length YAMAHA YZ250F 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 164 of 356

FRONT FORK

4-40

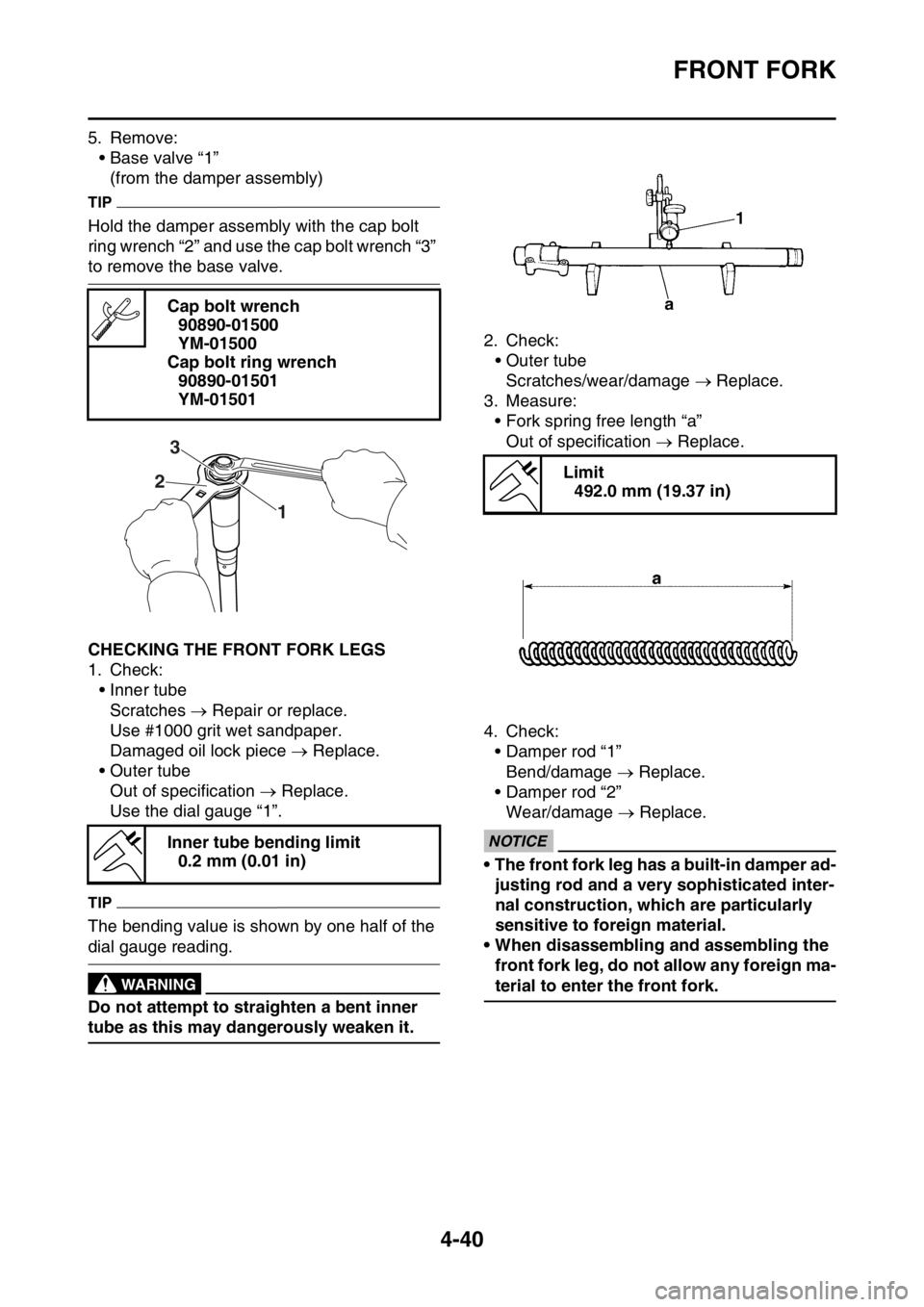

5. Remove:

• Base valve “1”

(from the damper assembly)

TIP

Hold the damper assembly with the cap bolt

ring wrench “2” and use the cap bolt wrench “3”

to remove the base valve.

EAS1SM9166CHECKING THE FRONT FORK LEGS

1. Check:

• Inner tube

Scratches Repair or replace.

Use #1000 grit wet sandpaper.

Damaged oil lock piece Replace.

• Outer tube

Out of specification Replace.

Use the dial gauge “1”.

TIP

The bending value is shown by one half of the

dial gauge reading.

EWA13650

WARNING

Do not attempt to straighten a bent inner

tube as this may dangerously weaken it.2. Check:

• Outer tube

Scratches/wear/damage Replace.

3. Measure:

• Fork spring free length “a”

Out of specification Replace.

4. Check:

• Damper rod “1”

Bend/damage Replace.

• Damper rod “2”

Wear/damage Replace.

ECA1DX1010

NOTICE

• The front fork leg has a built-in damper ad-

justing rod and a very sophisticated inter-

nal construction, which are particularly

sensitive to foreign material.

• When disassembling and assembling the

front fork leg, do not allow any foreign ma-

terial to enter the front fork. Cap bolt wrench

90890-01500

YM-01500

Cap bolt ring wrench

90890-01501

YM-01501

Inner tube bending limit

0.2 mm (0.01 in)

1 23

Limit

492.0 mm (19.37 in)

Page 188 of 356

CHAIN DRIVE

4-64

EAS1SM9188REMOVING THE DRIVE CHAIN

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Joint clip

• Drive chain joint “1”

• Drive chain “2”

