check engine YAMAHA YZ250F 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YZ250F, Model: YAMAHA YZ250F 2016Pages: 356, PDF Size: 11.25 MB

Page 7 of 356

EAS1SM9005

SAFETY INFORMATION

THIS MACHINE IS DESIGNED STRICTLY FOR COMPETITION USE, ONLY ON A CLOSED

COURSE. It is illegal for this machine to be operated on any public street, road, or highway. Off-road

use on public lands may also be illegal. Please check local regulations before riding.

• THIS MACHINE IS TO BE OPERATED BY AN EXPERIENCED RIDER ONLY.

Do not attempt to operate this machine at maximum power until you are totally familiar with its char-

acteristics.

• THIS MACHINE IS DESIGNED TO BE RIDDEN BY THE OPERATOR ONLY.

Do not carry passengers on this machine.

• ALWAYS WEAR PROTECTIVE APPAREL.

When operating this machine, always wear an approved helmet with goggles or a face shield. Also

wear heavy boots, gloves, and protective clothing. Always wear proper fitting clothing that will not

be caught in any of the moving parts or controls of the machine.

• ALWAYS MAINTAIN YOUR MACHINE IN PROPER WORKING ORDER.

For safety and reliability, the machine must be properly maintained. Always perform the pre-oper-

ation checks indicated in this manual.

Correcting a mechanical problem before you ride may prevent an accident.

• GASOLINE IS HIGHLY FLAMMABLE.

Always turn off the engine while refueling. Take care to not spill any gasoline on the engine or ex-

haust system. Never refuel in the vicinity of an open flame, or while smoking.

• GASOLINE CAN CAUSE INJURY.

If you should swallow some gasoline, inhale excess gasoline vapors, or allow any gasoline to get

into your eyes, contact a doctor immediately. If any gasoline spills onto your skin or clothing, imme-

diately wash skin areas with soap and water, and change your clothes.

• ONLY OPERATE THE MACHINE IN AN AREA WITH ADEQUATE VENTILATION.

Never start the engine or let it run for any length of time in an enclosed area. Exhaust fumes are

poisonous. These fumes contain carbon monoxide, which by itself is odorless and colorless. Car-

bon monoxide is a dangerous gas which can cause unconsciousness or can be lethal.

• PARK THE MACHINE CAREFULLY; TURN OFF THE ENGINE.

Always turn off the engine if you are going to leave the machine. Do not park the machine on a slope

or soft ground as it may fall over.

• THE ENGINE, EXHAUST PIPE AND MUFFLER WILL BE VERY HOT AFTER THE ENGINE HAS

BEEN RUN.

Be careful not to touch them or to allow any clothing item to contact them during inspection or repair.

• PROPERLY SECURE THE MACHINE BEFORE TRANSPORTING IT.

For safety, drain the gasoline from the fuel tank before transporting the vehicle.

