Front fork YAMAHA YZ426F 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: YZ426F, Model: YAMAHA YZ426F 2000Pages: 608, PDF Size: 45.52 MB

Page 196 of 608

3 - 27

INSP

ADJ

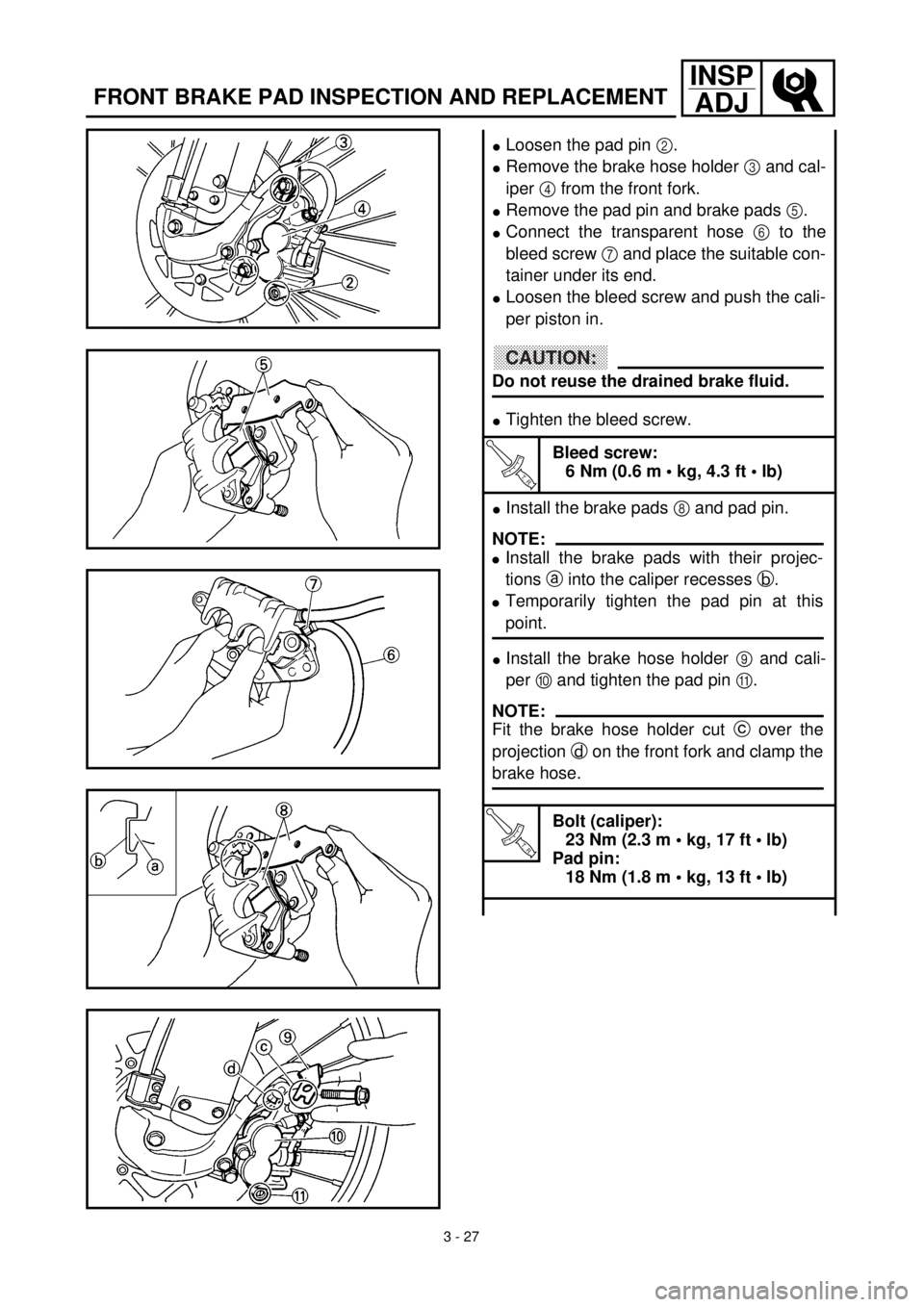

FRONT BRAKE PAD INSPECTION AND REPLACEMENT

lLoosen the pad pin 2.

lRemove the brake hose holder 3 and cal-

iper 4 from the front fork.

lRemove the pad pin and brake pads 5.

lConnect the transparent hose 6 to the

bleed screw 7 and place the suitable con-

tainer under its end.

lLoosen the bleed screw and push the cali-

per piston in.

lTighten the bleed screw.

T R..

Bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

lInstall the brake pads 8 and pad pin.

lInstall the brake hose holder 9 and cali-

per 0 and tighten the pad pin A.

T R..

Bolt (caliper):

23 Nm (2.3 m • kg, 17 ft • lb)

Pad pin:

18 Nm (1.8 m • kg, 13 ft • lb)

CAUTION:

Do not reuse the drained brake fluid.

NOTE:

lInstall the brake pads with their projec-

tions a into the caliper recesses b.

lTemporarily tighten the pad pin at this

point.

NOTE:

Fit the brake hose holder cut c over the

projection d on the front fork and clamp the

brake hose.