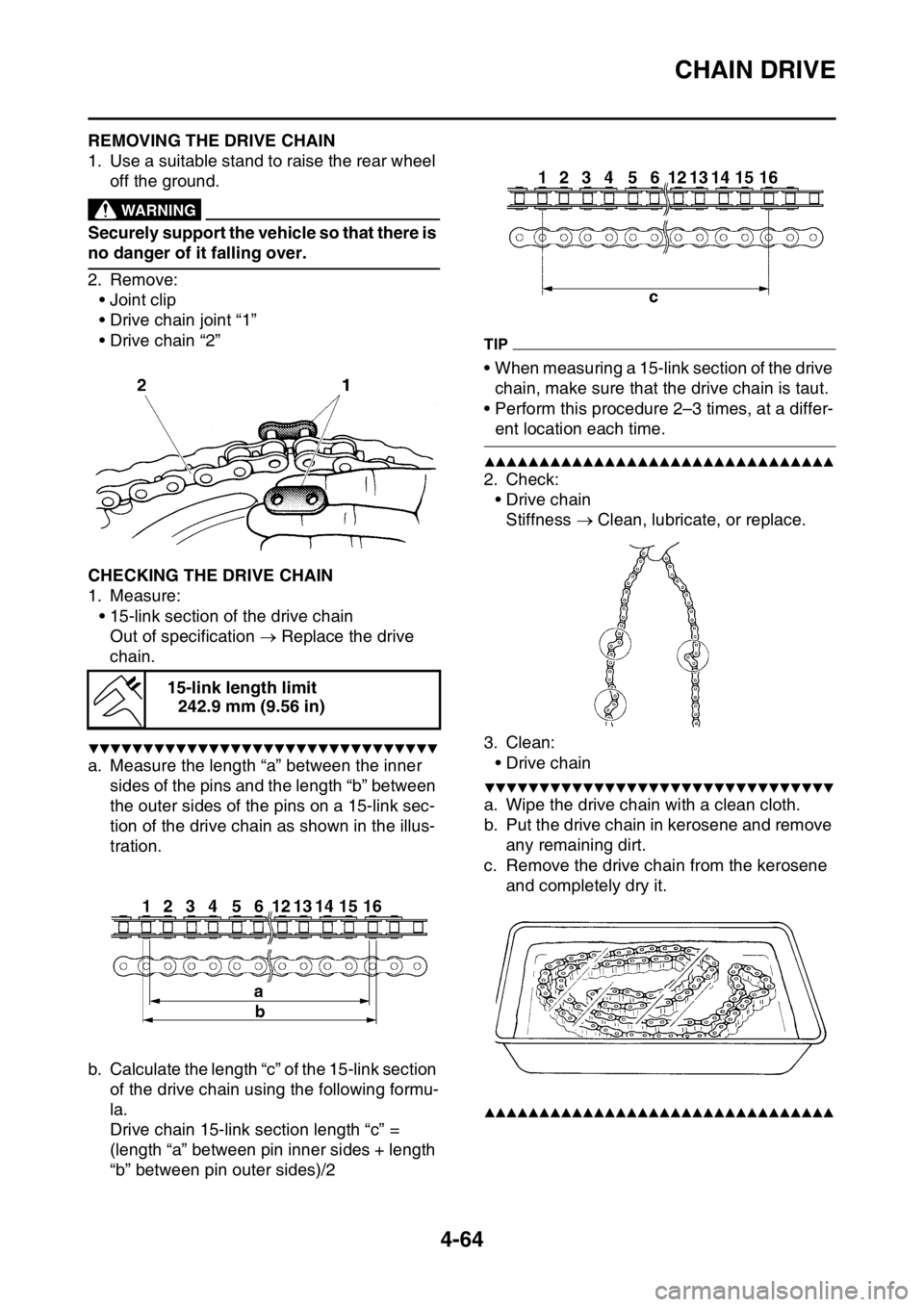

EAS1SM9189CHECKING THE DRIVE CHAIN

1. Measure:

• 15-link section of the drive chain

Out of specification Replace the drive

chain.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Measure the length “a” between the inner

sides of the pins and the length “b” between

the outer sides of the pins on a 15-link sec-

tion of the drive chain as shown in the illus-

tration.

b. Calculate the length “c” of the 15-link section

of the drive chain using the following formu-

la.

Drive chain 15-link section length “c” =

(length “a” between pin inner sides + length

“b” between pin outer sides)/2

TIP

• When measuring a 15-link section of the drive

chain, make sure that the drive chain is taut.

• Perform this procedure 2–3 times, at a differ-

ent location each time.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Check:

•Drive chain

Stiffness Clean, lubricate, or replace.

3. Clean:

•Drive chain

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Wipe the drive chain with a clean cloth.

b. Put the drive chain in kerosene and remove

any remaining dirt.

c. Remove the drive chain from the kerosene

and completely dry it.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

15-link length limit

242.9 mm (9.56 in)

Page 220 of 356

VALVES AND VALVE SPRINGS

5-27

h. Install the valve into the cylinder head.

i. Press the valve through the valve guide and

onto the valve seat to make a clear impres-

sion.

j. Measure the valve seat contact width “c”

again. If the valve seat contact width is out of

specification, reface and lap the valve seat.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

