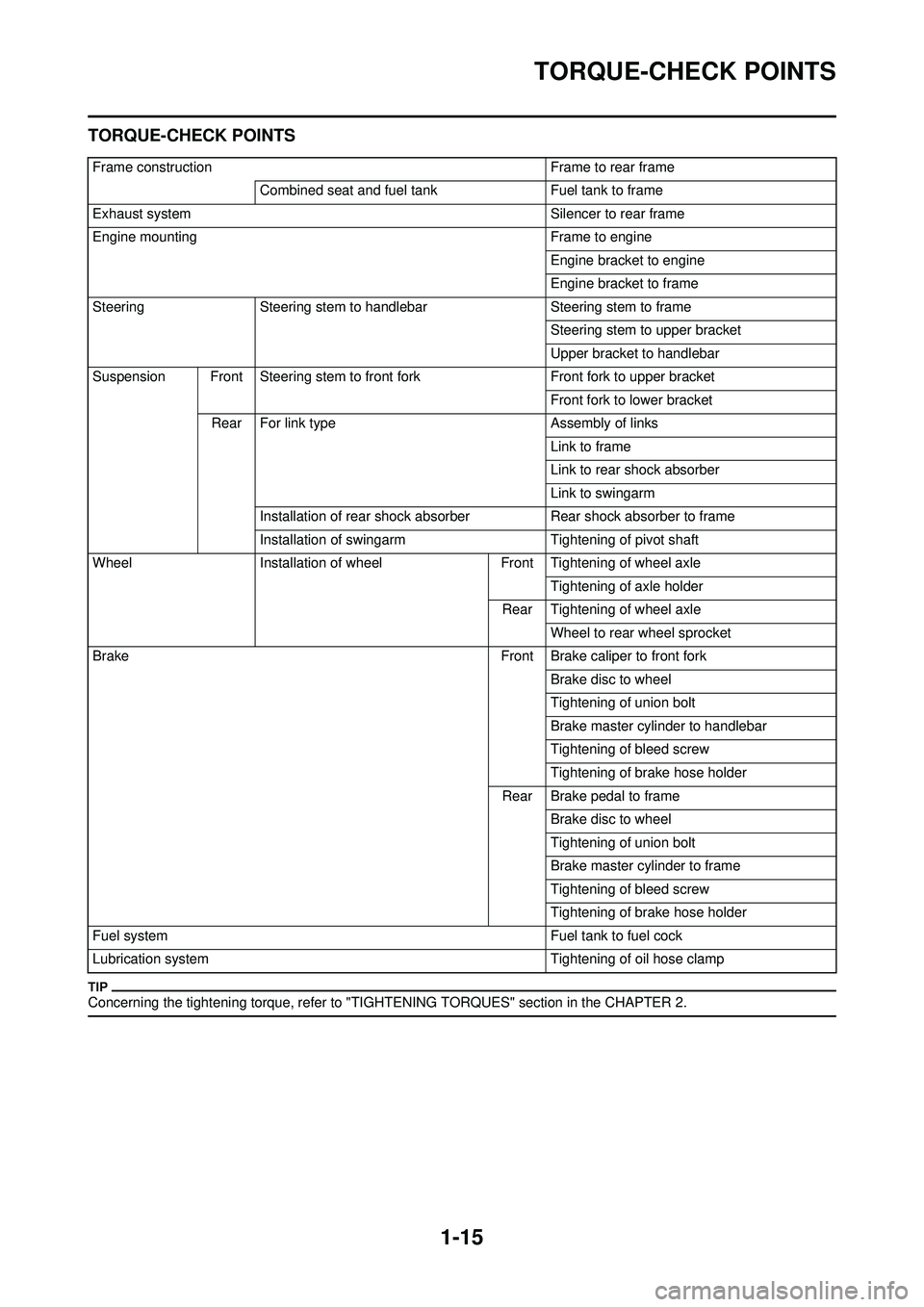

TORQUE-CHECK POINTS

TORQUE-CHECK POINTS

Concerning the tightening torque, refer to "TIGHTENING TORQUES" section in the CHAPTER 2.

Frame constructionFrame to rear frame

Combined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front forkFront fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Installation of rear shock absorber Rear shock absorber to frame

Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle

Tightening of axle holder

Rear Tightening of wheel axle Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel system Fuel tank to fuel cock