Page 208 of 608

3 - 33

INSP

ADJ

FRONT FORK INSPECTION

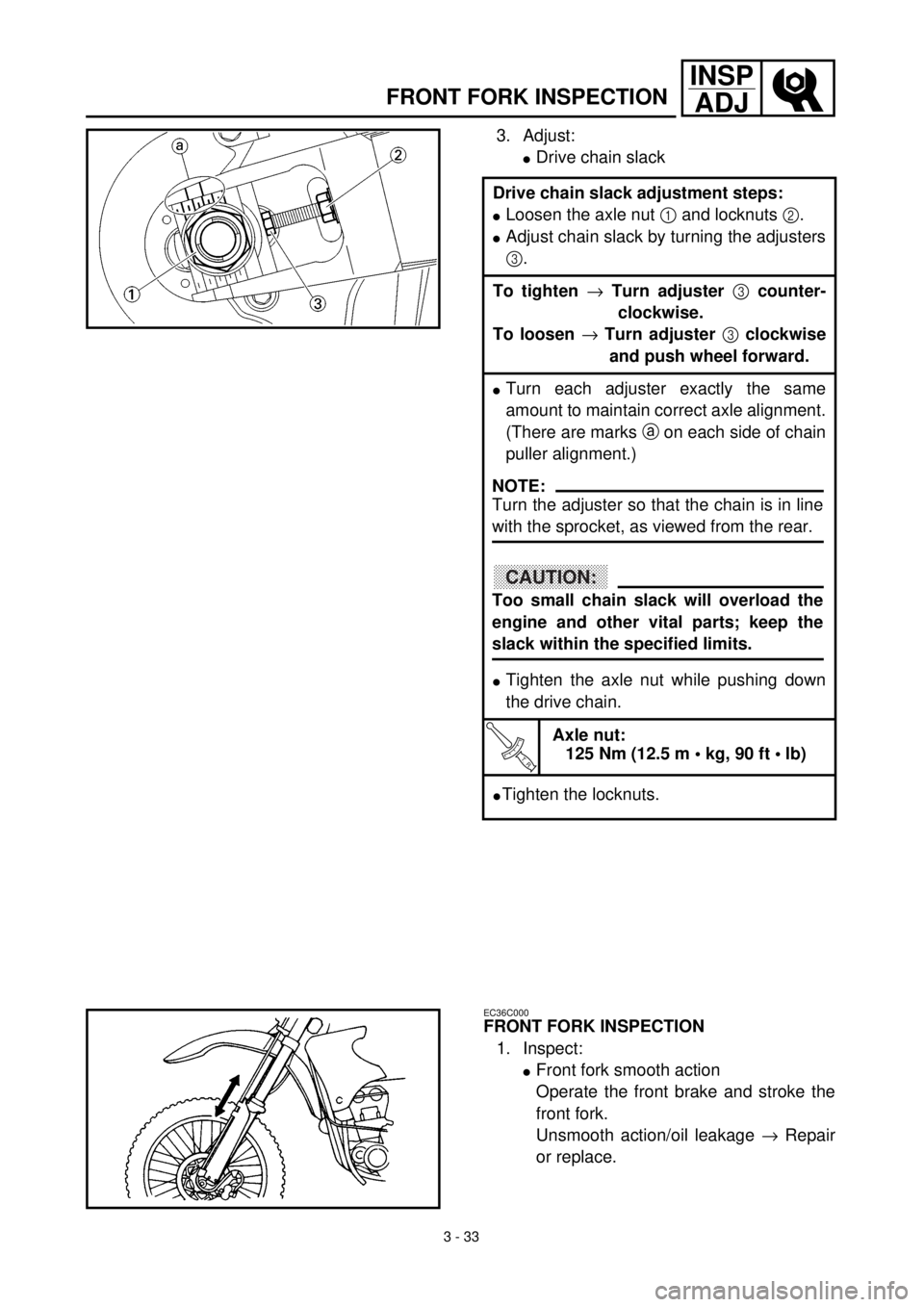

3. Adjust:

lDrive chain slack

Drive chain slack adjustment steps:

lLoosen the axle nut 1 and locknuts 2.

lAdjust chain slack by turning the adjusters

3.

To tighten ® Turn adjuster 3 counter-

clockwise.

To loosen ® Turn adjuster 3 clockwise

and push wheel forward.

lTurn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

lTighten the axle nut while pushing down

the drive chain.

T R..

Axle nut:

125 Nm (12.5 m • kg, 90 ft • lb)

lTighten the locknuts.

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

EC36C000

FRONT FORK INSPECTION

1. Inspect:

lFront fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage ® Repair

or replace.