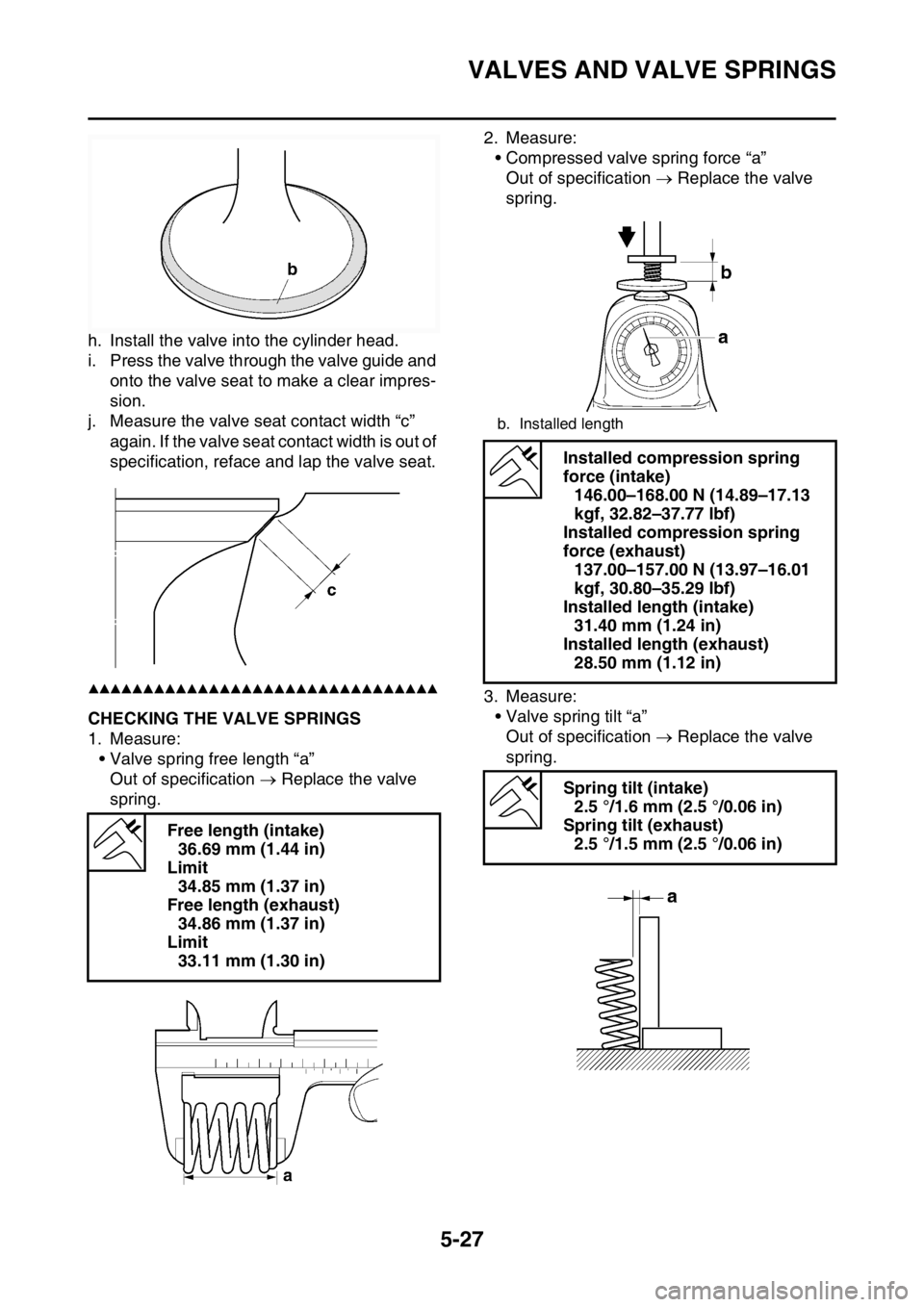

EAS1SM9221CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length “a”

Out of specification Replace the valve

spring.2. Measure:

• Compressed valve spring force “a”

Out of specification Replace the valve

spring.

3. Measure:

• Valve spring tilt “a”

Out of specification Replace the valve

spring.

Free length (intake)

36.69 mm (1.44 in)

Limit

34.85 mm (1.37 in)

Free length (exhaust)

34.86 mm (1.37 in)

Limit

33.11 mm (1.30 in)

b. Installed length

Installed compression spring

force (intake)

146.00–168.00 N (14.89–17.13

kgf, 32.82–37.77 lbf)

Installed compression spring

force (exhaust)

137.00–157.00 N (13.97–16.01

kgf, 30.80–35.29 lbf)

Installed length (intake)

31.40 mm (1.24 in)

Installed length (exhaust)

28.50 mm (1.12 in)

Spring tilt (intake)

2.5 °/1.6 mm (2.5 °/0.06 in)

Spring tilt (exhaust)

2.5 °/1.5 mm (2.5 °/0.06 in)

Page 231 of 356

CLUTCH

5-38

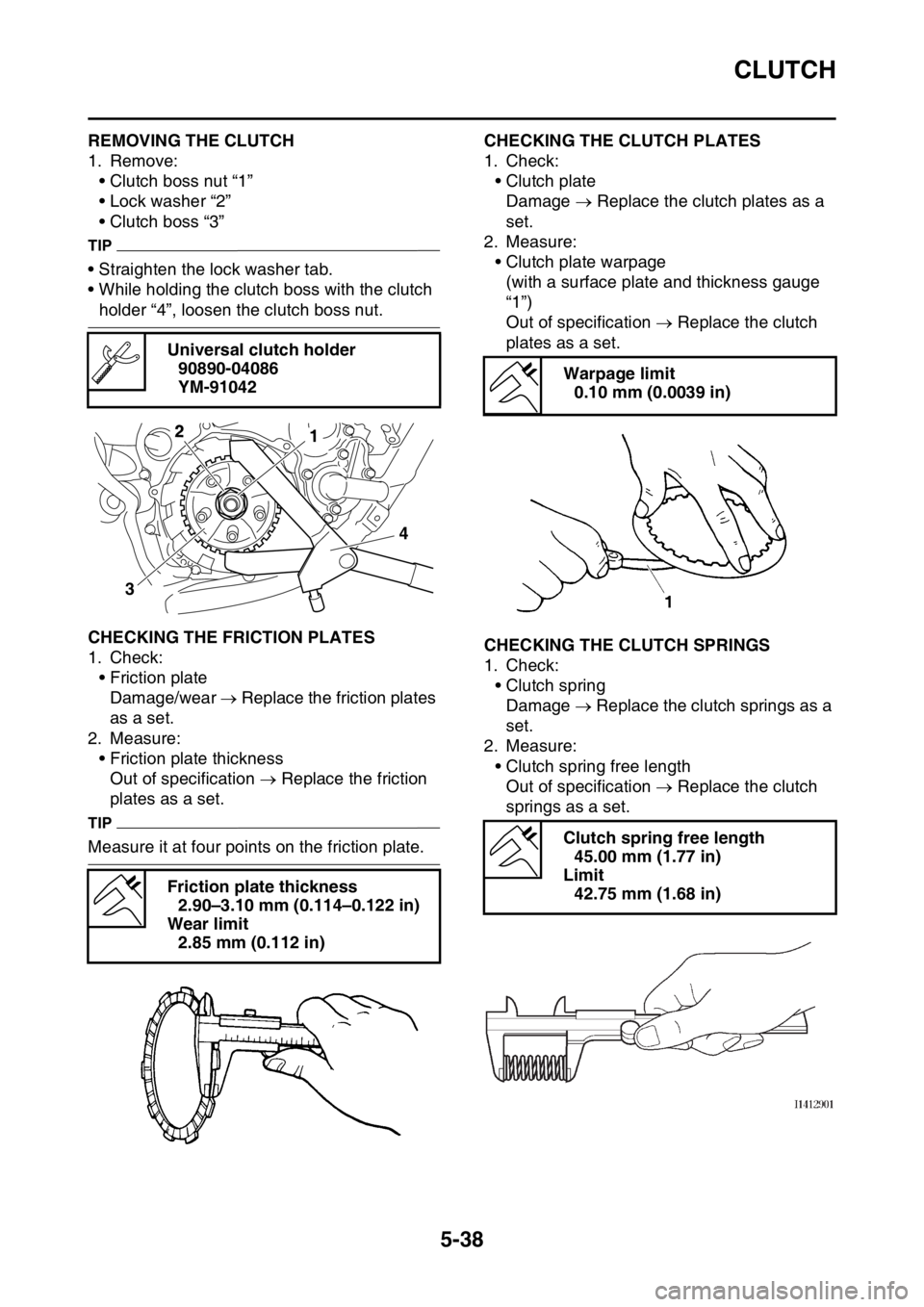

EAS1SM9231REMOVING THE CLUTCH

1. Remove:

• Clutch boss nut “1”

• Lock washer “2”

• Clutch boss “3”

TIP

• Straighten the lock washer tab.

• While holding the clutch boss with the clutch

holder “4”, loosen the clutch boss nut.