Page 11 of 356

1

2

3

4

5

6

7

8

9

10 TABLE OF CONTENTS

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC CHECKS AND

ADJUSTMENTS

CHASSIS

ENGINE

COOLING SYSTEM

FUEL SYSTEM

ELECTRICAL SYSTEM

TROUBLESHOOTING

TUNING

Page 14 of 356

STARTING AND BREAK-IN.......................................................................... 1-20

FUEL ........................................................................................................ 1-20

STARTING A COLD ENGINE .................................................................. 1-20

STARTING A WARM ENGINE ................................................................. 1-21

BREAK-IN PROCEDURES ...................................................................... 1-21

MAINTENANCE AFTER BREAK-IN.............................................................. 1-22

MAJOR MAINTENANCE .......................................................................... 1-22

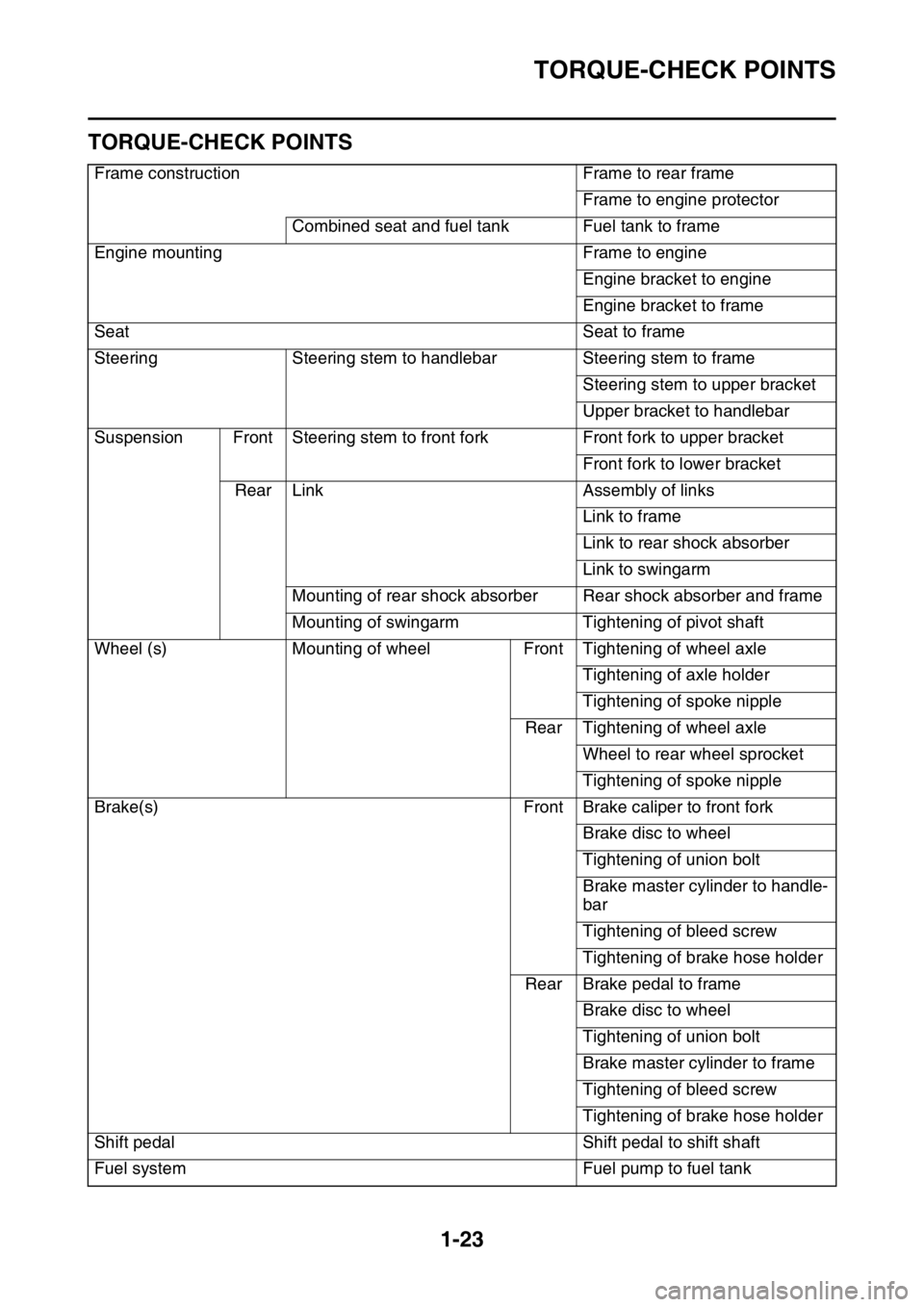

TORQUE-CHECK POINTS............................................................................ 1-23

CLEANING AND STORAGE.......................................................................... 1-25

