transmission oil YAMAHA YZ250LC 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250LC, Model: YAMAHA YZ250LC 2001Pages: 578, PDF Size: 14.12 MB

Page 310 of 578

4-50

YPVS GOVERNORENG

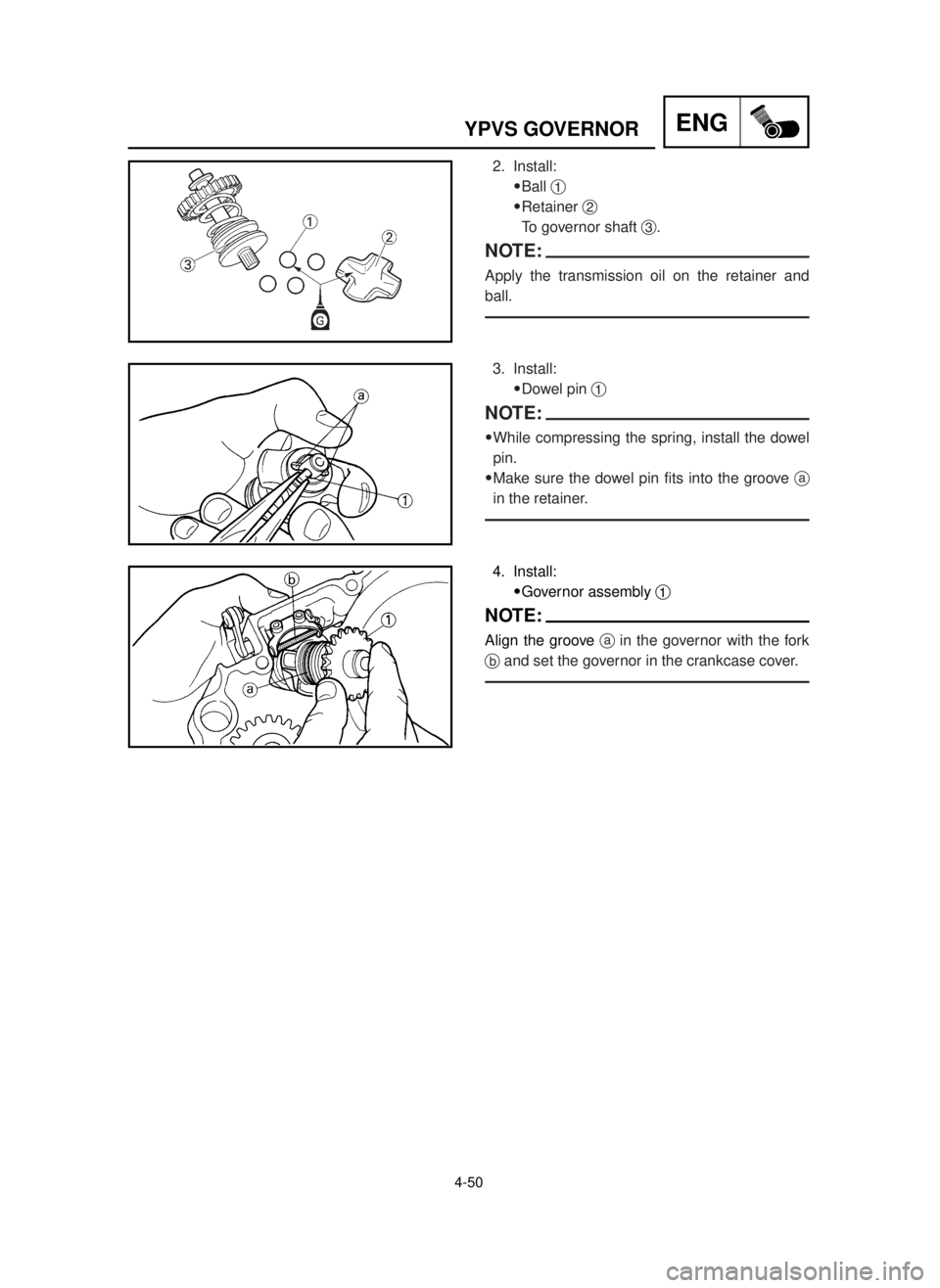

4. Install:

9Governor assembly 1

NOTE:

Align the groove ain the governor with the fork

band set the governor in the crankcase cover.

3. Install:

9Dowel pin 1

NOTE:

9While compressing the spring, install the dowel

pin.

9Make sure the dowel pin fits into the groove a

in the retainer.

2. Install:

9Ball 1

9Retainer 2

To governor shaft 3.

NOTE:

Apply the transmission oil on the retainer and

ball.