EAS1SM9232CHECKING THE FRICTION PLATES

1. Check:

• Friction plate

Damage/wear Replace the friction plates

as a set.

2. Measure:

• Friction plate thickness

Out of specification Replace the friction

plates as a set.

TIP

Measure it at four points on the friction plate.

EAS1SM9233CHECKING THE CLUTCH PLATES

1. Check:

• Clutch plate

Damage Replace the clutch plates as a

set.

2. Measure:

• Clutch plate warpage

(with a surface plate and thickness gauge

“1”)

Out of specification Replace the clutch

plates as a set.

EAS1SM9234CHECKING THE CLUTCH SPRINGS

1. Check:

• Clutch spring

Damage Replace the clutch springs as a

set.

2. Measure:

• Clutch spring free length

Out of specification Replace the clutch

springs as a set. Universal clutch holder

90890-04086

YM-91042

Friction plate thickness

2.90–3.10 mm (0.114–0.122 in)

Wear limit

2.85 mm (0.112 in)

34

12

Warpage limit

0.10 mm (0.0039 in)

Clutch spring free length

45.00 mm (1.77 in)

Limit

42.75 mm (1.68 in)

Page 343 of 356

10

TUNING

CHASSIS........................................................................................................ 10-1

SELECTION OF THE SECONDARY REDUCTION

RATIO (SPROCKET) .............................................................................. 10-1

DRIVE AND REAR WHEEL SPROCKETS SETTING PARTS ................ 10-1

TIRE PRESSURE..................................................................................... 10-2

FRONT FORK SETTING.......................................................................... 10-2

CHANGE IN AMOUNT AND CHARACTERISTICS OF FORK OIL.......... 10-2

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-3

FRONT FORK SETTING PARTS............................................................. 10-3

REAR SUSPENSION SETTING .............................................................. 10-3

CHOOSING SET LENGTH ...................................................................... 10-3

SETTING OF SPRING AFTER REPLACEMENT .................................... 10-4

REAR SHOCK ABSORBER SETTING PARTS ....................................... 10-5

SUSPENSION SETTING (FRONT FORK)............................................... 10-6

SUSPENSION SETTING (REAR SHOCK ABSORBER) ......................... 10-7

Page 346 of 356

CHASSIS

10-3

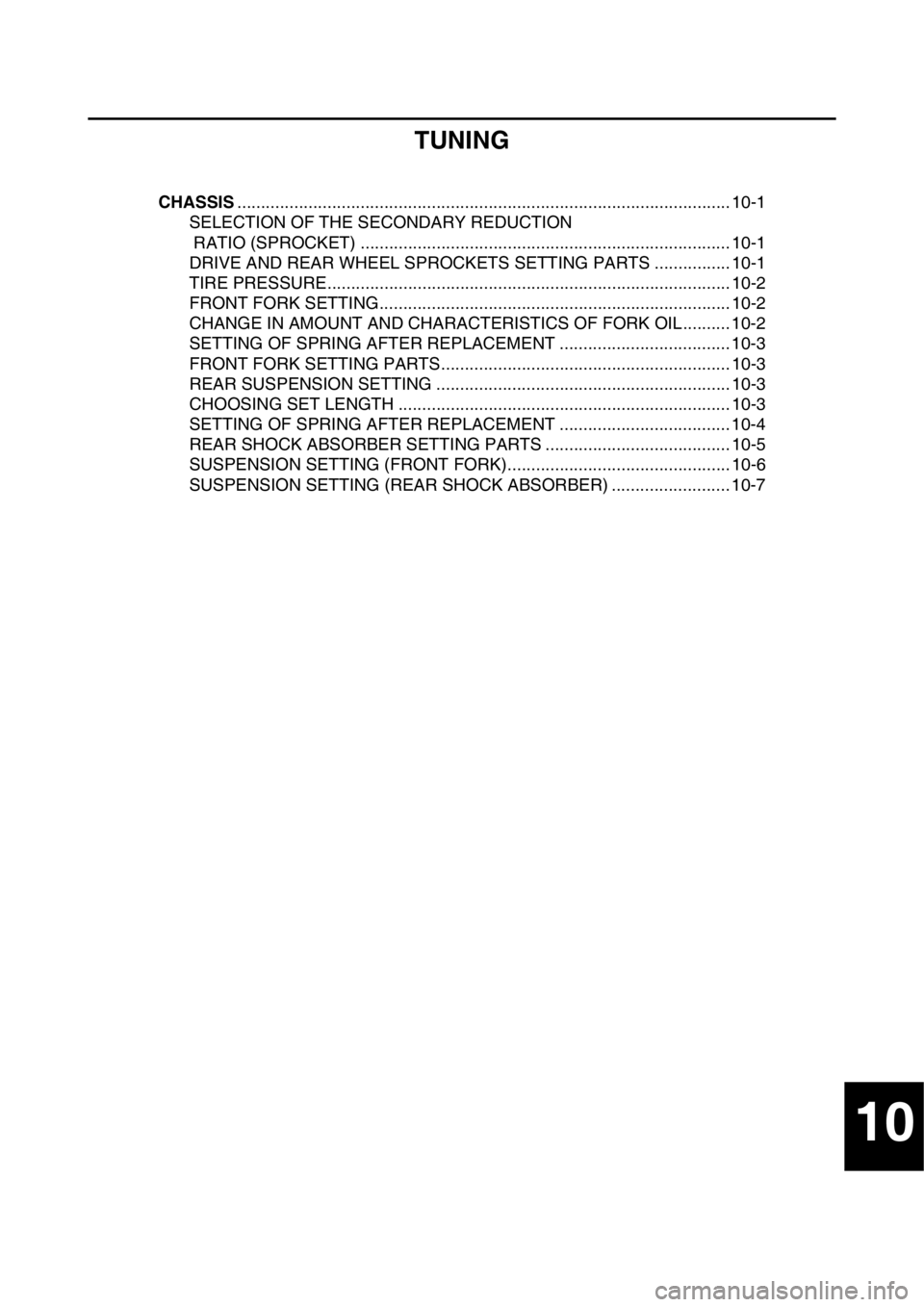

EAS1SM9372SETTING OF SPRING AFTER REPLACE-

MENT

As the front fork setting can be easily affected

by the rear suspension, take care so that the

front and the rear are balanced (in position etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping force.

Turn out one or two clicks.

• Change the compression damping force.

Turn in one or two clicks.

TIP

Generally a soft spring gives a soft riding feel-

ing. Rebound damping tends to become stron-

ger and the front fork may sink deeply over a

series of gaps.

2. Use of stiff spring

• Change the rebound damping force.

