YAMAHA YZ250F 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: YZ250F, Model: YAMAHA YZ250F 2015Pages: 356, PDF Size: 11.39 MB

Page 341 of 356

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-6

*1: Symbols used in the explanations of the malfunction history

: Normal

: There is currently a malfunction or abnormal condition.

: A malfunction or abnormal condition occurred previously, but the affected system or component

is currently operating normally.

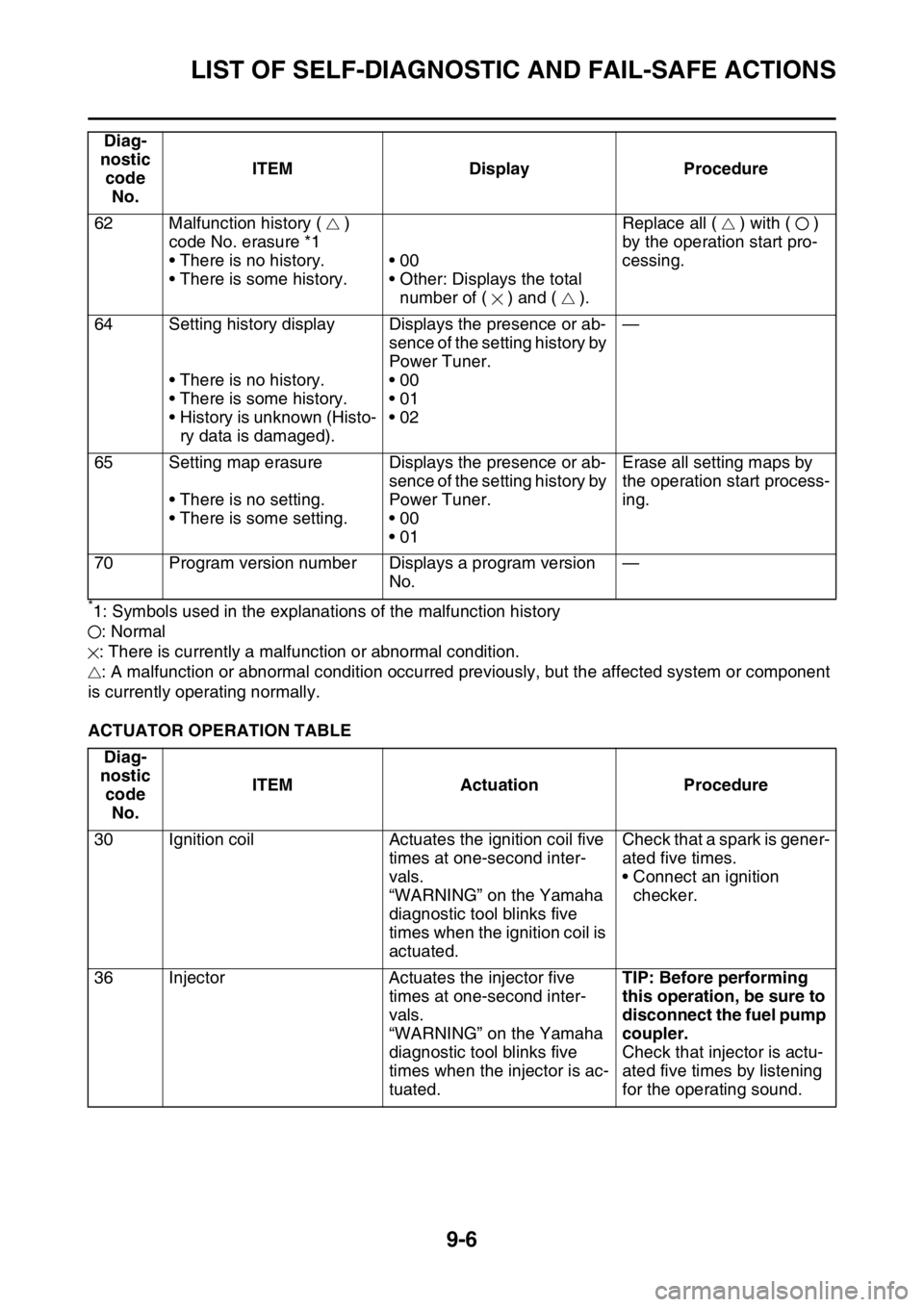

ACTUATOR OPERATION TABLE62 Malfunction history ( )

code No. erasure *1

• There is no history.

• There is some history.•00

• Other: Displays the total

number of ( ) and ( ).Replace all ( ) with ( )

by the operation start pro-

cessing.

64 Setting history display

• There is no history.

• There is some history.

• History is unknown (Histo-

ry data is damaged).Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01

•02—

65 Setting map erasure

• There is no setting.

• There is some setting.Displays the presence or ab-

sence of the setting history by

Power Tuner.

•00

•01Erase all setting maps by

the operation start process-

ing.

70 Program version number Displays a program version

No.—

Diag-

nostic

code

No.ITEM Actuation Procedure

30 Ignition coil Actuates the ignition coil five

times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the ignition coil is

actuated.Check that a spark is gener-

ated five times.

• Connect an ignition

checker.

36 Injector Actuates the injector five

times at one-second inter-

vals.

“WARNING” on the Yamaha

diagnostic tool blinks five

times when the injector is ac-

tuated.TIP: Before performing

this operation, be sure to

disconnect the fuel pump

coupler.