Lubrication system Tightening of oil hose clamp

Page 36 of 196

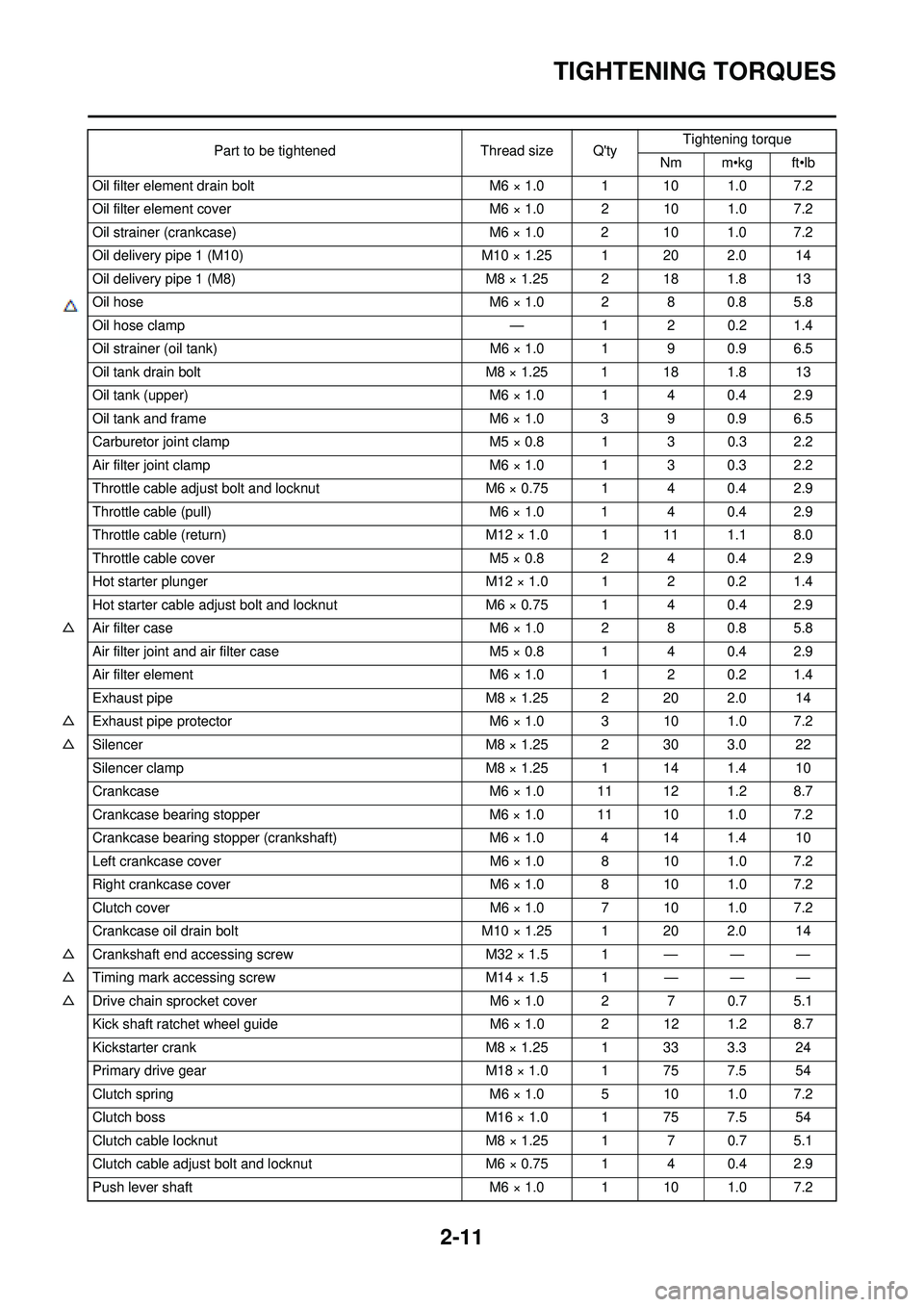

2-10

TIGHTENING TORQUES

ELECTRICAL

TIGHTENING TORQUES

ENGINE

△- marked portion shall be checked for torque ti ghtening after break-in or before each race.

Item StandardLimit

Ignition system: Advancer type Electrical----

CDI: Magneto-model (stator)/manufacturer 17D-50/YAMAHA----

Charging coil 1 resistance (color) 720–1,080 Ωat 20 °C (68 °F)

(Green–Brown) ----

Charging coil 2 resistance (color) 44–66 Ωat 20 °C (68 °F) (Black–Pink) ----

Pickup coil resistance (color) 248–372 Ωat 20 °C (68 °F) (White–Red) ----

CDI unit-model/manufacturer 17D-50/YAMAHA (For USA and CDN) ----

17D-60/YAMAHA (Except for USA and

CDN) ----

Ignition coil: Model/manufacturer 5UL-20/DENSO----

Minimum spark gap 6 mm (0.24 in)----

Primary coil resistance 0.08–0.10 Ωat 20 °C (68 °F) ----

Secondary coil resistance 4.6–6.8 kΩat 20 °C (68 °F) ----

Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Spark plug M10S × 1.0 1 13 1.3 9.4

Camshaft cap M6 × 1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12 × 1.0 1 28 2.8 20

Cylinder head (stud bolt) M6 × 1.0 2 7 0.7 5.1

Cylinder head (stud bolt) M8 × 1.25 1 15 1.5 11

Cylinder head (bolt) M9 × 1.25 4 38 3.8 27

Cylinder head (nut) M6 × 1.0 2 10 1.0 7.2

Cylinder head cover M6 × 1.0 2 10 1.0 7.2

Cylinder M6 × 1.0 1 10 1.0 7.2

Balancer weight M6 × 1.0 2 10 1.0 7.2

Balancer shaft driven gear M14 × 1.0 1 50 5.0 36

Timing chain guide (intake side) M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner cap bolt M6 × 1.0 1 7 0.7 5.1

Impeller M8 × 1.25 1 14 1.4 10

Radiator hose clamp M6 × 1.0 10 2 0.2 1.4

Coolant drain bolt M6 × 1.0 1 10 1.0 7.2

Water pump housing M6 × 1.0 4 10 1.0 7.2

Radiator M6 × 1.0 6 10 1.0 7.2

Radiator pipe M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 1.7 0.17 1.2