CLEANING ............................................................................................... 1-25

STORAGE ................................................................................................ 1-25

Page 18 of 356

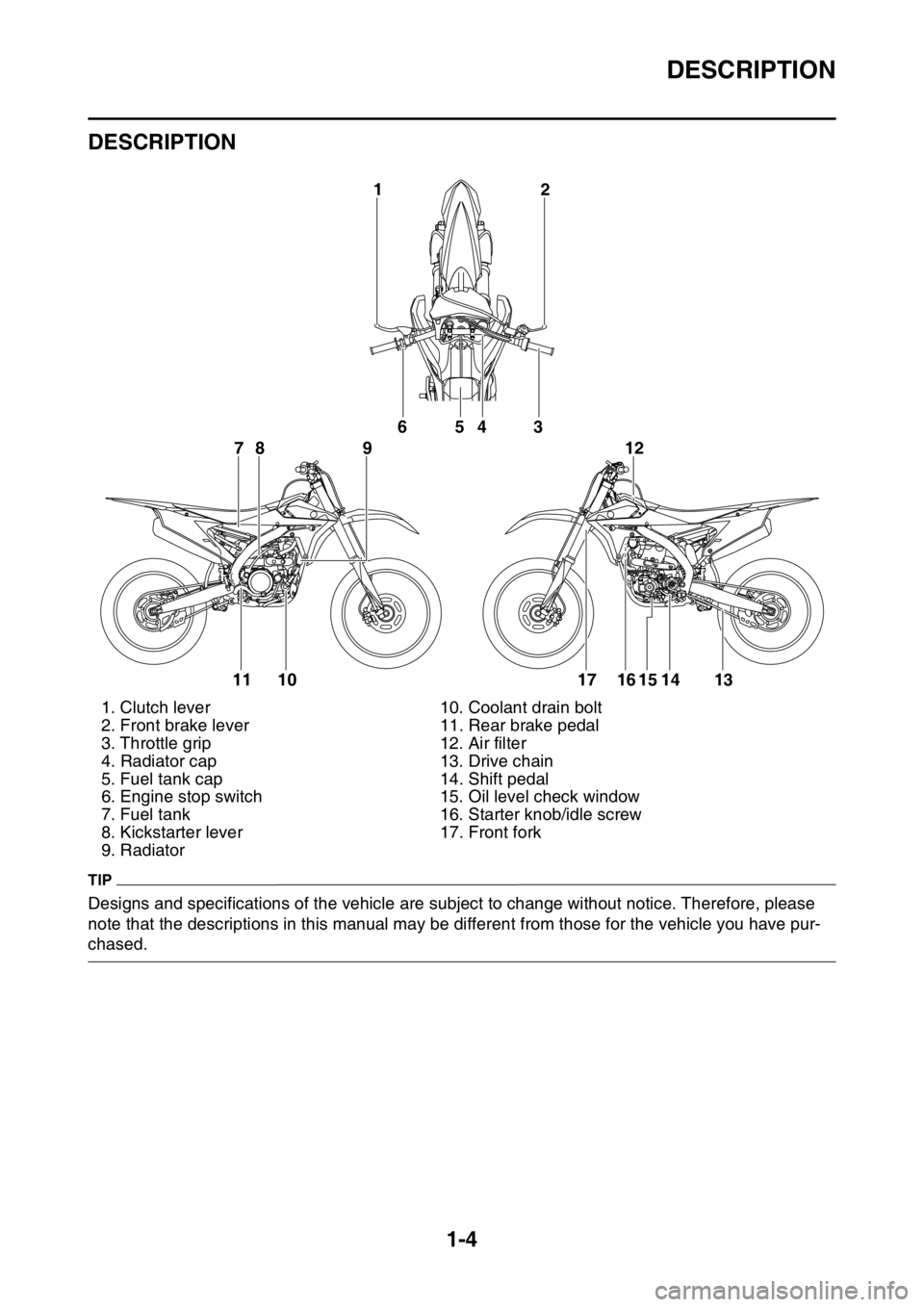

DESCRIPTION

1-4

EAS1SM9009

DESCRIPTION

TIP

Designs and specifications of the vehicle are subject to change without notice. Therefore, please

note that the descriptions in this manual may be different from those for the vehicle you have pur-

chased.1. Clutch lever 10. Coolant drain bolt

2. Front brake lever 11. Rear brake pedal

3. Throttle grip 12. Air filter

4. Radiator cap 13. Drive chain

5. Fuel tank cap 14. Shift pedal

6. Engine stop switch 15. Oil level check window

7. Fuel tank 16. Starter knob/idle screw

8. Kickstarter lever 17. Front fork

9. Radiator

2 1

6

78 954 3

11 10 17 16 15 14 1312

Page 22 of 356

IMPORTANT INFORMATION

1-8

EAS20180

IMPORTANT INFORMATION

EAS1SM9020PREPARATION FOR REMOVAL AND DIS-

ASSEMBLY

1. Before the jobs, completely remove mud,

dust, and the like in order to prevent the en-

try of them into the inside during the jobs.

