ECO mode YAMAHA YZ250F 2011 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2011, Model line: YZ250F, Model: YAMAHA YZ250F 2011Pages: 196, PDF Size: 14.15 MB

Page 22 of 196

1-12

CONTROL FUNCTIONS

CONTROL FUNCTIONS

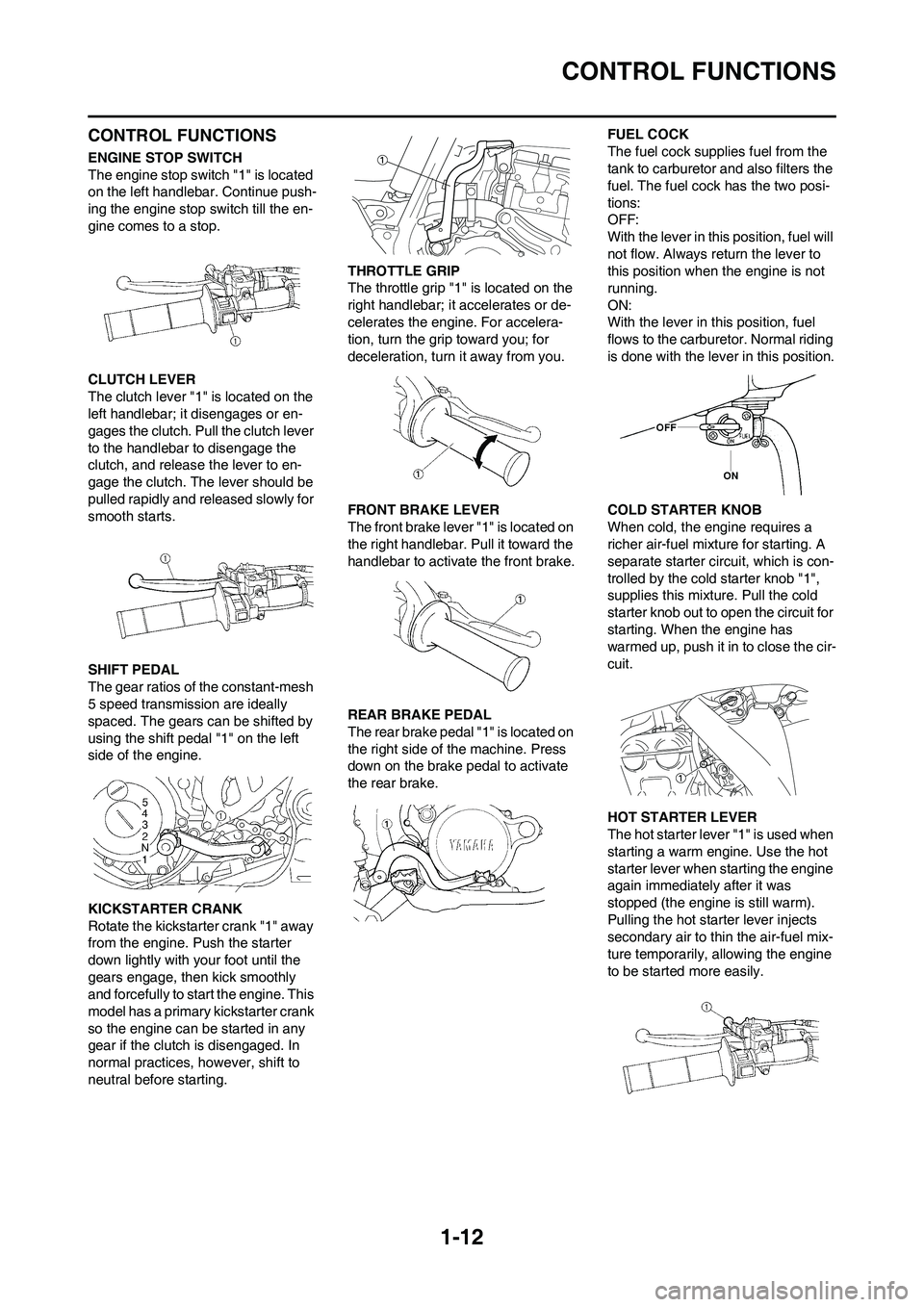

ENGINE STOP SWITCH

The engine stop switch "1" is located

on the left handlebar. Continue push-

ing the engine stop switch till the en-

gine comes to a stop.

