engine oil YAMAHA YZ250F 2014 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ250F, Model: YAMAHA YZ250F 2014Pages: 356, PDF Size: 11.39 MB

Page 289 of 356

IGNITION SYSTEM

8-3

EAS1SM1323

1. Crankshaft position sensor

2. AC magneto

3. Rectifier/regulator

4. Joint connector

5. Condenser

7. Engine stop switch

9. ECU

10.Ignition coil

11.Spark plug

Page 290 of 356

IGNITION SYSTEM

8-4

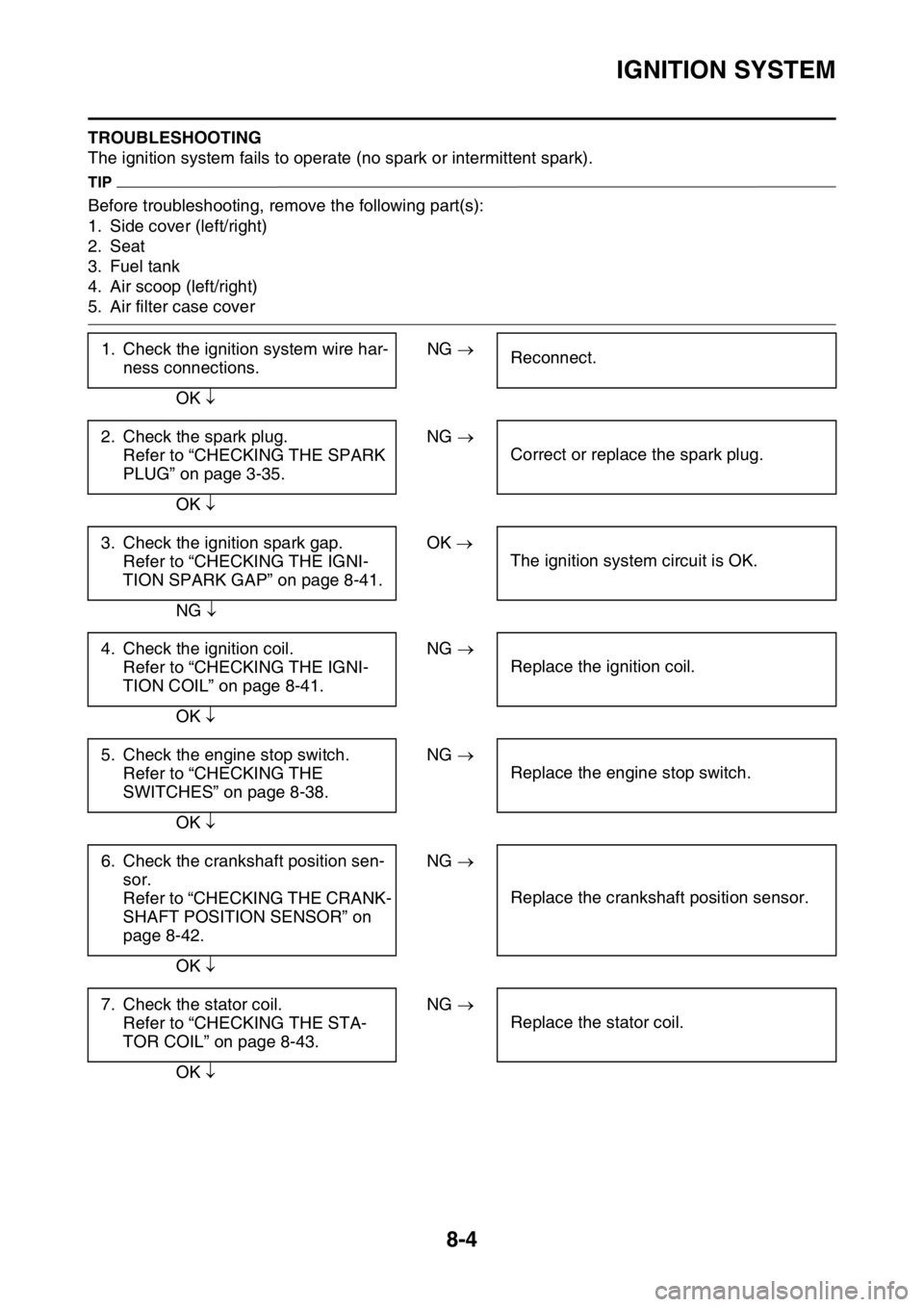

TROUBLESHOOTING

The ignition system fails to operate (no spark or intermittent spark).