Oil pump M6 × 1.0 3 10 1.0 7.2

Page 37 of 196

2-11

TIGHTENING TORQUES

Oil filter element drain boltM6 × 1.0 1 10 1.0 7.2

Oil filter element cover M6 × 1.0 2 10 1.0 7.2

Oil strainer (crankcase) M6 × 1.0 2 10 1.0 7.2

Oil delivery pipe 1 (M10) M10 × 1.25 1 20 2.0 14

Oil delivery pipe 1 (M8) M8 × 1.25 2 18 1.8 13

Oil hose M6 × 1.0 2 8 0.8 5.8

△ Oil hose clamp —1 2 0.2 1.4

Oil strainer (oil tank) M6 × 1.0 1 9 0.9 6.5

Oil tank drain bolt M8 × 1.25 1 18 1.8 13

Oil tank (upper) M6 × 1.0 1 4 0.4 2.9

Oil tank and frame M6 × 1.0 3 9 0.9 6.5

Carburetor joint clamp M5 × 0.8 1 3 0.3 2.2

Air filter joint clamp M6 × 1.0 1 3 0.3 2.2

Throttle cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Throttle cable (pull) M6 × 1.0 1 4 0.4 2.9

Throttle cable (return) M12 × 1.0 1 11 1.1 8.0

Throttle cable cover M5 × 0.8 2 4 0.4 2.9

Hot starter plunger M12 × 1.0 1 2 0.2 1.4

Hot starter cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

△ Air filter case M6 × 1.0 2 8 0.8 5.8

Air filter joint and air filter case M5 × 0.8 1 4 0.4 2.9

Air filter element M6 × 1.0 1 2 0.2 1.4

Exhaust pipe M8 × 1.25 2 20 2.0 14

△ Exhaust pipe protector M6 × 1.0 3 10 1.0 7.2

△ Silencer M8 × 1.25 2 30 3.0 22

Silencer clamp M8 × 1.25 1 14 1.4 10

Crankcase M6 × 1.0 11 12 1.2 8.7

Crankcase bearing stopper M6 × 1.0 11 10 1.0 7.2

Crankcase bearing stopper (crankshaft) M6 × 1.0 4 14 1.4 10

Left crankcase cove r M6 × 1.0 8 10 1.0 7.2

Right crankcase cove r M6 × 1.0 8 10 1.0 7.2