Check that injector is actu-

ated five times by listening

for the operating sound. Diag-

nostic

code

No.ITEM Display Procedure

Page 342 of 356

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-7

Page 343 of 356

10

TUNING

CHASSIS........................................................................................................ 10-1

SELECTION OF THE SECONDARY REDUCTION

RATIO (SPROCKET) .............................................................................. 10-1

DRIVE AND REAR WHEEL SPROCKETS SETTING PARTS ................ 10-1

TIRE PRESSURE..................................................................................... 10-2

FRONT FORK SETTING.......................................................................... 10-2

CHANGE IN AMOUNT AND CHARACTERISTICS OF FORK OIL.......... 10-2

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-3

FRONT FORK SETTING PARTS............................................................. 10-3

REAR SUSPENSION SETTING .............................................................. 10-3

CHOOSING SET LENGTH ...................................................................... 10-3

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-4

REAR SHOCK ABSORBER SETTING PARTS ....................................... 10-5

SUSPENSION SETTING (FRONT FORK)............................................... 10-6

SUSPENSION SETTING (REAR SHOCK ABSORBER) ......................... 10-7

Page 344 of 356

CHASSIS

10-1

EAS1SM5367

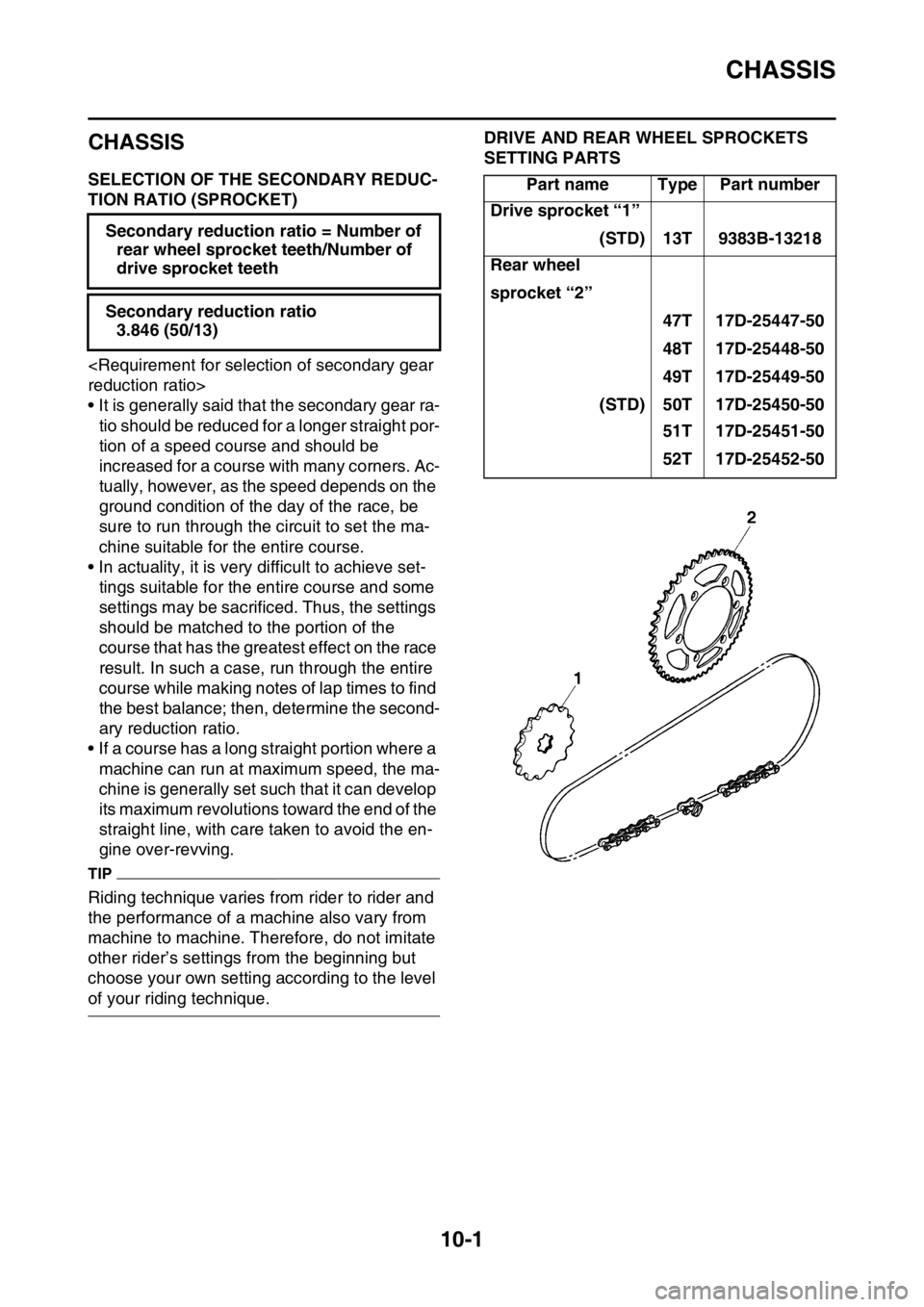

CHASSIS

EAS1SM5368SELECTION OF THE SECONDARY REDUC-

TION RATIO (SPROCKET)

• It is generally said that the secondary gear ra-

tio should be reduced for a longer straight por-

tion of a speed course and should be

increased for a course with many corners. Ac-

tually, however, as the speed depends on the

ground condition of the day of the race, be

sure to run through the circuit to set the ma-

chine suitable for the entire course.