TIP

Before troubleshooting, remove the following part(s):

1. Side cover (left/right)

2. Seat

3. Fuel tank

4. Air scoop (left/right)

5. Air filter case cover

1. Check the ignition system wire har-

ness connections.NG

Reconnect.

OK

2. Check the spark plug.

Refer to “CHECKING THE SPARK

PLUG” on page 3-35.NG

Correct or replace the spark plug.

OK

3. Check the ignition spark gap.

Refer to “CHECKING THE IGNI-

TION SPARK GAP” on page 8-41.OK

The ignition system circuit is OK.

NG

4. Check the ignition coil.

Refer to “CHECKING THE IGNI-

TION COIL” on page 8-41.NG

Replace the ignition coil.

OK

5. Check the engine stop switch.

Refer to “CHECKING THE

SWITCHES” on page 8-38.NG

Replace the engine stop switch.

OK

6. Check the crankshaft position sen-

sor.

Refer to “CHECKING THE CRANK-

SHAFT POSITION SENSOR” on

page 8-42.NG

Replace the crankshaft position sensor.

OK

7. Check the stator coil.

Refer to “CHECKING THE STA-

TOR COIL” on page 8-43.NG

Replace the stator coil.

OK

Page 309 of 356

FUEL INJECTION SYSTEM

8-23

Fault code 33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.30

ActuationActuates the ignition coil five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when-

ever the ignition coil is actuated.

ProcedureCheck that a spark is generated five times.

• Connect an ignition checker.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of ignition coil

coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Wire harness continuity. Open or short circuit Re-

place the wire harness.

Between ignition coil coupler

and ECU coupler.

orange–orangeAfter starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

4 Mounted condition of ignition

coil.

Check for looseness or

pinching.

Check the mounted condition

for correctness.Improperly mounted ignition

coil Remount or replace

the ignition coil.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

5 Defective ignition coil (test

the primary coils for continu-

ity).Check the primary resistance

of the ignition coil.