5MW-9-30-4C 7/3/00 7:40 PM Page 4

Page 314 of 578

4-52

WATER PUMPENG

EC4G3000

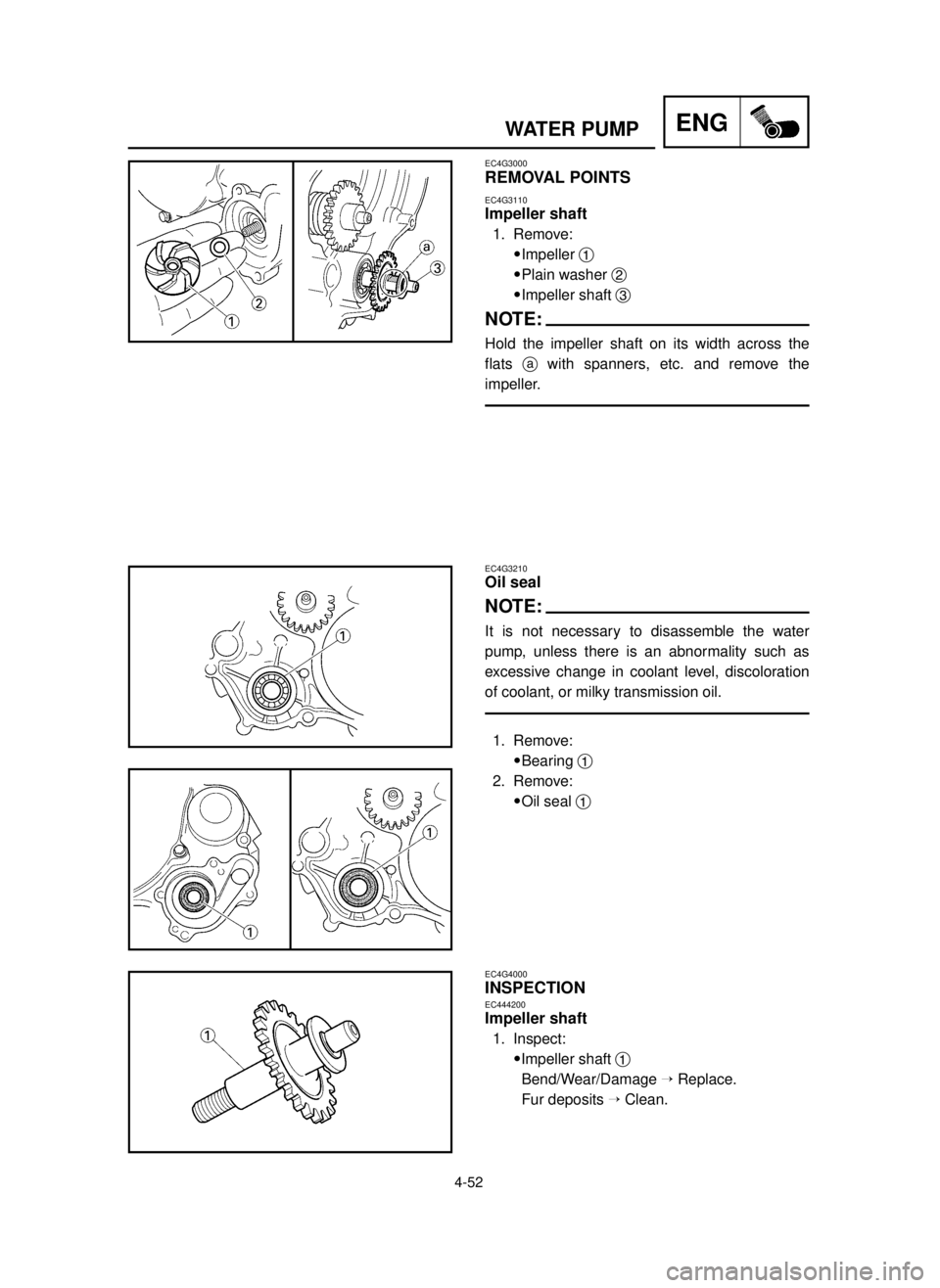

REMOVAL POINTS

EC4G3110

Impeller shaft

1. Remove:

9Impeller 1

9Plain washer 2

9Impeller shaft 3

NOTE:

Hold the impeller shaft on its width across the

flats awith spanners, etc. and remove the

impeller.

EC4G3210

Oil seal

NOTE:

It is not necessary to disassemble the water

pump, unless there is an abnormality such as

excessive change in coolant level, discoloration

of coolant, or milky transmission oil.

1. Remove:

9Bearing 1

2. Remove:

9Oil seal 1

EC4G4000

INSPECTIONEC444200

Impeller shaft

1. Inspect:

9Impeller shaft 1

Bend/Wear/Damage

ÕReplace.

Fur deposits

ÕClean.