• Before cleaning with high-pressure water of

washers, cover the following parts.

Air duct

Silencer exhaust port

Drain hole on the cylinder head (right side)

Hole under the water pump housing

2. Use proper special tools and equipment.

See “SPECIAL TOOLS”.

3. During disassembly, check and measure the

required parts, and make a record of them

so that you may refer to the record when in-

stalling them. Moreover, arrange gears, cyl-

inders, pistons, and other parts for each

section so as not to confuse or lose them.4. During disassembly, clean each of the parts,

and store them in trays for each section.

5. Flammable. Keep servicing areas away

from any source of fire.

6. During servicing, take special care not to re-

ceive an injury or a burn on the engine, the

exhaust pipe, the silencer, or the like.

7. If coolant is left adhered to the chassis, paint

and plating will be damaged. Therefore,

rinse it out with water in good time.

EWA

WARNING

Coolant is potentially harmful and should

be handled with special care.

• If it enters your eyes, wash it away with wa-

ter enough and then get medical attention

• If it splashes on your skin or clothes,

quickly wash it away with water and then

with soapy water.

• If it is swallowed, immediately induce vom-

iting and get medical attention.

EAS1SM9021REPLACEMENT PARTS

Make sure that the parts and grease or oil to be

used for repair of the vehicle, including periodic

replacement parts, are new YAMAHA genuine

parts and recommended parts.

Do not use any used parts, because these may

not be genuine though they have similar ap-

pearances or because the quality may be

changed by aging.