“CHECKING THE IGNITION

COIL” on page 8-41.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

Page 310 of 356

FUEL INJECTION SYSTEM

8-24

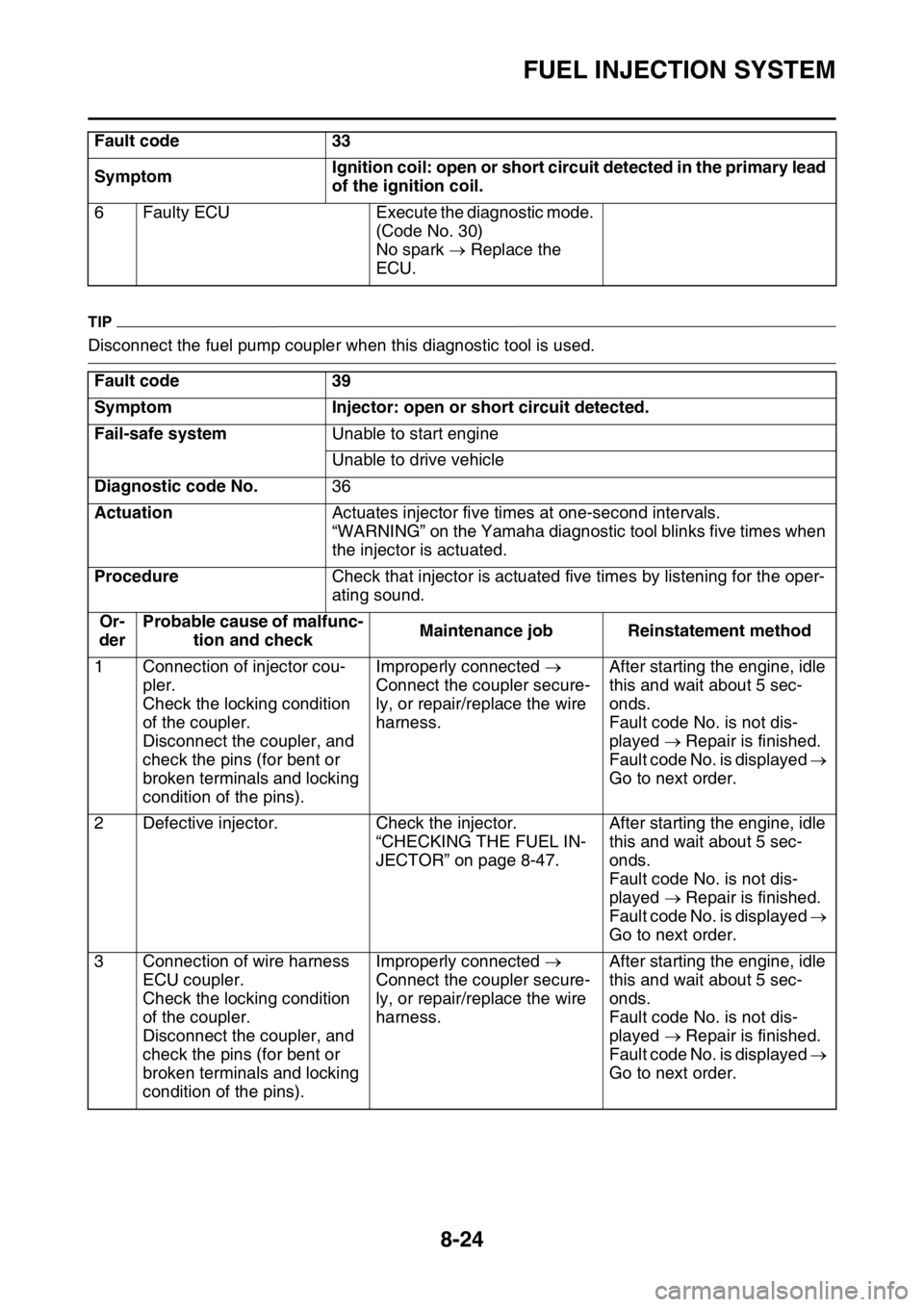

TIP

Disconnect the fuel pump coupler when this diagnostic tool is used. 6 Faulty ECU Execute the diagnostic mode.

(Code No. 30)

No spark Replace the

ECU.

Fault code 39

Symptom Injector: open or short circuit detected.

Fail-safe systemUnable to start engine

Unable to drive vehicle

Diagnostic code No.36

ActuationActuates injector five times at one-second intervals.

“WARNING” on the Yamaha diagnostic tool blinks five times when

the injector is actuated.

ProcedureCheck that injector is actuated five times by listening for the oper-

ating sound.

Or-

derProbable cause of malfunc-

tion and checkMaintenance job Reinstatement method

1 Connection of injector cou-

pler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

2 Defective injector. Check the injector.

“CHECKING THE FUEL IN-

JECTOR” on page 8-47.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order.

3 Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler, and

check the pins (for bent or

broken terminals and locking

condition of the pins).Improperly connected

Connect the coupler secure-

ly, or repair/replace the wire

harness.After starting the engine, idle

this and wait about 5 sec-

onds.

Fault code No. is not dis-

played Repair is finished.

Fault code No. is displayed

Go to next order. Fault code 33

SymptomIgnition coil: open or short circuit detected in the primary lead

of the ignition coil.