Turn in one or two clicks.

• Change the compression damping force.

Turn out one or two clicks.

TIP

Generally a stiff spring gives a stiff riding feel-

ing. Rebound damping tends to become weak-

er, resulting in lack of a sense of contact with

the road surface or in a vibrating handlebar.

EAS1SM9373FRONT FORK SETTING PARTS

• Front fork spring “1”

*Except for USA and CAN

TIP

The I.D. mark (slits) “a” is proved on the end of

the spring.

EAS1SM9374REAR SUSPENSION SETTING

The rear shock absorber setting should be

made depending on the rider’s feeling of an ac-

tual run and the circuit conditions.

The rear suspension setting includes the fol-

lowing two factors:

1. Setting of spring preload

• Change the set length of the spring.

• Change the spring.

2. Setting of damping force

• Change the rebound damping force.

• Change the compression damping force.

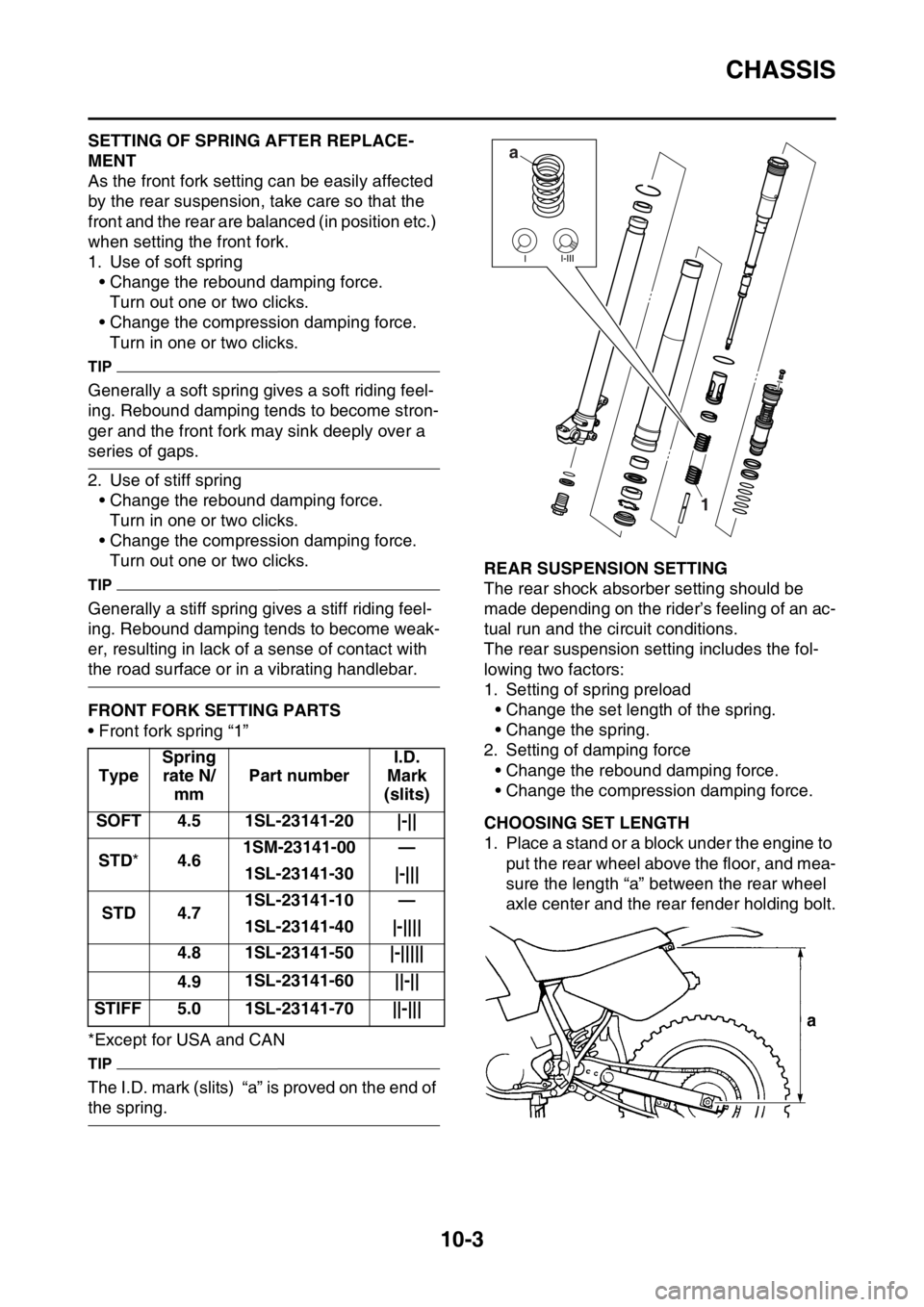

EAS1SM9375CHOOSING SET LENGTH

1. Place a stand or a block under the engine to

put the rear wheel above the floor, and mea-

sure the length “a” between the rear wheel

axle center and the rear fender holding bolt. TypeSpring

rate N/

mmPart numberI.D.

Mark

(slits)

SOFT 4.5 1SL-23141-20 |-||

STD*4.61SM-23141-00 —

1SL-23141-30 |-|||

STD 4.71SL-23141-10 —

1SL-23141-40 |-||||

4.8 1SL-23141-50 |-|||||

4.91SL-23141-60 ||-||

STIFF 5.0 1SL-23141-70 ||-|||

a

1

Page 347 of 356

CHASSIS

10-4

2. Remove the stand or block from the engine

and, with a rider astride the seat, measure

the sunken length “b” between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut “1” and make adjustment

by turning the adjuster “2” to achieve the

standard figure from the subtraction of the

length “b” from the length “a”.

TIP

• If the machine is new and after it is broken in,

the same set length of the spring may change

because of the initial fatigue, etc. of the

spring. Therefore, be sure to make reevalua-

tion.

• If the standard figure cannot be achieved by

adjusting the adjuster and changing the set

length, replace the spring with an optional one

and make readjustment.