Page 31 of 356

SPECIAL TOOLS

1-17

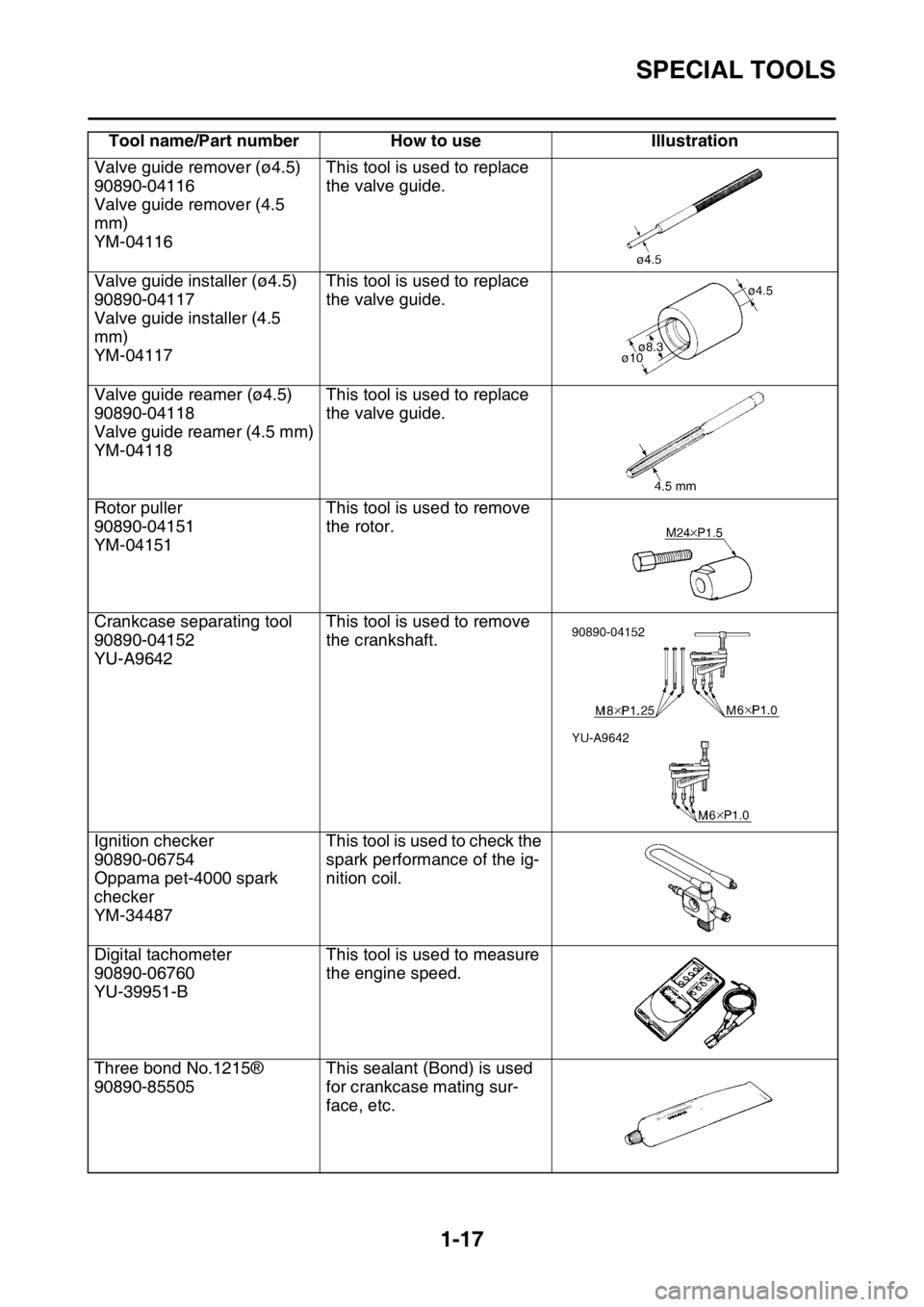

Valve guide remover (ø4.5)

90890-04116

Valve guide remover (4.5

mm)

YM-04116This tool is used to replace

the valve guide.

Valve guide installer (ø4.5)

90890-04117

Valve guide installer (4.5

mm)

YM-04117This tool is used to replace

the valve guide.

Valve guide reamer (ø4.5)

90890-04118

Valve guide reamer (4.5 mm)

YM-04118This tool is used to replace

the valve guide.

Rotor puller

90890-04151

YM-04151This tool is used to remove

the rotor.

Crankcase separating tool

90890-04152

YU-A9642This tool is used to remove

the crankshaft.

Ignition checker

90890-06754

Oppama pet-4000 spark

checker

YM-34487This tool is used to check the

spark performance of the ig-

nition coil.

Digital tachometer

90890-06760

YU-39951-BThis tool is used to measure

the engine speed.