Page 210 of 608

3 - 34

INSP

ADJFRONT FORK OIL SEAL AND DUST SEAL CLEANING/

FRONT FORK REBOUND DAMPING FORCE ADJUSTMENT

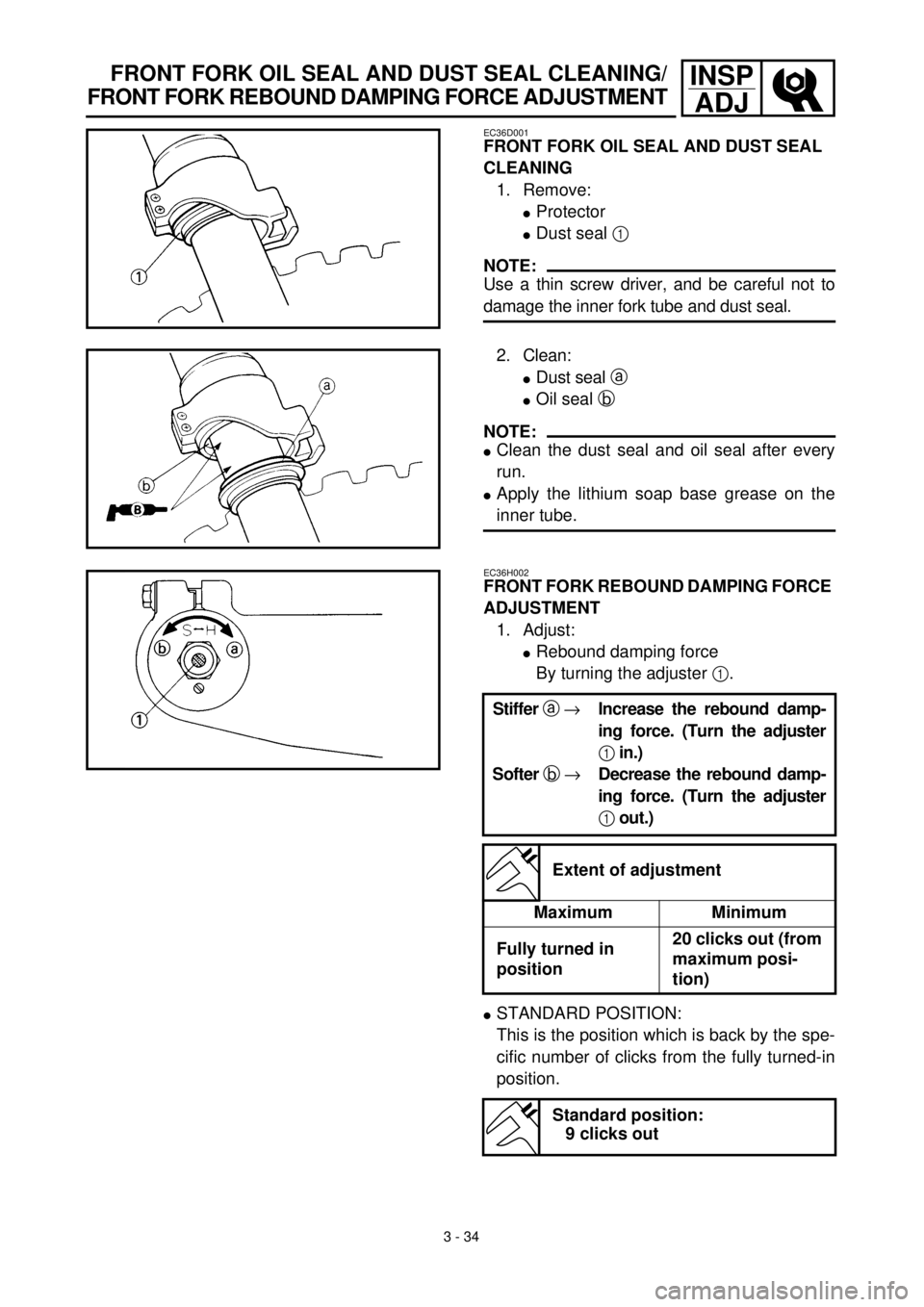

EC36D001

FRONT FORK OIL SEAL AND DUST SEAL

CLEANING

1. Remove:

lProtector

lDust seal 1

NOTE:

Use a thin screw driver, and be careful not to

damage the inner fork tube and dust seal.

2. Clean:

lDust seal a

lOil seal b

NOTE:

lClean the dust seal and oil seal after every

run.

lApply the lithium soap base grease on the

inner tube.

EC36H002

FRONT FORK REBOUND DAMPING FORCE

ADJUSTMENT

1. Adjust:

lRebound damping force

By turning the adjuster 1.

lSTANDARD POSITION:

This is the position which is back by the spe-

cific number of clicks from the fully turned-in

position. Stiffer a ®Increase the rebound damp-

ing force. (Turn the adjuster

1 in.)

Softer b ®Decrease the rebound damp-

ing force. (Turn the adjuster

1 out.)

Extent of adjustment

Maximum Minimum

Fully turned in

position20 clicks out (from

maximum posi-

tion)

Standard position:

9 clicks out

Page 212 of 608

3 - 35

INSP

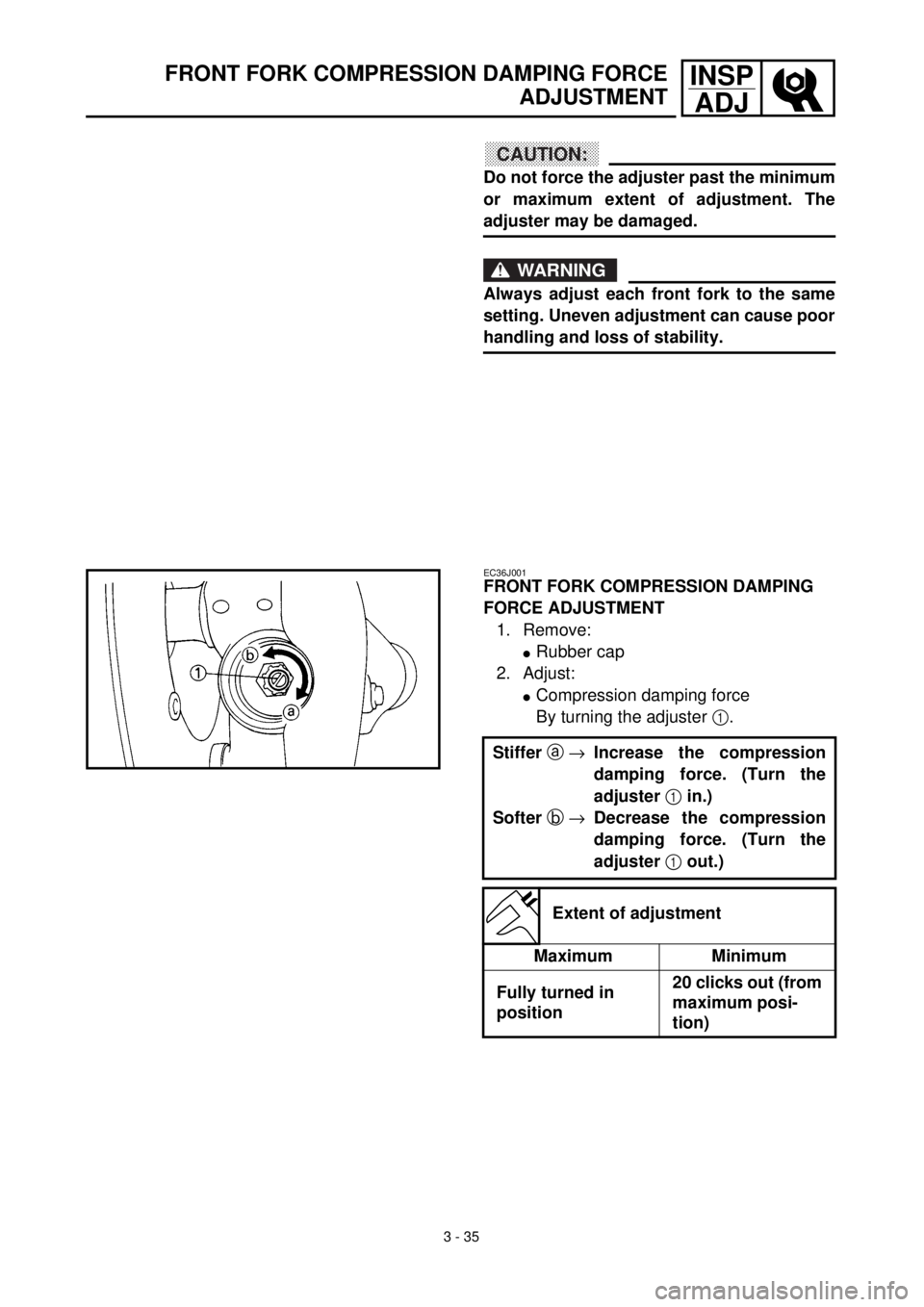

ADJFRONT FORK COMPRESSION DAMPING FORCE

ADJUSTMENT

CAUTION:

Do not force the adjuster past the minimum

or maximum extent of adjustment. The

adjuster may be damaged.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

EC36J001

FRONT FORK COMPRESSION DAMPING

FORCE ADJUSTMENT

1. Remove:

lRubber cap

2. Adjust:

lCompression damping force

By turning the adjuster 1.

Stiffer a ®Increase the compression

damping force. (Turn the

adjuster 1 in.)

Softer b ®Decrease the compression

damping force. (Turn the

adjuster 1 out.)

Extent of adjustment

Maximum Minimum

Fully turned in

position20 clicks out (from

maximum posi-

tion)