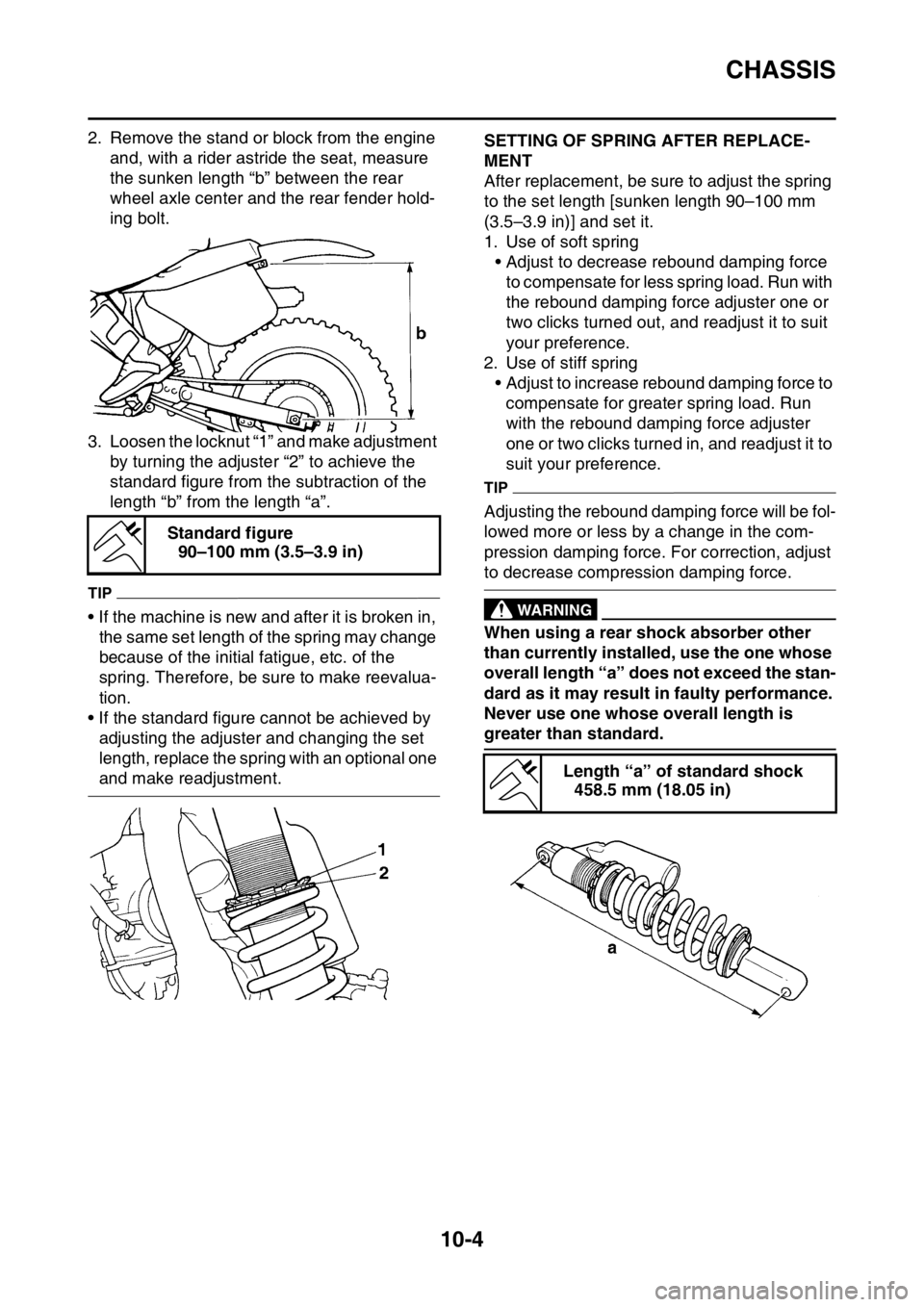

EAS1SM9376SETTING OF SPRING AFTER REPLACE-

MENT

After replacement, be sure to adjust the spring

to the set length [sunken length 90–100 mm

(3.5–3.9 in)] and set it.

1. Use of soft spring

• Adjust to decrease rebound damping force

to compensate for less spring load. Run with

the rebound damping force adjuster one or

two clicks turned out, and readjust it to suit

your preference.

2. Use of stiff spring

• Adjust to increase rebound damping force to

compensate for greater spring load. Run

with the rebound damping force adjuster

one or two clicks turned in, and readjust it to

suit your preference.

TIP

Adjusting the rebound damping force will be fol-

lowed more or less by a change in the com-

pression damping force. For correction, adjust

to decrease compression damping force.

EWA1DX4002

WARNING

When using a rear shock absorber other

than currently installed, use the one whose

overall length “a” does not exceed the stan-

dard as it may result in faulty performance.

Never use one whose overall length is

greater than standard. Standard figure

90–100 mm (3.5–3.9 in)

Length “a” of standard shock

458.5 mm (18.05 in)