Three bond No.1215®

90890-85505This sealant (Bond) is used

for crankcase mating sur-

face, etc. Tool name/Part number How to use Illustration

Page 35 of 356

STARTING AND BREAK-IN

1-21

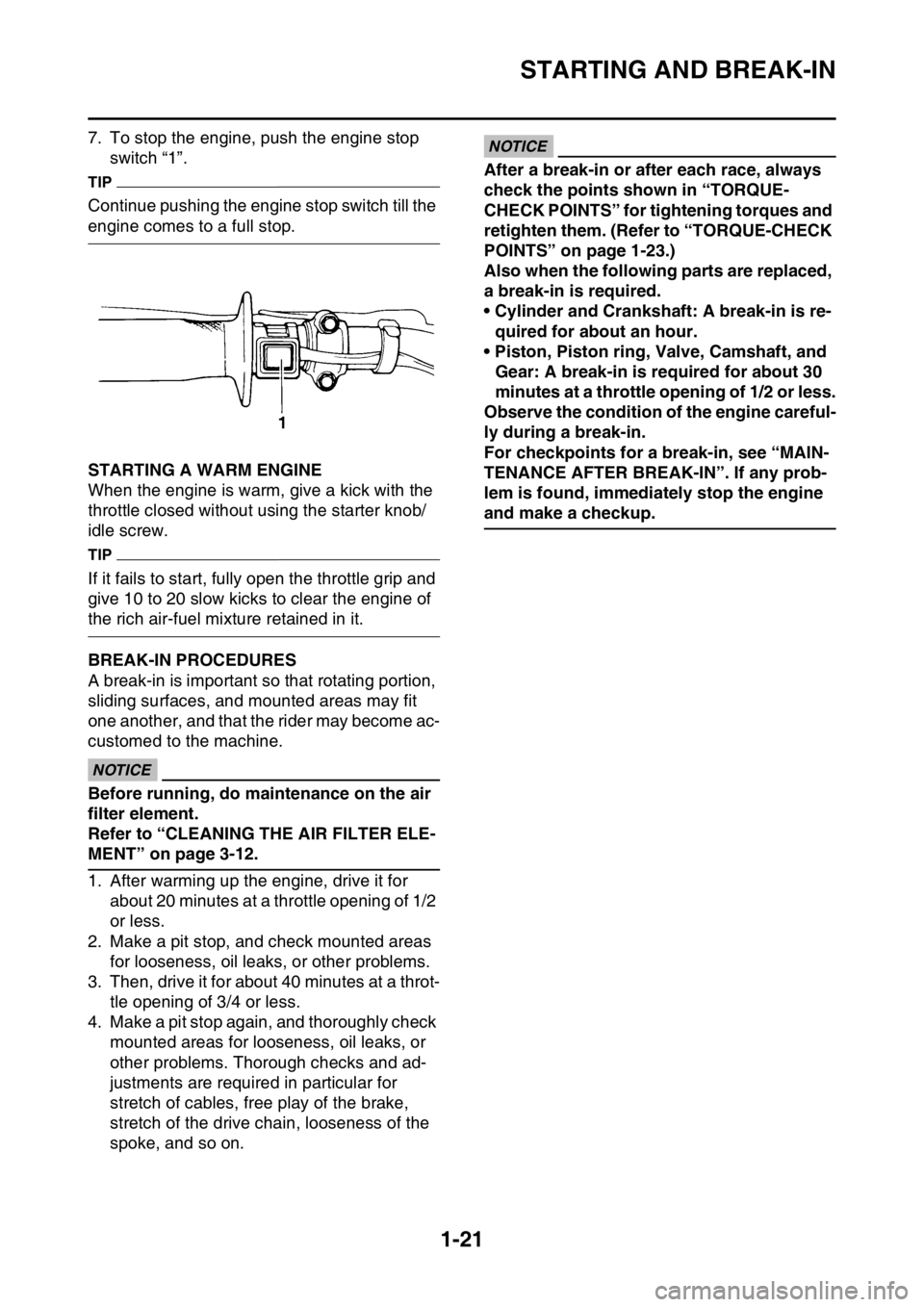

7. To stop the engine, push the engine stop

switch “1”.

TIP

Continue pushing the engine stop switch till the

engine comes to a full stop.

EAS1SM9042STARTING A WARM ENGINE

When the engine is warm, give a kick with the

throttle closed without using the starter knob/

idle screw.

TIP

If it fails to start, fully open the throttle grip and

give 10 to 20 slow kicks to clear the engine of

the rich air-fuel mixture retained in it.

EAS1SM9043BREAK-IN PROCEDURES

A break-in is important so that rotating portion,

sliding surfaces, and mounted areas may fit

one another, and that the rider may become ac-

customed to the machine.

ECA

NOTICE

Before running, do maintenance on the air

filter element.

Refer to “CLEANING THE AIR FILTER ELE-

MENT” on page 3-12.

1. After warming up the engine, drive it for

about 20 minutes at a throttle opening of 1/2

or less.

2. Make a pit stop, and check mounted areas

for looseness, oil leaks, or other problems.

3. Then, drive it for about 40 minutes at a throt-

tle opening of 3/4 or less.

4. Make a pit stop again, and thoroughly check

mounted areas for looseness, oil leaks, or

other problems. Thorough checks and ad-

justments are required in particular for

stretch of cables, free play of the brake,

stretch of the drive chain, looseness of the

spoke, and so on.

ECA

NOTICE

After a break-in or after each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to “TORQUE-CHECK

POINTS” on page 1-23.)

Also when the following parts are replaced,

a break-in is required.

• Cylinder and Crankshaft: A break-in is re-

quired for about an hour.

• Piston, Piston ring, Valve, Camshaft, and

Gear: A break-in is required for about 30

minutes at a throttle opening of 1/2 or less.

Observe the condition of the engine careful-

ly during a break-in.

For checkpoints for a break-in, see “MAIN-

TENANCE AFTER BREAK-IN”. If any prob-

lem is found, immediately stop the engine

and make a checkup.

Page 36 of 356

MAINTENANCE AFTER BREAK-IN

1-22

EAS1SM9044

MAINTENANCE AFTER BREAK-IN

After a break-in, perform careful maintenance

to get ready for the next practice or race.

Refer to “PRE-OPERATION INSPECTION

AND MAINTENANCE” on page 3-7.