Page 214 of 608

3 - 36

INSP

ADJ

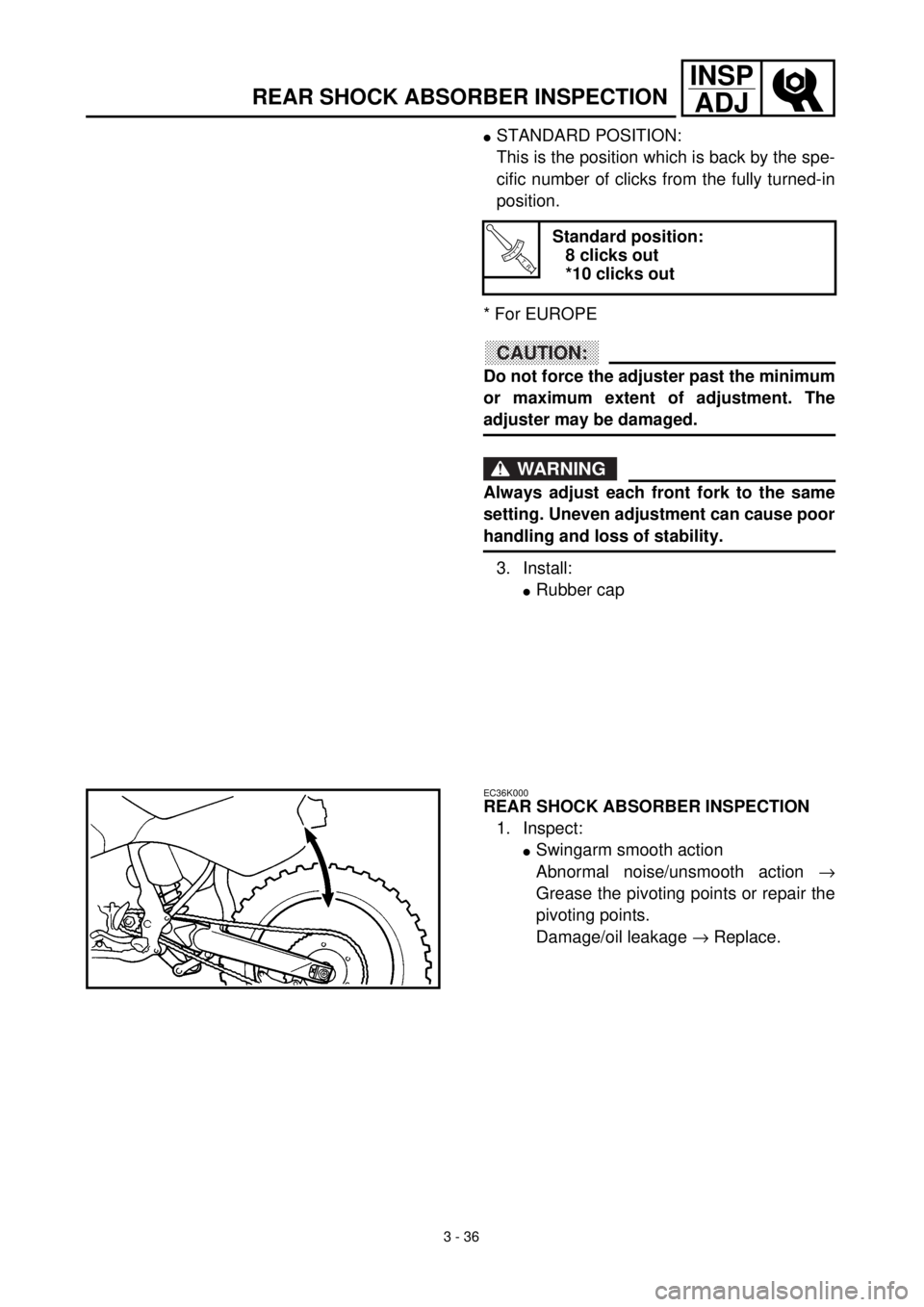

REAR SHOCK ABSORBER INSPECTION

lSTANDARD POSITION:

This is the position which is back by the spe-

cific number of clicks from the fully turned-in

position.

* For EUROPE

CAUTION:

Do not force the adjuster past the minimum

or maximum extent of adjustment. The

adjuster may be damaged.

WARNING

Always adjust each front fork to the same

setting. Uneven adjustment can cause poor

handling and loss of stability.

3. Install:

lRubber cap

T R..

Standard position:

8 clicks out

*10 clicks out

EC36K000

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

lSwingarm smooth action

Abnormal noise/unsmooth action ®

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage ® Replace.

Page 226 of 608

3 - 42

INSP

ADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

2. Inspect:

lBearing free play

Exist play ® Replace.

EC36U012

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering shaft

Grasp the bottom of the forks and gen-

tly rock the fork assembly back and

forth.

Free play ® Adjust steering head.

3. Check:

lSteering smooth action

Turn the handlebar lock to lock.

Unsmooth action ® Adjust steering ring

nut.

4. Adjust:

lSteering ring nut

Steering ring nut adjustment steps:

lRemove the number plate.

lRemove the handlebar and handle crown.

lLoosen the ring nut 1 using the ring nut

wrench 2.

Ring nut wrench:

YM-33975/90890-01403

Page 424 of 608

5 - 6

CHASFRONT WHEEL AND REAR WHEEL

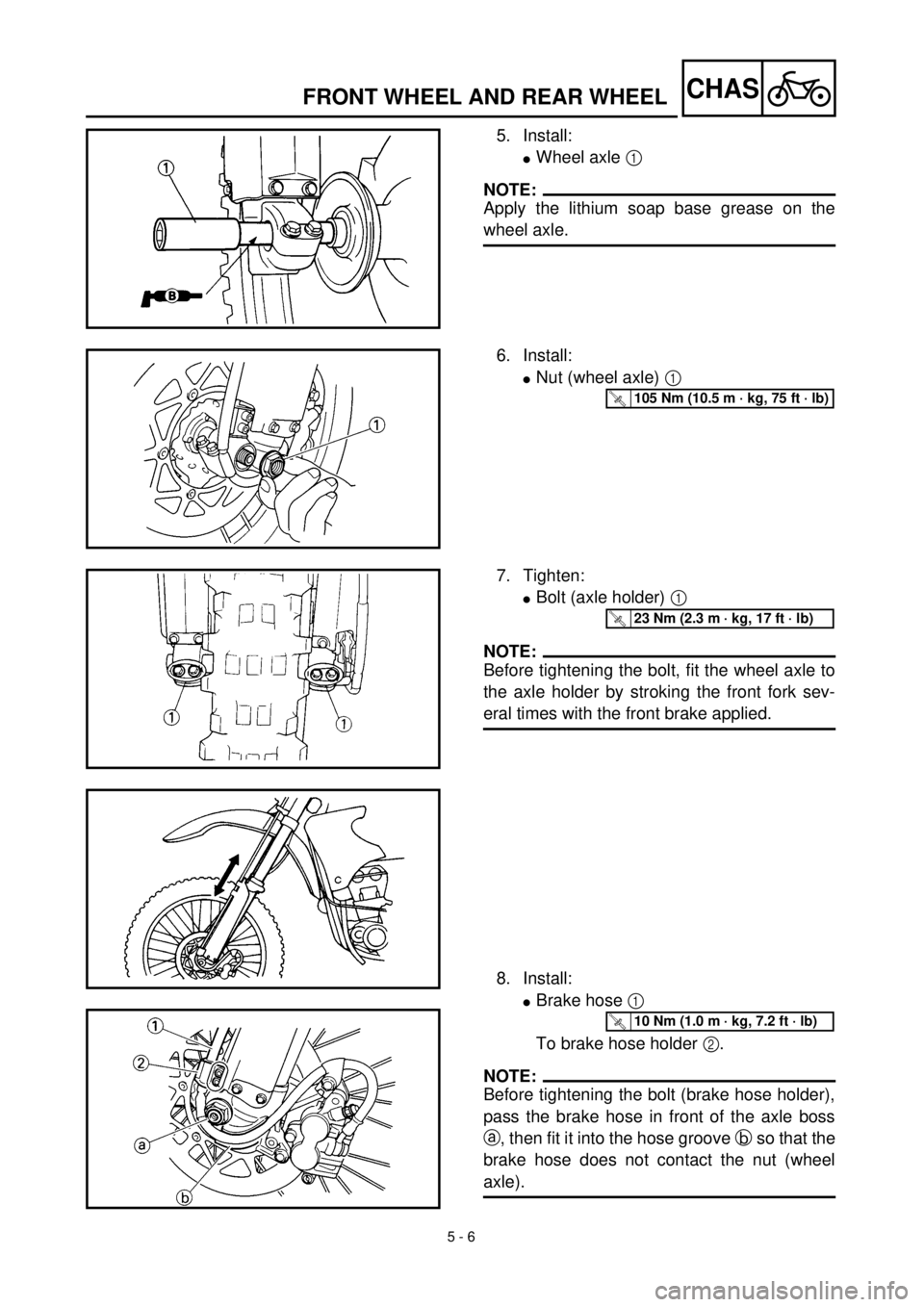

5. Install:

lWheel axle 1

NOTE:

Apply the lithium soap base grease on the

wheel axle.

6. Install:

lNut (wheel axle) 1

T R..105 Nm (10.5 m · kg, 75 ft · lb)

7. Tighten:

lBolt (axle holder) 1

NOTE:

Before tightening the bolt, fit the wheel axle to

the axle holder by stroking the front fork sev-

eral times with the front brake applied.

8. Install:

lBrake hose 1

To brake hose holder 2.

NOTE:

Before tightening the bolt (brake hose holder),

pass the brake hose in front of the axle boss

a, then fit it into the hose groove b so that the

brake hose does not contact the nut (wheel

axle).

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 448 of 608

5 - 18

CHASFRONT BRAKE AND REAR BRAKE

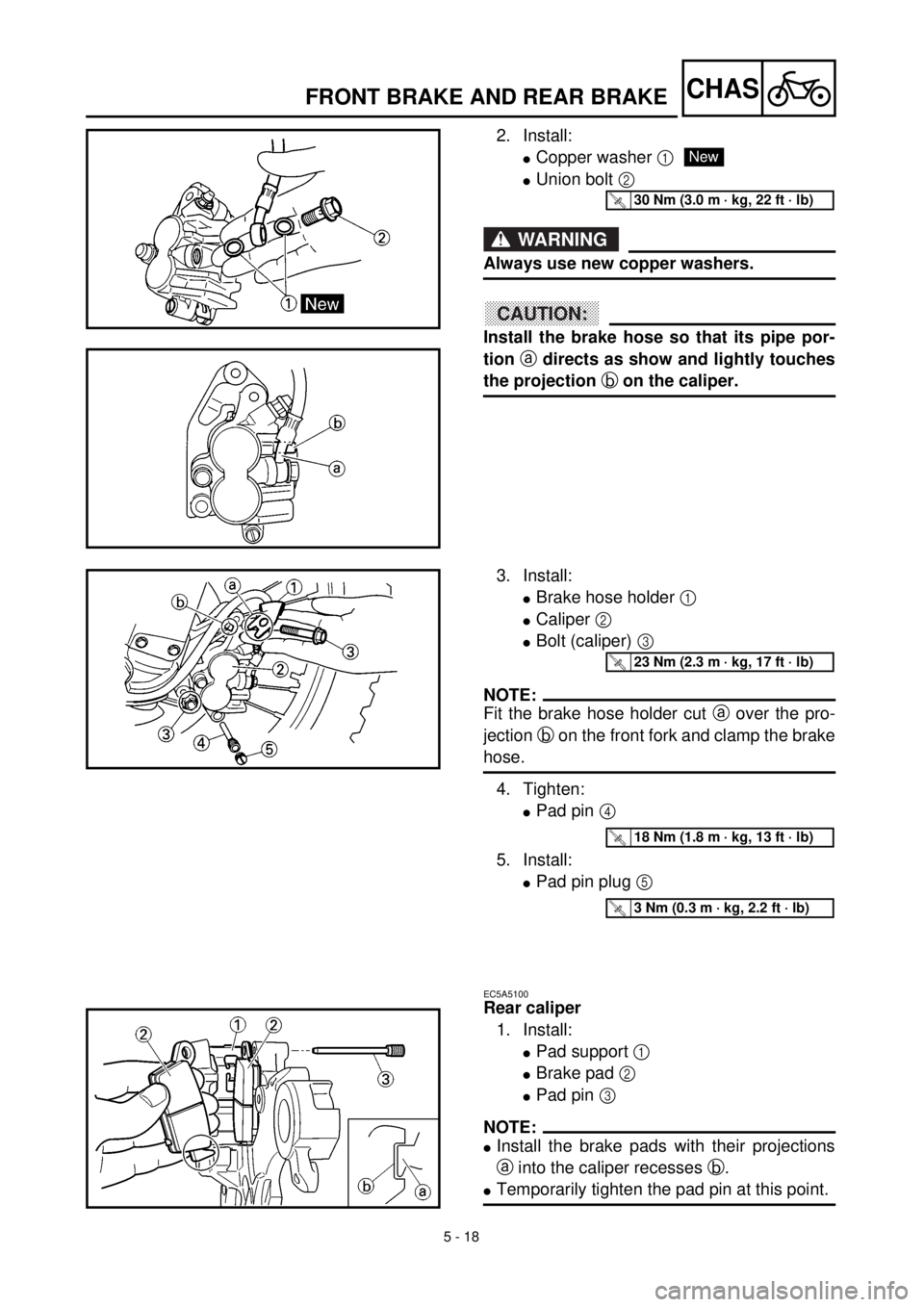

2. Install:

lCopper washer 1

lUnion bolt 2

WARNING

Always use new copper washers.