• In actuality, it is very difficult to achieve set-

tings suitable for the entire course and some

settings may be sacrificed. Thus, the settings

should be matched to the portion of the

course that has the greatest effect on the race

result. In such a case, run through the entire

course while making notes of lap times to find

the best balance; then, determine the second-

ary reduction ratio.

• If a course has a long straight portion where a

machine can run at maximum speed, the ma-

chine is generally set such that it can develop

its maximum revolutions toward the end of the

straight line, with care taken to avoid the en-

gine over-revving.

TIP

Riding technique varies from rider to rider and

the performance of a machine also vary from

machine to machine. Therefore, do not imitate

other rider’s settings from the beginning but

choose your own setting according to the level

of your riding technique.

EAS1SM5369

DRIVE AND REAR WHEEL SPROCKETS

SETTING PARTS

Secondary reduction ratio = Number of

rear wheel sprocket teeth/Number of

drive sprocket teeth

Secondary reduction ratio

3.846 (50/13)

Part name Type Part number

Drive sprocket “1”

(STD) 13T 9383B-13218

Rear wheel

sprocket “2”

47T 17D-25447-50

48T 17D-25448-50

49T 17D-25449-50

(STD) 50T 17D-25450-50

51T 17D-25451-50

52T 17D-25452-50

Page 345 of 356

CHASSIS

10-2

EAS1SM5370TIRE PRESSURE

Tire pressure should be adjusted to suit the

road surface condition of the circuit.

• Under a rainy, a muddy, a sandy, or a slippery

condition, the tire pressure should be lower

for a larger area of contact with the road sur-

face.

• Under a stony or a hard road condition, the

tire pressure should be higher to prevent a flat

tire.

EAS1SM5371FRONT FORK SETTING

The front fork setting should be made depend-

ing on the rider’s feeling of an actual run and

the circuit conditions.

The front fork setting includes the following

three factors:

1. Setting of air spring characteristics

• Change the fork oil amount.

2. Setting of spring preload

• Change the spring.

3. Setting of damping force

• Change the compression damping force.

• Change the rebound damping force.

The spring acts on the load and the damping

force acts on the cushion travel speed.

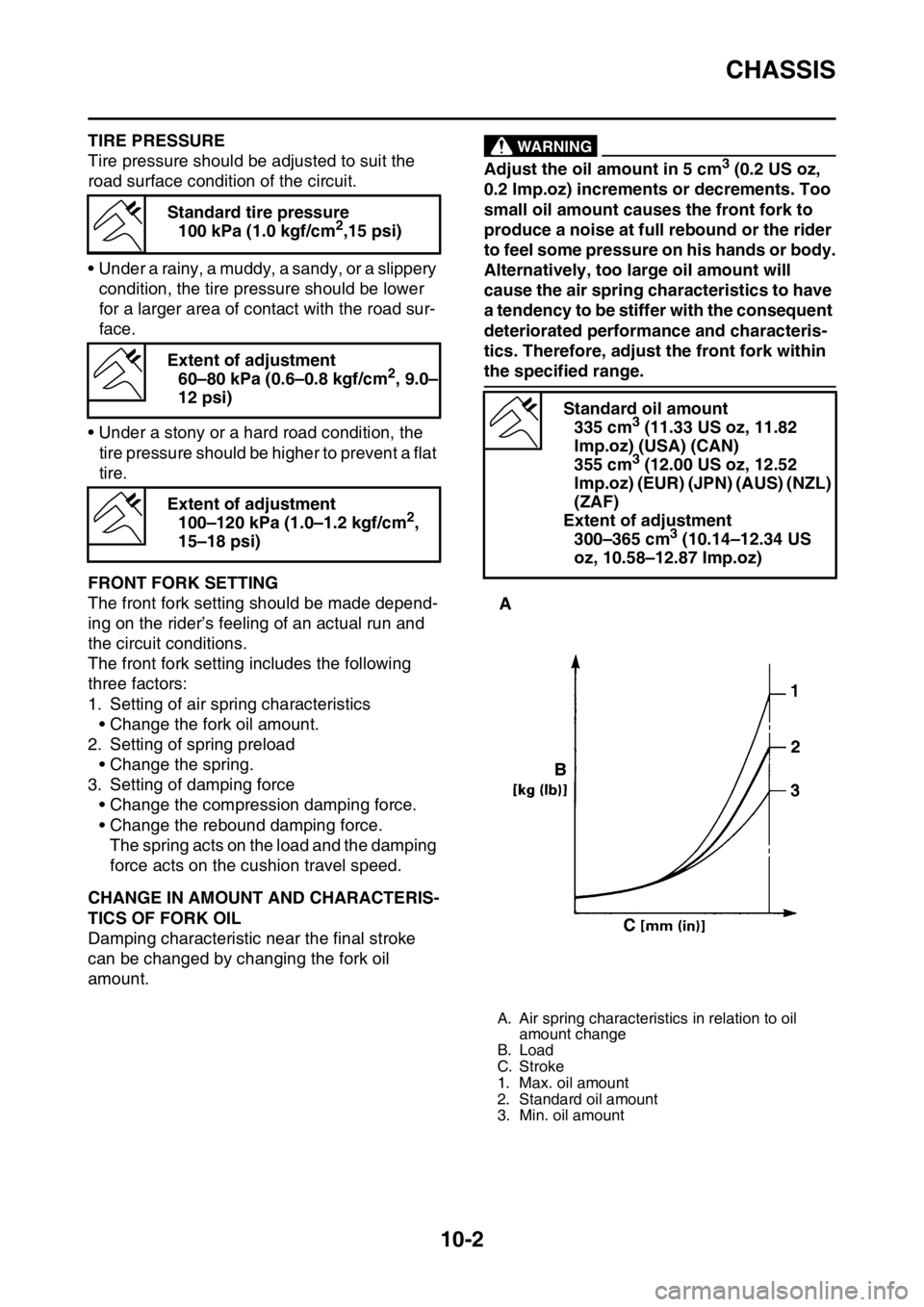

EAS1SM5372CHANGE IN AMOUNT AND CHARACTERIS-

TICS OF FORK OIL

Damping characteristic near the final stroke

can be changed by changing the fork oil

amount.