EAS1SM9045MAJOR MAINTENANCE

1. For the engine

• Leaks around the engine

Check for pressure leaks from the cylinder

head or the cylinder, oil leaks from the

crankcase or the case cover, leaks from the

coolant system, and other leaks.

• Check that the valve, the cylinder head, the

cylinder, the piston, and the piston ring fit

one another, and that contact between the

valve and the cylinder head, and that be-

tween the cylinder and the piston are cor-

rect.

• Engine oil change

Drain the oil, and check for dirt and foreign

materials such as metal chips. (If any foreign

material is mixed, disassemble and check

the crankcase.)

Pour the specified amount of the recom-

mended oil.

• AC magneto

Check for looseness in mounted areas of

the rotor and the stator.

Check that the connector is not being dis-

connected.

• Silencer

Check the main body and stay for cracks.

Check for leaks.

• Mounting bolts and nuts

Check for looseness in mounted areas of

parts, as well as engine mounting bolts and

engine brackets.

2. For the chassis

• Check welds and mounted areas of the

frame, the swingarm, the link, the bracket,

and so on, for looseness and cracks.

• Wheel (s)

Check the wheel for runout. Check the

spoke for looseness.

• Brake(s)

Check the brake disc mounting bolt for

looseness.

Check that the reservoir contains the speci-

fied amount of brake fluid. Check for leaks.• Cable

Grease and adjust cables.

•Drive chain

Lubricate the drive chain and adjust its ten-

sion.

• Fuel tank

Clean the inside of the fuel tank. Check for

leaks.

• Suspension

Check for oil leaks in the front fork or the rear

shock absorber. Check that the mounted

conditions are good.

• Sprocket

Check for looseness in the sprocket mount-

ed on the rear wheel.

• Mounting bolts and nuts

Check mounted areas for looseness.

ECA

NOTICE

After a break-in or before each race, always

check the points shown in “TORQUE-

CHECK POINTS” for tightening torques and

retighten them. (Refer to “TORQUE-CHECK

POINTS” on page 1-23.)

• Greasing and oiling

Always grease or oil the specified points.

Page 37 of 356

TORQUE-CHECK POINTS

1-23

EAS1SM9046

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Frame to engine protector

Combined seat and fuel tank Fuel tank to frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Seat Seat to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear Link Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Mounting of rear shock absorber Rear shock absorber and frame

Mounting of swingarm Tightening of pivot shaft

Wheel (s) Mounting of wheel Front Tightening of wheel axle

Tightening of axle holder

Tightening of spoke nipple

Rear Tightening of wheel axle

Wheel to rear wheel sprocket

Tightening of spoke nipple

Brake(s) Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handle-

bar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Shift pedal Shift pedal to shift shaft