ACHTUNG:CAUTION:

Install the brake hose so that its pipe por-

tion a directs as show and lightly touches

the projection b on the caliper.

New

T R..30 Nm (3.0 m · kg, 22 ft · lb)

3. Install:

lBrake hose holder 1

lCaliper 2

lBolt (caliper) 3

NOTE:

Fit the brake hose holder cut a over the pro-

jection b on the front fork and clamp the brake

hose.

4. Tighten:

lPad pin 4

5. Install:

lPad pin plug 5

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..18 Nm (1.8 m · kg, 13 ft · lb)

T R..3 Nm (0.3 m · kg, 2.2 ft · lb)

EC5A5100

Rear caliper

1. Install:

lPad support 1

lBrake pad 2

lPad pin 3

NOTE:

lInstall the brake pads with their projections

a into the caliper recesses b.

lTemporarily tighten the pad pin at this point.

Page 466 of 608

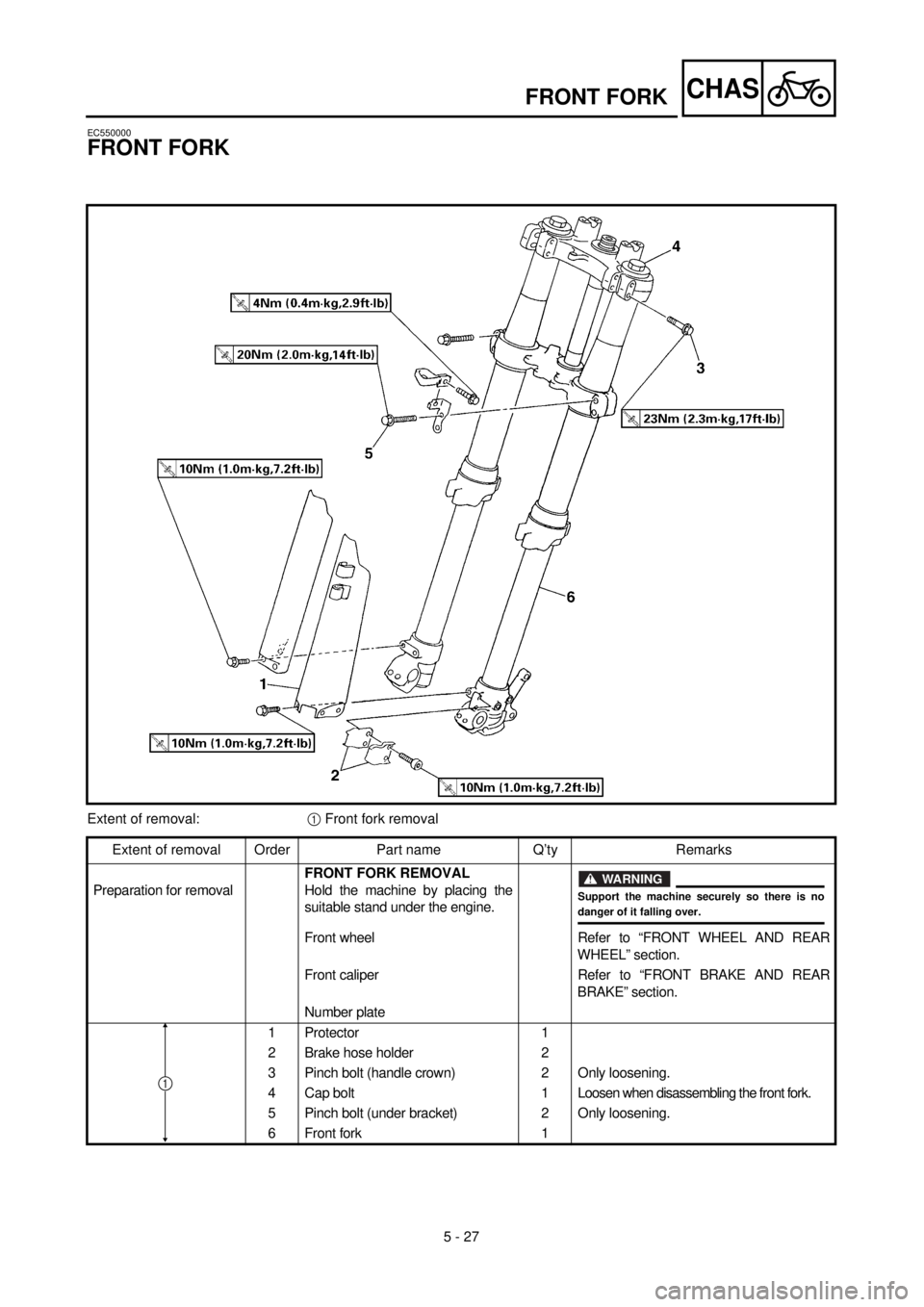

5 - 27

CHASFRONT FORK

EC550000

FRONT FORK

Extent of removal:1 Front fork removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removalFRONT FORK REMOVAL

Hold the machine by placing the

suitable stand under the engine.