CLUTCH LEVER

The clutch lever "1" is located on the

left handlebar; it disengages or en-

gages the clutch. Pull the clutch lever

to the handlebar to disengage the

clutch, and release the lever to en-

gage the clutch. The lever should be

pulled rapidly and released slowly for

smooth starts.

SHIFT PEDAL

The gear ratios of the constant-mesh

5 speed transmission are ideally

spaced. The gears can be shifted by

using the shift pedal "1" on the left

side of the engine.

KICKSTARTER CRANK

Rotate the kickstarter crank "1" away

from the engine. Push the starter

down lightly with your foot until the

gears engage, then kick smoothly

and forcefully to start the engine. This

model has a primary kickstarter crank

so the engine can be started in any

gear if the clutch is disengaged. In

normal practices, however, shift to

neutral before starting.THROTTLE GRIP

The throttle grip "1" is located on the

right handlebar; it accelerates or de-

celerates the engine. For accelera-

tion, turn the grip toward you; for

deceleration, turn it away from you.

FRONT BRAKE LEVER

The front brake lever "1" is located on

the right handlebar. Pull it toward the

handlebar to activate the front brake.

REAR BRAKE PEDAL

The rear brake pedal "1" is located on

the right side of the machine. Press

down on the brake pedal to activate

the rear brake.FUEL COCK

The fuel cock supplies fuel from the

tank to carburetor and also filters the

fuel. The fuel cock has the two posi-

tions:

OFF:

With the lever in this position, fuel will

not flow. Always return the lever to

this position when the engine is not

running.

ON:

With the lever in this position, fuel

flows to the carburetor. Normal riding

is done with the lever in this position.

COLD STARTER KNOB

When cold, the engine requires a

richer air-fuel mixture for starting. A

separate starter circuit, which is con-

trolled by the cold starter knob "1",

supplies this mixture. Pull the cold

starter knob out to open the circuit for

starting. When the engine has

warmed up, push it in to close the cir-

cuit.

HOT STARTER LEVER

The hot starter lever "1" is used when

starting a warm engine. Use the hot

starter lever when starting the engine

again immediately after it was

stopped (the engine is still warm).

Pulling the hot starter lever injects

secondary air to thin the air-fuel mix-

ture temporarily, allowing the engine

to be started more easily.

Page 23 of 196

1-13

STARTING AND BREAK-IN

STARTING AND BREAK-IN

FUEL

Always use the recommended fuel as

stated below. Also, be sure to use

new gasoline the day of a race.

Use only unleaded gasoline. The

use of leaded gasoline will cause

severe damage to the engine inter-

nal parts such as valves, piston

rings, and exhaust system, etc.

If knocking or pinging occurs, use a

different brand of gasoline or higher

octane grade.

• For refueling, be sure to stop the

engine and use enough care not

to spill any fuel. Also be sure to

avoid refueling close to a fire.

• Refuel after the engine, exhaust

pipe, etc. have cooled off.

HANDLING NOTE

Never start or run the engine in a

closed area. The exhaust fumes

are poisonous; they can cause

loss of consciousness and death

in a very short time. Always oper-

ate the machine in a well-ventilated

area.

• The carburetor on this machine

has a built-in accelerator pump.

Therefore, when starting the en-

gine, do not operate the throttle

or the spark plug will foul.

• Unlike a two-stroke engine, this

engine cannot be kick started

when the throttle is open be-

cause the kickstarter may kick

back. Also, if the throttle is open

the air/fuel mixture may be too

lean for the engine to start.

• Before starting the machine, per-

form the checks in the pre-opera-

tion check list.

AIR FILTER MAINTENANCE

According to "CLEANING THE AIR

FILTER ELEMENT" section in the

CHAPTER 3, apply the foam-air-filter

oil or its equivalent to the element.

(Excess oil in the element may ad-

versely affect engine starting.)