EWA1DX4001

WARNING

Adjust the oil amount in 5 cm3 (0.2 US oz,

0.2 Imp.oz) increments or decrements. Too

small oil amount causes the front fork to

produce a noise at full rebound or the rider

to feel some pressure on his hands or body.

Alternatively, too large oil amount will

cause the air spring characteristics to have

a tendency to be stiffer with the consequent

deteriorated performance and characteris-

tics. Therefore, adjust the front fork within

the specified range. Standard tire pressure

100 kPa (1.0 kgf/cm

2,15 psi)

Extent of adjustment

60–80 kPa (0.6–0.8 kgf/cm

2, 9.0–

12 psi)

Extent of adjustment

100–120 kPa (1.0–1.2 kgf/cm

2,

15–18 psi)

Standard oil amount

335 cm3 (11.33 US oz, 11.82

lmp.oz) (USA) (CAN)

355 cm

3 (12.00 US oz, 12.52

lmp.oz) (EUR) (JPN) (AUS) (NZL)

(ZAF)

Extent of adjustment

300–365 cm

3 (10.14–12.34 US

oz, 10.58–12.87 Imp.oz)

A. Air spring characteristics in relation to oil

amount change

B. Load

C. Stroke

1. Max. oil amount

2. Standard oil amount

3. Min. oil amount

Page 346 of 356

CHASSIS

10-3

EAS1SM5373SETTING OF SPRING AFTER REPLACE-

MENT

As the front fork setting can be easily affected

by the rear suspension, take care so that the

front and the rear are balanced (in position etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping force.

Turn out one or two clicks.

• Change the compression damping force.

Turn in one or two clicks.

TIP

Generally a soft spring gives a soft riding feel-

ing. Rebound damping tends to become stron-

ger and the front fork may sink deeply over a

series of gaps.

2. Use of stiff spring

• Change the rebound damping force.

Turn in one or two clicks.

• Change the compression damping force.

Turn out one or two clicks.