Page 348 of 356

CHASSIS

10-5

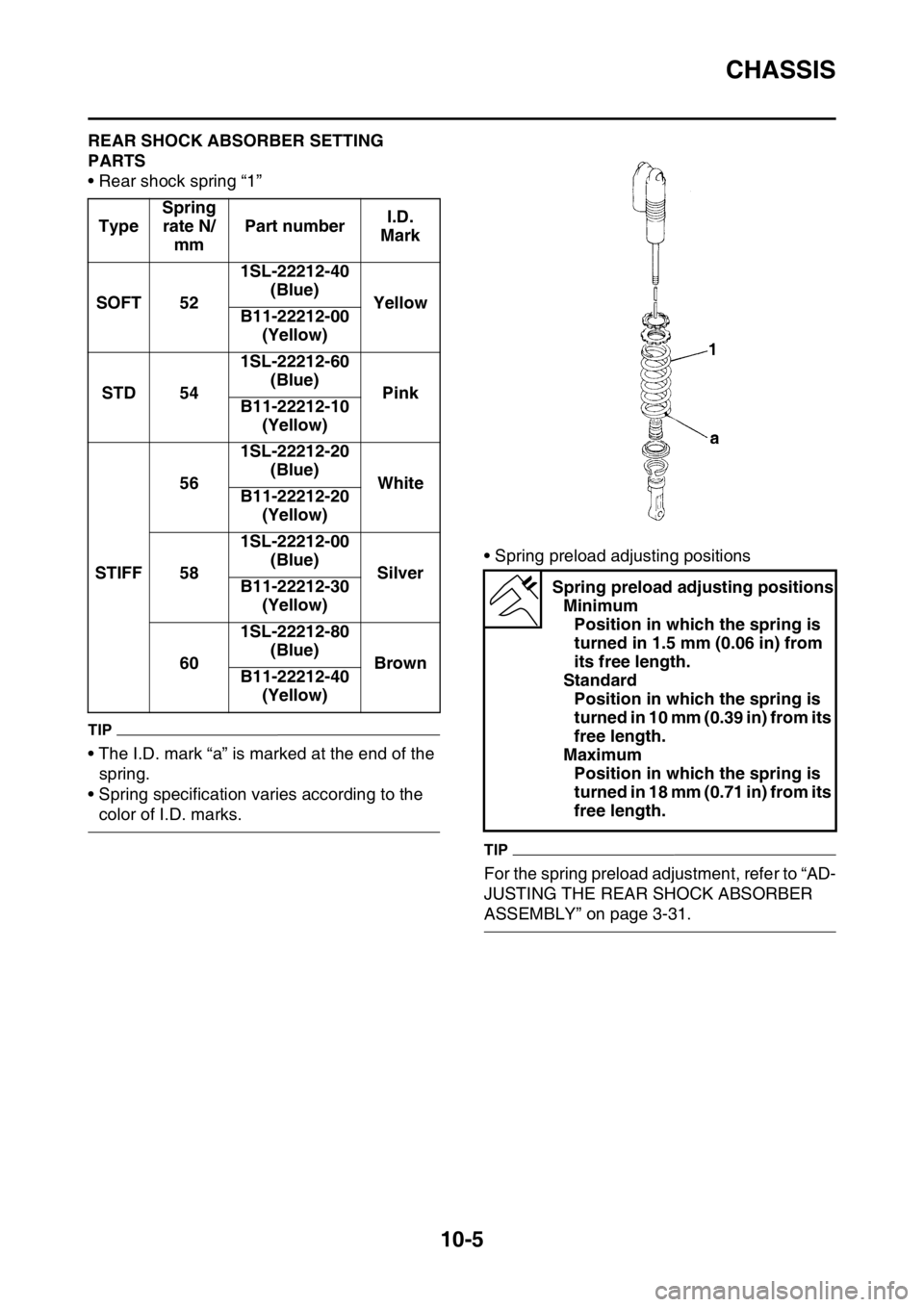

EAS1SM9377REAR SHOCK ABSORBER SETTING

PARTS

• Rear shock spring “1”

TIP

• The I.D. mark “a” is marked at the end of the

spring.

• Spring specification varies according to the

color of I.D. marks.• Spring preload adjusting positions

TIP

For the spring preload adjustment, refer to “AD-

JUSTING THE REAR SHOCK ABSORBER

ASSEMBLY” on page 3-31. TypeSpring

rate N/

mmPart numberI.D.

Mark

SOFT 521SL-22212-40

(Blue)

Yellow

B11-22212-00

(Yellow)

STD 541SL-22212-60

(Blue)

Pink

B11-22212-10

(Yellow)

STIFF561SL-22212-20

(Blue)

White

B11-22212-20

(Yellow)

581SL-22212-00

(Blue)

Silver

B11-22212-30

(Yellow)

601SL-22212-80

(Blue)

Brown

B11-22212-40

(Yellow)

Spring preload adjusting positions

Minimum

Position in which the spring is

turned in 1.5 mm (0.06 in) from

its free length.

Standard

Position in which the spring is

turned in 10 mm (0.39 in) from its

free length.

Maximum

Position in which the spring is

turned in 18 mm (0.71 in) from its

free length.

Page 349 of 356

CHASSIS

10-6

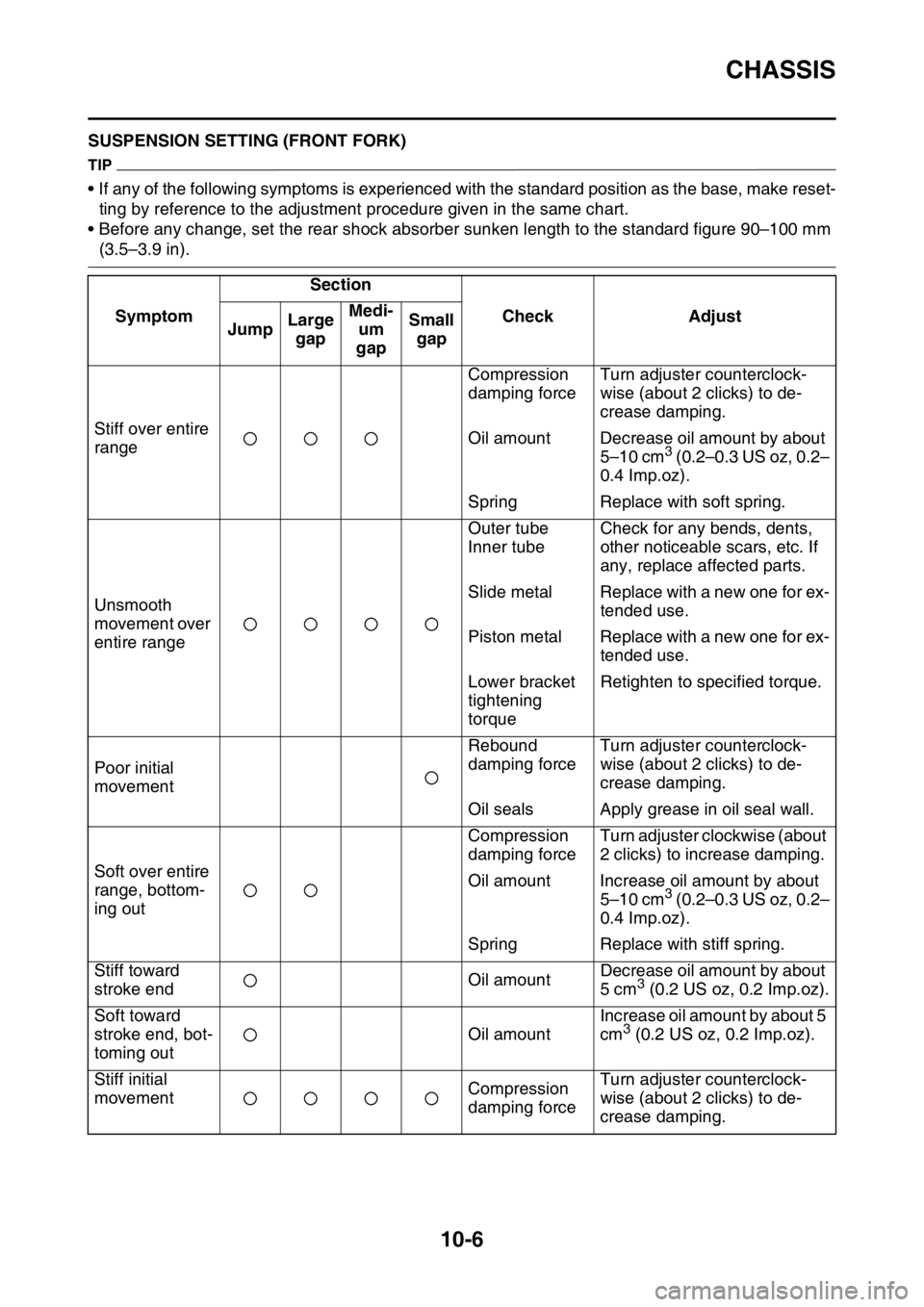

EAS1SM9378SUSPENSION SETTING (FRONT FORK)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Before any change, set the rear shock absorber sunken length to the standard figure 90–100 mm

(3.5–3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff over entire

rangeCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with soft spring.