Front wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Front caliper Refer to “FRONT BRAKE AND REAR

BRAKE” section.

Number plate

1 Protector 1

2 Brake hose holder 2

3 Pinch bolt (handle crown) 2 Only loosening.

4 Cap bolt 1Loosen when disassembling the front fork.

5 Pinch bolt (under bracket) 2 Only loosening.

6 Front fork 1

WARNING

Support the machine securely so there is nodanger of it falling over.

1

Page 468 of 608

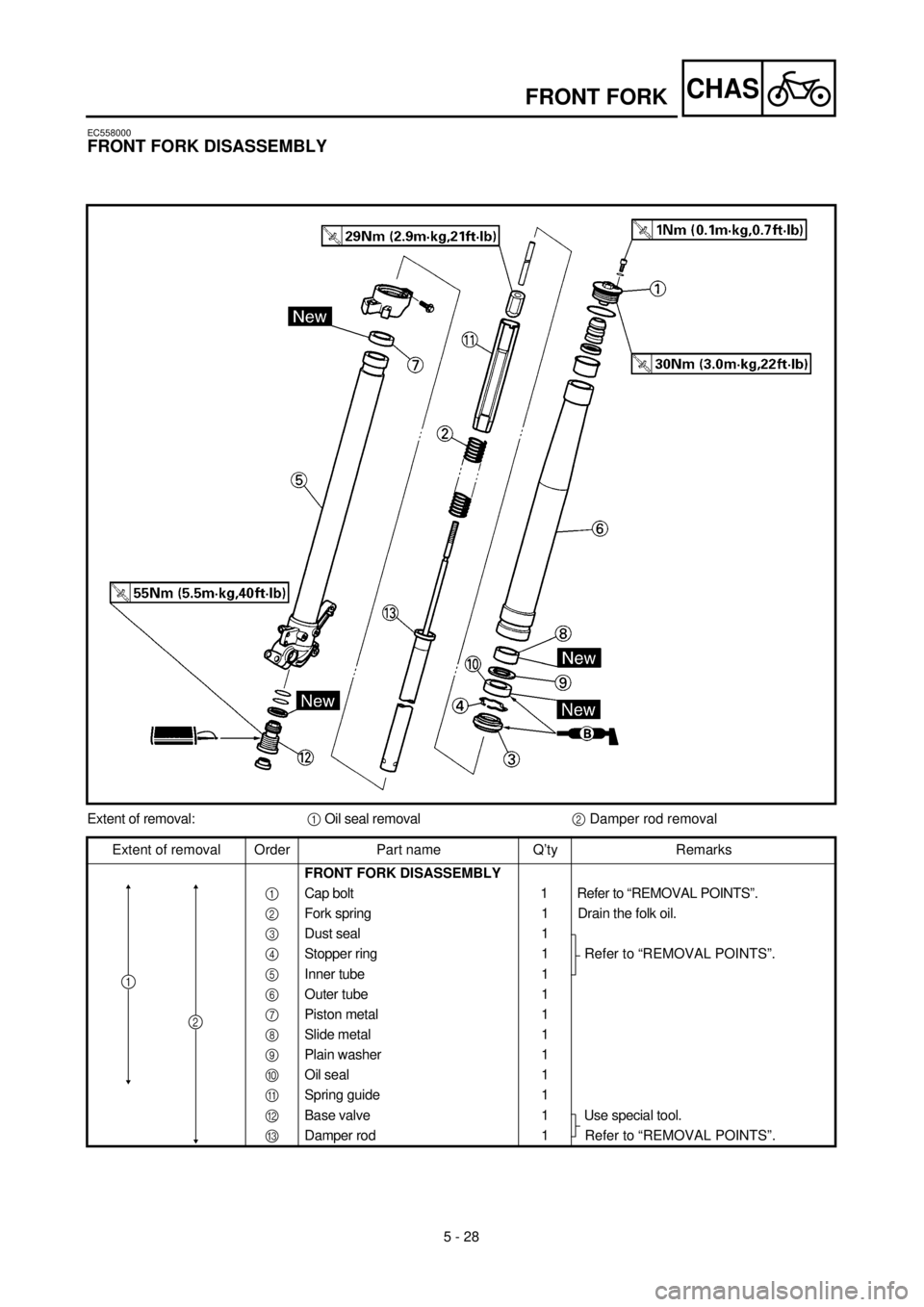

5 - 28

CHASFRONT FORK

EC558000

FRONT FORK DISASSEMBLY

Extent of removal:1 Oil seal removal2 Damper rod removal

Extent of removal Order Part name Q’ty Remarks

FRONT FORK DISASSEMBLY

1 Cap bolt 1 Refer to “REMOVAL POINTS”.

2 Fork spring 1 Drain the folk oil.

3 Dust seal 1

Refer to “REMOVAL POINTS”. 4 Stopper ring 1

5 Inner tube 1

6 Outer tube 1

7 Piston metal 1

8 Slide metal 1

9 Plain washer 1

0 Oil seal 1

A Spring guide 1

B Base valve 1 Use special tool.

C Damper rod 1Refer to “REMOVAL POINTS”.

1

2