Page 327 of 356

ELECTRICAL COMPONENTS

8-41

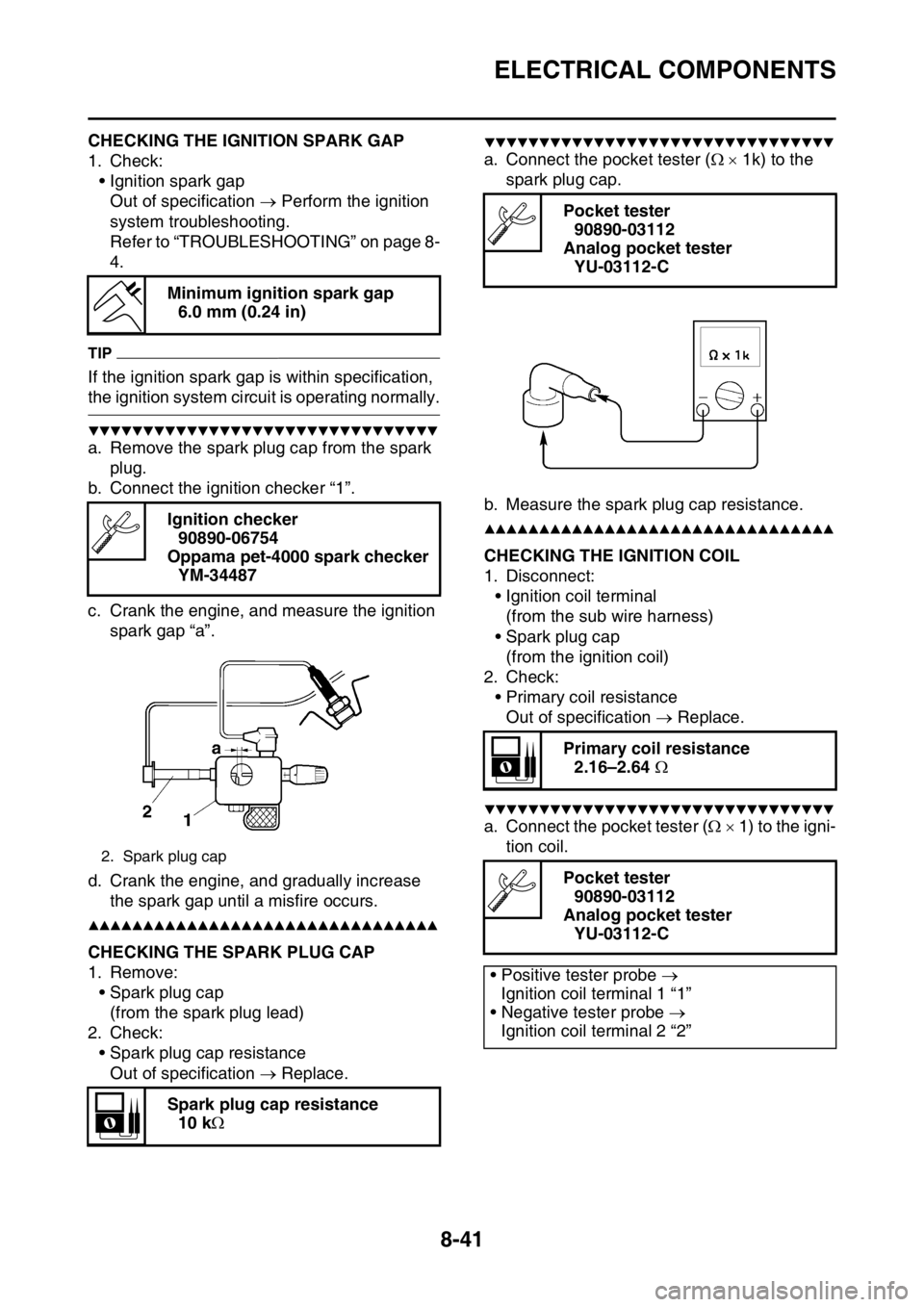

EAS1SM1336CHECKING THE IGNITION SPARK GAP

1. Check:

• Ignition spark gap

Out of specification Perform the ignition

system troubleshooting.

Refer to “TROUBLESHOOTING” on page 8-

4.