Clutch cover M6 × 1.0 7 10 1.0 7.2

Crankcase oil drain bolt M10 × 1.25 1 20 2.0 14

△ Crankshaft end accessing screw M32 × 1.5 1 — — —

△ Timing mark accessing screw M14 × 1.5 1 — — —

△ Drive chain sprocket cover M6 × 1.0 2 7 0.7 5.1

Kick shaft ratchet wheel guide M6 × 1.0 2 12 1.2 8.7

Kickstarter crank M8 × 1.25 1 33 3.3 24

Primary drive gear M18 × 1.0 1 75 7.5 54

Clutch spring M6 × 1.0 5 10 1.0 7.2

Clutch boss M16 × 1.0 1 75 7.5 54

Clutch cable locknut M8 × 1.25 1 7 0.7 5.1

Clutch cable adjust bolt and locknut M6 × 0.75 1 4 0.4 2.9

Push lever shaft M6 × 1.0 1 10 1.0 7.2

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Page 38 of 196

2-12

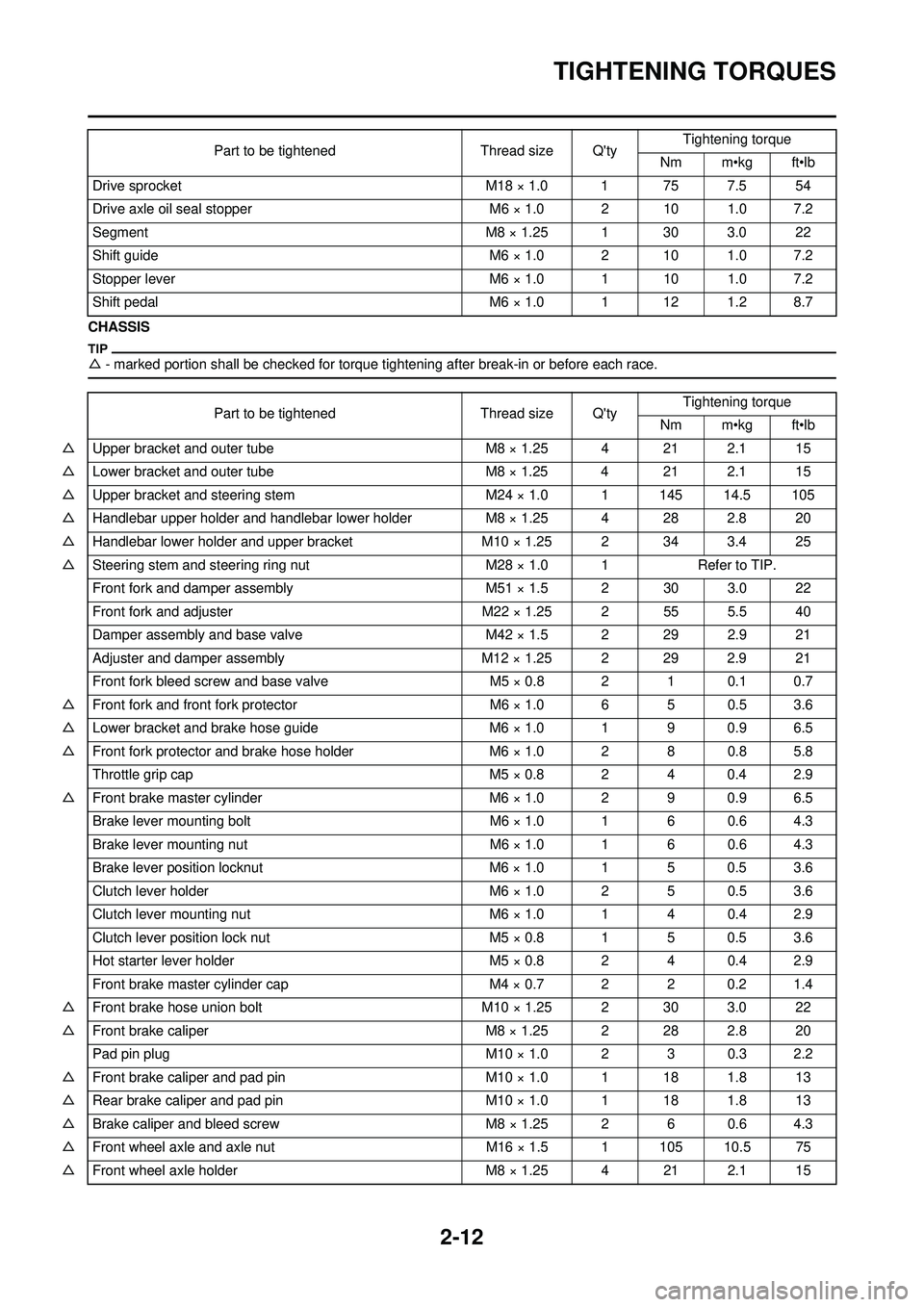

TIGHTENING TORQUES

CHASSIS

△- marked portion shall be checked for torque ti ghtening after break-in or before each race.

Drive sprocket M18 × 1.0 1 75 7.5 54

Drive axle oil seal stopper M6 × 1.0 2 10 1.0 7.2

Segment M8 × 1.25 1 30 3.0 22

Shift guide M6 × 1.0 2 10 1.0 7.2

Stopper lever M6 × 1.0 1 10 1.0 7.2

Shift pedal M6 × 1.0 1 12 1.2 8.7

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

△ Upper bracket and outer tube M8 × 1.25 4 21 2.1 15

△ Lower bracket and outer tube M8 × 1.25 4 21 2.1 15

△ Upper bracket and steeri ng stem M24 × 1.0 1 145 14.5 105

△ Handlebar upper holder and handlebar lower holder M8 × 1.25 4 28 2.8 20

△ Handlebar lower holder and upper bracket M10 × 1.25 2 34 3.4 25

△ Steering stem and steering ring nut M28 × 1.0 1Refer to TIP.