Unsmooth

movement over

entire rangeOuter tube

Inner tubeCheck for any bends, dents,

other noticeable scars, etc. If

any, replace affected parts.

Slide metal Replace with a new one for ex-

tended use.

Piston metal Replace with a new one for ex-

tended use.

Lower bracket

tightening

torqueRetighten to specified torque.

Poor initial

movementRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Oil seals Apply grease in oil seal wall.

Soft over entire

range, bottom-

ing outCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Oil amount Increase oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

Spring Replace with stiff spring.

Stiff toward

stroke endOil amountDecrease oil amount by about

5 cm

3 (0.2 US oz, 0.2 Imp.oz).

Soft toward

stroke end, bot-

toming outOil amountIncrease oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

Stiff initial

movementCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Page 350 of 356

CHASSIS

10-7

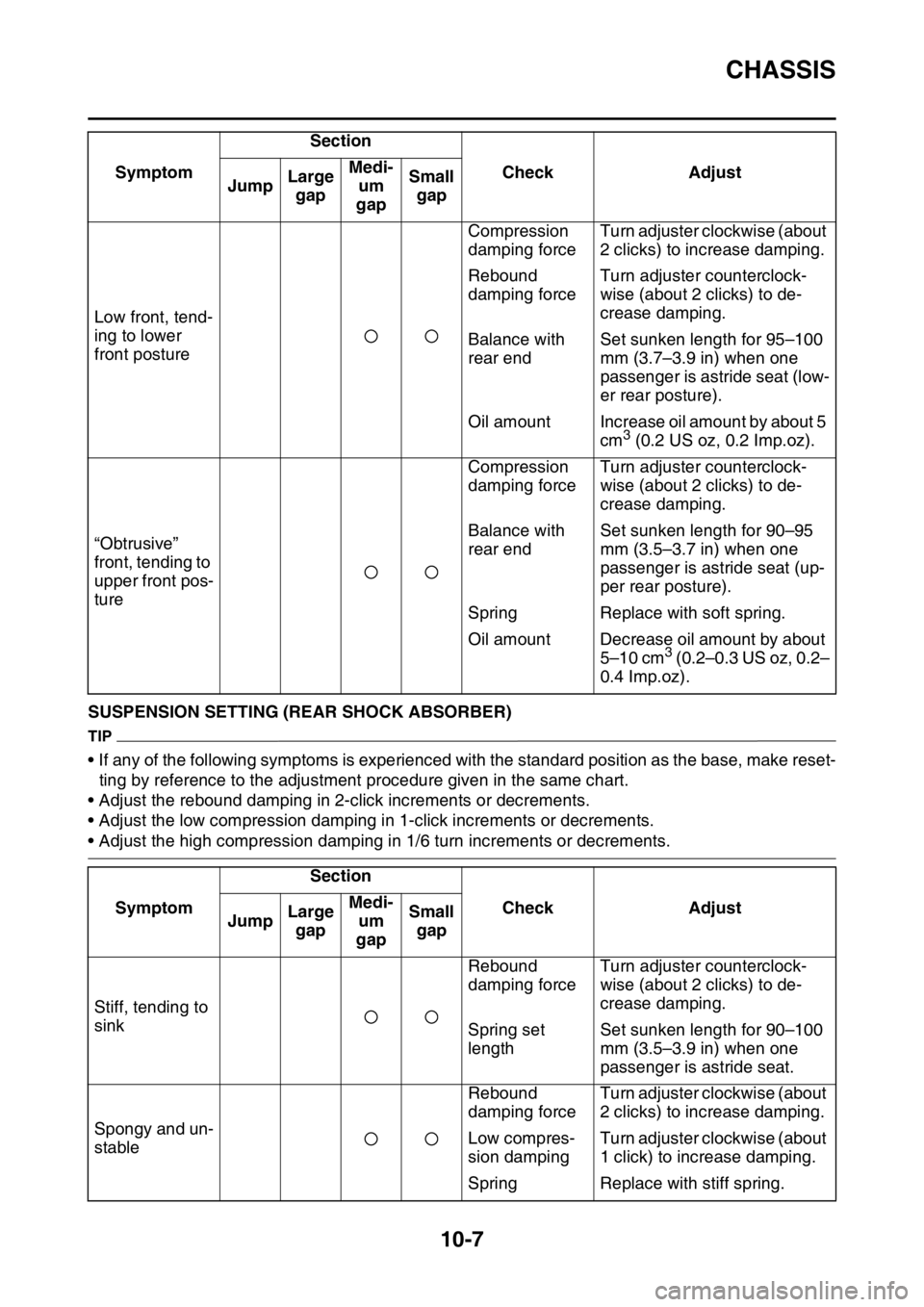

EAS1SM9379SUSPENSION SETTING (REAR SHOCK ABSORBER)

TIP

• If any of the following symptoms is experienced with the standard position as the base, make reset-

ting by reference to the adjustment procedure given in the same chart.

• Adjust the rebound damping in 2-click increments or decrements.

• Adjust the low compression damping in 1-click increments or decrements.

• Adjust the high compression damping in 1/6 turn increments or decrements. Low front, tend-

ing to lower

front postureCompression

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Rebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 95–100

mm (3.7–3.9 in) when one

passenger is astride seat (low-

er rear posture).

Oil amount Increase oil amount by about 5

cm

3 (0.2 US oz, 0.2 Imp.oz).

“Obtrusive”

front, tending to

upper front pos-

tureCompression

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Balance with

rear endSet sunken length for 90–95

mm (3.5–3.7 in) when one

passenger is astride seat (up-

per rear posture).

Spring Replace with soft spring.

Oil amount Decrease oil amount by about

5–10 cm

3 (0.2–0.3 US oz, 0.2–

0.4 Imp.oz).

SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap

Stiff, tending to

sinkRebound

damping forceTurn adjuster counterclock-

wise (about 2 clicks) to de-

crease damping.

Spring set

lengthSet sunken length for 90–100

mm (3.5–3.9 in) when one

passenger is astride seat.

Spongy and un-

stableRebound

damping forceTurn adjuster clockwise (about

2 clicks) to increase damping.

Low compres-

sion dampingTurn adjuster clockwise (about

1 click) to increase damping.

Spring Replace with stiff spring. SymptomSection

Check Adjust

JumpLarge

gapMedi-

um

gapSmall

gap