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

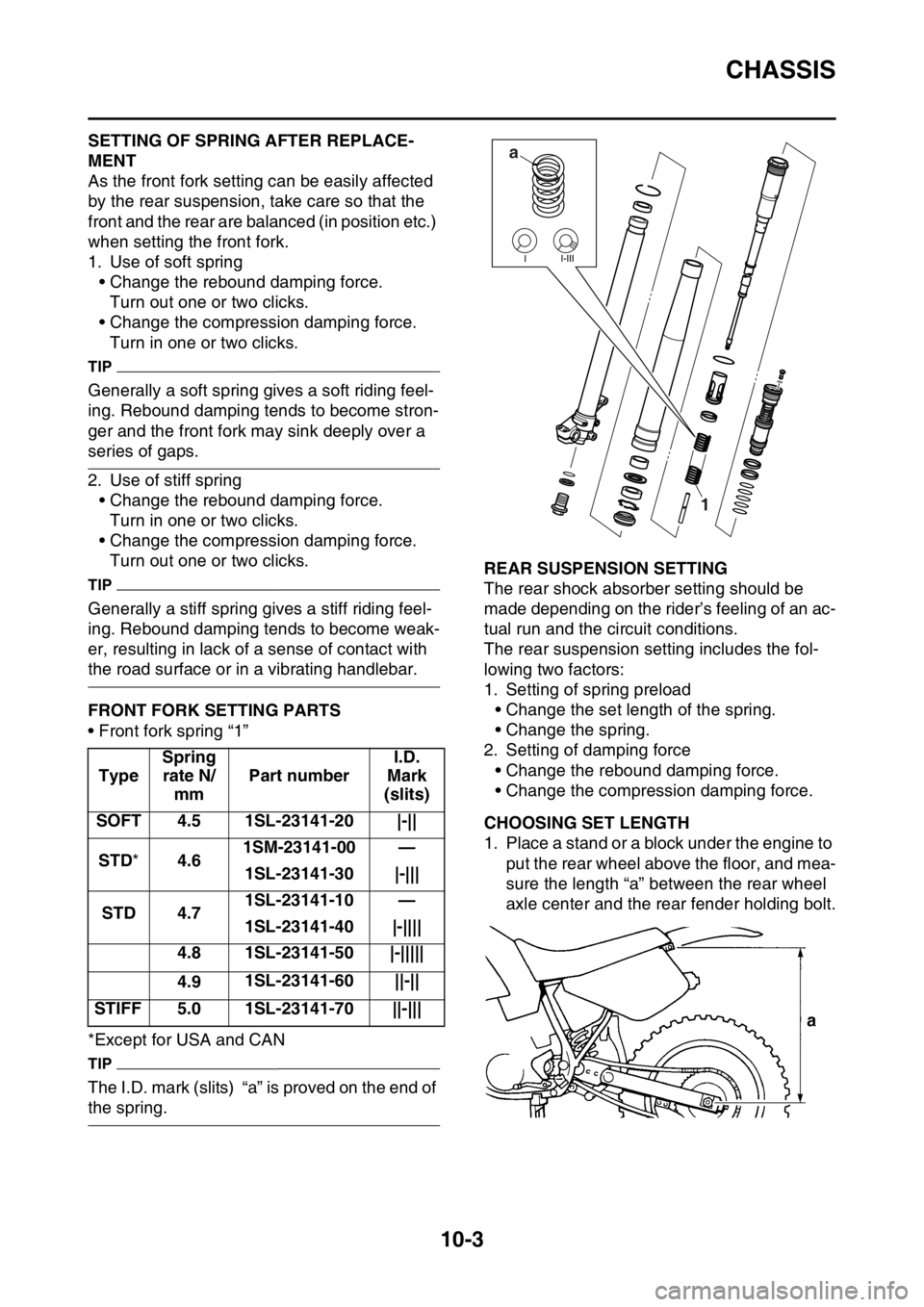

EAS1SM5374FRONT FORK SETTING PARTS

• Front fork spring “1”

*Except for USA and CAN

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS1SM5375REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider’s feeling of an ac-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

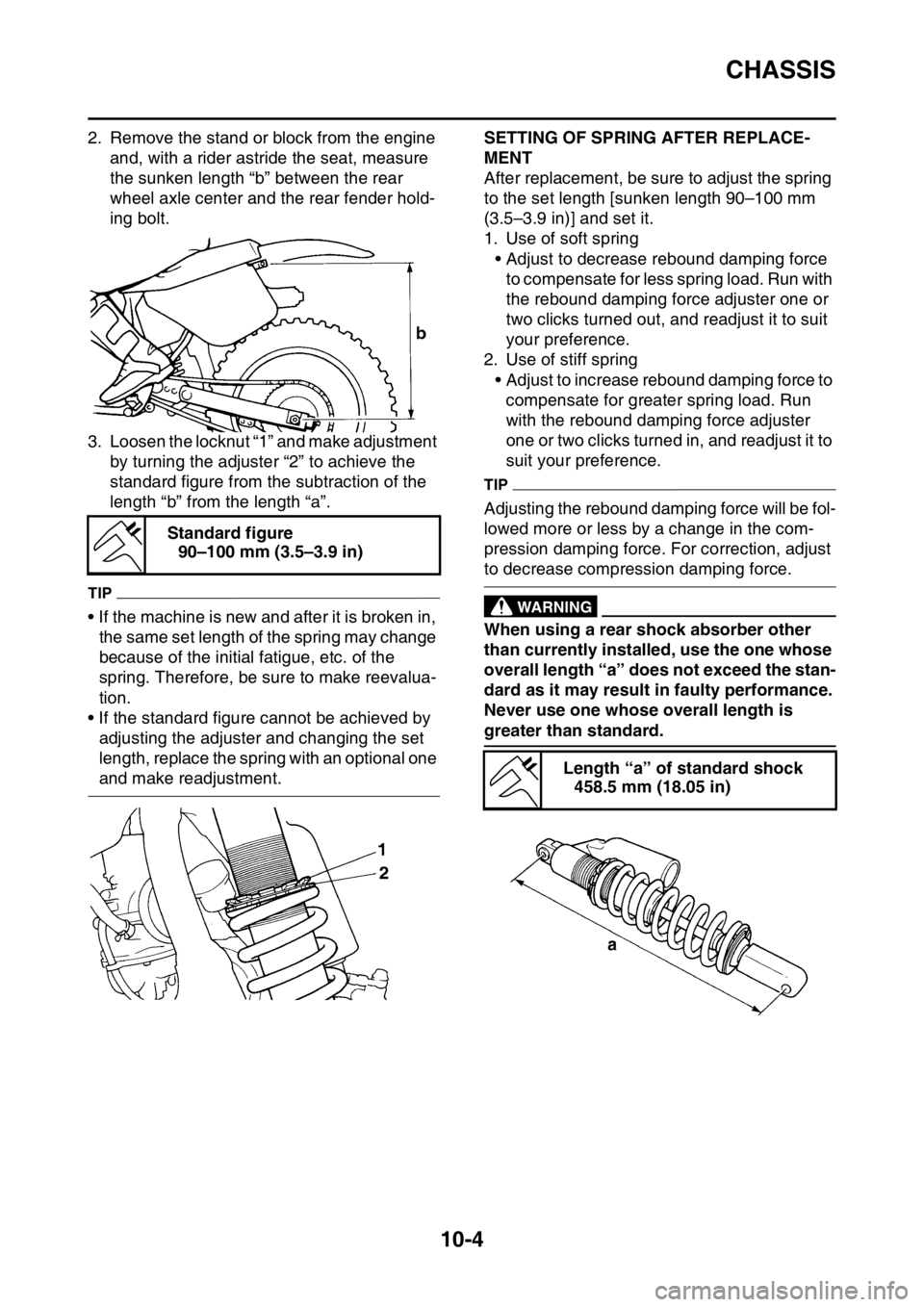

EAS1SM5376CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt. TypeSpring

rate N/

mmPart numberI.D.