5MW-9-30-4C 7/3/00 7:42 PM Page 8

Page 346 of 578

4-68

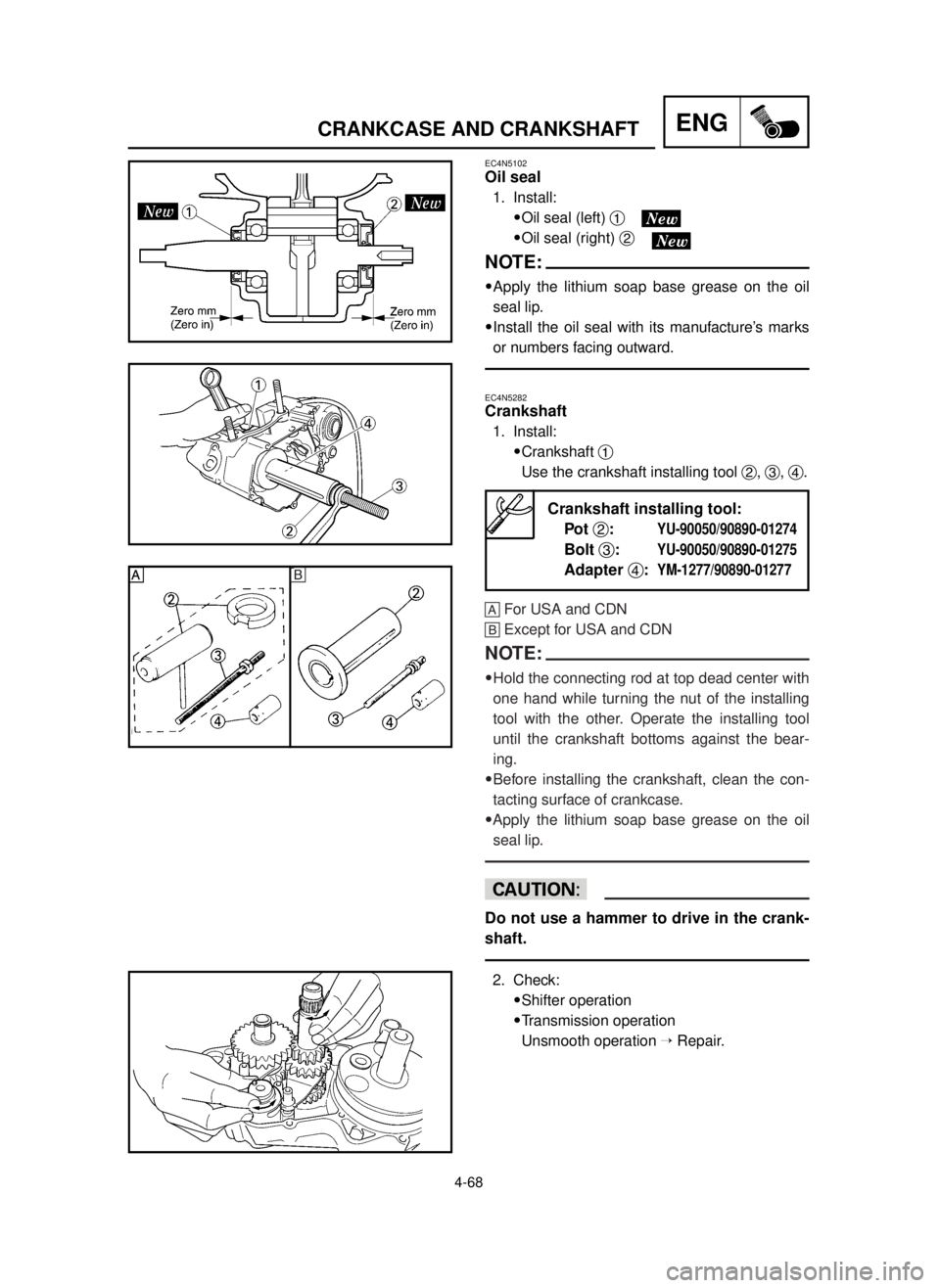

CRANKCASE AND CRANKSHAFTENG

EC4N5282

Crankshaft

1. Install:

9Crankshaft 1

Use the crankshaft installing tool 2, 3, 4.

EC4N5102

Oil seal

1. Install:

9Oil seal (left) 1

9Oil seal (right) 2

NOTE:

9Apply the lithium soap base grease on the oil

seal lip.

9Install the oil seal with its manufacture’s marks

or numbers facing outward.

Crankshaft installing tool:

Pot 2:

YU-90050/90890-01274

Bolt 3:YU-90050/90890-01275

Adapter 4:YM-1277/90890-01277

2. Check:

9Shifter operation

9Transmission operation

Unsmooth operation

ÕRepair.

Œ ŒB

ŒFor USA and CDN

ºExcept for USA and CDN

NOTE:

9Hold the connecting rod at top dead center with

one hand while turning the nut of the installing

tool with the other. Operate the installing tool

until the crankshaft bottoms against the bear-

ing.

9Before installing the crankshaft, clean the con-

tacting surface of crankcase.

9Apply the lithium soap base grease on the oil

seal lip.

cC

Do not use a hammer to drive in the crank-

shaft.

5MW-9-30-4C 7/4/00 9:28 AM Page 40

Page 350 of 578

4-70

CRANKCASE AND CRANKSHAFTENG

8. Tighten:

9Segment 1

9Bolt (segment) 2

NOTE:

9When installing the segment onto the shift cam

3, align the punch mark awith the dowel pin

b.

9Turn the segment clockwise until it stops and

tighten the bolt.

30 Nm (3.0 m•kg, 22 ft•lb)

7. Install:

9Tension spring 1

9Holder 2

9Bolt (holder) 3

NOTE:

Install the holder so that it contacts the projec-

tion aon the crankcase (right).

10 Nm (1.0 m•kg, 7.2 ft•lb)

9. Remove:

9Sealant

Forced out on the cylinder mating surface.

10. Apply:

9Engine oil

To the crank pin, bearing, oil delivery hole

and connecting rod big end washer.

11. Check:

9Crankshaft and transmission operation

Unsmooth operation

ÕRepair.

5MW-9-30-4C 7/4/00 9:29 AM Page 44

Page 356 of 578

4-73

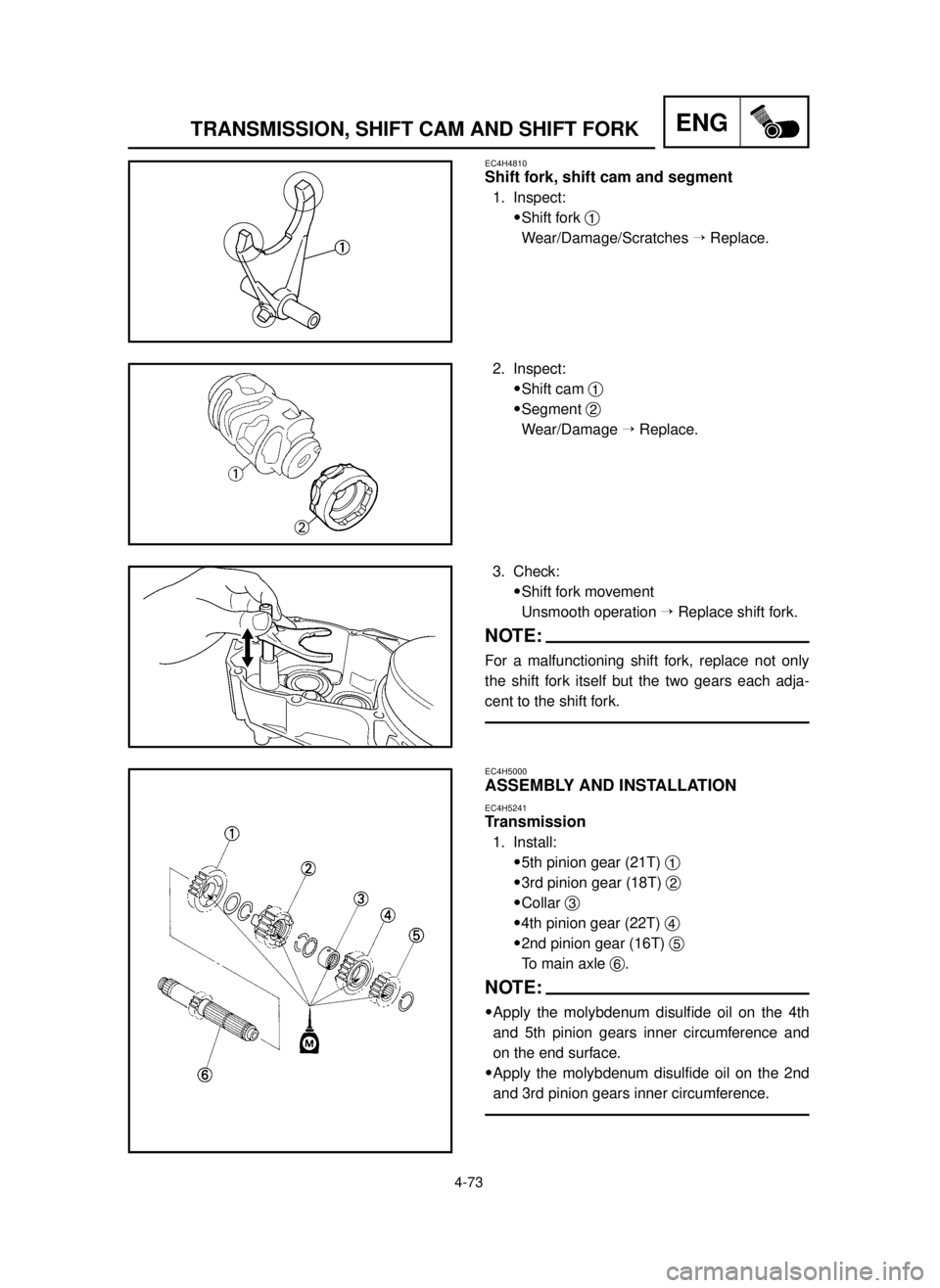

TRANSMISSION, SHIFT CAM AND SHIFT FORKENG

EC4H5000

ASSEMBLY AND INSTALLATION

EC4H5241

Transmission

1. Install:

95th pinion gear (21T) 1

93rd pinion gear (18T) 2

9Collar 3

94th pinion gear (22T) 4

92nd pinion gear (16T) 5

To main axle 6.

NOTE:

9Apply the molybdenum disulfide oil on the 4th

and 5th pinion gears inner circumference and

on the end surface.

9Apply the molybdenum disulfide oil on the 2nd

and 3rd pinion gears inner circumference.

3. Check:

9Shift fork movement

Unsmooth operation

ÕReplace shift fork.

NOTE:

For a malfunctioning shift fork, replace not only

the shift fork itself but the two gears each adja-

cent to the shift fork.

2. Inspect:

9Shift cam 1

9Segment 2

Wear/Damage

ÕReplace.

EC4H4810

Shift fork, shift cam and segment

1. Inspect:

9Shift fork 1

Wear/Damage/Scratches

ÕReplace.

5MW-9-30-4C 7/4/00 9:32 AM Page 50

Page 358 of 578

4-74

TRANSMISSION, SHIFT CAM AND SHIFT FORKENG

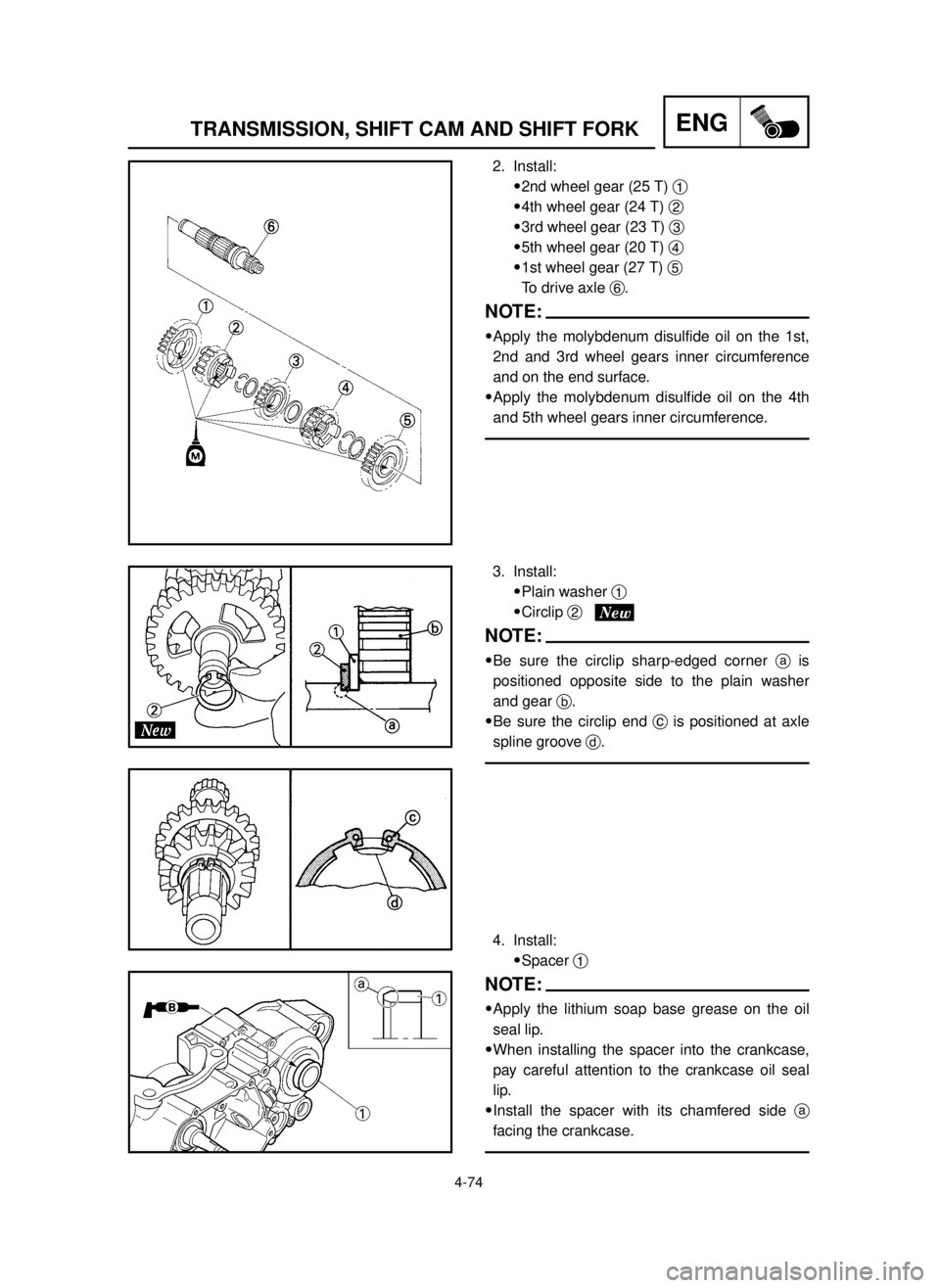

4. Install:

9Spacer 1

NOTE:

9Apply the lithium soap base grease on the oil

seal lip.

9When installing the spacer into the crankcase,

pay careful attention to the crankcase oil seal

lip.

9Install the spacer with its chamfered side a

facing the crankcase.

3. Install:

9Plain washer 1

9Circlip 2

NOTE:

9Be sure the circlip sharp-edged corner ais

positioned opposite side to the plain washer

and gear b.

9Be sure the circlip end cis positioned at axle

spline groove d.

2. Install:

92nd wheel gear (25 T) 1

94th wheel gear (24 T) 2

93rd wheel gear (23 T) 3

95th wheel gear (20 T) 4

91st wheel gear (27 T) 5

To drive axle 6.

NOTE:

9Apply the molybdenum disulfide oil on the 1st,

2nd and 3rd wheel gears inner circumference

and on the end surface.

9Apply the molybdenum disulfide oil on the 4th

and 5th wheel gears inner circumference.