Front fork and damper assembly M51 × 1.5 2 30 3.0 22

Front fork and adjuster M22 × 1.25 2 55 5.5 40

Damper assembly and base valve M42 × 1.5 2 29 2.9 21

Adjuster and damper assembly M12 × 1.25 2 29 2.9 21

Front fork bleed screw and base valve M5 × 0.8 2 1 0.1 0.7

△ Front fork and front fork protector M6 × 1.0 6 5 0.5 3.6

△ Lower bracket and brake hose guide M6 × 1.0 1 9 0.9 6.5

△ Front fork protector and brake hose holder M6 × 1.0 2 8 0.8 5.8

Throttle grip cap M5 × 0.8 2 4 0.4 2.9

△ Front brake master cylinder M6 × 1.0 2 9 0.9 6.5

Brake lever mounting bolt M6 × 1.0 1 6 0.6 4.3

Brake lever mounting nut M6 × 1.0 1 6 0.6 4.3

Brake lever position locknut M6 × 1.0 1 5 0.5 3.6

Clutch lever holder M6 × 1.0 2 5 0.5 3.6

Clutch lever mounting nut M6 × 1.0 1 4 0.4 2.9

Clutch lever position lock nut M5 × 0.8 1 5 0.5 3.6

Hot starter lever holder M5 × 0.8 2 4 0.4 2.9

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

△ Front brake hose union bolt M10 × 1.25 2 30 3.0 22

△ Front brake caliper M8 × 1.25 2 28 2.8 20

Pad pin plug M10 × 1.0 2 3 0.3 2.2

△ Front brake caliper and pad pin M10 × 1.0 1 18 1.8 13

△ Rear brake caliper and pad pin M10 × 1.0 1 18 1.8 13

△ Brake caliper and bleed screw M8 × 1.25 2 6 0.6 4.3

△ Front wheel axle and axle nut M16 × 1.5 1 105 10.5 75

△ Front wheel axle holder M8 × 1.25 4 21 2.1 15

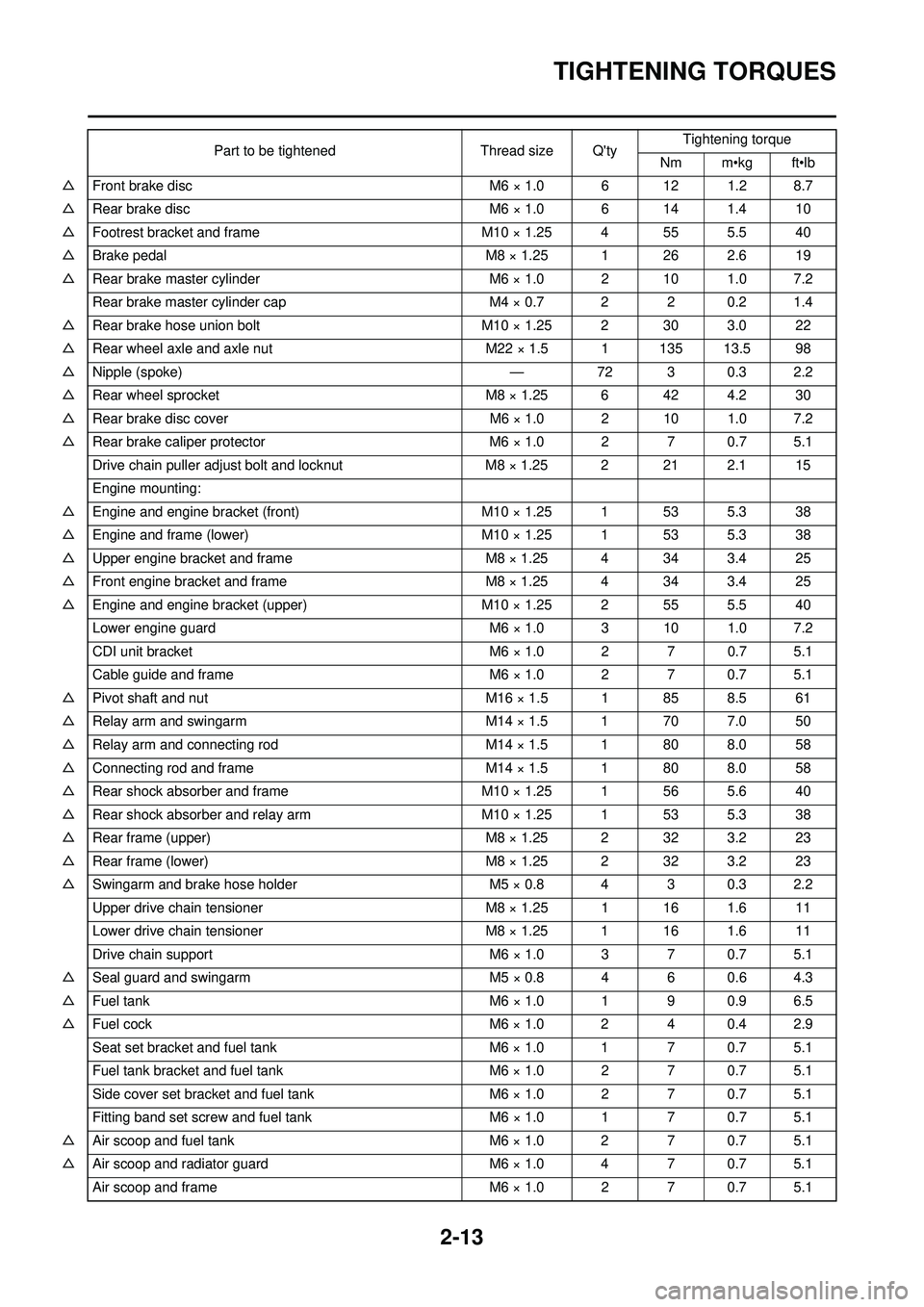

Page 39 of 196

2-13

TIGHTENING TORQUES

△Front brake disc M6 × 1.0 6 12 1.2 8.7

△ Rear brake disc M6 × 1.0 6 14 1.4 10

△ Footrest bracket and frame M10 × 1.25 4 55 5.5 40

△ Brake pedal M8 × 1.25 1 26 2.6 19

△ Rear brake master cylinder M6 × 1.0 2 10 1.0 7.2

Rear brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

△ Rear brake hose union bolt M10 × 1.25 2 30 3.0 22

△ Rear wheel axle and axle nut M22 × 1.5 1 135 13.5 98

△ Nipple (spoke) —72 3 0.3 2.2

△ Rear wheel sprocket M8 × 1.25 6 42 4.2 30

△ Rear brake disc cover M6 × 1.0 2 10 1.0 7.2

△ Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 21 2.1 15

Engine mounting:

△ Engine and engine bracket (front) M10 × 1.25 1 53 5.3 38

△ Engine and frame (lower) M10 × 1.25 1 53 5.3 38

△ Upper engine bracket and frame M8 × 1.25 4 34 3.4 25

△ Front engine bracket and frame M8 × 1.25 4 34 3.4 25

△ Engine and engine bracket (upper) M10 × 1.25 2 55 5.5 40

Lower engine guard M6 × 1.0 3 10 1.0 7.2

CDI unit bracket M6 × 1.0 2 7 0.7 5.1

Cable guide and frame M6 × 1.0 2 7 0.7 5.1

△ Pivot shaft and nut M16 × 1.5 1 85 8.5 61

△ Relay arm and swingarm M14 × 1.5 1 70 7.0 50

△ Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

△ Connecting rod and frame M14 × 1.5 1 80 8.0 58

△ Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

△ Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

△ Rear frame (upper) M8 × 1.25 2 32 3.2 23

△ Rear frame (lower) M8 × 1.25 2 32 3.2 23

△ Swingarm and brake hose holder M5 × 0.8 4 3 0.3 2.2

Upper drive chain tensioner M8 × 1.25 1 16 1.6 11

Lower drive chain tensioner M8 × 1.25 1 16 1.6 11

Drive chain support M6 × 1.0 3 7 0.7 5.1

△ Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

△ Fuel tank M6 × 1.0 1 9 0.9 6.5

△ Fuel cock M6 × 1.0 2 4 0.4 2.9

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 2 7 0.7 5.1

Side cover set bracket and fuel tank M6 × 1.0 2 7 0.7 5.1

Fitting band set screw and fuel tank M6 × 1.0 1 7 0.7 5.1

△ Air scoop and fuel tank M6 × 1.0 2 7 0.7 5.1

△ Air scoop and radiator guard M6 × 1.0 4 7 0.7 5.1

Air scoop and frame M6 × 1.0 2 7 0.7 5.1

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

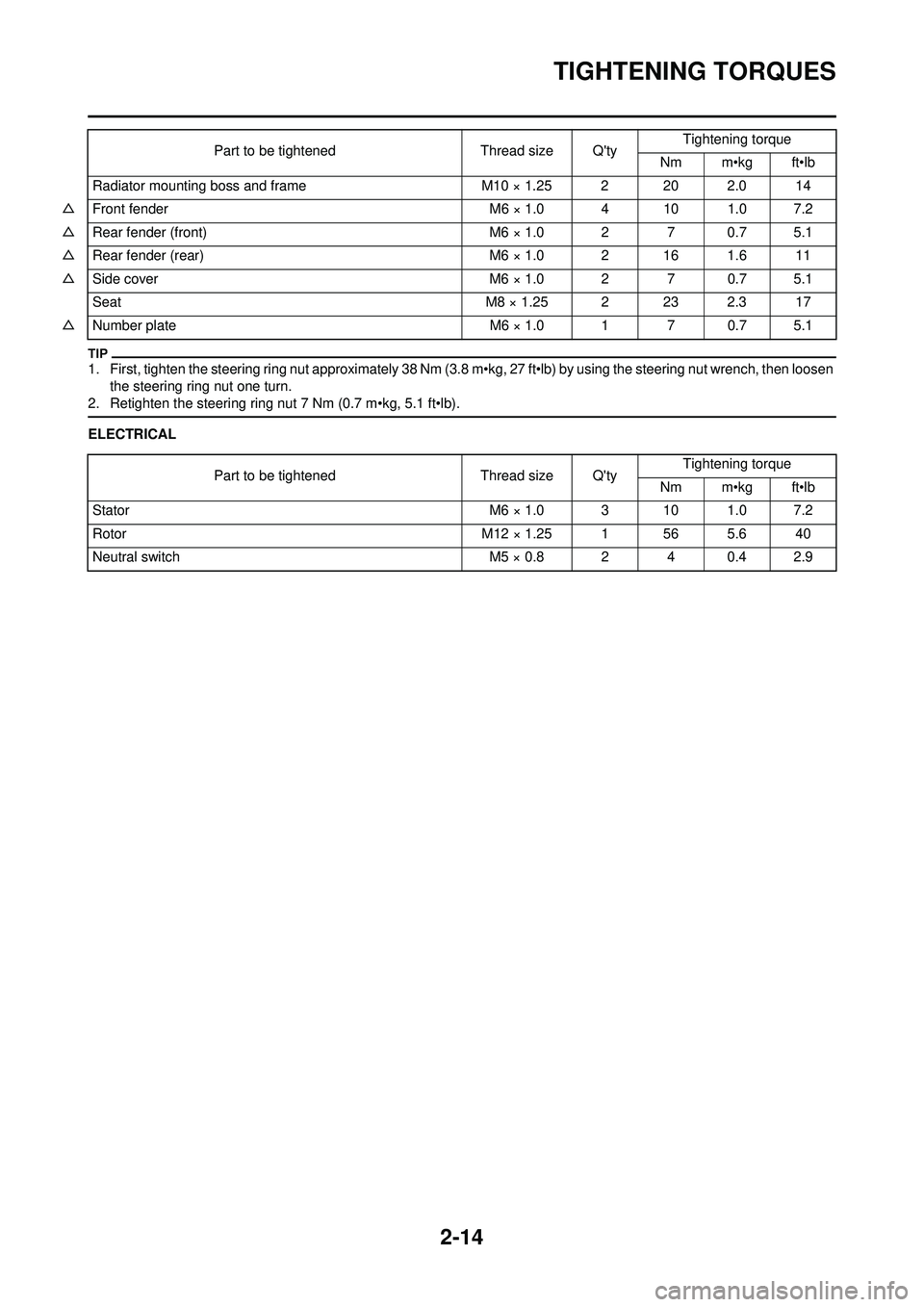

Page 40 of 196

2-14

TIGHTENING TORQUES

1. First, tighten the steering ring nut approximately 38 Nm (3.8 m•kg, 27 ft•lb) by using the steering nut wrench, then loosen

the steering ring nut one turn.

2. Retighten the steering ring nut 7 Nm (0.7 m•kg, 5.1 ft•lb).

ELECTRICAL Radiator mounting boss and frame

M10 × 1.25 2 20 2.0 14

△ Front fender M6 × 1.0 4 10 1.0 7.2

△ Rear fender (front) M6 × 1.0 2 7 0.7 5.1

△ Rear fender (rear) M6 × 1.0 2 16 1.6 11

△ Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 23 2.3 17

△ Number plate M6 × 1.0 1 7 0.7 5.1

Part to be tightened

Thread size Q'tyTightening torque

Nm m•kg ft•lb

Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Stator M6 × 1.0 3 10 1.0 7.2