Mark

(slits)

SOFT 4.5 1SL-23141-20 |-||

STD*4.61SM-23141-00 —

1SL-23141-30 |-|||

STD 4.71SL-23141-10 —

1SL-23141-40 |-||||

4.8 1SL-23141-50 |-|||||

4.91SL-23141-60 ||-||

STIFF 5.0 1SL-23141-70 ||-|||

a

1

Page 347 of 356

CHASSIS

10-4

2. Remove the stand or block from the engine

and, with a rider astride the seat, measure

the sunken length “b” between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut “1” and make adjustment

by turning the adjuster “2” to achieve the

standard figure from the subtraction of the

length “b” from the length “a”.

TIP

• If the machine is new and after it is broken in,

the same set length of the spring may change

because of the initial fatigue, etc. of the

spring. Therefore, be sure to make reevalua-

tion.

• If the standard figure cannot be achieved by

adjusting the adjuster and changing the set

length, replace the spring with an optional one

and make readjustment.

EAS1SM5377

SETTING OF SPRING AFTER REPLACE-

MENT

After replacement, be sure to adjust the spring

to the set length [sunken length 90–100 mm

(3.5–3.9 in)] and set it.

1. Use of soft spring

• Adjust to decrease rebound damping force

to compensate for less spring load. Run with

the rebound damping force adjuster one or

two clicks turned out, and readjust it to suit

your preference.

2. Use of stiff spring

• Adjust to increase rebound damping force to

compensate for greater spring load. Run

with the rebound damping force adjuster

one or two clicks turned in, and readjust it to

suit your preference.

TIP

Adjusting the rebound damping force will be fol-

lowed more or less by a change in the com-

pression damping force. For correction, adjust

to decrease compression damping force.

EWA1DX4002

WARNING

When using a rear shock absorber other

than currently installed, use the one whose

overall length “a” does not exceed the stan-

dard as it may result in faulty performance.

Never use one whose overall length is

greater than standard. Standard figure

90–100 mm (3.5–3.9 in)

Length “a” of standard shock

458.5 mm (18.05 in)

Page 348 of 356

CHASSIS

10-5

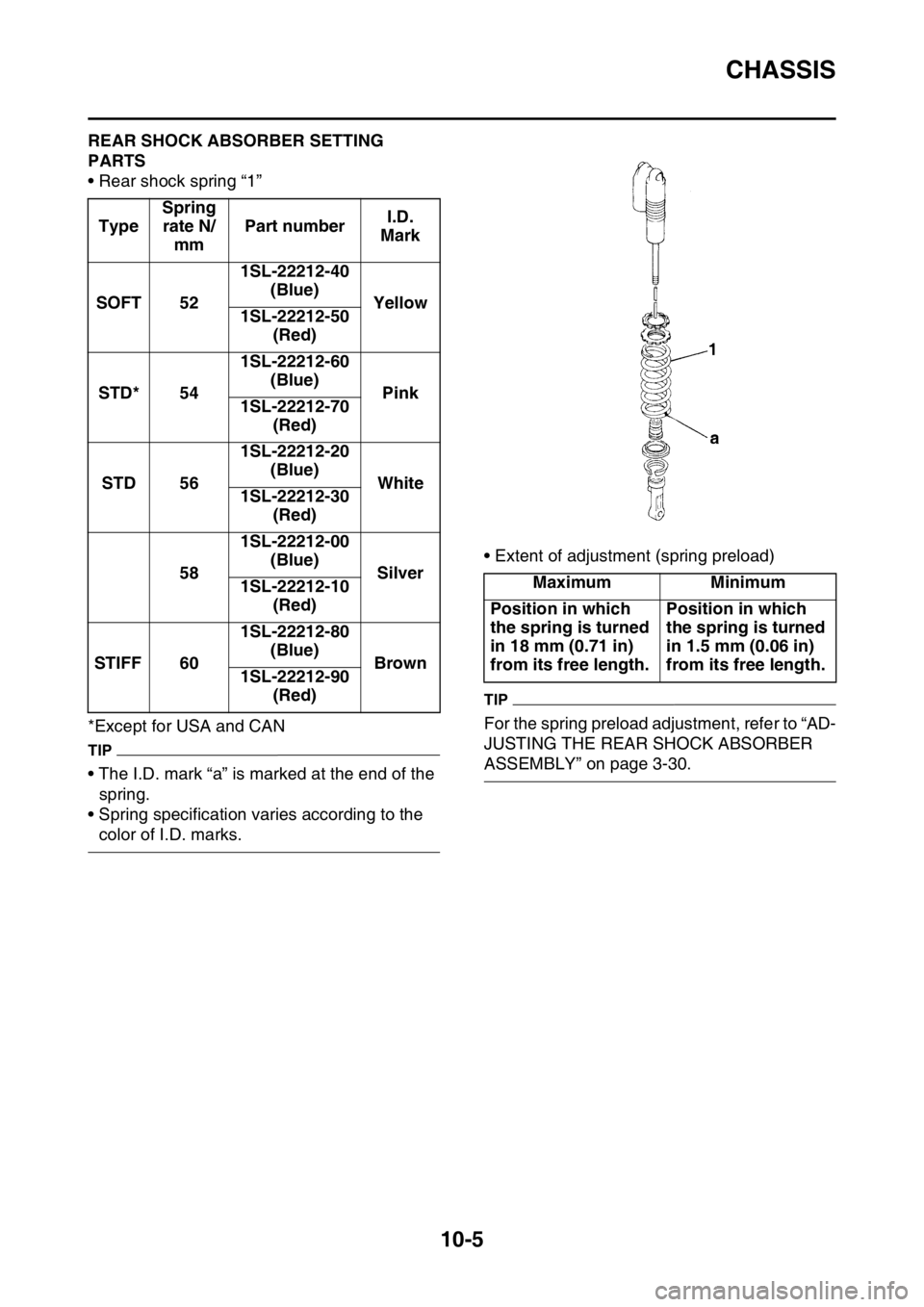

EAS1SM5378REAR SHOCK ABSORBER SETTING

PARTS

• Rear shock spring “1”

*Except for USA and CAN

TIP

• The I.D. mark “a” is marked at the end of the

spring.