Fuel system Fuel pump to fuel tank

Page 53 of 356

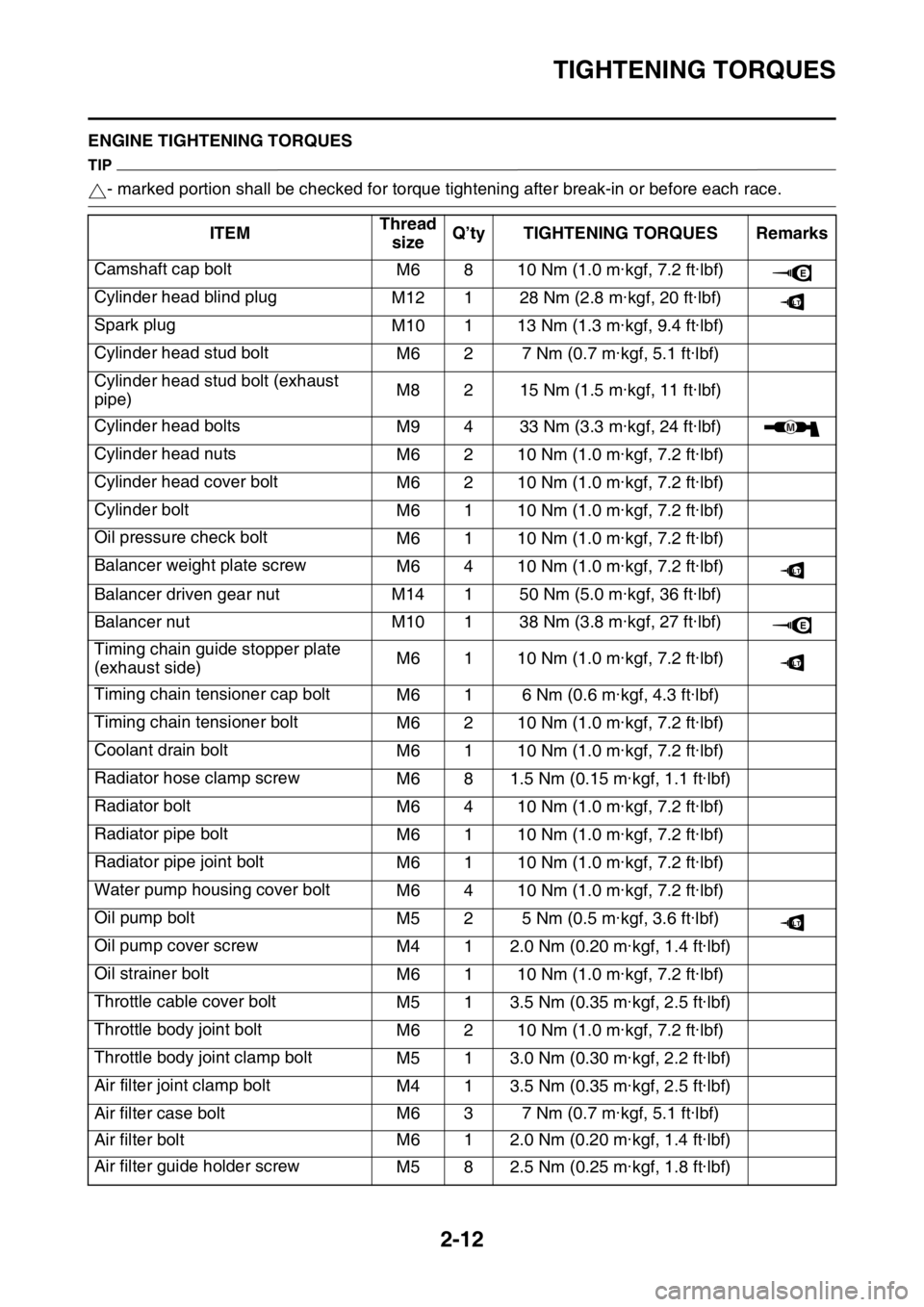

TIGHTENING TORQUES

2-12

EAS1SM9055ENGINE TIGHTENING TORQUES

TIP

- marked portion shall be checked for torque tightening after break-in or before each race.

ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

Camshaft cap bolt

M6 8 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head blind plug

M12 1 28 Nm (2.8 m·kgf, 20 ft·lbf)

Spark plug

M10 1 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Cylinder head stud bolt

M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Cylinder head stud bolt (exhaust

pipe)M8 2 15 Nm (1.5 m·kgf, 11 ft·lbf)

Cylinder head bolts

M9 4 33 Nm (3.3 m·kgf, 24 ft·lbf)

Cylinder head nuts

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder head cover bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Cylinder bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pressure check bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer weight plate screw

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Balancer driven gear nut M14 1 50 Nm (5.0 m·kgf, 36 ft·lbf)

Balancer nut M10 1 38 Nm (3.8 m·kgf, 27 ft·lbf)

Timing chain guide stopper plate

(exhaust side)M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Timing chain tensioner cap bolt

M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Timing chain tensioner bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Coolant drain bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator hose clamp screw

M6 8 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Radiator bolt

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Radiator pipe joint bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Water pump housing cover bolt

M6 4 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil pump bolt

M5 2 5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Oil pump cover screw

M4 1 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Oil strainer bolt

M6 1 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Throttle cable cover bolt

M5 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Throttle body joint bolt

M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Throttle body joint clamp bolt

M5 1 3.0 Nm (0.30 m·kgf, 2.2 ft·lbf)

Air filter joint clamp bolt

M4 1 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf)

Air filter case bolt M6 3 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Air filter bolt M6 1 2.0 Nm (0.20 m·kgf, 1.4 ft·lbf)

Air filter guide holder screw

M5 8 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

E

LT

M

LT

E

LT

LT