TIP

If the ignition spark gap is within specification,

the ignition system circuit is operating normally.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the spark plug cap from the spark

plug.

b. Connect the ignition checker “1”.

c. Crank the engine, and measure the ignition

spark gap “a”.

d. Crank the engine, and gradually increase

the spark gap until a misfire occurs.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS1SM1337CHECKING THE SPARK PLUG CAP

1. Remove:

• Spark plug cap

(from the spark plug lead)

2. Check:

• Spark plug cap resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1k) to the

spark plug cap.

b. Measure the spark plug cap resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS1SM1338CHECKING THE IGNITION COIL

1. Disconnect:

• Ignition coil terminal

(from the sub wire harness)

• Spark plug cap

(from the ignition coil)

2. Check:

• Primary coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1) to the igni-

tion coil. Minimum ignition spark gap

6.0 mm (0.24 in)

Ignition checker

90890-06754

Oppama pet-4000 spark checker

YM-34487

2. Spark plug cap

Spark plug cap resistance

10 k

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Primary coil resistance

2.16–2.64

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Ignition coil terminal 1 “1”

• Negative tester probe

Ignition coil terminal 2 “2”

Page 329 of 356

ELECTRICAL COMPONENTS

8-43

CHECKING THE ECU

1. Check:

• Mounted condition of ECU.

Improperly mounted Remount.

TIP

• The lean angle sensor is built into the ECU.

• The lean angle sensor stops the engine in

case of a turnover.

• To ensure that the lean angle sensor operates

correctly, do not change the installed condi-

tion of the ECU.