• Spring specification varies according to the

color of I.D. marks.• Extent of adjustment (spring preload)

TIP

For the spring preload adjustment, refer to “AD-

JUSTING THE REAR SHOCK ABSORBER

ASSEMBLY” on page 3-30. TypeSpring

rate N/

mmPart numberI.D.

Mark

SOFT 521SL-22212-40

(Blue)

Yellow

1SL-22212-50

(Red)

STD* 541SL-22212-60

(Blue)

Pink

1SL-22212-70

(Red)

STD 561SL-22212-20

(Blue)

White

1SL-22212-30

(Red)

581SL-22212-00

(Blue)

Silver

1SL-22212-10

(Red)

STIFF 601SL-22212-80

(Blue)

Brown

1SL-22212-90

(Red)

Maximum Minimum

Position in which

the spring is turned

in 18 mm (0.71 in)

from its free length.Position in which

the spring is turned

in 1.5 mm (0.06 in)

from its free length.

Page 349 of 356

CHASSIS

10-6

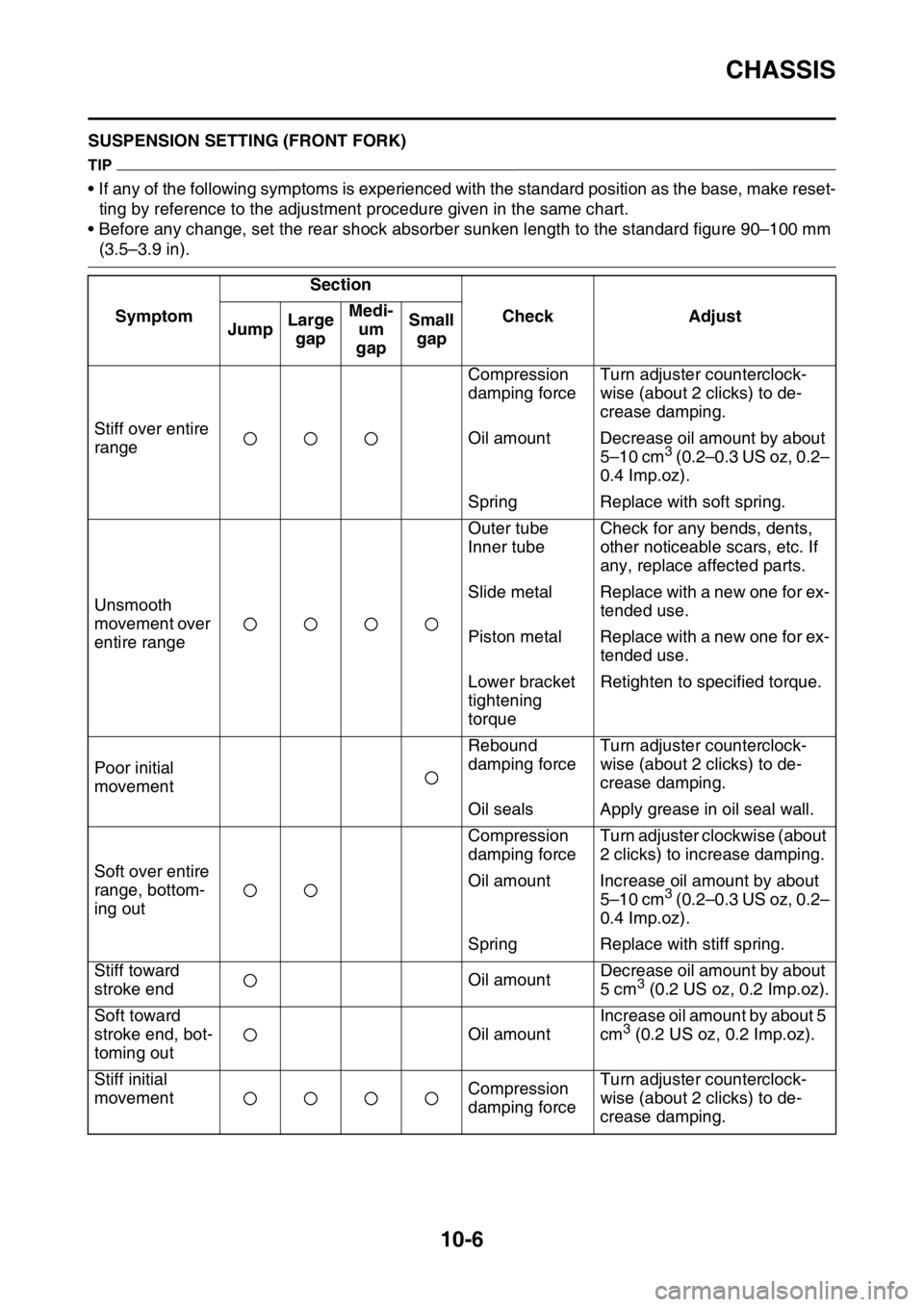

EAS1SM5379SUSPENSION SETTING (FRONT FORK)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm

(3.5–3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

rangeCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with soft spring.