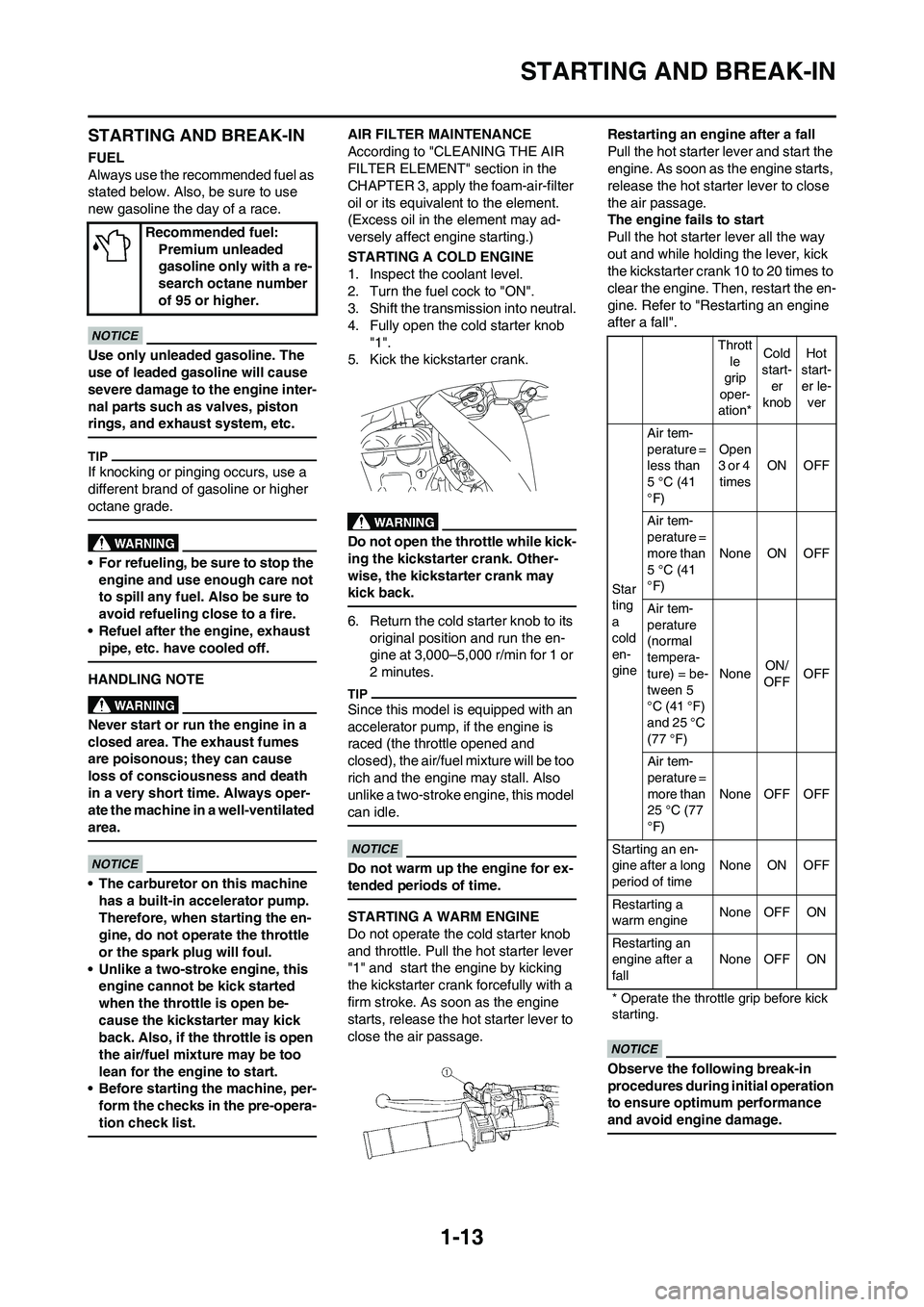

STARTING A COLD ENGINE

1. Inspect the coolant level.

2. Turn the fuel cock to "ON".

3. Shift the transmission into neutral.

4. Fully open the cold starter knob

"1".

5. Kick the kickstarter crank.

Do not open the throttle while kick-

ing the kickstarter crank. Other-

wise, the kickstarter crank may

kick back.

6. Return the cold starter knob to its

original position and run the en-

gine at 3,000–5,000 r/min for 1 or

2 minutes.

Since this model is equipped with an

accelerator pump, if the engine is

raced (the throttle opened and

closed), the air/fuel mixture will be too

rich and the engine may stall. Also

unlike a two-stroke engine, this model

can idle.

Do not warm up the engine for ex-

tended periods of time.

STARTING A WARM ENGINE

Do not operate the cold starter knob

and throttle. Pull the hot starter lever

"1" and start the engine by kicking

the kickstarter crank forcefully with a

firm stroke. As soon as the engine

starts, release the hot starter lever to

close the air passage.Restarting an engine after a fall

Pull the hot starter lever and start the

engine. As soon as the engine starts,

release the hot starter lever to close

the air passage.

The engine fails to start

Pull the hot starter lever all the way

out and while holding the lever, kick

the kickstarter crank 10 to 20 times to

clear the engine. Then, restart the en-

gine. Refer to "Restarting an engine

after a fall".

Observe the following break-in

procedures during initial operation

to ensure optimum performance

and avoid engine damage.

Recommended fuel:

Premium unleaded

gasoline only with a re-

search octane number

of 95 or higher.

Thrott

le

grip

oper-

ation*Cold

start-

er

knobHot

start-

er le-

ver

Star

ting

a

cold

en-

gineAir tem-

perature =

less than

5 °C (41

°F)Open

3 or 4

timesON OFF

Air tem-

perature =

more than

5 °C (41

°F)None ON OFF

Air tem-

perature

(normal

tempera-

ture) = be-

tween 5

°C (41 °F)

and 25 °C

(77 °F)NoneON/

OFFOFF

Air tem-

perature =

more than

25 °C (77

°F)None OFF OFF

Starting an en-

gine after a long

period of timeNone ON OFF

Restarting a

warm engineNone OFF ON

Restarting an

engine after a

fallNone OFF ON

* Operate the throttle grip before kick

starting.

Page 27 of 196

2-1

GENERAL SPECIFICATIONS

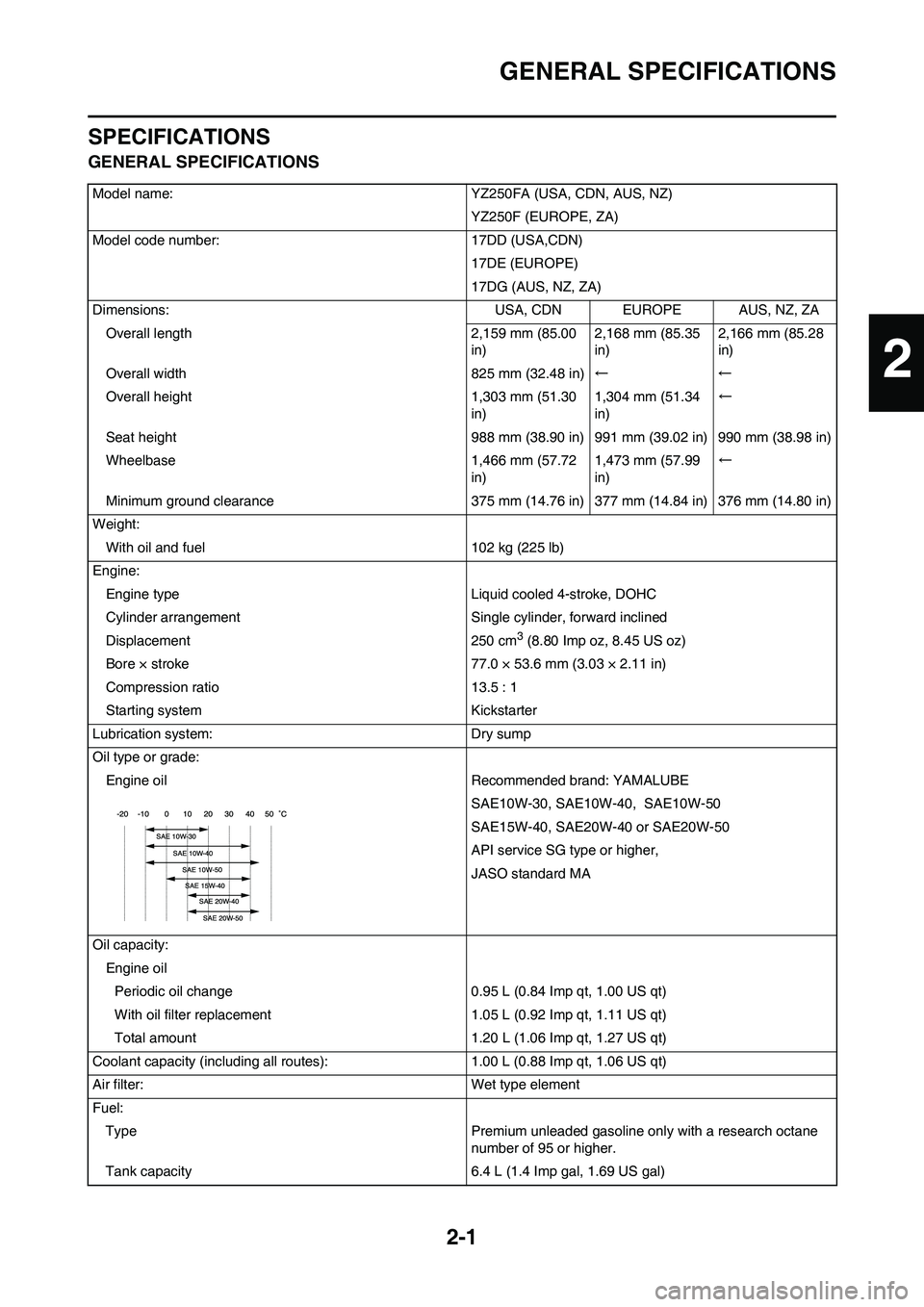

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model name: YZ250FA (USA, CDN, AUS, NZ)YZ250F (EUROPE, ZA)

Model code number: 17DD (USA,CDN) 17DE (EUROPE)

17DG (AUS, NZ, ZA)

Dimensions: USA, CDN EUROPE AUS, NZ, ZA Overall length 2,159 mm (85.00 in)2,168 mm (85.35

in)2,166 mm (85.28

in)

Overall width 825 mm (32.48 in) ←←

Overall height 1,303 mm (51.30 in)1,304 mm (51.34

in)←

Seat height 988 mm (38.90 in) 991 mm (39.02 in) 990 mm (38.98 in)

Wheelbase 1,466 mm (57.72 in)1,473 mm (57.99

in)←

Minimum ground clearance 375 mm (14.76 in) 377 mm (14.84 in) 376 mm (14.80 in)

Weight: With oil and fuel 102 kg (225 lb)

Engine: Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 250 cm

3 (8.80 Imp oz, 8.45 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 13.5 : 1

Starting system Kickstarter

Lubrication system: Dry sump

Oil type or grade: Engine oil Recommended brand: YAMALUBE SAE10W-30, SAE10W-40, SAE10W-50

SAE15W-40, SAE20W-40 or SAE20W-50

API service SG type or higher,

JASO standard MA

Oil capacity: Engine oilPeriodic oil change 0.95 L (0.84 Imp qt, 1.00 US qt)

With oil filter replacement 1.05 L (0.92 Imp qt, 1.11 US qt)

Total amount 1.20 L (1.06 Imp qt, 1.27 US qt)

Coolant capacity (including all routes): 1.00 L (0 .88 Imp qt, 1.06 US qt)

Air filter: Wet type element

Fuel: Type Premium unleaded gasoline on ly with a research octane

number of 95 or higher.

Tank capacity 6.4 L (1.4 Imp gal, 1.69 US gal)

2

Page 36 of 196

2-10

TIGHTENING TORQUES

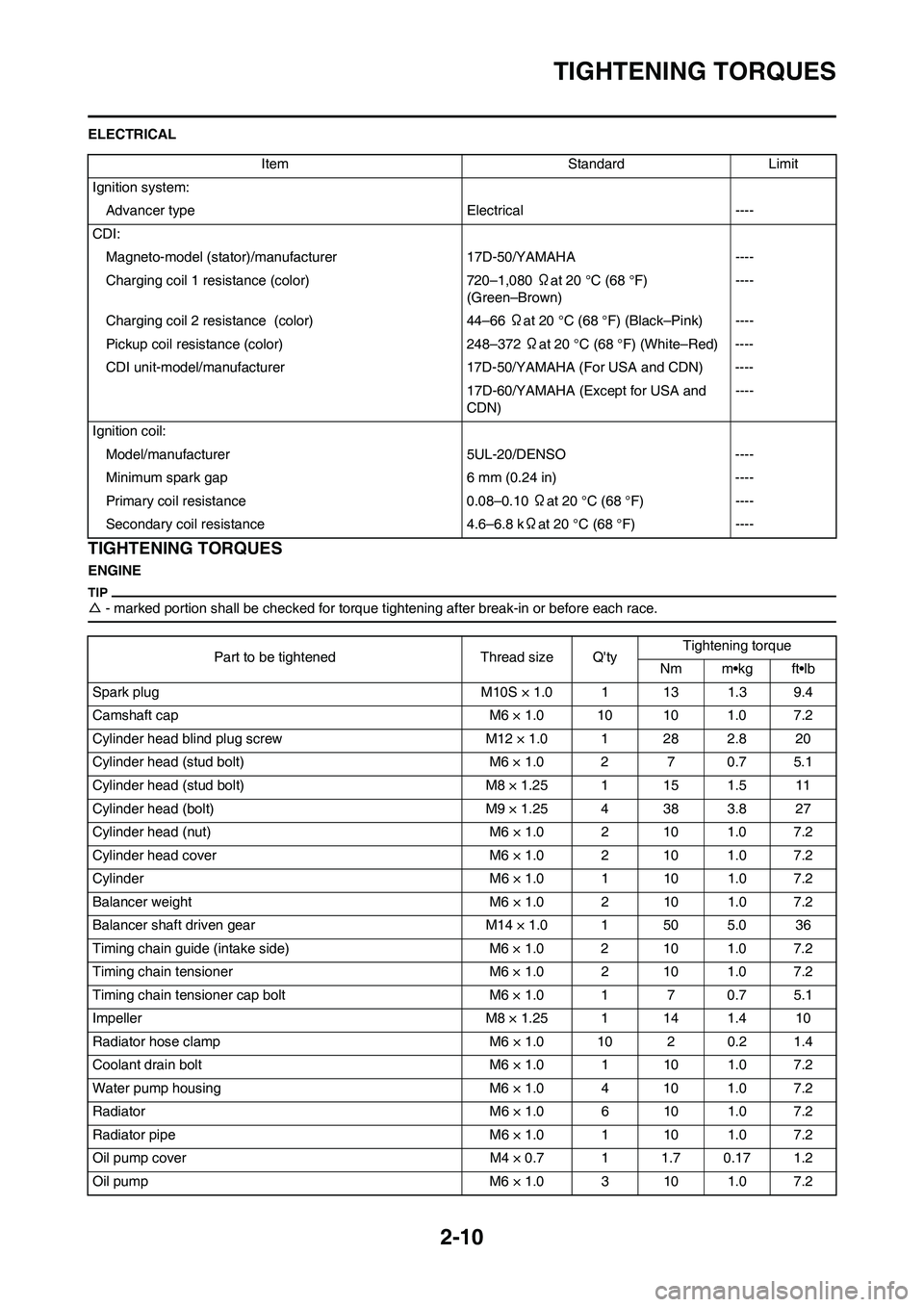

ELECTRICAL

TIGHTENING TORQUES

ENGINE

△- marked portion shall be checked for torque tightening after break-in or before each race.

Item Standard Limit

Ignition system:

Advancer type Electrical ----

CDI:

Magneto-model (stator)/manufacturer 17D-50/YAMAHA ----

Charging coil 1 resistance (color) 720–1,080 Ωat 20 °C (68 °F)

(Green–Brown)----

Charging coil 2 resistance (color) 44–66 Ωat 20 °C (68 °F) (Black–Pink) ----

Pickup coil resistance (color) 248–372 Ωat 20 °C (68 °F) (White–Red) ----

CDI unit-model/manufacturer 17D-50/YAMAHA (For USA and CDN) ----

17D-60/YAMAHA (Except for USA and

CDN)----

Ignition coil:

Model/manufacturer 5UL-20/DENSO ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 0.08–0.10 Ωat 20 °C (68 °F) ----

Secondary coil resistance 4.6–6.8 kΩat 20 °C (68 °F) ----

Part to be tightened Thread size Q'tyTightening torque

Nm m•kg ft•lb

Spark plug M10S × 1.0 1 13 1.3 9.4

Camshaft cap M6 × 1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12 × 1.0 1 28 2.8 20

Cylinder head (stud bolt) M6 × 1.0 2 7 0.7 5.1

Cylinder head (stud bolt) M8 × 1.25 1 15 1.5 11

Cylinder head (bolt) M9 × 1.25 4 38 3.8 27

Cylinder head (nut) M6 × 1.0 2 10 1.0 7.2

Cylinder head cover M6 × 1.0 2 10 1.0 7.2

Cylinder M6 × 1.0 1 10 1.0 7.2

Balancer weight M6 × 1.0 2 10 1.0 7.2

Balancer shaft driven gear M14 × 1.0 1 50 5.0 36

Timing chain guide (intake side) M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner M6 × 1.0 2 10 1.0 7.2

Timing chain tensioner cap bolt M6 × 1.0 1 7 0.7 5.1

Impeller M8 × 1.25 1 14 1.4 10

Radiator hose clamp M6 × 1.0 10 2 0.2 1.4

Coolant drain bolt M6 × 1.0 1 10 1.0 7.2

Water pump housing M6 × 1.0 4 10 1.0 7.2

Radiator M6 × 1.0 6 10 1.0 7.2

Radiator pipe M6 × 1.0 1 10 1.0 7.2

Oil pump cover M4 × 0.7 1 1.7 0.17 1.2

Oil pump M6 × 1.0 3 10 1.0 7.2