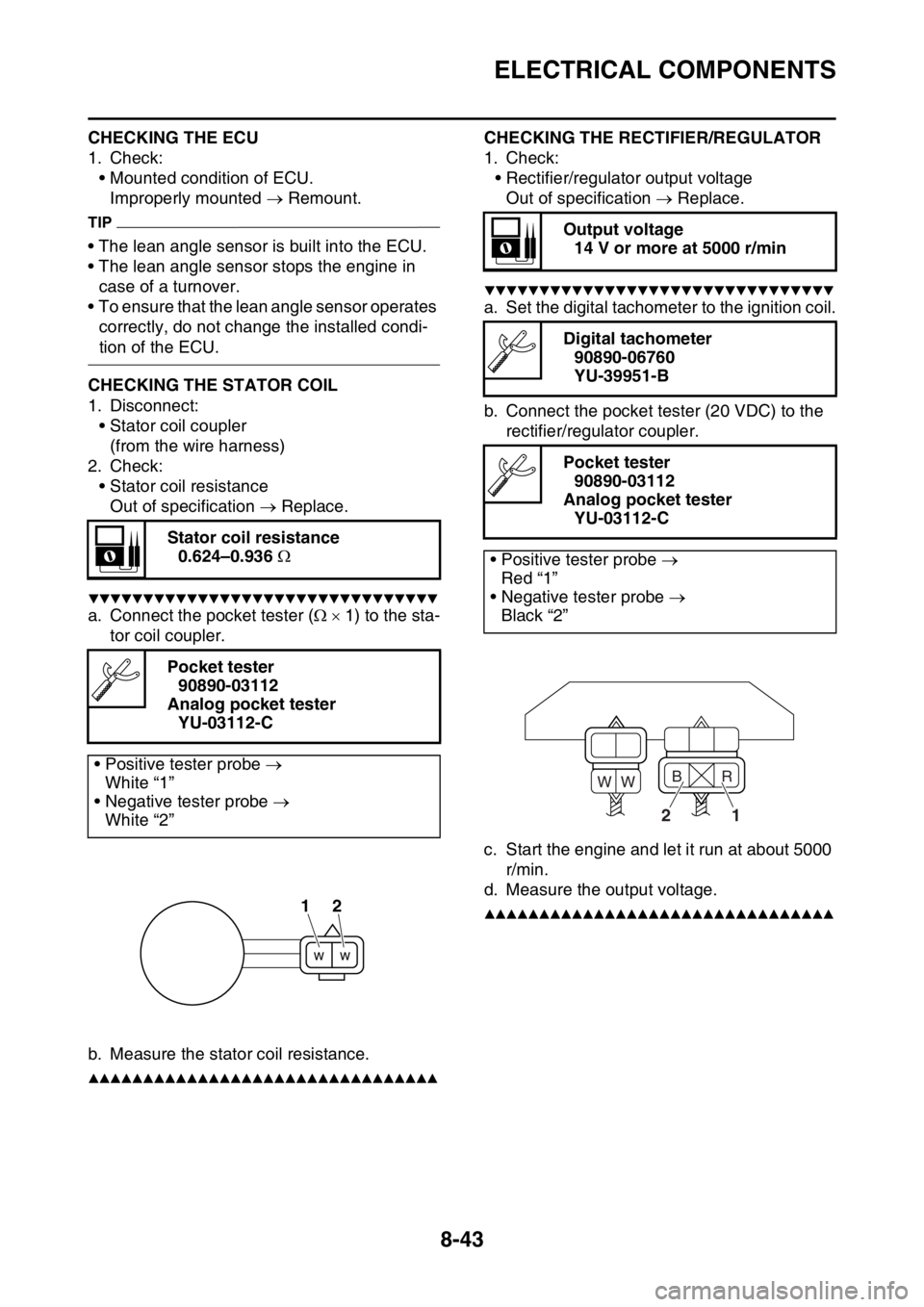

EAS1SM1341CHECKING THE STATOR COIL

1. Disconnect:

• Stator coil coupler

(from the wire harness)

2. Check:

• Stator coil resistance

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester ( 1) to the sta-

tor coil coupler.

b. Measure the stator coil resistance.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS1SM1342