Unsmooth

movement over

entire rangeOuter tube

Inner tubeCheck for any bends, dents,

other noticeable scars, etc. If

any, replace affected parts.

Slide metal Replace with a new one for ex-

tended use.

Piston metal Replace with a new one for ex-

tended use.

Lower bracket

tightening

torqueRetighten to specified torque.

Poor initial

movementRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil seals Apply grease in oil seal wall.

Soft over entire

range, bottom-

ing outCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Oil amount Increase oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with stiff spring.

Stiff toward

stroke endOil amountDecrease oil amount by about

5 cm

3 (0.2 US oz, 0.2 Imp.oz).

Soft toward

stroke end, bot-

toming outOil amountIncrease oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

Stiff initial

movementCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Page 350 of 356

CHASSIS

10-7

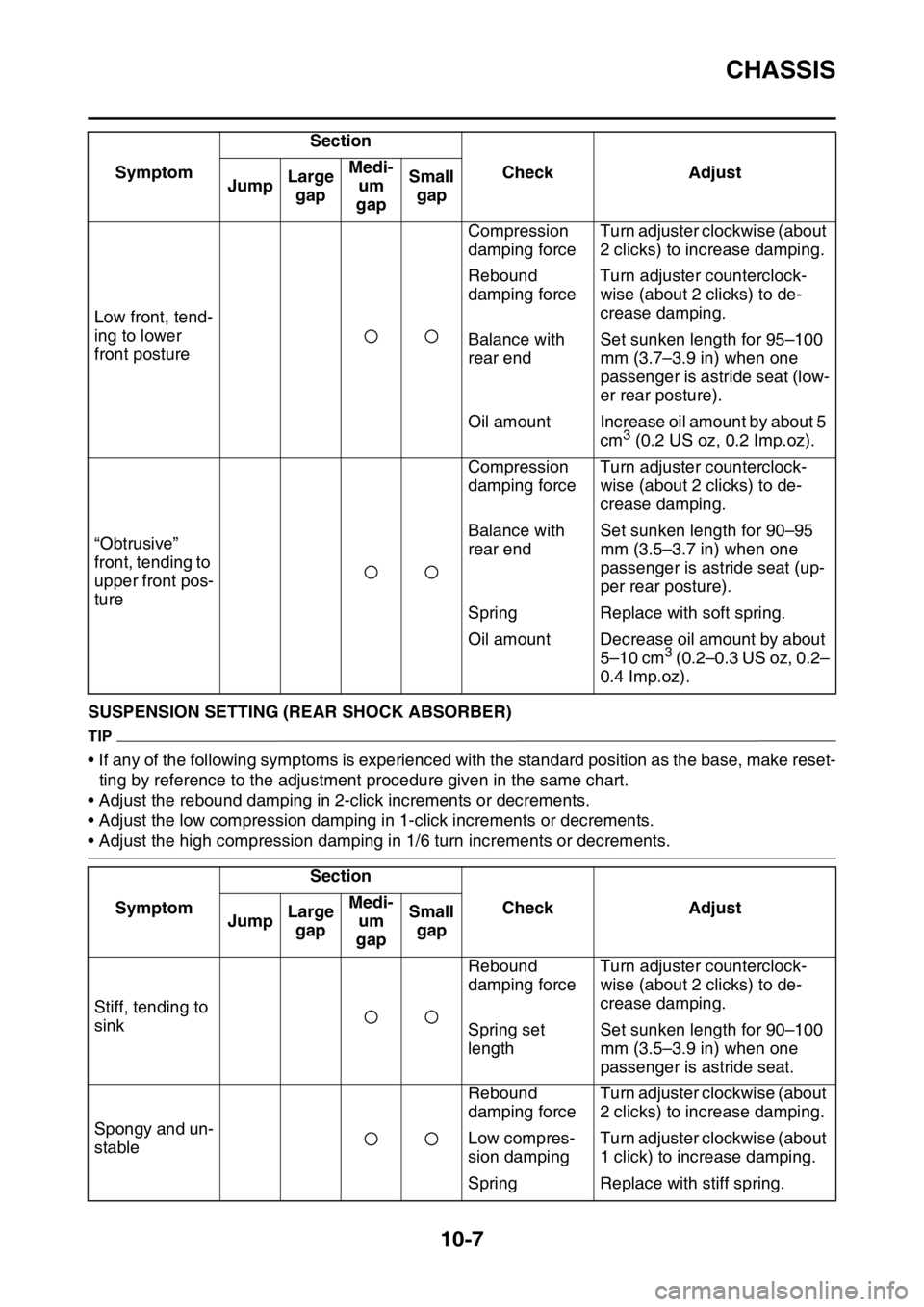

EAS1SM5380SUSPENSION SETTING (REAR SHOCK ABSORBER)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Adjust the rebound damping in 2-click increments or decrements.

• Adjust the low compression damping in 1-click increments or decrements.

• Adjust the high compression damping in 1/6 turn increments or decrements. Low front, tend-

ing to lower

front postureCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Rebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 95–100

mm (3.7–3.9 in) when one

passenger is astride seat (low-

er rear posture).

Oil amount Increase oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

“Obtrusive”

front, tending to

upper front pos-

tureCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 90–95

mm (3.5–3.7 in) when one

passenger is astride seat (up-

per rear posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff, tending to

sinkRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spongy and un-

stableRebound

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Low compres-

sion dampingTurn adjuster clockwise (about

1 click) to increase damping.

Spring Replace with stiff spring. SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap