fuel pump YAMAHA YZ426F 2000 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZ426F, Model: YAMAHA YZ426F 2000Pages: 608, PDF-Größe: 45.52 MB

Page 22 of 608

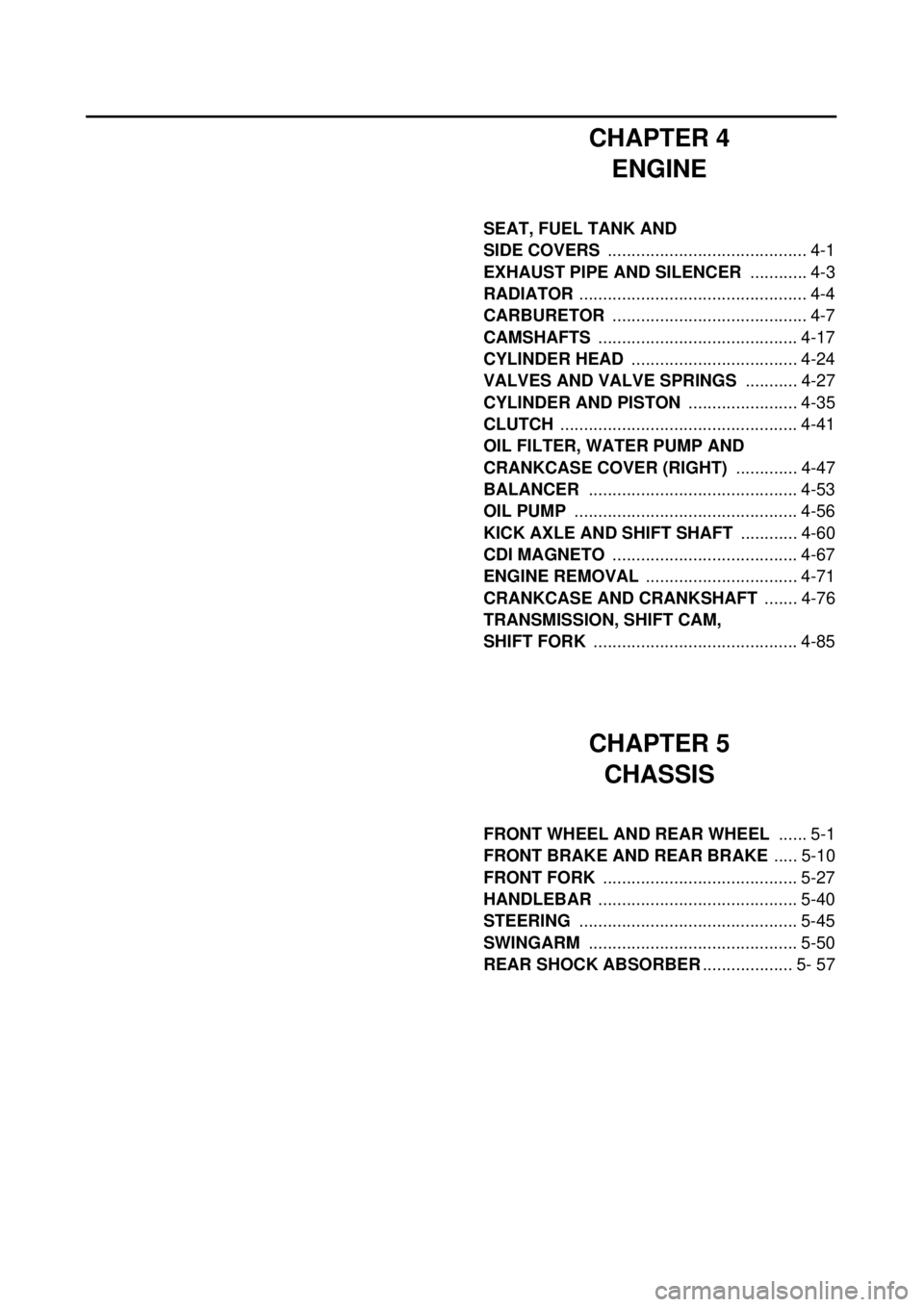

CHAPTER 4

ENGINE

SEAT, FUEL TANK AND

SIDE COVERS

.......................................... 4-1

EXHAUST PIPE AND SILENCER

............ 4-3

RADIATOR

................................................ 4-4

CARBURETOR

......................................... 4-7

CAMSHAFTS

.......................................... 4-17

CYLINDER HEAD

................................... 4-24

VALVES AND VALVE SPRINGS

........... 4-27

CYLINDER AND PISTON

....................... 4-35

CLUTCH

.................................................. 4-41

OIL FILTER, WATER PUMP AND

CRANKCASE COVER (RIGHT)

............. 4-47

BALANCER

............................................ 4-53

OIL PUMP

............................................... 4-56

KICK AXLE AND SHIFT SHAFT

............ 4-60

CDI MAGNETO

....................................... 4-67

ENGINE REMOVAL

................................ 4-71

CRANKCASE AND CRANKSHAFT

....... 4-76

TRANSMISSION, SHIFT CAM,

SHIFT FORK

........................................... 4-85

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL

...... 5-1

FRONT BRAKE AND REAR BRAKE

..... 5-10

FRONT FORK

......................................... 5-27

HANDLEBAR

.......................................... 5-40

STEERING

.............................................. 5-45

SWINGARM

............................................ 5-50

REAR SHOCK ABSORBER

................... 5- 57

Page 54 of 608

1 - 13

GEN

INFO

STARTING AND BREAK-IN

EC190000

STARTING AND BREAK-IN

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

CAUTION:

lThe carburetor on this motorcycle has a

built-in accelerator pump. Therefore,

when starting the engine, do not operate

the throttle or the spark plug will foul.

lUnlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kick starter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the

engine to start.

lNever use the decompression lever after

the engine is started. The engine may be

damaged if you use the decompression

lever while it is running.

lBefore starting the machine, perform the

checks in the pre-operation check list.

EC191001

STARTING A COLD ENGINE

1. Inspect the coolant level.

2. Turn the fuel cock to “ON”.

3. Shift the transmission into neutral.

4. Fully open the cold starter knob.

5. Without pulling in the decompression

lever, slowly depress the kick starter until

the compression stroke is found. When

considerable resistance of the kick starter

is felt, the engine is on the compression

stroke. If the engine is on the exhaust

stroke, resistance will only be felt when

the kick starter is initially depressed, not

through the entire range of depression

(as when the engine is on the compres-

sion stroke); therefore, depress the kick

starter a few more times.

Page 56 of 608

1 - 14

GEN

INFO

STARTING AND BREAK-IN

6. Pull the decompression lever to the han-

dlebar and depress the kick starter 10 ~

30˚.

7. Release the decompression lever and

return the kick starter to its original posi-

tion and then kick the kick starter.

WARNING

Do not open the throttle while kicking the

kick starter. Otherwise, the kick starter may

kick back.

8. Return the cold starter knob to its original

position and run the engine at 3,000 ~

5,000 r/min for 1 or 2 minutes.

NOTE:

Since this model is equipped with an accelera-

tor pump, if the engine is raced (the throttle

opened and closed), the air/fuel mixture will be

too rich and the engine may stall. Also unlike a

two-stroke engine, this model can idle.

CAUTION:

Do not warm up the engine for extended

periods of time.

Page 139 of 608

3 - 2

INSP

ADJ

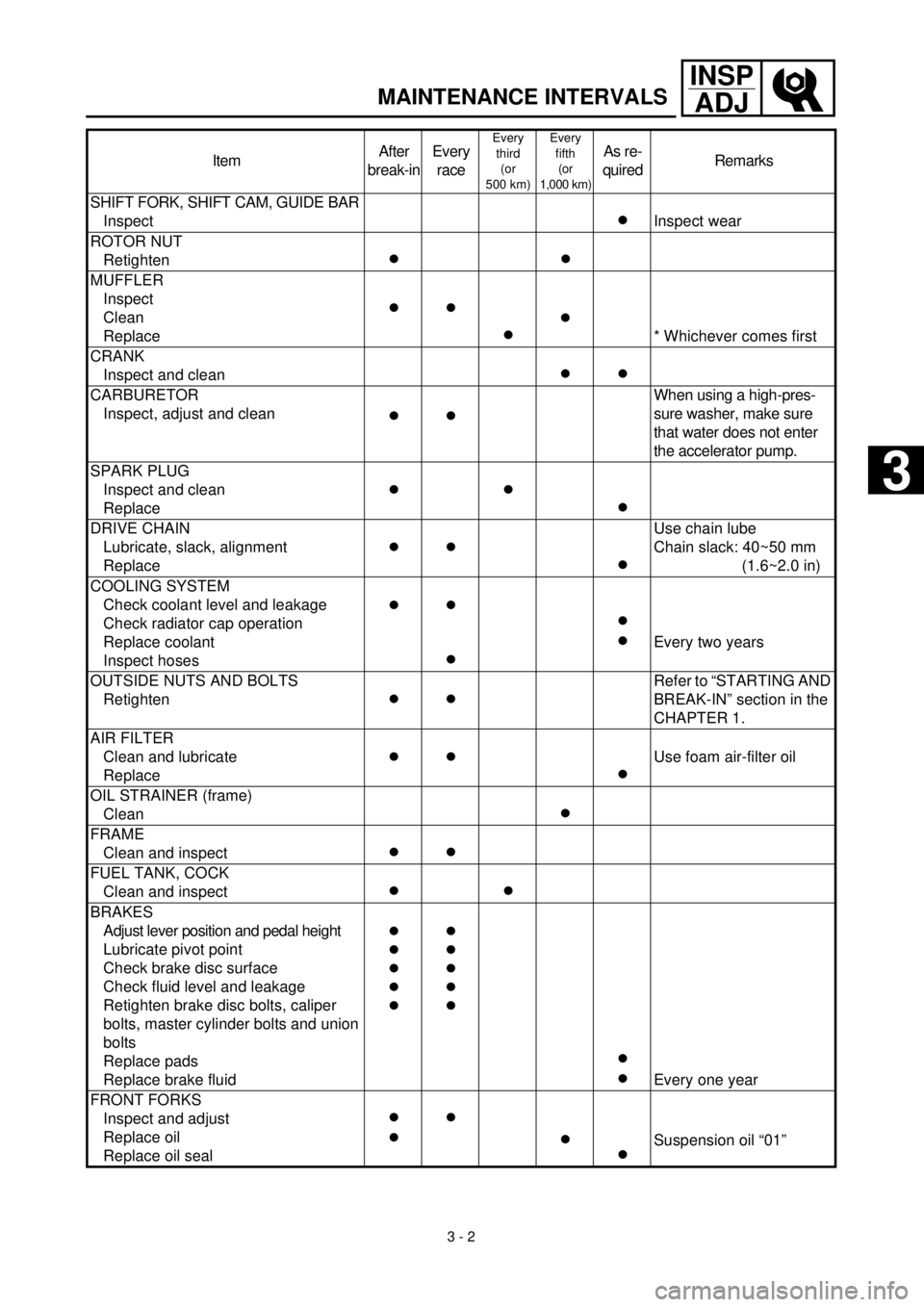

MAINTENANCE INTERVALS

SHIFT FORK, SHIFT CAM, GUIDE BAR

Inspect

c

Inspect wear

ROTOR NUT

Retighten

cc

MUFFLER

Inspect

Clean

Replace

cc

cc

* Whichever comes first

CRANK

Inspect and clean

cc

CARBURETOR

Inspect, adjust and clean

cc

When using a high-pres-

sure washer, make sure

that water does not enter

the accelerator pump.

SPARK PLUG

Inspect and clean

Replace

cc

c

DRIVE CHAIN

Lubricate, slack, alignment

Replace

cc

c

Use chain lube

Chain slack: 40~50 mm

(1.6~2.0 in)

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant

Inspect hoses

cc

cc

c

Every two years

OUTSIDE NUTS AND BOLTS

Retighten

cc

Refer to “STARTING AND

BREAK-IN” section in the

CHAPTER 1.

AIR FILTER

Clean and lubricate

Replace

cc

c

Use foam air-filter oil

OIL STRAINER (frame)

Clean

c

FRAME

Clean and inspect

cc

FUEL TANK, COCK

Clean and inspect

cc

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid

c

c

c

c

cc

c

c

c

c

c

c

Every one year

FRONT FORKS

Inspect and adjust

Replace oil

Replace oil seal

c

cc

c

c

Suspension oil “01” ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)

As re-

quiredRemarks

3

Page 174 of 608

3 - 17

INSP

ADJ

PILOT SCREW ADJUSTMENT

12. Check:

lOil pressure

Checking steps:

lSlightly loosen the oil gallery bolt 1.

lStart the engine and keep it idling until oil

starts to seep from the oil gallery bolt. If no

oil comes out after one minute, turn the

engine off so it will not seize.

lCheck oil passages, oil filter and oil pump

for damage or leakage.

lStart the engine after solving the prob-

lem(s) and recheck the oil pressure.

lTighten the oil gallery bolt to specification.

T R..

Oil gallery bolt:

18 Nm (1.8 m • kg, 13 ft • lb)

PILOT SCREW ADJUSTMENT

1. Adjust:

lPilot screw 1

* Except for USAAdjusting steps:

lTurn in the pilot screw until it is lightly

seated.

lTurn out the pilot screw by the factory-set

number of turns.

Pilot screw:

1-3/4 turns out

* 1-1/2 turns out

(for reference only)

NOTE:

To optimize the fuel flow at a smaller throt-

tle opening, each machine’s pilot screw has

been individually set at the factory. Before

adjusting the pilot screw, turn it in fully and

count the number of turns. Record this

number as the factory-set number of turns

out.

Page 562 of 608

7 - 1

TUN

EC700000

TUNING

EC710000

ENGINE

Carburetor setting

l

The air/fuel mixture will vary depending on

atmospheric conditions. Therefore, it is nec-

essary to take into consideration the air pres-

sure, ambient temperature, humidity, etc.,

when adjusting the carburetor.

l

Perform a test run to check for proper engine

performance (e.g., throttle response) and

spark plug(-s) discoloration or fouling. Use

these readings to determine the best possi-

ble carburetor setting.

NOTE:

It is recommended to keep a record of all car-

buretor settings and external conditions (e.g.,

atmospheric conditions, track/surface condi-

tions, lap times) to make future carburetor set-

ting easier.

WARNING

l

The carburetor is a part of the fuel line.

Therefore, be sure to install it in a well-

ventilated area, away from flammable

objects and any sources of fire.

l

Never look into the carburetor intake.

Flames may shoot out from the pipe if the

engine backfires while it is being started.

Gasoline may be discharged from the

accelerator pump nozzle when the carbu-

retor has been removed.

CAUTION:

l

The carburetor is extremely sensitive to

foreign matter (dirt, sand, water, etc.).

During installation, do not allow foreign

matter to get into the carburetor.

l

Always handle the carburetor and its com-

ponents carefully. Even slight scratches,

bends or damage to carburetor parts may

prevent the carburetor from functioning

correctly. Carefully perform all servicing

with the appropriate tools and without

applying excessive force.

l

When the engine is stopped or when

riding at no load, do not open and close

the throttle unnecessarily. Otherwise, too

much fuel may be discharged, starting

may become difficult or the engine may

not run well.

SETTING

7

Page 578 of 608

7 - 9

TUN

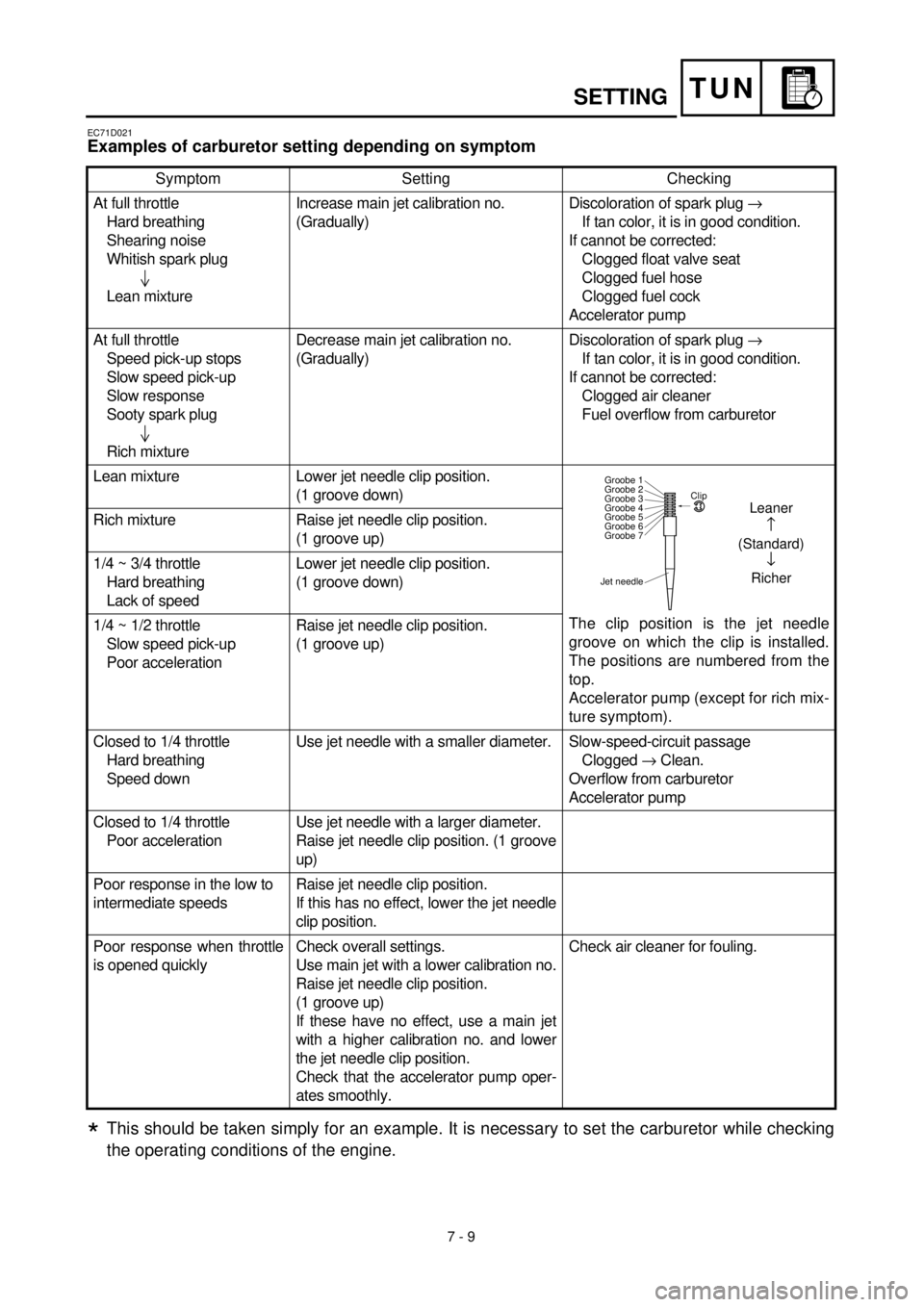

EC71D021

Examples of carburetor setting depending on symptom

This should be taken simply for an example. It is necessary to set the carburetor while checking

the operating conditions of the engine.

Symptom Setting Checking

At full throttle

Hard breathing

Shearing noise

Whitish spark plug

Lean mixtureIncrease main jet calibration no.

(Gradually)Discoloration of spark plug ®

If tan color, it is in good condition.

If cannot be corrected:

Clogged float valve seat

Clogged fuel hose

Clogged fuel cock

Accelerator pump

At full throttle

Speed pick-up stops

Slow speed pick-up

Slow response

Sooty spark plug

Rich mixtureDecrease main jet calibration no.

(Gradually)Discoloration of spark plug ®

If tan color, it is in good condition.

If cannot be corrected:

Clogged air cleaner

Fuel overflow from carburetor

Lean mixture Lower jet needle clip position.

(1 groove down)

The clip position is the jet needle

groove on which the clip is installed.

The positions are numbered from the

top.

Accelerator pump (except for rich mix-

ture symptom). Rich mixture Raise jet needle clip position.

(1 groove up)

1/4 ~ 3/4 throttle

Hard breathing

Lack of speedLower jet needle clip position.

(1 groove down)

1/4 ~ 1/2 throttle

Slow speed pick-up

Poor accelerationRaise jet needle clip position.

(1 groove up)

Closed to 1/4 throttle

Hard breathing

Speed downUse jet needle with a smaller diameter. Slow-speed-circuit passage

Clogged ® Clean.

Overflow from carburetor

Accelerator pump

Closed to 1/4 throttle

Poor accelerationUse jet needle with a larger diameter.

Raise jet needle clip position. (1 groove

up)

Poor response in the low to

intermediate speedsRaise jet needle clip position.

If this has no effect, lower the jet needle

clip position.

Poor response when throttle

is opened quicklyCheck overall settings.

Use main jet with a lower calibration no.

Raise jet needle clip position.

(1 groove up)

If these have no effect, use a main jet

with a higher calibration no. and lower

the jet needle clip position.

Check that the accelerator pump oper-

ates smoothly.Check air cleaner for fouling.

Jet needleClip

Groobe 7 Groobe 6

Groobe 5

Groobe 4

Groobe 3

Groobe 2

Groobe 1

Leaner

(Standard)

¯

Richer

*

SETTING