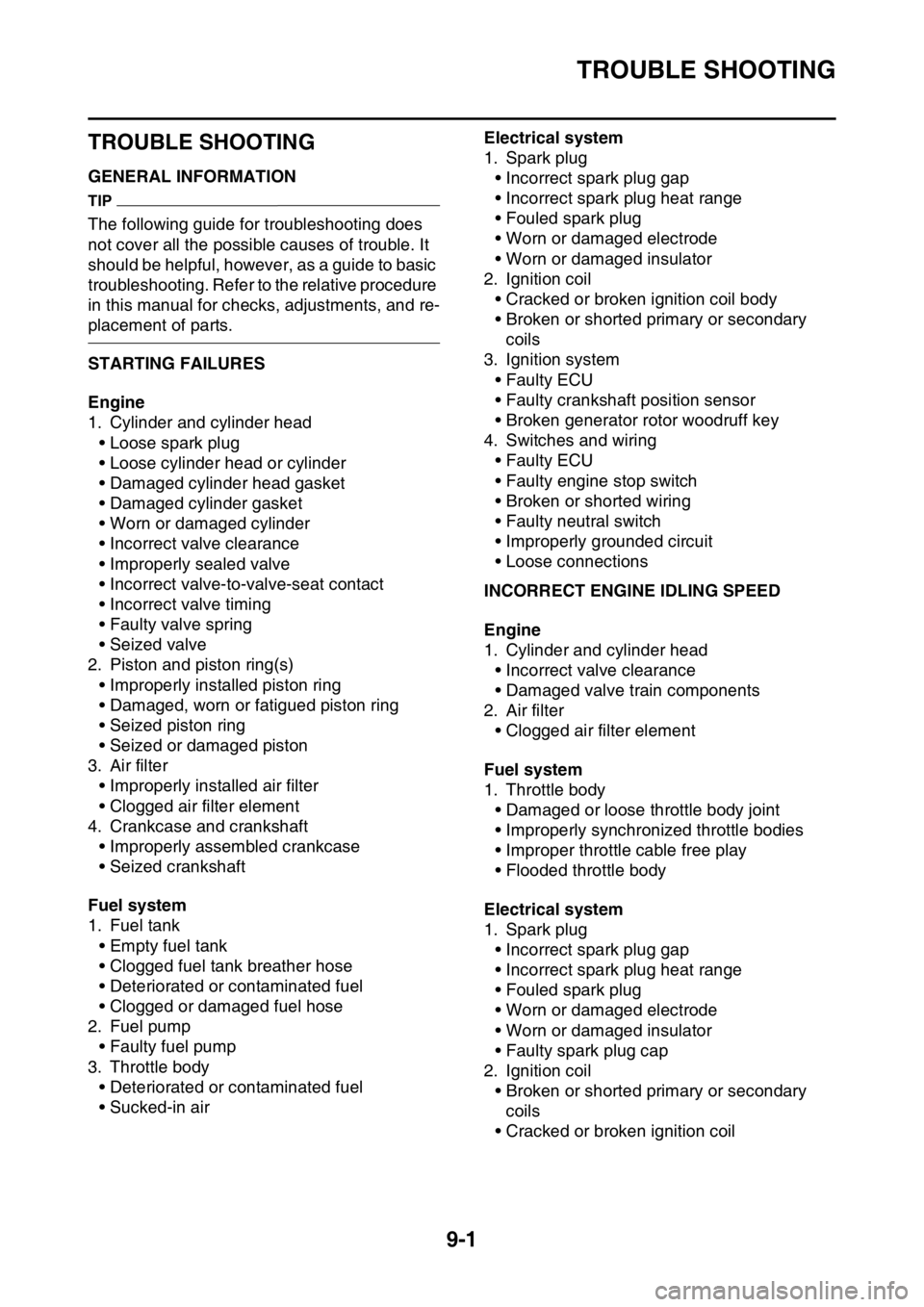

CHECKING THE RECTIFIER/REGULATOR

1. Check:

• Rectifier/regulator output voltage

Out of specification Replace.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Set the digital tachometer to the ignition coil.

b. Connect the pocket tester (20 VDC) to the

rectifier/regulator coupler.

c. Start the engine and let it run at about 5000

r/min.

d. Measure the output voltage.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲EAS1SM1343

Stator coil resistance

0.624–0.936

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

White “1”

• Negative tester probe

White “2”

12

Output voltage

14 V or more at 5000 r/min

Digital tachometer

90890-06760

YU-39951-B

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

Red “1”

• Negative tester probe

Black “2”

21

B

WWR

Page 336 of 356

TROUBLE SHOOTING

9-1

EAS1SM1350

TROUBLE SHOOTING

EAS1SM1351GENERAL INFORMATION

TIP

The following guide for troubleshooting does

not cover all the possible causes of trouble. It

should be helpful, however, as a guide to basic

troubleshooting. Refer to the relative procedure

in this manual for checks, adjustments, and re-

placement of parts.

EAS1SM1352STARTING FAILURES

Engine

1. Cylinder and cylinder head

• Loose spark plug

• Loose cylinder head or cylinder

• Damaged cylinder head gasket

• Damaged cylinder gasket

• Worn or damaged cylinder

• Incorrect valve clearance

• Improperly sealed valve

• Incorrect valve-to-valve-seat contact

• Incorrect valve timing

• Faulty valve spring

• Seized valve

2. Piston and piston ring(s)

• Improperly installed piston ring

• Damaged, worn or fatigued piston ring

• Seized piston ring

• Seized or damaged piston

3. Air filter

• Improperly installed air filter

• Clogged air filter element

4. Crankcase and crankshaft

• Improperly assembled crankcase

• Seized crankshaft

Fuel system

1. Fuel tank

• Empty fuel tank

• Clogged fuel tank breather hose

• Deteriorated or contaminated fuel

• Clogged or damaged fuel hose

2. Fuel pump

• Faulty fuel pump

3. Throttle body

• Deteriorated or contaminated fuel

• Sucked-in airElectrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

2. Ignition coil

• Cracked or broken ignition coil body

• Broken or shorted primary or secondary

coils

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

4. Switches and wiring

• Faulty ECU

• Faulty engine stop switch

• Broken or shorted wiring

• Faulty neutral switch

• Improperly grounded circuit

• Loose connections

EAS1SM1353INCORRECT ENGINE IDLING SPEED

Engine

1. Cylinder and cylinder head

• Incorrect valve clearance

• Damaged valve train components

2. Air filter

• Clogged air filter element

Fuel system

1. Throttle body

• Damaged or loose throttle body joint

• Improperly synchronized throttle bodies

• Improper throttle cable free play

• Flooded throttle body

Electrical system

1. Spark plug

• Incorrect spark plug gap

• Incorrect spark plug heat range

• Fouled spark plug

• Worn or damaged electrode

• Worn or damaged insulator

• Faulty spark plug cap

2. Ignition coil

• Broken or shorted primary or secondary

coils

• Cracked or broken ignition coil

Page 337 of 356

TROUBLE SHOOTING

9-2

3. Ignition system

• Faulty ECU

• Faulty crankshaft position sensor

• Broken generator rotor woodruff key

EAS1SM1354POOR MEDIUM-AND-HIGH-SPEED PER-

FORMANCE

Refer to “STARTING FAILURES” on page 9-1.

Engine

1. Air filter

• Clogged air filter element

Fuel system

1. Fuel pump

• Faulty fuel pump

2. Throttle body

• Defective throttle body

3. ECU

• Faulty ECU

EAS1SM1355FAULTY GEAR SHIFTING

Shifting is difficult

Refer to “CLUTCH” on page 5-35.

EAS1SM1356SHIFT PEDAL DOES NOT MOVE

Shift shaft

• Bent shift shaft

Shift drum and shift forks

• Foreign object in a shift drum groove

• Seized shift fork

• Bent shift fork guide bar

Transmission

• Seized transmission gear

• Foreign object between transmission gears

• Improperly assembled transmission

EAS1SM1357JUMPS OUT OF GEAR

Shift shaft

• Incorrect shift pedal position

• Improperly returned stopper lever

Shift forks

• Worn shift fork

Shift drum

• Incorrect axial play

• Worn shift drum groove

Transmission

• Worn gear dog

EAS1SM1358FAULTY CLUTCH

Clutch slips

1. Clutch

• Improperly assembled clutch

• Loose or fatigued clutch spring

• Worn friction plate

• Worn clutch plate

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (low)

• Deteriorated oil

Clutch drags

1. Clutch

• Unevenly tensioned clutch springs

• Warped pressure plate

• Bent clutch plate

• Swollen friction plate

• Bent clutch push rod

• Damaged clutch boss

• Burnt primary driven gear bushing

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity (high)

• Deteriorated oil

EAS1SM1359OVERHEATING

Engine

1. Cylinder head and piston

• Heavy carbon buildup

• Clogged coolant passages

2. Engine oil

• Incorrect oil level

• Incorrect oil viscosity

• Inferior oil quality

Cooling system

1. Coolant

• Low coolant level

2. Radiator

• Damaged or leaking radiator

• Faulty radiator cap

• Bent or damaged radiator fin

3. Water pump

• Damaged or faulty water pump

• Damaged hose

• Improperly connected hose

• Damaged pipe

• Improperly connected pipe

Page 352 of 356

EAS1SM1381

WIRING DIAGRAM

YZ250F 2014

1. Crankshaft position sensor

2. AC magneto

3. Rectifier/regulator

4. Joint connector

5. Condenser

6. Coupler for connecting option-

al part

7. Engine stop switch

8. Neutral switch

9. ECU

10. Ignition coil

11. Spark plug

12. Injector

13. Fuel pump

14. Intake air temperature sensor

15. Coolant temperature sensor

16. Throttle position sensor

17. Intake air pressure sensor

EAS1SM1382COLOR CODE

BBlack

Gy Gray

LBlue

Lg Light green

O Orange

PPink

RRed

Sb Sky blue

Y Yellow

B/L Black/Blue

B/R Black/Red

B/W Black/White

B/Y Black/Yellow

Br/W Brown/White

G/W Green/White

P/B Pink/Black

R/B Red/Black