5MW-9-30-4C 7/4/00 9:32 AM Page 52

Page 360 of 578

4-75

TRANSMISSION, SHIFT CAM AND SHIFT FORKENG

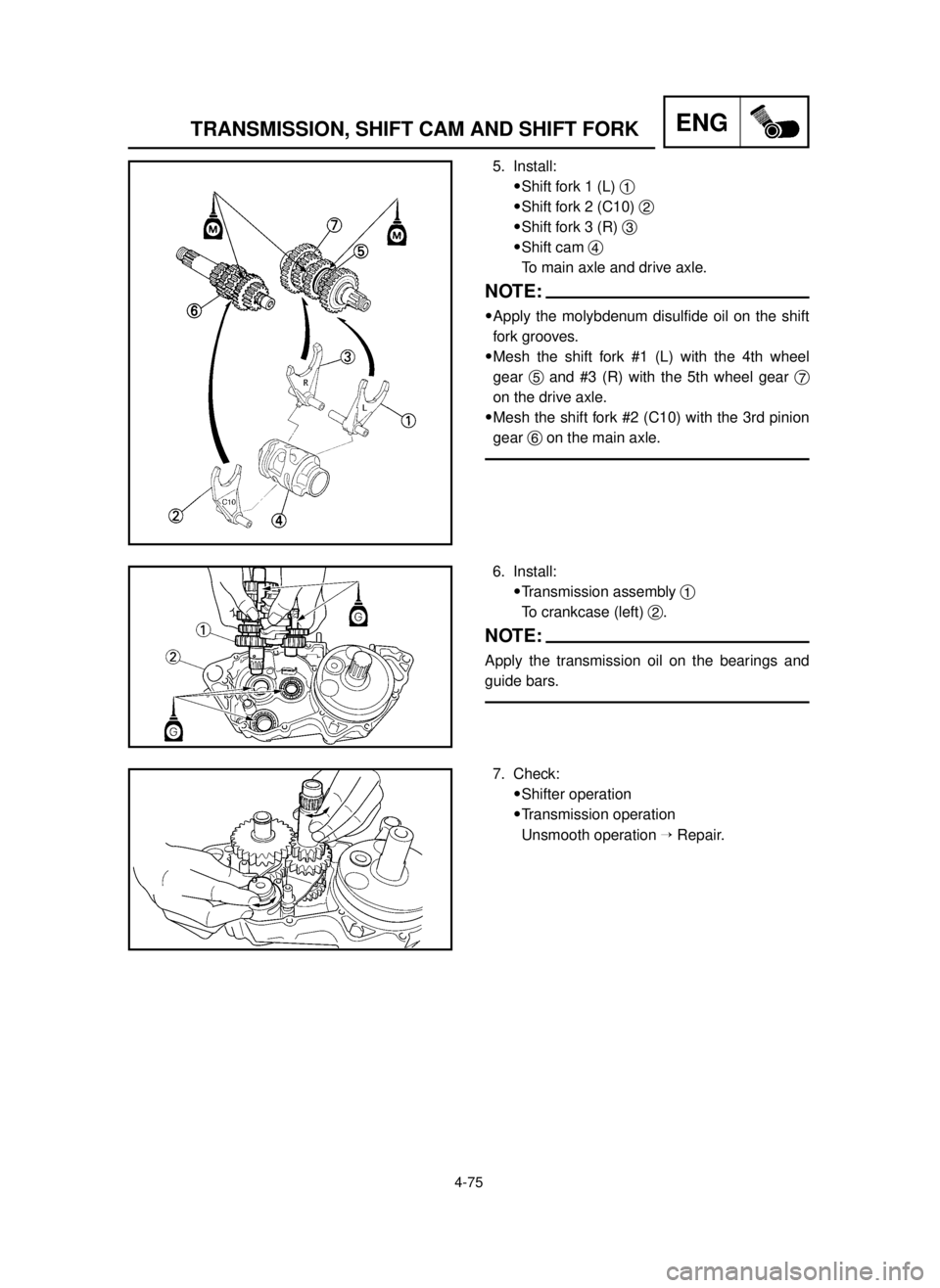

5. Install:

9Shift fork 1 (L) 1

9Shift fork 2 (C10) 2

9Shift fork 3 (R) 3

9Shift cam 4

To main axle and drive axle.

NOTE:

9Apply the molybdenum disulfide oil on the shift

fork grooves.

9Mesh the shift fork #1 (L) with the 4th wheel

gear 5and #3 (R) with the 5th wheel gear 7

on the drive axle.

9Mesh the shift fork #2 (C10) with the 3rd pinion

gear 6on the main axle.

6. Install:

9Transmission assembly 1

To crankcase (left) 2.

NOTE:

Apply the transmission oil on the bearings and

guide bars.

7. Check:

9Shifter operation

9Transmission operation

Unsmooth operation

ÕRepair.

5MW-9-30-4C 7/4/00 9:33 AM Page 54

Page 367 of 578

5-3

CHAS

ROUE AVANT ET ROUE ARRIERE

VORDERRAD UND HINTERRAD

RUOTA ANTERIORE E RUOTA POSTERIORE

AUSBAUPUNKTE

Hinterrad

1. Ausbauen:

9Rad 1

ANMERKUNG:

Das Rad nach vorne stoßen und die

Antriebskette 2abnehmen.

Radlager (wenn erforderlich)

1. Ausbauen:

9Lager 1

ANMERKUNG:

Das Lager unter Verwendung einer

allgemeinen Lager-Abziehvorrichtung

2ausbauen.

INSPEKTION

Rad

1. Messen:

9Felgenschlag

Außerhalb des GrenzwertesÕ

Reparieren/Erneuern.

2. Prüfen:

9Lager

Den inneren Laufring mit

einem Finger drehen.

Rauhe Stellen/FreßspurenÕ

Erneuern.

ANMERKUNG:

Die Lager, die Öldichtung und die

Radhülse als Satz erneuern.