Rotor M12 × 1.25 1 56 5.6 40

Neutral switch M5 × 0.8 2 4 0.4 2.9

Page 41 of 196

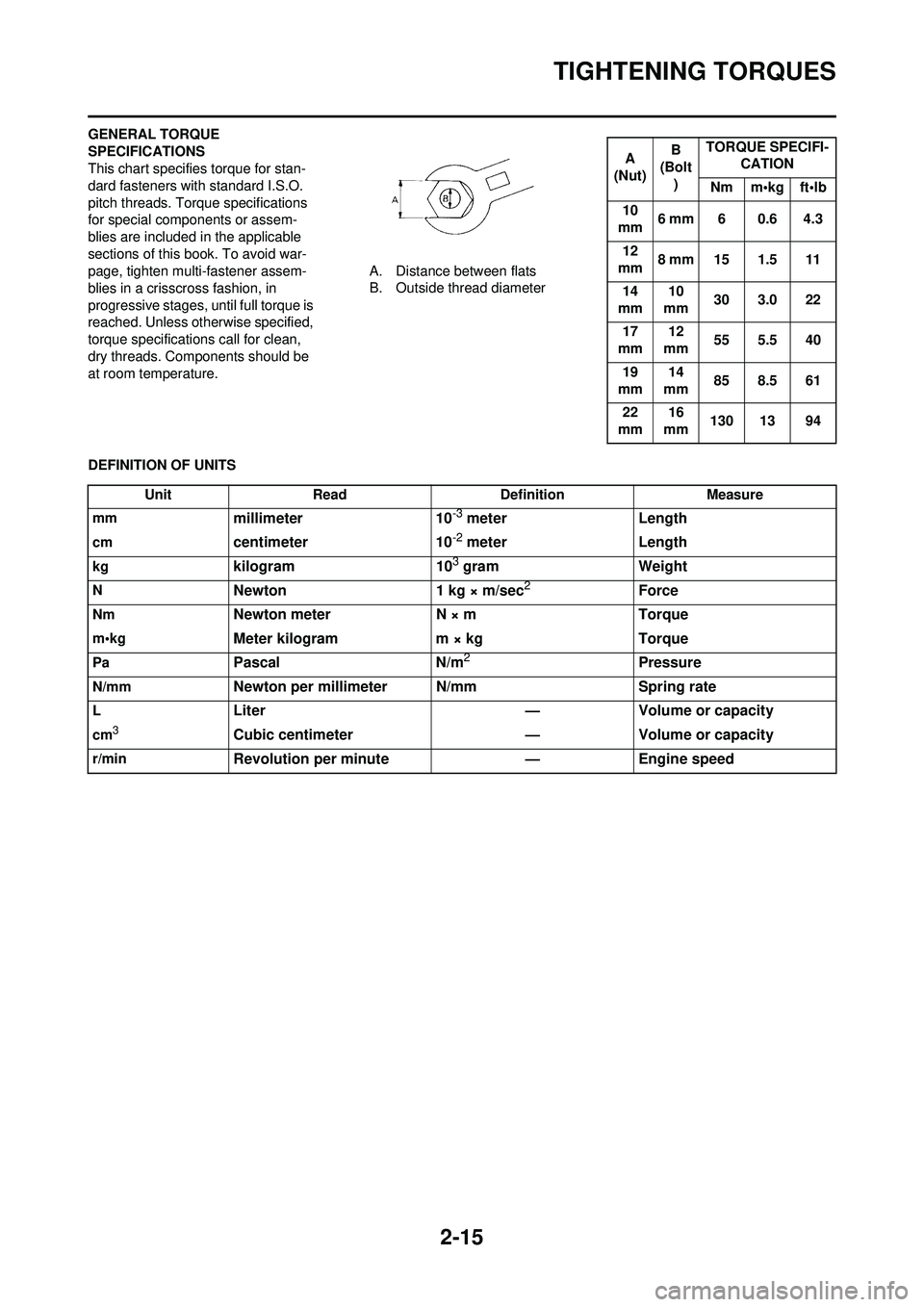

2-15

TIGHTENING TORQUES

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for stan-

dard fasteners with standard I.S.O.

pitch threads. Torque specifications

for special components or assem-

blies are included in the applicable

sections of this book. To avoid war-

page, tighten multi-fastener assem-

blies in a crisscross fashion, in

progressive stages, until full torque is

reached. Unless otherwise specified,

torque specifications call for clean,

dry threads. Components should be

at room temperature.A. Distance between flats

B. Outside thread diameter

DEFINITION OF UNITS

A

(Nut) B

(Bolt

) TORQUE SPECIFI-

CATION

Nm m•kg ft•lb

10

mm 6 mm 6 0.6 4.3

12

mm 8 mm 15 1.5 11

14

mm 10

mm 30 3.0 22

17

mm 12

mm 55 5.5 40

19

mm 14

mm 85 8.5 61

22

mm 16

mm 130 13 94

Unit

Read Definition Measure

mm

millimeter 10-3 meterLength

cmcentimeter 10-2 meterLength

kgkilogram 103 gramWeight

NNewton 1 kg × m/sec2Force

NmNewton meter N × mTorque

m•kgMeter kilogram m × kg Torque

PaPascalN/m2Pressure

N/mmNewton per millimeter N/mm Spring rate

LLiter—Volume or capacity

cm3Cubic centimeter —Volume or capacity

r/minRevolution per minute —Engine speed

Page 71 of 196

3-21

CHASSIS

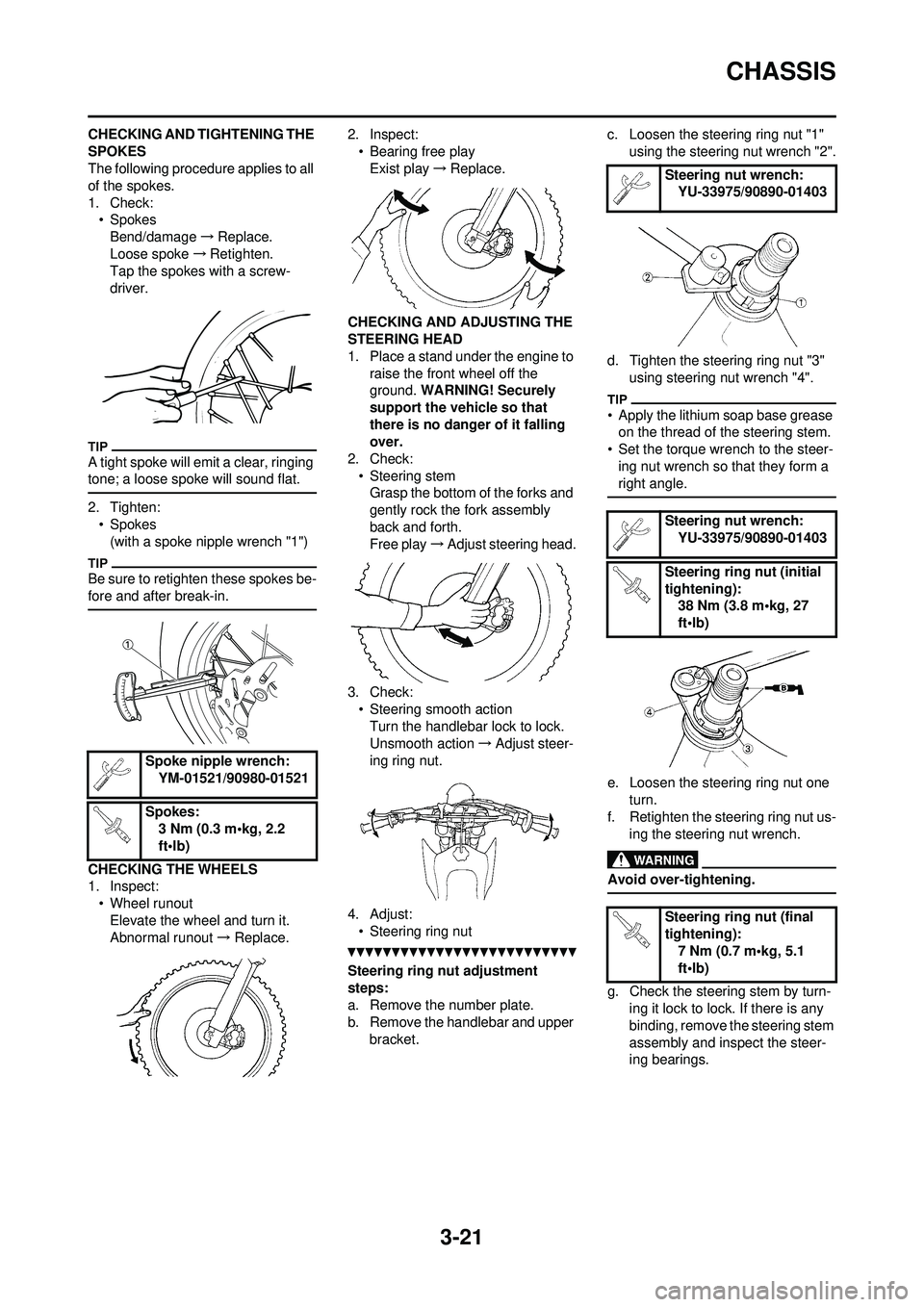

CHECKING AND TIGHTENING THE

SPOKES

The following procedure applies to all

of the spokes.

1. Check:• SpokesBend/damage →Replace.

Loose spoke →Retighten.

Tap the spokes with a screw-

driver.

A tight spoke will emit a clear, ringing

tone; a loose spoke will sound flat.

2. Tighten: • Spokes

(with a spoke nipple wrench "1")

Be sure to retighten these spokes be-

fore and after break-in.

CHECKING THE WHEELS

1. Inspect:• Wheel runout

Elevate the wheel and turn it.

Abnormal runout → Replace. 2. Inspect:

• Bearing free playExist play →Replace.

CHECKING AND ADJUSTING THE

STEERING HEAD

1. Place a stand under the engine to raise the front wheel off the

ground. WARNING! Securely

support the vehicle so that

there is no danger of it falling

over.

2. Check: • Steering stemGrasp the bottom of the forks and

gently rock the fork assembly

back and forth.

Free play →Adjust steering head.

3. Check: • Steering smooth actionTurn the handlebar lock to lock.

Unsmooth action →Adjust steer-

ing ring nut.

4. Adjust: • Steering ring nut

Steering ring nut adjustment

steps:

a. Remove the number plate.

b. Remove the handlebar and upper

bracket. c. Loosen the steering ring nut "1"

using the steering nut wrench "2".

d. Tighten the steering ring nut "3" using steering nut wrench "4".

• Apply the lithium soap base grease on the thread of the steering stem.

• Set the torque wrench to the steer-

ing nut wrench so that they form a

right angle.

e. Loosen the steering ring nut one turn.

f. Retighten the steering ring nut us- ing the steering nut wrench.

Avoid over-tightening.

g. Check the steering stem by turn-ing it lock to lock. If there is any

binding, remove the steering stem

assembly and inspect the steer-

ing bearings.

Spoke nipple wrench:

YM-01521/90980-01521

Spokes: 3 Nm (0.3 m•kg, 2.2

ft•lb)

Steering nut wrench:YU-33975/90890-01403

Steering nut wrench: YU-33975/90890-01403

Steering ring nut (initial

tightening): 38 Nm (3.8 m•kg, 27

ft•lb)

Steering ring nut (final

tightening): 7 Nm (0.7 m•kg, 5.1

ft•lb)