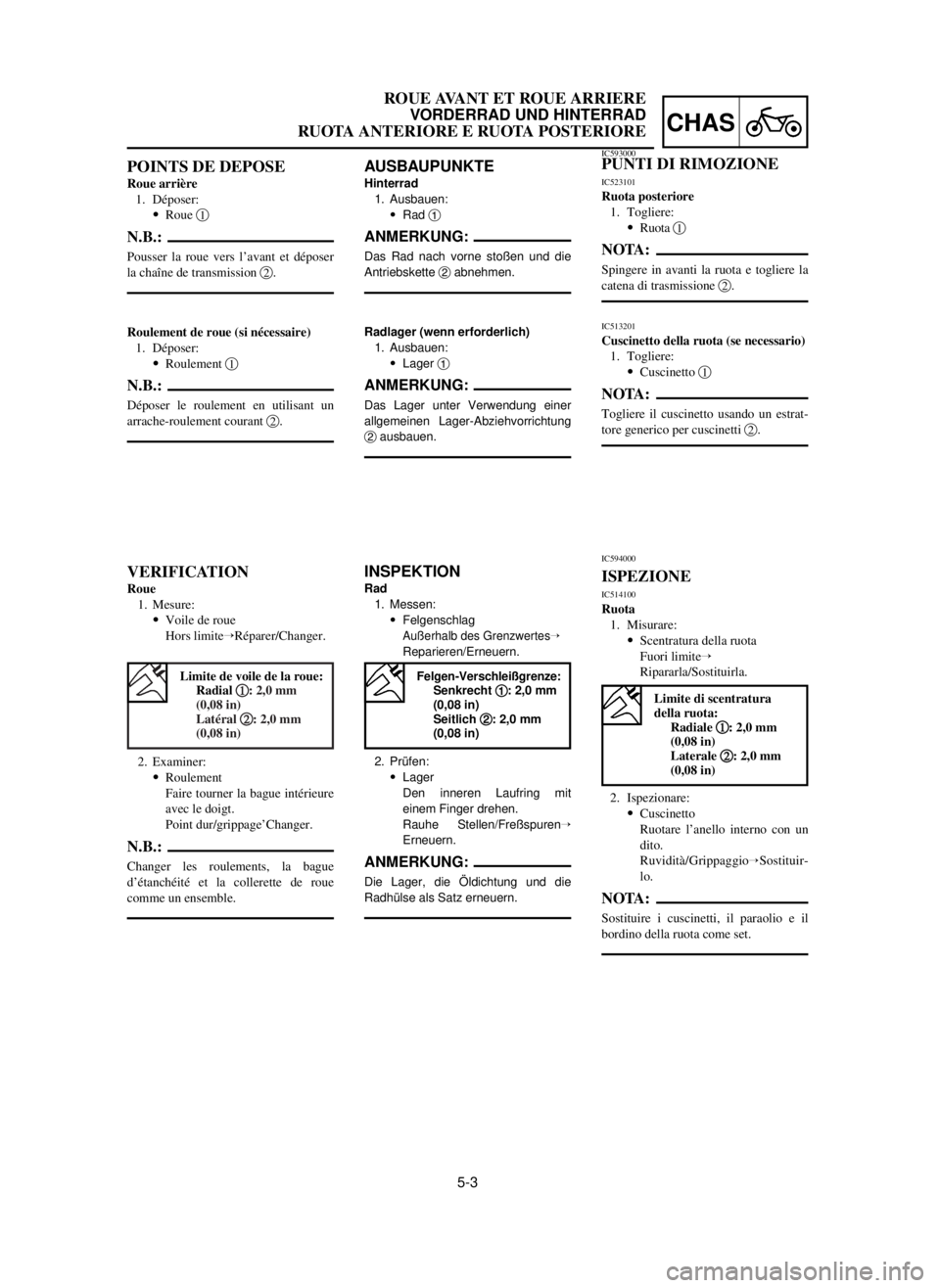

POINTS DE DEPOSE

Roue arrière

1. Déposer:

9Roue 1

N.B.:

Pousser la roue vers l’avant et déposer

la chaîne de transmission 2.

Roulement de roue (si nécessaire)

1. Déposer:

9Roulement 1

N.B.:

Déposer le roulement en utilisant un

arrache-roulement courant 2.

VERIFICATION

Roue

1. Mesure:

9Voile de roue

Hors limiteÕRéparer/Changer.

2. Examiner:

9Roulement

Faire tourner la bague intérieure

avec le doigt.

Point dur/grippage’Changer.

N.B.:

Changer les roulements, la bague

d’étanchéité et la collerette de roue

comme un ensemble.

IC593000PUNTI DI RIMOZIONE

IC523101

Ruota posteriore

1. Togliere:

9Ruota 1

NOTA:

Spingere in avanti la ruota e togliere la

catena di trasmissione 2.

IC513201

Cuscinetto della ruota (se necessario)

1. Togliere:

9Cuscinetto 1

NOTA:

Togliere il cuscinetto usando un estrat-

tore generico per cuscinetti 2.

IC594000

ISPEZIONE

IC514100

Ruota

1. Misurare:

9Scentratura della ruota

Fuori limiteÕ

Ripararla/Sostituirla.

2. Ispezionare:

9Cuscinetto

Ruotare l’anello interno con un

dito.

Ruvidità/Grippaggio

ÕSostituir-

lo.

NOTA:

Sostituire i cuscinetti, il paraolio e il

bordino della ruota come set.

Limite de voile de la roue:

Radial 1 1

: 2,0 mm

(0,08 in)

Latéral 2 2

: 2,0 mm

(0,08 in)

Limite di scentratura

della ruota:

Radiale 1 1

: 2,0 mm

(0,08 in)

Laterale 2 2

: 2,0 mm

(0,08 in)

Felgen-Verschleißgrenze:Senkrecht 1 1

: 2,0 mm

(0,08 in)

Seitlich 2 2

: 2,0 mm

(0,08 in)

5MW-9-30-5A 7/6/00 8:21 AM Page 7